Built Around Your Pump System — We are an application-custom partner.

Verification of insulation integrity and dielectric strength to confirm electrical safety under harsh industrial operating conditions, including humidity and temperature extremes, before production release.

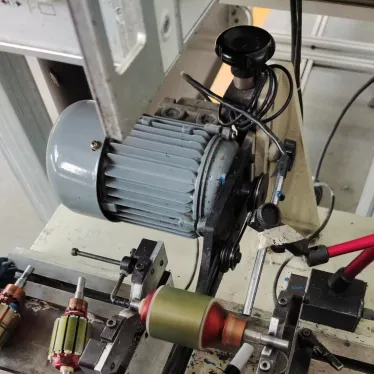

Evaluate motor performance under no-load and full-load conditions to ensure torque stability, current behavior, and output consistency during real actuator operation cycles.

Verification of the motor's ability to start reliably under load and sudden resistance conditions, ensuring smooth and consistent operation of the actuator in valve control applications.

Simulating jamming or blockage scenarios to verify the motor's ability to recover and resume stable operation without failure, ensuring resilience in demanding environments.

Assessment of temperature rise under continuous-duty conditions, ensuring that the motor remains stable and reliable even during long-term operation without overheating.

Repeated start-stop cycling to evaluate the motor’s endurance and performance under frequent usage conditions, typical in valve-control systems.

Evaluation of noise and vibration levels under normal operating conditions, ensuring smooth and quiet operation, which is essential for the longevity and performance of the valve control system.

Verification of motor dimensions and external features (shaft, flange/face, mounting interface) to ensure compatibility with various valve control systems and conformity to design specifications.

Get Template

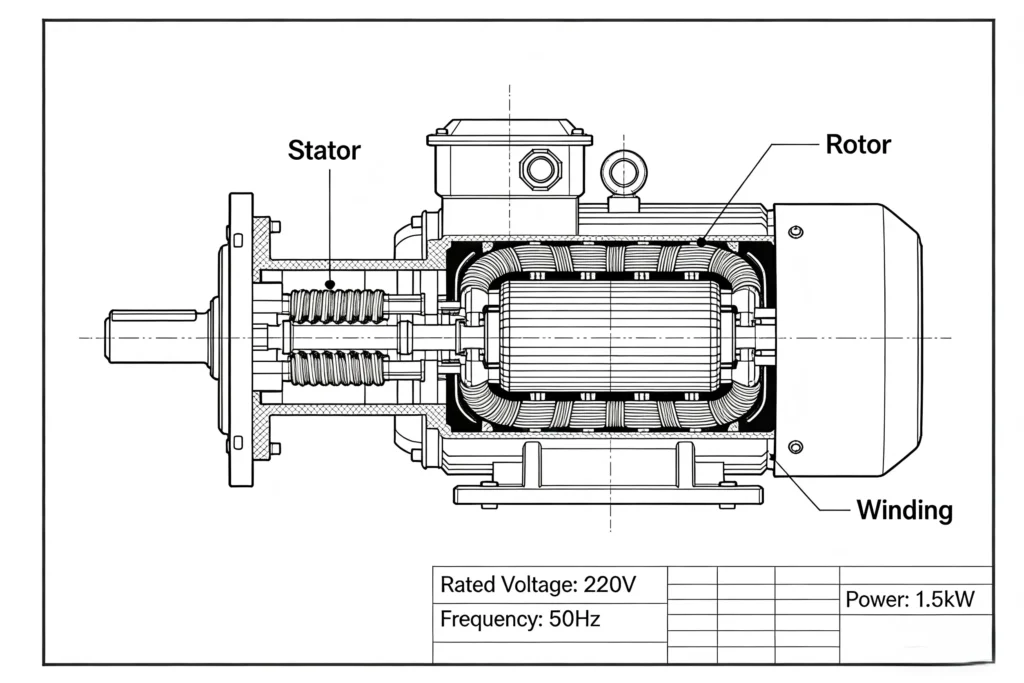

Design a motor solution that delivers precise, reliable torque control for valve actuators while maintaining durability and energy efficiency in harsh industrial environments.

