Built Around Your Pump System — We are an application-custom partner.

Verification of insulation integrity and dielectric strength to confirm electrical safety under humid and high-load conditions before production release.

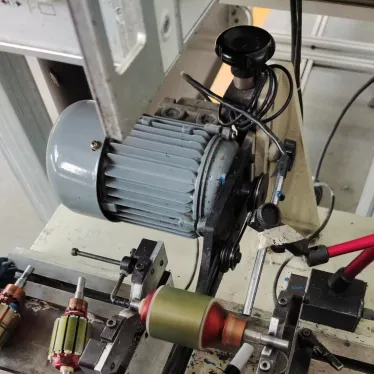

Evaluate motor performance under both no-load and load conditions to ensure speed stability, current behavior, and output consistency during textile machinery operations.

Verification of the motor's ability to start under heavy load conditions, ensuring reliable performance under varying operational demands.

Simulating abnormal conditions, such as temporary mechanical blockage or resistance in textile machinery, to verify the motor’s ability to recover and continue stable operation.

Assessment of temperature rise under continuous-duty conditions, ensuring that the motor can handle long operational periods without overheating or performance degradation.

Repeated start-stop cycling to evaluate the motor’s endurance and reliability under real-world operational conditions, typical of textile machinery use.

Evaluating noise and vibration levels under representative operating conditions to ensure smooth, quiet operation, crucial for maintaining product quality and comfort.

Verification of motor dimensions and external features (shaft, flange/face, mounting interface) to ensure compatibility and consistency with textile machinery systems.

Get Template

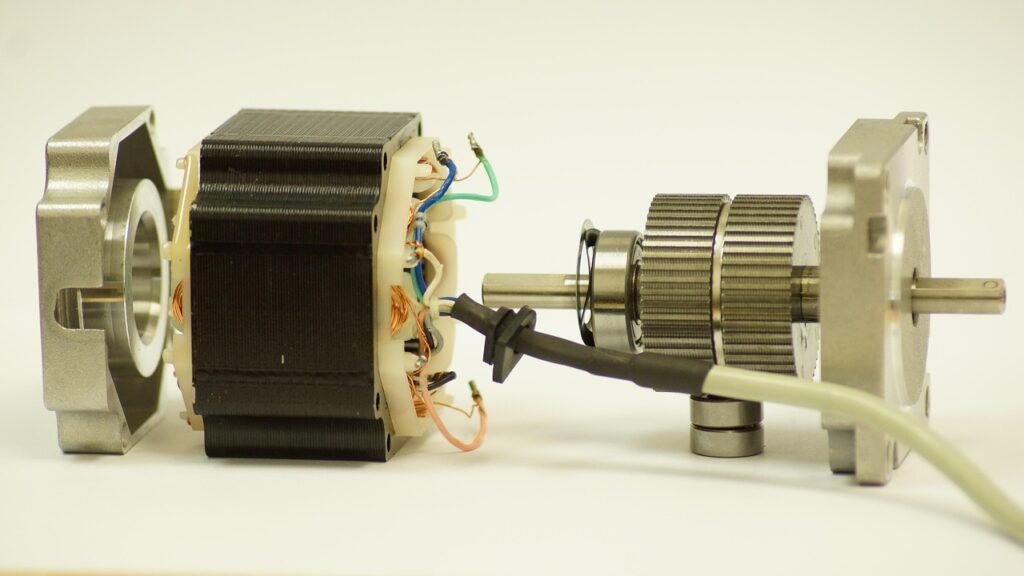

Design a motor solution for weaving machines that ensures precise speed control, minimal vibration, and reliable continuous-duty performance in a dust-prone and high-heat textile factory environment.

We developed a BLDC motor platform with optimized thermal management and vibration-damping design. The motor features corrosion-resistant materials and IP54-rated enclosures for enhanced durability. We also optimized the rotor design for high-speed precision, ensuring stable and reliable operation across all weaving machine speeds.

Starting capability validated under heavy load and resistance conditions; thermal stability verified during continuous operation; vibration and noise levels kept within industry standards for smooth, quiet operation. Dimensional and mounting interface verification completed to ensure easy integration into weaving machines. Electrical safety tests passed, with dielectric strength confirmed.

