You encounter high efficiency motor technology in numerous settings every day, from factories and homes to smart devices. Permanent magnet motors stand out for their exceptional energy savings and reliable performance.

Permanent magnet synchronous motors can be up to 15% more efficient than traditional induction motors.

These motors use up to 42% less energy in appliances and deliver 24% higher efficiency at low speeds.

The permanent magnet asynchronous motor market is expanding rapidly as industries seek improved sustainability and reduced operational costs.

Key Takeaways

Permanent magnet motors have strong magnets in the rotor. This helps lower energy loss and heat. They can be up to 15% more efficient than asynchronous motors.

These motors stay cooler and last longer. They need less maintenance because they have fewer parts that can break. There are no rotor copper losses.

Permanent magnet motors give better speed and torque control with electronic drives. This lets machines work smoothly and use less energy.

They give more power for their size and keep high efficiency. They work well even at low speeds or with light loads. This helps save energy in things like pumps and factories.

Permanent magnet motors cost more at first. But they save money over time by lowering energy bills and repair costs.

Structural Differences Driving Efficiency

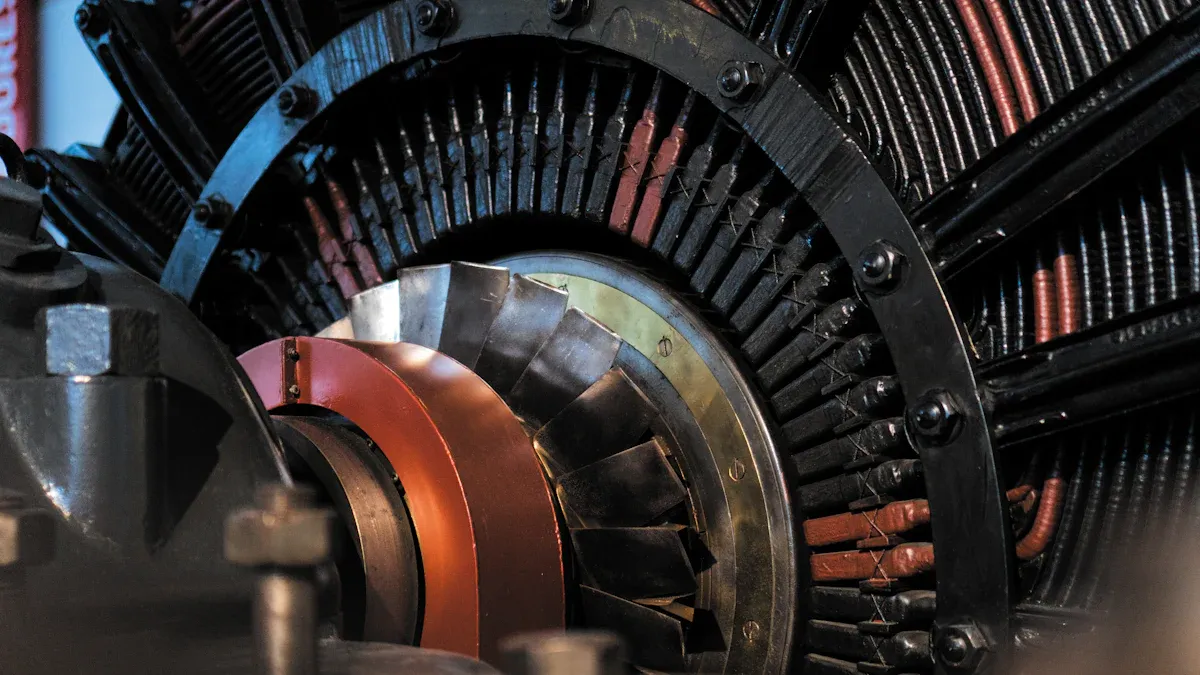

Permanent Magnet Rotor

When you look inside, the rotor is different. Permanent magnet motors have strong magnets in the rotor. These magnets are often made from rare earth materials. The magnets make a steady magnetic field all the time. The rotor does not need electric current to make this field. This means the permanent magnet asynchronous motor does not waste energy as heat in the rotor. There are no rotor copper losses, so it works better. The motor stays cooler and lasts longer. High efficiency motor technology uses these magnets to give more torque. The motor can be smaller and lighter. You can run it at low speeds and still get good power.

Tip: Permanent magnet motors keep their torque steady even when the speed drops. This helps you save energy in many applications.