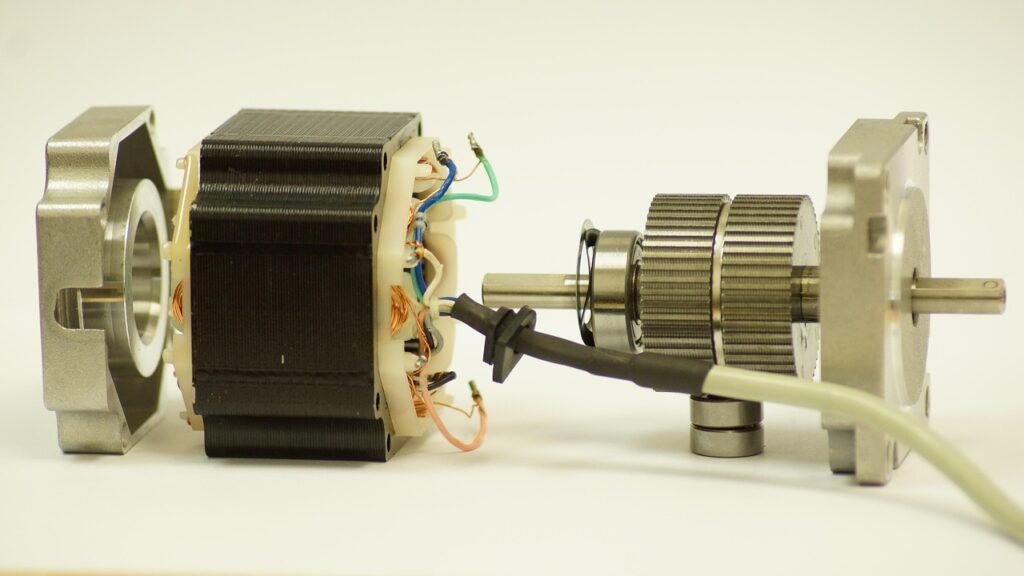

We developed a BLDC motor platform optimized for valve control applications. The motor features high-torque precision, low noise and vibration, and energy-efficient design to reduce operational costs. It is housed in a corrosion-resistant, IP65-rated enclosure, ensuring long-term durability in industrial environments. The motor is designed for modular integration, ensuring compatibility with a variety of valve types and control systems.

Starting capability validated under load and resistance conditions; thermal stability confirmed during continuous operation; noise and vibration levels kept within industry standards; dimensions and mounting interfaces verified for easy integration into valve control systems. Electrical safety tests passed with dielectric strength verified.

The true torque curve does not come from a single rated point, but is defined by the load condition. We usually lock in three types of information:

① startup and limit events (startup mode, stalling/jamming, peak load duration);

② Working range (target speed, continuous/intermittent duty, load variation with speed);

③ Environmental and electrical boundaries (voltage window, temperature, heat dissipation conditions). In the EVT stage, the torque envelope is inferred using measured current speed temperature rise data to obtain a matching “effective torque curve” instead of a catalog curve.

The MOQ is 500 units. Samples are chargeable and can be delivered within 15 days; sample cost is refundable upon batch order. Batch delivery time is 25-30 days. We offer expedited communication and production for urgent projects.

All products meet CE and UL certifications. Materials comply with RoHS and REACH. Our factories hold ISO9001 and IATF16949 certifications. Every motor undergoes rigorous electrical safety, mechanical performance, appearance, and dimensional inspections before shipment. Batch sampling includes load characteristics, temperature rise, and life expectancy tests, accompanied by certification and test reports.

Firstly, clarify the responsibility at the system level: whether it is borne by the motor, reducer, brake, or structural self-locking. Decision basis based on three points:

① Load reverse drive risk (gravity, rebound, impact);

② Failure behavior requirements (maintain/return/release after power outage, project definition);

③ Energy consumption and lifespan (continuous power on maintenance vs. mechanical maintenance). Verify the holding force, reverse drive threshold, and temperature rise in DVT to confirm that safety and durability are still met under worst-case conditions.

Firstly, perform exposure zoning (condensation, splashing, chemical medium type and frequency), and then select materials and protective strategies (coating, sealing, shaft seal, drainage path). Validation is divided into three steps:

① Accelerated condensation/infiltration and chemical compatibility testing;

② Insulation, current, and noise monitoring under electrical aging;

③ Recovery assessment (functionality after drying). Determine long-term stability through trends rather than single point qualification.

Address:No.121,Xinlong Road,Zhonglou Xinzha Subdistrict,Changzhou City, Jiangsu Province, China

Phone: +86-18261152679

Whatsapp: +86-18261152679

Email: sales@honestmotor.cn

Privacy Policy / Terms of Services / Cookie Settings / Site Map

© 2025 Honest All Rights Reserved.