Solution Approach: We ensure that our motors meet all necessary regulatory certifications for medical devices, including durable components and design features that meet safety and performance standards. Additionally, we conduct extensive testing to ensure long-term durability in real-world applications.

Options & Customization (4 Pillars That Reduce Device Risk)

Verification of insulation integrity and dielectric strength to confirm electrical safety under intended operating conditions before production release.

Evaluation under no-load and loaded conditions, verifying speed stability, current behavior, and output consistency to confirm correct design and assembly before scaling.

Verification of reliable starts under load, including high-start torque conditions and load increases, ensuring stable operation in real concentrator environments.

Simulation of abnormal conditions such as motor jamming or blockage, verifying the motor’s ability to recover and operate reliably in case of unexpected resistance or disruptions.

Assessment of temperature rise under continuous-duty operation, ensuring that the motor remains stable and efficient over long periods without overheating or performance degradation.

Repeated on-off cycling to evaluate motor reliability under frequent switching conditions, ensuring durability before production release.

Evaluation of noise and vibration behavior under representative operating conditions to ensure minimal environmental disturbance and patient comfort.

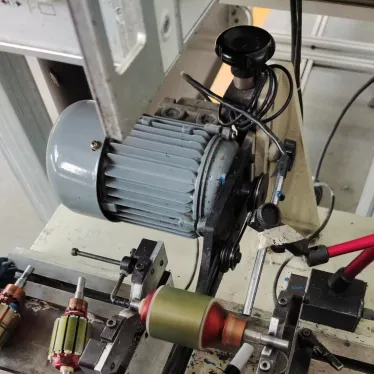

Verification of key dimensions and external features (shaft, flange/face, mounting interface, terminal box) to ensure consistent fitment and production quality.

