Why Brushless Motors Are Revolutionizing High-Performance Applications

-1024x680.jpg)

Brushless motors are a big step forward in engineering. They don’t use brushes, so there’s less friction and wear. This makes them last longer and need less fixing. Brushless motors work up to 90% efficiently, better than brushed ones at 75%. Using these motors can save up to 30% on energy. They run smoothly with electronic controls, making them great for jobs needing accuracy, strength, and flexibility.

Key Takeaways

-

Brushless motors work with up to 90% efficiency. They use less energy than brushed motors, which are only 75-85% efficient.

-

These motors need little maintenance because they don’t have brushes. This lowers repair costs and helps them last longer, making them great for high-performance uses.

-

Brushless motors are small and light. They can fit in tight spaces without losing power, so they work well in things like drones and medical tools.

-

They are quiet and don’t vibrate much, which makes them more comfortable to use. This is especially helpful in places like hospitals where quietness is important.

-

Brushless motors might cost more at first, but they save money over time by using less energy and needing fewer repairs.

Key Advantages of Brushless Motors

High Efficiency and Energy Savings

Brushless motors are great at saving energy. They lose less energy compared to brushed motors. This is because they don’t have brushes, which cause friction. Brushless motors can work up to 90% efficiently. Brushed motors only reach about 75-85% efficiency.

In electric cars, this means big benefits. Brushless motors help cars go farther and use less power. They also support regenerative braking, which saves even more energy. These motors are strong but still efficient, making them perfect for high-performance tasks.

Low Maintenance and Extended Lifespan

Brushless motors need very little upkeep. Brushed motors use carbon brushes that wear out and need replacing. Brushless motors don’t have brushes, so they last longer. The only part that wears out is the bearing, which lasts a long time.

This makes brushless motors cheaper to maintain over time. In factories, where stopping work costs money, brushless motors are reliable. They keep working without needing much fixing. Here’s a comparison:

|

Feature |

Brushed Motors |

Brushless Motors |

|---|---|---|

|

Lifespan & Maintenance |

Brushes wear out, need replacing and cause downtime |

Bearings wear out slowly; almost no maintenance needed |

Choosing brushless motors saves money and keeps things running smoothly.

Quiet Operation and Reduced Vibration

Brushless motors are quiet and don’t shake much. Brushed motors can be noisy and vibrate a lot. Brushless motors are designed to work smoothly and quietly. They make less electrical noise and cause less vibration.

This is helpful for medical machines like oxygen concentrators. Patients feel more comfortable with quieter equipment. At home, brushless motors are used in air purifiers and garbage disposers. They work well without being loud, making them useful in many places.

Compact and Lightweight Design

Brushless motors are small and light, making them great for tight spaces. They are powerful but fit into smaller frames than brushed motors. This makes them easy to use in devices without losing performance.