Induction Motor Rotor

Ac induction motors work in another way. The rotor does not have any magnets. It uses metal bars or windings instead. The stator makes a magnetic field that goes to the rotor. This makes current flow in the rotor. The current makes another magnetic field, and the rotor turns. But this causes copper losses in the rotor. The motor gets hot and loses some efficiency. You need more energy to keep it running, especially at low speeds. Ac induction motors are heavier because they have more windings and metal parts in the rotor.

Here is a quick comparison:

Feature | Permanent Magnet Motor | AC Induction Motor |

|---|---|---|

Rotor Magnetic Field | Permanent magnets | Induced by rotor current |

Rotor Copper Losses | None | Present |

Weight | Lighter | Heavier |

Torque at Low Speed | High | Lower |

Stator & Magnetic Design

Both types of motors use a stator with coils and slots. The big difference is how the rotor works with the stator’s magnetic field. In a permanent magnet asynchronous motor, the rotor and stator fields stay together. There is no slip or lag. This gives a high power factor and better efficiency. The stator in a permanent magnet motor can use better materials to lower core losses. Ac induction motors often use regular steel, which can lose more energy as heat. High efficiency motor technology in permanent magnet motors helps save energy and keeps the motor cooler. You get a motor that is smaller, lighter, and more reliable.

Technology Advantages of Permanent Magnet Motors

Reduced Rotor Losses

Permanent magnet motors work better because they have strong magnets in the rotor. These magnets mean you do not need extra current to make a magnetic field. With a permanent magnet asynchronous motor, you do not get the electrical losses and heat that happen in older motors. This design keeps the motor cooler and uses less energy. You can save between 20% and 50% more energy than with old induction motors. The no-load current is about one-third of what you see in asynchronous motors. This makes the motor use less energy, even at different speeds or loads. Less heat also means the motor lasts longer and does not need as much cooling.

Note: Permanent magnet motors help you save energy and spend less on repairs because they make less heat and lose less electricity.

Synchronous Operation

Permanent magnet motors spin the rotor at the same speed as the stator’s magnetic field. This is called synchronous operation. There is no slip, which is when the rotor falls behind the magnetic field in asynchronous motors. No slip means you do not waste energy on extra currents. You get very good speed control, even if the load changes. This makes permanent magnet synchronous motors great for jobs that need steady speed and high efficiency. You can count on these motors to work well in things like factory machines and smart home devices.

Synchronous motors turn the rotor at the same speed as the stator’s magnetic field.

Permanent magnet synchronous motors use magnets to make a magnetic field without needing extra energy.

No slip means you do not lose energy, so the motor works better.

Synchronous operation gives you exact speed control, no matter the load.

These features make permanent magnet motors perfect for jobs that need to be efficient and reliable.

Enhanced Control

You can use special control methods with permanent magnet motors to make them work even better. Field-oriented control (FOC) lets you control torque and speed separately, so the motor reacts quickly and correctly. This high efficiency motor technology helps you use every bit of current well. Digital control converters help make the motor stronger and lighter. These motors also work with smart systems and IoT devices, so you can watch and change how they work in real time. Honest’s products use these controls to give you very efficient motors for many uses.

Aspect | Explanation |

|---|---|

Control Strategies | Field-Oriented Control (FOC) gives you exact and quick motor control. |

Maximum Torque per Ampere | You get more torque for each ampere, making control about 5% better. |

Robustness | The control stays good even if the motor changes. |

Digital Control Converters | Make the motor stronger and lighter for its size. |

Application Impact | Better control lets PMSMs take the place of old mechanical systems. |

Experimental Verification | Tests show better control and output with the best settings. |

These advanced controls help your permanent magnet motors replace old, less efficient systems. You get faster response, smoother running, and more energy savings. This makes permanent magnet asynchronous motors a smart pick for anyone who wants a very efficient motor in their machines.

Energy Efficiency in Real-World Performance

High Power Density

Permanent magnet motors give more power from a smaller size. They have high power density, so they make more torque and speed. You can fit them into small spaces easily. These motors are lighter, so moving machines is easier. Permanent magnet synchronous motors give 30% to 60% more torque than asynchronous motors. Machines can start and stop faster, which helps in factories. Fast speed changes are good for many jobs.

Permanent magnet motors use strong magnets for a powerful field.

You get better torque, so machines work harder without getting bigger.

The motors react fast, which is important for control in factories.