All products meet CE and UL certifications. Materials comply with RoHS and REACH. Our factories hold ISO9001 and IATF16949 certifications. Every motor undergoes rigorous electrical safety, mechanical performance, appearance, and dimensional inspections before shipment. Batch sampling includes load characteristics, temperature rise, and life expectancy tests, accompanied by certification and test reports.

We not only look at rated points, but also establish continuous operating condition models based on real loads and duty cycles. Under the worst voltage, highest ambient temperature, and worst heat dissipation conditions, perform long-term steady-state operation, record temperature rise trends rather than instantaneous values, and verify whether the thermal equilibrium point is below the material and insulation limits.

Firstly, define the level and source of dust/fiber exposure, and use diversion, isolation, or cleanable paths in the structure instead of simply increasing the air volume. During verification, perform electrified dust accumulation operation, observe air duct blockage, temperature rise changes, and performance degradation to ensure an acceptable maintenance window.

First, create exposure zones to distinguish between rainwater, splashes, dust, salt spray, and condensation frequency; Re match materials, protection, and drainage paths instead of just stacking IP ratings. The focus of verification is on the long-term trend under powered on conditions, rather than a single waterproof test.

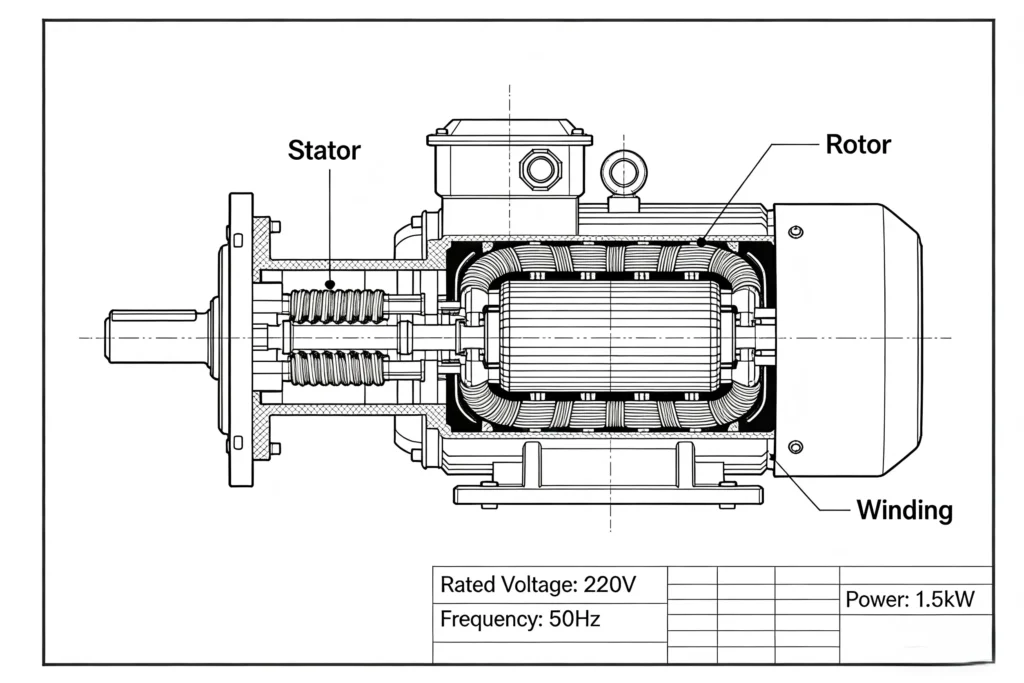

Induction motors are suitable for continuous loads with harsh environments, cost sensitivity, and low control requirements; PMSM/BLDC is more suitable for applications with high efficiency, low noise, wide speed regulation, or high lifespan requirements. The choice depends on the system efficiency goal, control complexity, and full lifecycle cost.

Pro Tip: Uploading a nameplate photo helps us match 50% faster.

Address:No.121,Xinlong Road,Zhonglou Xinzha Subdistrict,Changzhou City, Jiangsu Province, China

Phone: +86-18261152679

Whatsapp: +86-18261152679

Email: sales@honestmotor.cn

Privacy Policy / Terms of Services / Cookie Settings / Site Map

© 2025 Honest All Rights Reserved.