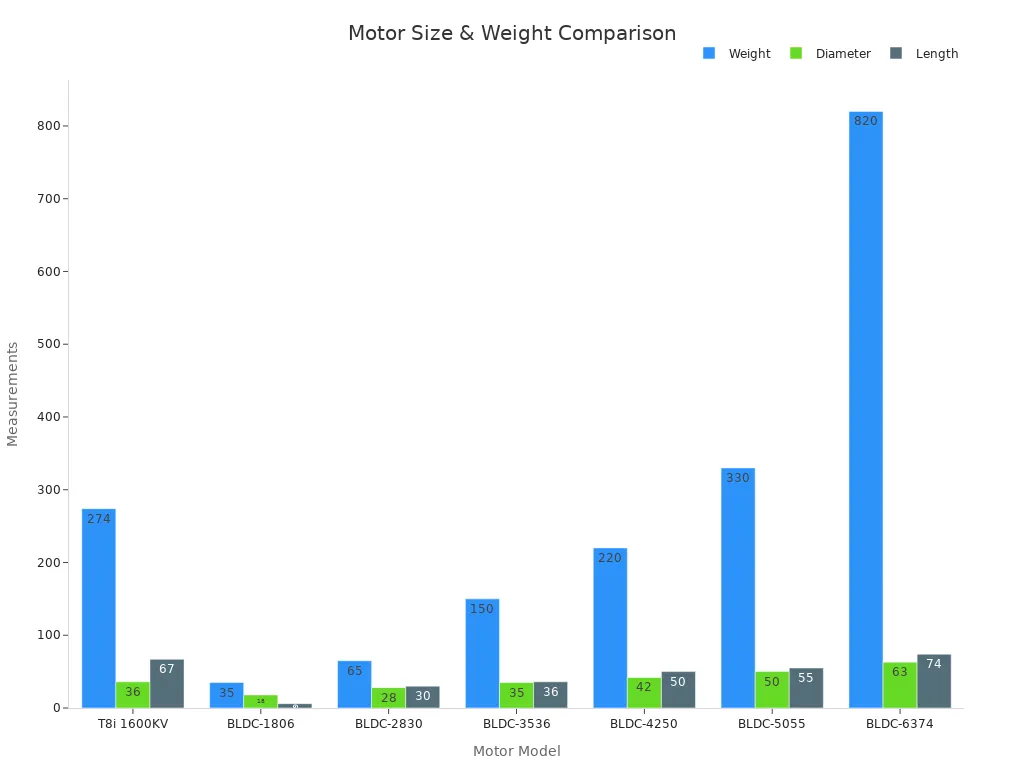

These motors work well in many gadgets. Drones, scooters, and medical tools benefit from their size and weight. For example, the BLDC-1806 motor weighs only 35 grams and is 18 mm wide and 6 mm long. Bigger motors like the BLDC-6374 weigh 820 grams and measure 63 mm wide and 74 mm long. Both motors perform well but suit different needs.

Here’s a table showing how brushless motors vary in size:

|

Motor Model |

Weight (g) |

Diameter (mm) |

Length (mm) |

|---|---|---|---|

|

T8i 1600KV |

274 |

36 |

67 |

|

BLDC-1806 |

35 |

18 |

6 |

|

BLDC-2830 |

65 |

28 |

30 |

|

BLDC-3536 |

150 |

35 |

36 |

|

BLDC-4250 |

220 |

42 |

50 |

|

BLDC-5055 |

330 |

50 |

55 |

|

BLDC-6374 |

820 |

63 |

74 |

Tip: Pick a motor based on its size and weight. Small motors like the BLDC-1806 are good for light devices. Larger ones like the BLDC-6374 work better for heavy-duty jobs.

Smaller motors also save energy. Lighter devices need less power to run. In electric cars, this helps batteries last longer. In drones, it improves flight time and control.

Check out this chart to see how motor sizes compare:

The small design of brushless motors allows for new ideas. You can make portable devices that are still strong. Whether building robots or medical tools, these motors give you the freedom to innovate.

High-Performance Uses of Brushless Motors

Electric Cars: Better Range and Efficiency

Brushless motors are changing electric cars by improving range and efficiency. They waste less energy, helping cars go farther on one charge. For example, using brushless motors can increase travel range by 32.6% compared to older motors. This makes electric cars more attractive to eco-friendly buyers.

These motors also help batteries last longer by using less power. The International Energy Agency says motors use 45% of the world’s electricity. Switching to brushless motors could cut global electricity use by 10% by 2030. Companies like Toyota report 22% less energy use in their hybrid cars with brushless motors.

This progress supports the need for greener, energy-saving cars. As electric cars grow in popularity, brushless motors will lead the way in innovation and helping the environment.

Robots: Accurate and Reliable Automation

Robots need to be precise and dependable, and brushless motors deliver both. These motors give robots great control for detailed tasks. They provide steady torque, ensuring smooth and accurate movements, which is vital for automation.

Brushless motors are also tough and need little care. Unlike brushed motors, they don’t have parts that wear out fast, like brushes. This makes them perfect for long-term use in robots. They reduce downtime and save on repair costs, boosting productivity in automated industries.

Here’s why brushless motors are great for robots:

|

Feature |

Benefit |

|---|---|

|

Efficiency |

Better control and wide speed range. |

|

Torque |

Allows precise and adjustable speeds. |

|

Durability |

No brushes mean less maintenance. |

|

Quiet Operation |

Runs quieter than brushed motors. |

These qualities make brushless motors essential for robotic arms, drones, and automated vehicles. They respond quickly and handle heavy tasks while staying precise. As automation grows, brushless motors will keep advancing robotic technology.

Factory Machines: Improving Work Output

Factory machines need strong, efficient motors to handle tough jobs. Brushless motors meet these needs with energy savings, precise control, and sturdy designs. They are especially useful in factories where productivity and automation are key.

The market for brushless motors in factories is growing fast. In 2023, it was worth $15 billion and could reach $35 billion by 2032, growing 10% yearly. This shows how much industries rely on these motors to save money and boost output.

Benefits of brushless motors in factories include:

-

Accurate motion control for detailed tasks.

-

High energy savings, cutting power costs.

-

Long-lasting design, reducing repairs and downtime.

-

Works well with automated systems, improving efficiency.

For instance, brushless motors are used in conveyor belts, CNC machines, and packaging tools. They run quietly and save energy, making them ideal for places needing low noise and high efficiency. As factories adopt more automation, brushless motors will lead in improving work and innovation.

Medical Equipment: Quiet and Reliable Solutions

Medical tools need to work well, last long, and stay quiet. Brushless dc motors meet these needs, making them ideal for healthcare devices. They are built to run smoothly, make little noise, and last a long time. These qualities are important in hospitals and clinics.

