Built Around Your Pump System — We are an application-custom partner.

Verification of insulation integrity and dielectric strength to confirm electrical safety under humid and corrosive food-processing environments before production release.

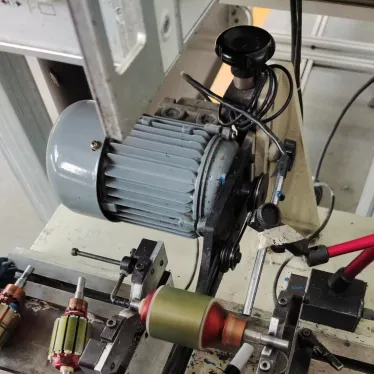

Evaluation of motor performance under no-load and loaded conditions to ensure torque stability, current behavior, and output consistency during real food processing operations.

Verification of the motor's ability to start reliably under load conditions, ensuring consistent performance during heavy-duty operations such as grinding or mixing.

Simulating jamming or mechanical resistance scenarios to verify the motor’s ability to recover and continue stable operation without failure.

Assessment of temperature rise during continuous-duty cycles to ensure the motor can operate for extended periods without overheating or performance degradation.

Repeated start-stop cycling to evaluate the motor’s reliability and endurance under frequent usage, typical in food processing environments.

Evaluating noise and vibration levels under typical operating conditions to ensure smooth, quiet operation, which is crucial for maintaining a comfortable work environment in food processing plants.

Verification of motor dimensions and external features (shaft, flange/face, mounting interface) to ensure compatibility with various food processing equipment and conformity to design specifications.

Get Template

Design a motor solution for mixing and grinding equipment in food processing that can deliver high torque, high efficiency, and durability, while ensuring compliance with hygiene standards and reliable operation under continuous duty.