Get Template

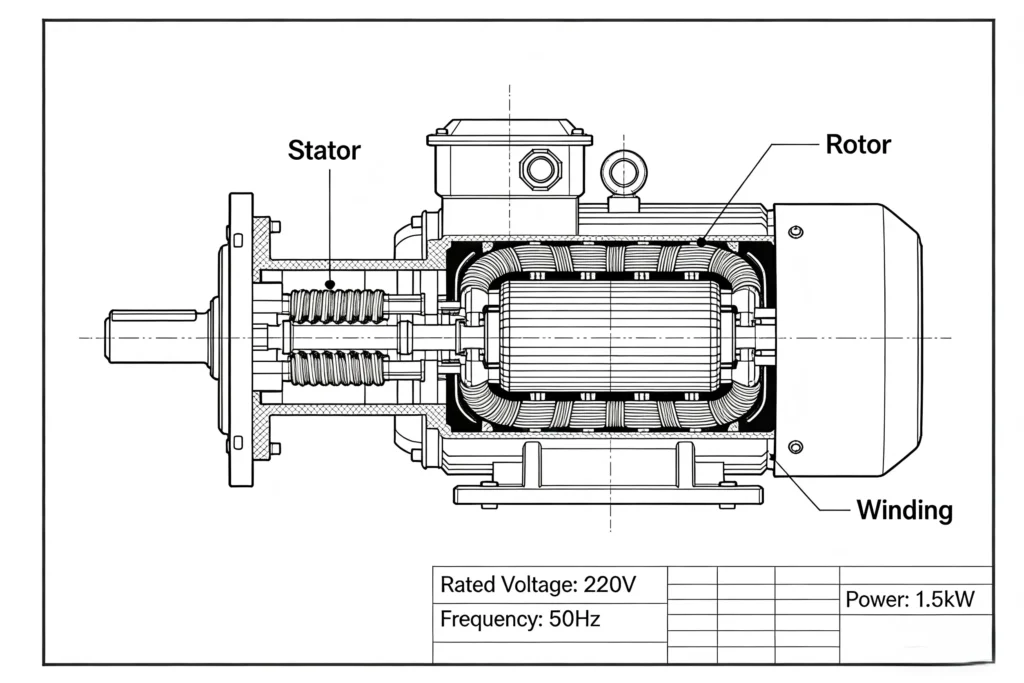

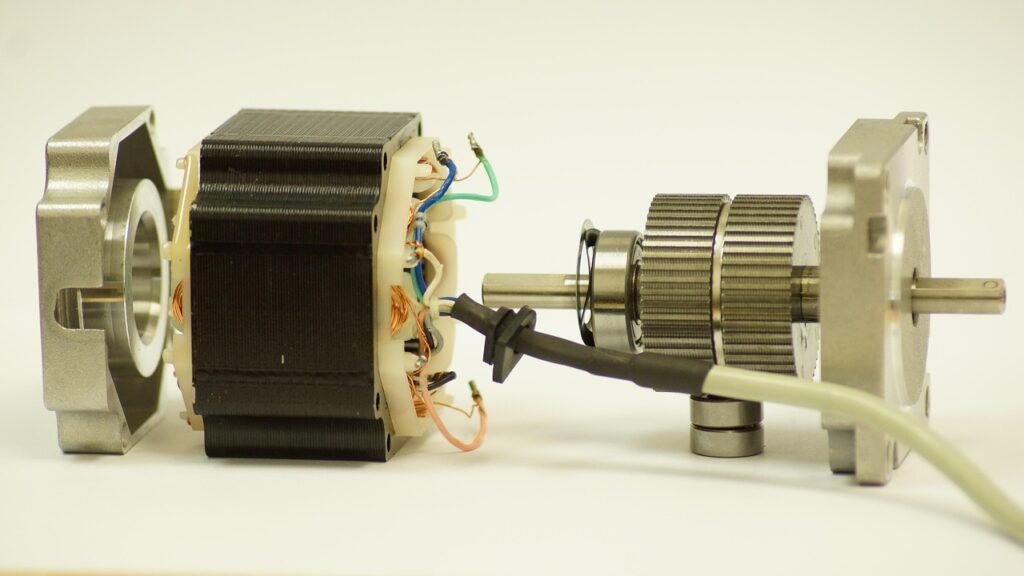

Design a motor solution for oxygen concentrators that guarantees reliable, efficient, and quiet performance while meeting medical-grade regulatory requirements. The motor must operate continuously without overheating and minimize noise in sensitive healthcare environments.

We designed a BLDC motor with high efficiency, low noise, and optimized thermal stability. The motor includes an IP55-rated enclosure for dust and water resistance, ensuring durability and compliance with medical standards. For reliability, we incorporated low-vibration features and advanced thermal management to prevent overheating during long operation hours.

Starting capability validated under load with high-torque requirements; thermal stability verified during continuous operation; noise levels consistently below 50 dB under real-use conditions. Dimensions and mounting interfaces confirmed for easy integration into the concentrator’s compact design. Electrical safety tests passed, with dielectric strength compliance to medical standards.

Honest Motor provides one-on-one technical customization based on equipment host requirements. Customizable aspects include motor power, performance parameters, insulation level, installation method, specifications, and appearance color. Voltage range is AC single-phase 100V-240V, power range 10W-10kW, core outer diameter 20mm-260mm, suitable for industrial and civilian scenarios.

The MOQ is 500 units. Samples are chargeable and can be delivered within 15 days; sample cost is refundable upon batch order. Batch delivery time is 25-30 days. We offer expedited communication and production for urgent projects.

All products meet CE and UL certifications. Materials comply with RoHS and REACH. Our factories hold ISO9001 and IATF16949 certifications. Every motor undergoes rigorous electrical safety, mechanical performance, appearance, and dimensional inspections before shipment. Batch sampling includes load characteristics, temperature rise, and life expectancy tests, accompanied by certification and test reports.

We provide 2 years warranty and lifetime maintenance service, with engineers available online for rapid response within 12 hours. After-sales include technical consultation, troubleshooting, and spare parts supply to ensure stable operation under various conditions.

Honest Motor has multiple factories , enabling flexible small-batch production across sites. This reduces lead times and allows quick adaptation to varied production demands.

Pro Tip: Uploading a nameplate photo helps us match 50% faster.

Address:No.121,Xinlong Road,Zhonglou Xinzha Subdistrict,Changzhou City, Jiangsu Province, China

Phone: +86-18261152679

Whatsapp: +86-18261152679

Email: sales@honestmotor.cn

Privacy Policy / Terms of Services / Cookie Settings / Site Map

© 2025 Honest All Rights Reserved.