You’ll see these motors in ventilators, oxygen machines, and surgical tools. Their quiet design helps patients feel calm and comfortable. For example, ventilators with low noise keep intensive care units peaceful. Dental tools powered by brushless dc motors work precisely and gently, reducing discomfort for patients.

Here’s why these motors are great for medical devices:

|

Feature |

Benefit |

|---|---|

|

Noise Level |

Runs quietly, keeping medical spaces calm and undisturbed. |

|

Efficiency |

Uses energy wisely, ensuring reliable and steady performance. |

|

Applications |

Found in ventilators, dental tools, and surgical devices. |

|

Power Range |

Can power devices up to 300W, fitting many medical needs. |

|

Customization |

Can be adjusted to match specific device requirements. |

|

Torque Density |

Provides smooth and accurate control for fluid pumps. |

|

Longevity |

Lasts a long time, reducing the need for repairs. |

These motors are vital for healthcare. Their strong torque ensures precise control, which is key for infusion pumps and surgical robots. They also save energy, helping hospitals cut costs.

Another benefit is reduced vibration. This makes patients more comfortable and improves accuracy during delicate tasks. For example, in fluid pumps, brushless dc motors ensure steady flow rates, keeping patients safe.

Note: Fewer breakdowns and less maintenance mean these motors are perfect for life-saving equipment.

Choosing brushless dc motors for medical tools ensures quiet, efficient, and reliable performance. They improve patient care and support the need for advanced healthcare technology.

Discover the Outer Rotor Motor

Explore the advanced features and benefits of the Outer Rotor Brushless DC Motor for your projects.

Addressing Challenges and Misconceptions About Brushless Motors

Cost vs. Long-Term Value

Some people think brushless motors cost too much. But over time, they save money. These motors need more money upfront than older ones. However, they use less energy and last longer. This means big savings later. For example, systems like servo drives cut costs and boost efficiency. They also reduce waste and speed up production changes. This makes them a smart choice for eco-friendly work.

Picking brushless motors is like making a smart investment. You’ll pay less for energy and repairs while getting better results. This makes them great for businesses wanting to save money in the long run.

Complexity of Design and Manufacturing

Brushless motors are built with advanced parts to work better. But this makes them harder and pricier to make. They use magnets, special electronics, and precise controls. These features raise their cost. For example, studies show:

|

Aspect |

Details |

|---|---|

|

Advantages |

No brushes, better efficiency, cooler running, improved power use. |

|

Disadvantages |

Costs more due to magnets and electronics, harder to set up. |

|

Cost Factors |

High starting cost, but cheaper electronics may help soon. |

Other issues include interference from electromagnetic waves and changing material prices. Still, new technology is lowering costs, making these motors easier to afford.

Scalability Across Industries

Brushless motors can be used in many different ways. They work well in small gadgets and big machines. Their design helps them fit into all kinds of jobs. For example:

-

They power drones and factory conveyor belts.

-

They work in tiny tools and heavy equipment.

-

Their many sizes and types make them useful everywhere.

This flexibility makes brushless motors important in industries like healthcare and transportation. As technology improves, these motors will keep helping businesses grow and save energy.

Environmental Benefits and Sustainability

Brushless motors help the environment in big ways. They use less energy because they are very efficient. This lowers greenhouse gas emissions and supports cleaner energy use. For example, Permanent Magnet Synchronous Motors (PMSMs) work at up to 95% efficiency. This saves a lot of electricity over time. Using less electricity means less need for fossil fuels to make power.

Another benefit is that brushless motors last longer. They don’t wear out as fast as brushed motors. This means fewer replacements, which reduces waste. Less waste means fewer items in landfills and less need for manufacturing. Choosing brushless motors helps save resources and protect the planet.

Tip: Picking energy-saving motors like PMSMs helps fight climate change and saves money.

Still, there are challenges with sustainability. Brushless motors, like PMSMs, use rare earth materials for magnets. Mining these materials can harm the environment. But the energy saved during the motor’s life often makes up for this. Companies are also working on ways to use fewer rare earth materials to make motors greener.

Brushless motors are also important for renewable energy. They are used in wind turbines and solar trackers. Their accuracy and efficiency improve how much energy these systems produce. This makes renewable energy more dependable.

|

Environmental Benefits |

Impact |

|---|---|

|

High Efficiency |

Uses less energy and cuts emissions |

|

Long Lifespan |

Reduces waste and fewer replacements |

|

Renewable Energy Applications |

Boosts green energy system performance |

Using brushless motors helps create a sustainable future. They support global goals for saving energy and protecting the environment. These motors are a smart choice for people and industries that care about the planet.

The Future of Brushless Motors in Technology

Integration with AI and IoT

Brushless motors are getting smarter with AI and IoT. These tools help motors adjust to changes instantly. For example, AI can tweak motor settings based on how it’s used. This saves energy and makes the motor last longer. IoT lets motors predict problems before they happen. This reduces downtime and saves money.

