Motor performance is precision-matched to your machine’s load profile and duty envelope. We validate thermal stability and water-ingress protection before you scale.

Tailored for High-Pressure Applications — Application-Specific Engineering

Ensuring application-specific reliability through structured verification before mass production.

Verification of insulation integrity and dielectric strength to confirm electrical safety under extreme pressure and water exposure before production release.

Evaluate motor performance under both no-load and load conditions to verify stability in power delivery, current, and output during high-pressure washing cycles.

Verification of motor’s ability to start reliably under heavy initial load conditions, ensuring consistent performance even during peak power demands.

Simulating jamming or blockage scenarios to test motor’s ability to recover from temporary mechanical resistance, ensuring it operates without failure under adverse conditions.

Assessment of temperature rise during continuous high-load operation, ensuring that the motor can handle extended pressure washing cycles without overheating.

Repeated on/off cycling to evaluate motor reliability under frequent switching conditions, typical of commercial and industrial pressure washer usage.

Evaluating noise and vibration characteristics to ensure smooth operation and minimal environmental disturbance during use.

Verification of key dimensions (shaft, flange, mounting interface) to ensure consistent fitment with various pressure washer systems and conformity with design specifications.

Get Template

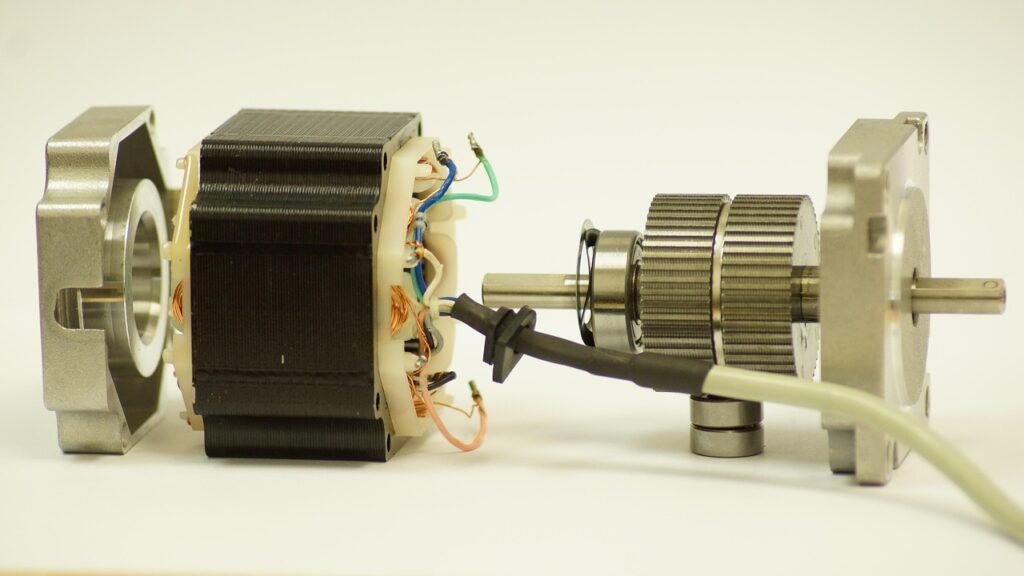

Design a motor solution capable of withstanding the intense vibration, high starting torque, and extended continuous duty cycles required for industrial-grade high-pressure washers, while maintaining low noise and long-term durability.

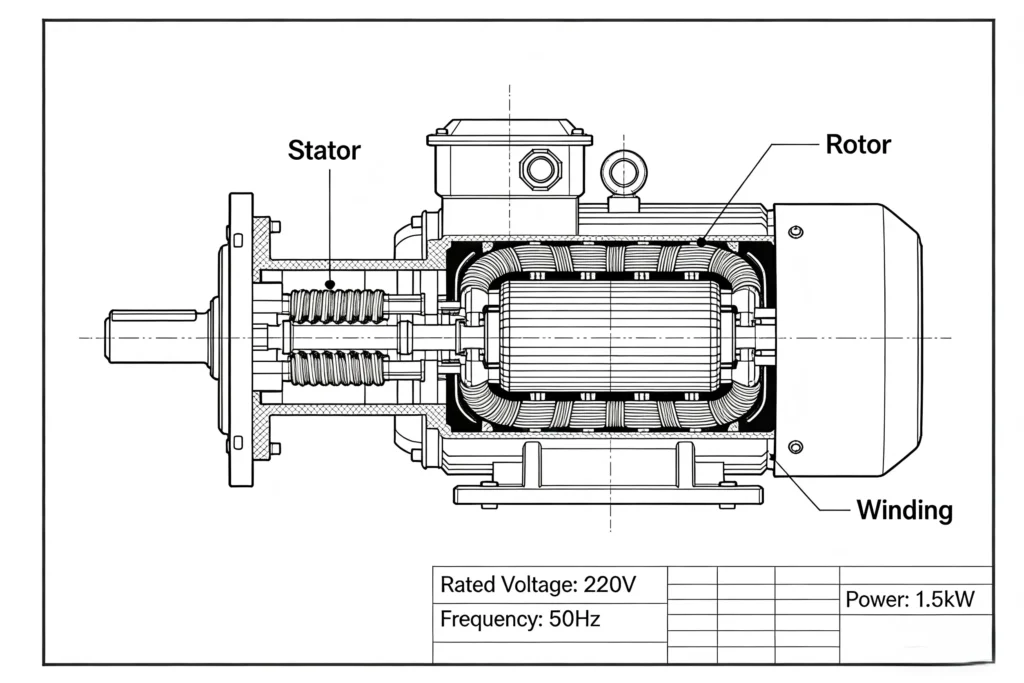

We developed a BLDC motor platform with high starting torque and low vibration, optimized for extended-duty cycles. The motor features a weatherproof, corrosion-resistant enclosure and high-efficiency cooling system, ensuring reliable operation in harsh environments. Modular mounting options and customizable interfaces ensure compatibility with various high-pressure washer models.

Starting capability verified under heavy load conditions; thermal stability confirmed during extended high-load operation; vibration and noise levels maintained within acceptable limits; mechanical and electrical integrity checked to confirm product suitability for industrial cleaning applications.

Universal: Best for entry-level, portable units needing high power-to-weight at a low cost.

Induction: Ideal for premium consumer or semi-pro units requiring long life and low noise.

BLDC/PMSM: The choice for high-end, cordless, or smart systems demanding maximum efficiency and digital control.

We prioritize pressure-load mapping combined with peak current logging and thermal rise cycles. This allows us to simulate “worst-case” consumer habits (rapid trigger pulls) and freeze the motor design within 1-2 validation loops.

Continuous-duty thermal mapping under peak load and high-cycle start/stop endurance testing. These DVT protocols ensure the motor stays within safe operating temperatures even in compact, low-airflow enclosures.

Pro Tip: Uploading a nameplate photo helps us match 50% faster.

Address:No.121,Xinlong Road,Zhonglou Xinzha Subdistrict,Changzhou City, Jiangsu Province, China

Phone: +86-18261152679

Whatsapp: +86-18261152679

Email: sales@honestmotor.cn

Privacy Policy / Terms of Services / Cookie Settings / Site Map

© 2025 Honest All Rights Reserved.