Here is a table that shows how efficient different motors are:

Motor Type | Typical Efficiency (%) | Key Characteristics |

|---|---|---|

Permanent Magnet Synchronous Motors (PMSMs) | Above 95% | High efficiency due to reduced rotor losses |

Synchronous Motors | 90-98% | High power output, precise speed control |

Induction Motors | 85-95% | Robust, widely used |

Permanent magnet motors can reach over 95% efficiency. This means you save energy and get better results.

Light-Load Efficiency

Permanent magnet motors work well even at low power. They stay efficient when not running at full strength. This is good for pumps, fans, and home appliances. Most machines do not use full power all the time. Permanent magnet synchronous motors keep over 90% efficiency from 25% to 120% of their rated load. Asynchronous motors lose efficiency fast when the load is low.

Here are some reasons why permanent magnet motors are better at light loads:

The magnets mean you do not need extra current, so you save energy.

The simple design cuts down on mechanical losses.

Strong magnets give high power density.

The magnetic circuit keeps losses low.

The rotor has no windings, so there are no rotor losses.

Smart controls help the motor work better.

Good temperature control keeps efficiency high.

Special magnetic materials like NdFeB make the motor stronger.

Sinusoidal back EMF lowers harmonic losses.

High power factor means less wasted power.

You get high efficiency at many speeds.

Permanent magnet motors have a power factor close to 1. This means you use less current and lose less energy in the stator. You can use smaller power supplies and save space and money.

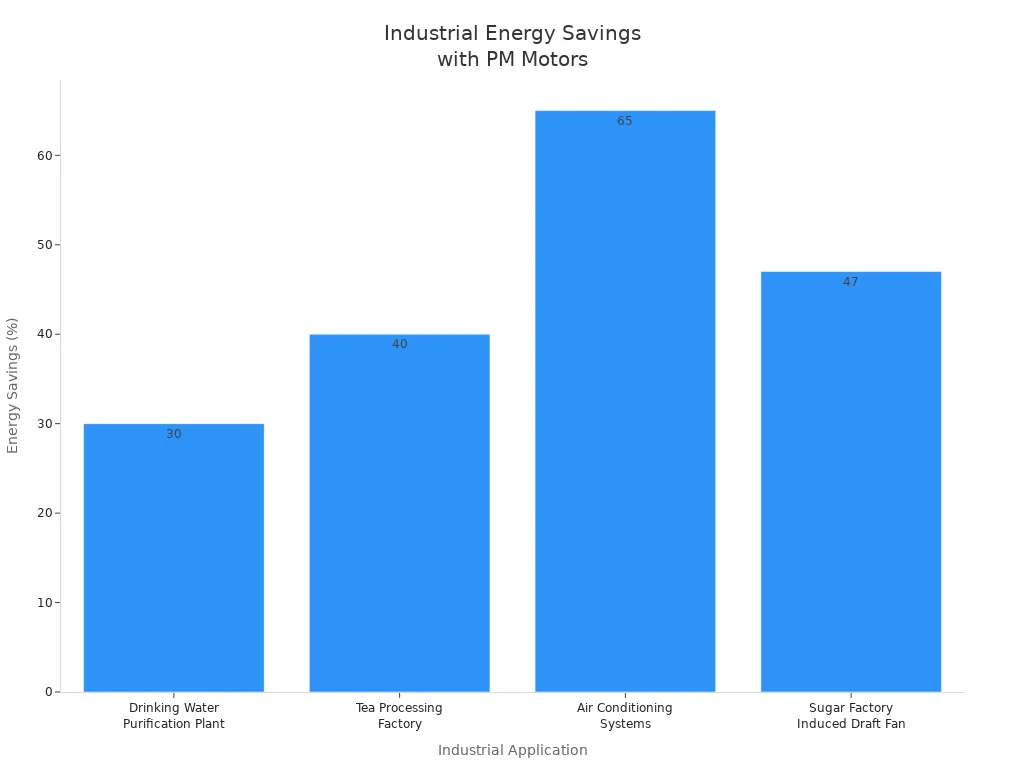

Industrial Savings

You see real energy savings in factories, water plants, and homes with permanent magnet motors. Honest’s solutions use these motors to cut energy use and costs. You get steady performance, high power factor, and good operation at different loads.