In factories, IoT-enabled motors talk to other machines. This creates smooth and efficient workflows. Engineers use digital twins to test motor performance virtually. They can spot issues early and fix them faster. With 5G and edge computing, motors will make decisions even quicker.

|

Aspect |

Details |

|---|---|

|

Adjusts to loads for better performance. |

|

|

Energy Efficiency |

Uses less power and lasts longer. |

|

Operational Benefits |

Cuts downtime with predictive maintenance. |

|

Enhanced Automation |

Faster decisions with 5G and edge computing. |

Advancements in Materials and Manufacturing

New materials and methods are improving brushless motors. Scientists are creating stronger magnets and better steels. These reduce energy waste and handle heat better. For example, magnetic 3D printing by KIMM skips molds. This lowers costs, cuts waste, and boosts motor performance.

Axial flux motors, made with these new methods, are becoming popular. They are small but powerful, perfect for robots and electric cars. Adding variable frequency drives (VFDs) makes them even more efficient for different tasks.

Expanding Applications in Emerging Technologies

Brushless motors are in high demand for new industries. In cars, they power electric vehicles, which are growing fast. These motors are efficient and strong, ideal for green transportation.

They are also key in renewable energy. Wind turbines and solar trackers use them for precise and reliable energy production. Factories using Industry 4.0 tech benefit from their ability to work with data systems. This shows how flexible brushless motors are for modern needs.

Note: High-power brushless motors are changing industries like cars and energy. They are driving innovation and efficiency forward.

Contribution to a Sustainable Future

Brushless motors help make the planet cleaner and healthier. They use less energy, which lowers electricity use and cuts greenhouse gases. This helps reduce air pollution and fight climate change. For example, motors in small electric cars save 35,000 tons of CO₂ each year. Electric motorcycle motors also cut emissions by 32,000 tons annually. These savings are important for protecting the environment.

Companies are finding ways to make motors more eco-friendly. They study how motors affect the environment from start to finish. This helps them find ways to waste less and recycle more. Many manufacturers now use recycled materials to build motors. This reduces the need for new resources. Motors are also being designed to be easier to recycle when they wear out.

|

Aspect |

Description |

|---|---|

|

Lifecycle Assessments |

Checks environmental effects from making to recycling motors. |

|

Use of Recycled Materials |

Uses old parts to make new motors. |

|

Manufacturing Efficiency |

Makes motors with less waste and energy. |

|

Design for Recycling |

Builds motors that are simple to recycle. |

Brushless motors also work well with green energy systems. They improve how solar panels and wind turbines use power. In farming, factories, and HVAC systems, these motors save energy and lower carbon footprints. This helps industries meet their eco-friendly goals.

Switching to brushless motors supports future carbon rules and attracts green-minded buyers. Choosing these motors means saving energy and helping the planet while enjoying their strong and reliable performance.

Tip: Using brushless motors is a smart way to save energy and protect the Earth for future generations.

Brushless motors are changing how we use high-performance machines. They save energy by working more efficiently and last longer because they don’t wear out quickly. These motors need little care, which saves both time and money. Their small size packs a lot of power, making them perfect for modern gadgets and systems.

|

Benefit |

What It Means |

|---|---|

|

Efficiency |

They turn electricity into motion better, wasting less energy. |

|

Durability |

They last longer since there are no brushes to wear out. |

|

Maintenance |

They need less fixing because there are no brushes to replace. |

|

Adaptability |

Their small size gives strong power, fitting tight spaces easily. |

As technology grows, brushless motors will lead the way in new ideas and eco-friendly solutions. They work well in many areas, making them important for future inventions. Choosing a brushless motor means picking a tool that is efficient, dependable, and ready for tomorrow’s needs.

FAQ

1. Why are brushless motors more efficient than brushed ones?

Brushless motors don’t use brushes, so there’s no friction. They use electronics to control power, wasting less energy. This design lets them work at 90% efficiency. Brushed motors only reach 75-85% efficiency.

2. Can brushless motors handle tough conditions?

Yes, they work well in extreme places. Their strong design resists damage from heat and dust. This makes them great for factory machines, outdoor tools, and green energy systems.

3. Are brushless motors good for small gadgets?

Yes, they are small and light, perfect for tiny devices. You’ll find them in drones, medical tools, and home appliances. They are powerful without being heavy or bulky.

4. How do brushless motors save on repairs?

Brushless motors don’t have brushes that wear out fast. Bearings are the only parts needing care sometimes. This means fewer fixes and lower costs over time.

5. Do brushless motors help the environment?

Yes, they use less energy and last longer, cutting waste. They work well in wind turbines and solar trackers, supporting clean energy solutions.