Tailored for Precision Grinding Systems — We are your application-specific engineering partner.

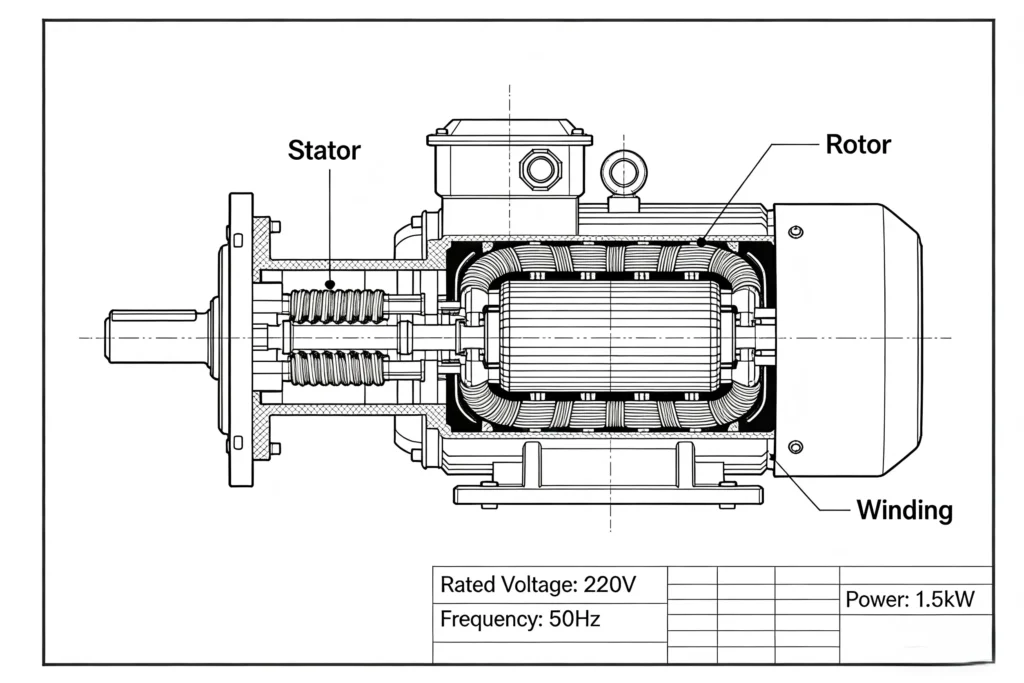

Verification of insulation integrity and dielectric strength to confirm electrical safety under the intended operating conditions before production release.

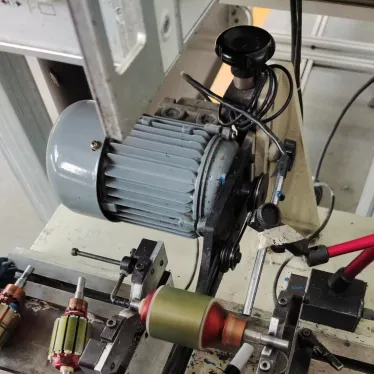

Evaluate motor performance (speed, current, output) under no-load and load conditions to verify design and assembly before mass production.

Verify starting performance and overload tolerance under load and sudden resistance increase, ensuring reliable motor startup and operation in expected conditions.

Simulation of jamming and stall scenarios to verify motor tolerance under abnormal operating conditions and the reliability of recovery operation prior to production approval.

Assess temperature rise under duty cycles with short operating periods, frequent start–stop, and high peak loads to confirm thermal design suitability before mass production.

Repeated on–off cycling to evaluate motor reliability under frequent switching conditions representative of real application usage, ensuring durability prior to production release.

Evaluation of noise and vibration behavior under representative operating conditions to identify potential mechanical or structural risks before mass production.

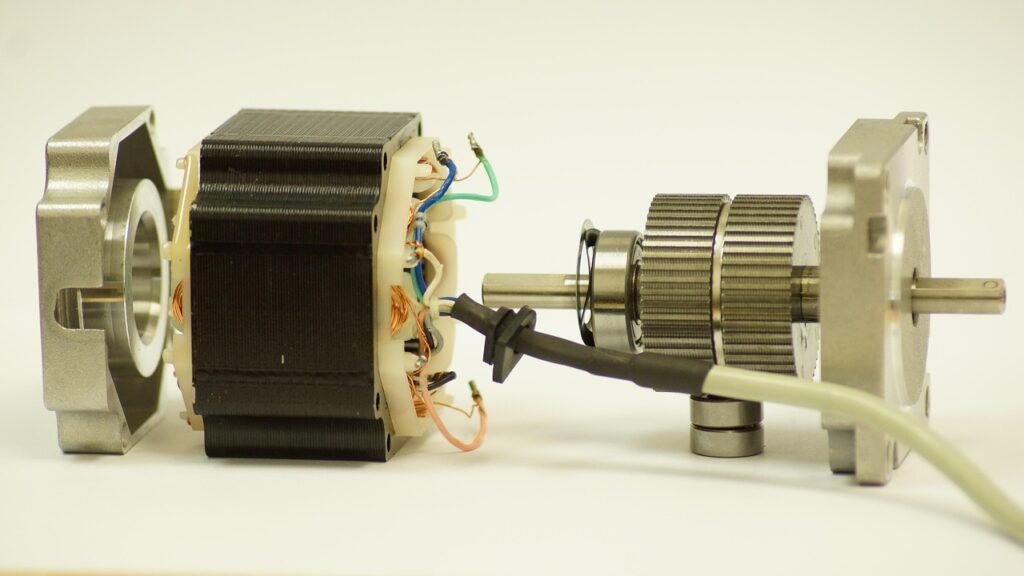

Verify key external features and dimensions (outer diameter, shaft, mounting interface, assembly) to ensure design conformity and readiness for consistent production.

Get Template

Frequent torque spikes during bean-crushing phases + heat accumulation during peak morning rush + strict café acoustic mandates.

High-Torque AC/BLDC Hybrid Platform + Specialized cooling airflow design + Dynamic sensor-controlled pulse handling.

Noise < 55dB (Commercial) verified; 1,000,000+ grind cycles tested; Peak thermal stability maintained in compact housings.

Ideally: Application duty cycle, torque/speed requirements, voltage/frequency, and mechanical interface dimensions. Photos of existing motors help significantly.

Yes. We configure windings for 100V, 110V, 120V, 220V, 230V, 240V at both 50Hz and 60Hz depending on your target market.

For standard platforms, MOQ is flexible. For highly customized tooling, we typically require 500-1000 units per order after pilot runs.

Our factories are ISO 9001 and IATF 16949 certified. We support component certification for UL, CE, CCC, RoHS, and REACH upon request.

Pro Tip: Uploading a nameplate photo helps us match 50% faster.

Адрес:No.121, Xinlong Road, Zhonglou Xinzha Subdistrict, Changzhou City, Jiangsu Province, China

Телефон: +86-18261152679

Whatsapp: +86-18261152679

Электронная почта: sales@honestmotor.cn

Политика конфиденциальности / Условия предоставления услуг / Настройки файлов cookie / Карта сайта

© 2025 Honest Все права защищены.