Here is a table showing how permanent magnet motors save energy in different places:

Industrial Application | Motor Control Method | Energy Savings (%) | Key Details |

|---|---|---|---|

Drinking Water Purification Plant, Egypt | Permanent Magnet Motor + VSD | ~30 | VSD pump motor vs. old throttling; less starting torque and current; better pressure control. |

Tea Processing (St. Combs Tea Factory) | VSD vs. Conventional Damper | 40 | Two 4 kW motors tested; VSD motor saved more energy. |

Air Conditioning Systems, Saudi Arabia | VSD vs. On/Off Control | 22-65 | Two 5-ton A/C units tested; VSD matches speed to cooling need. |

Sugar Factory Induced Draft Fan | VSD Installation | 47 | 400 HP fan motor with VSD; better air flow and energy use. |

Permanent magnet motors with variable speed drives (VSDs) match speed to the load. This stops energy waste from old control ways. You use less energy and pay lower bills. Smart controls, like those in Honest’s products, save even more energy by cutting copper and iron losses.

You also get steady performance and quick response. Permanent magnet motors keep high power factor and efficiency at many speeds and loads. Asynchronous motors need extra parts to fix power factor and lose efficiency at low speeds. Permanent magnet motors work well and need less fixing, which saves more energy and money for your business.

Tip: Honest’s high efficiency motor technology helps you save energy in factories, water plants, and homes. You get more value from every bit of energy you use.

Industrial Applications Showcasing Efficiency

Industrial Automation

Permanent magnet ac motors are changing how factories work. These motors help robots and machines move faster. They also use less energy. The magnets inside make a strong field. The motor does not need extra electricity for this. This saves energy and keeps the motor cooler. Permanent magnet ac motors are small but powerful. You can put them in tight spaces on factory floors.

Many factories use these motors in robots and vehicles. The motors help machines move with more control and speed. This is important for making things quickly and well. Permanent magnet motors last longer because they do not get as hot. You spend less money fixing them. You also do not need big cooling systems.

Tip: Permanent magnet ac motors help you spend less on repairs and keep machines working well.

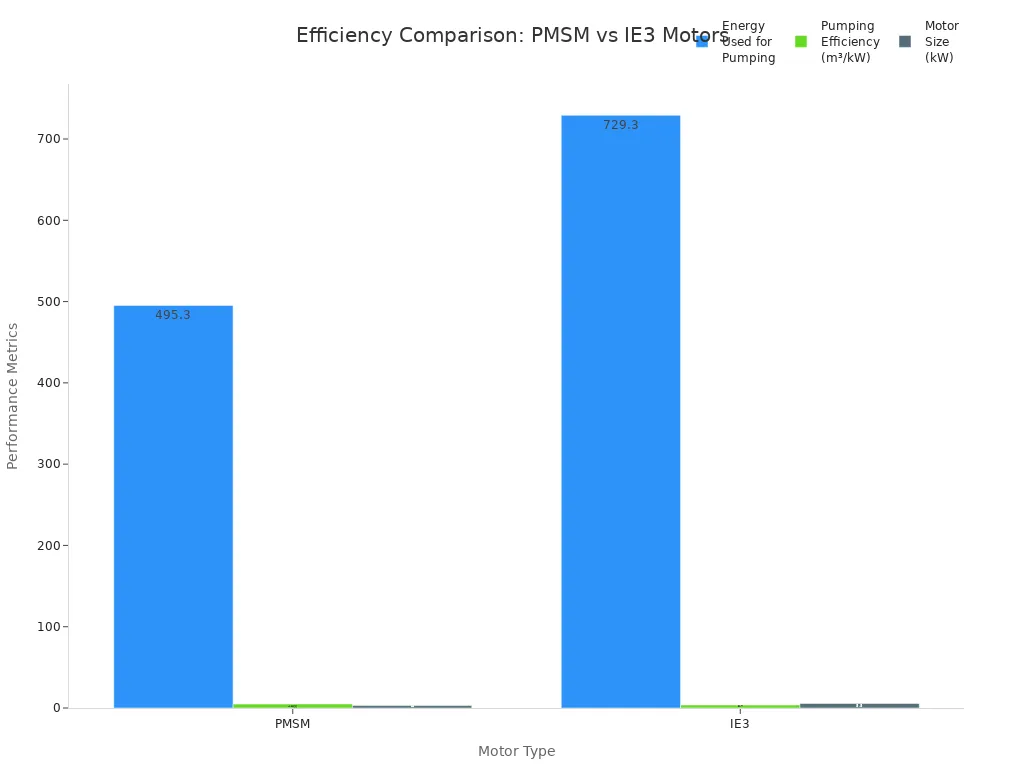

Pumps & Water Treatment

Permanent magnet ac motors work great in pumps and water plants. These motors make pumps run better and use less energy. They keep working well at different speeds and loads. Even when the pump is not at full power, they stay efficient. This helps you save energy every day.

Look at this table to see how these motors help pumps:

Feature | PMSM (Permanent Magnet AC Motor) | IE3 Asynchronous Motor |

|---|---|---|

Energy Used for Pumping | 495.3 kW for 2,410 m³ sludge | 729.3 kW for 2,699.5 m³ sludge |

Pumping Efficiency | 4.866 m³ per kW | 3.7 m³ per kW |

Motor Size | 3 kW | 5.5 kW |

Energy Savings | 24% less energy | — |

Return on Investment | 3 months | — |

Permanent magnet ac motors are good for the environment. They use less energy, so you make less pollution. Many water plants save money by using these motors. The system also gets quieter.

You can pump more sludge with less power. These motors last longer and do not need much fixing. This saves you money and helps the planet too.

Considerations and Trade-Offs

Cost vs Savings

Permanent magnet motors cost more at first. This is because they use special materials and technology. But you should think about the long-term savings. Permanent magnet motors use less energy and need fewer repairs. Their strong build and fewer moving parts mean less maintenance. You spend less money fixing or replacing them.

Aspect | Permanent Magnet Synchronous Motors (PMSMs) | Asynchronous Motors (Induction Motors) |

|---|---|---|

Initial Cost | Higher upfront price | Lower initial price |

Energy Efficiency | High, saves on utility bills | Lower, uses more energy |

Maintenance | Less frequent, fewer parts to replace | More frequent, more wear |

Operational Life | Longer lifespan | Shorter lifespan |

Total Cost of Ownership | Lower over time | Higher over time |

Note: Permanent magnet motors help you save money over time. You pay less for energy and repairs.

Control Requirements

Think about how you will control your motor. Permanent magnet motors need electronic drives for good speed and torque control. These drives keep the motor running at the same speed, even if the load changes. You get fast and accurate control. This is important for robots and smart machines. Asynchronous motors are easier to start and use with simple controls. But they do not give you as much precision.

Aspect | Permanent Magnet Motors | Asynchronous Motors |

|---|---|---|

Speed Control | Needs electronic drive | Simple, less precise |

Dynamic Response | Fast and accurate | Slower, less accurate |

Control Complexity | Higher | Lower |

Tip: If you need exact speed or torque, permanent magnet motors are better for control.

Maintenance Considerations

Permanent magnet motors help you spend less time fixing things. They have fewer parts that wear out. This means less downtime and lower repair costs. Good bearings and sensors let you find problems early. You get fewer surprise breakdowns. These motors run cooler, so you need less cooling equipment. Asynchronous motors need more checks and part replacements, especially in tough places.

Permanent magnet motors last longer and need less fixing.

You can restart them quickly after stopping.

Less heat means less stress on your system.

Picking the right motor helps you save money and keep your machines working well for years.

You save a lot of energy with permanent magnet motors. These motors work better and last longer. You can control them more easily.

In water plants, factories, and homes, you use less energy and pay lower bills.

Permanent magnet motors help cut pollution and make the world cleaner.

Their small size and strong performance help you do your job better.

Benefit | How It Helps You |

|---|---|

Higher efficiency | Less wasted energy, more savings |

Lower maintenance | Fewer fixes, longer motor life |

Smoother and safer machine work |

Choose the best motor for your job to save energy and make your machines work better.

FAQ

What makes permanent magnet motors more efficient than asynchronous motors?

Permanent magnet motors have strong magnets in the rotor. They do not need extra current for a magnetic field. This design cuts down on energy loss and heat. You get better efficiency with these motors.

Where can you use permanent magnet motors?

Permanent magnet motors work in factories and water plants. You can use them in home appliances too. They are good for robots, pumps, fans, and smart devices. These motors help save energy in many places.

Do permanent magnet motors need special controls?

Yes, you need electronic drives to control them. These drives let you change speed and torque easily. You get fast and exact control for different jobs.

How do permanent magnet motors help you save on maintenance?

Permanent magnet motors have fewer parts that wear out. They run cooler and last longer. You spend less time and money fixing them. Your machines work better and stay running longer.