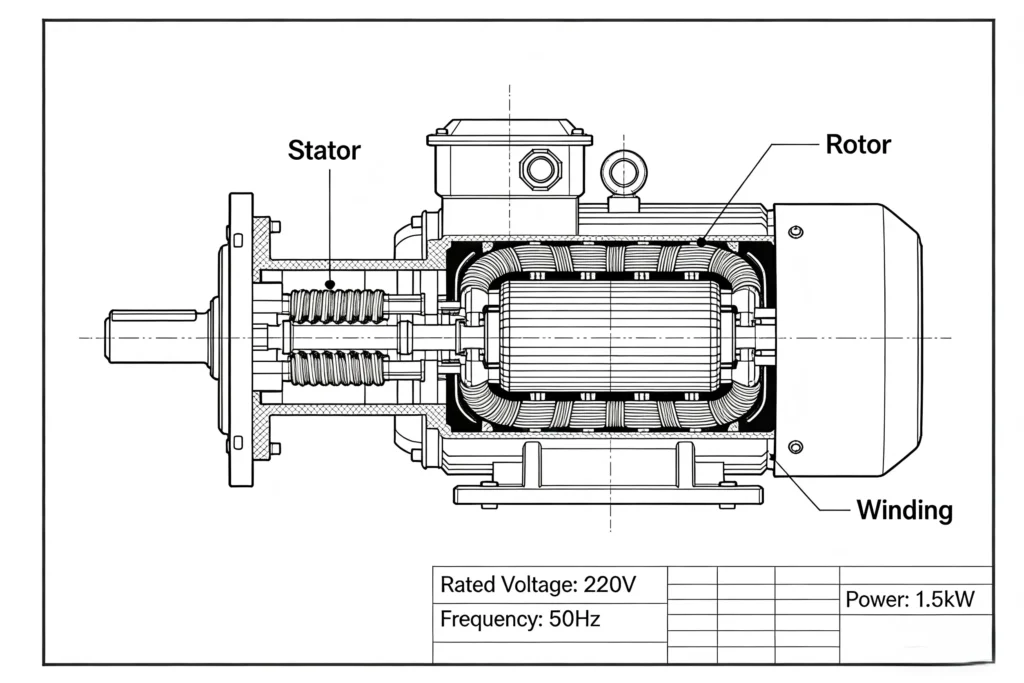

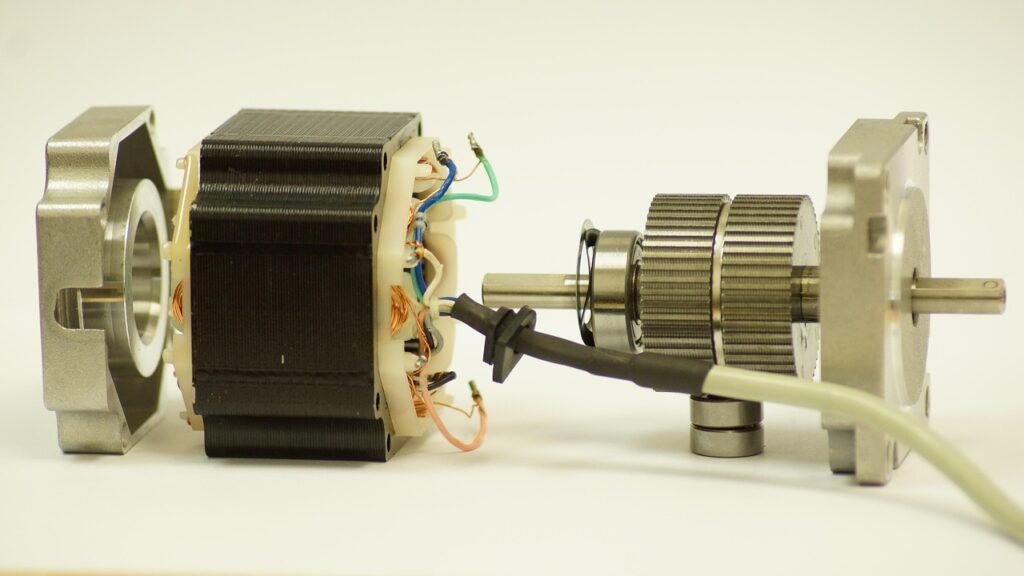

We developed a BLDC motor platform optimized for high torque and efficiency, with a focus on smooth, low-vibration operation. The motor is housed in a corrosion-resistant, IP65-rated enclosure to ensure durability in humid and wet environments. Our design meets HACCP and FDA standards for food safety, with easy-to-clean surfaces and stainless steel components.

Starting capability validated under heavy-load conditions; thermal stability confirmed during continuous operation; vibration and noise levels kept within industry standards. Dimensional and mounting interface verification completed for easy integration into food processing systems. Electrical safety tests passed, with dielectric strength verified.

“Heavy load” for grinders is defined by torque demand over time, not just motor power. Key data includes maximum material hardness, feed rate, particle size variation, and the worst-case jam scenario. Startup torque, transient overload during cutting, and load spikes caused by uneven material flow are critical. Buyers should also define duty cycle, stall tolerance, and acceptable speed drop under peak load to accurately characterize heavy-load conditions.

The MOQ is 500 units. Samples are chargeable and can be delivered within 15 days; sample cost is refundable upon batch order. Batch delivery time is 25-30 days. We offer expedited communication and production for urgent projects.

24/7 durability in hot environments is ensured through thermal margin design rather than nominal ratings. This includes high thermal-class insulation, heat-stable bearings and grease, and cooling strategies validated under elevated ambient temperatures. Continuous-duty motors are tested for temperature stabilization, not short-term operation. Validation focuses on sustained operation at worst-case load and airflow conditions to prevent accelerated aging and early failure.

PMSM or BLDC motors are preferred when efficiency, speed control, and torque precision are critical. They are commonly selected for applications requiring variable speed, fast response, lower operating temperature, or compact size. Induction motors remain suitable for constant-speed, robust, and cost-sensitive applications. The choice depends on control requirements, energy efficiency targets, thermal constraints, and system integration rather than motor type alone.

Stainless housing and hygiene requirements are addressed through material selection and surface treatment rather than enclosure thickness alone. Motors designed for hygienic environments use corrosion-resistant materials, smooth external surfaces, sealed interfaces, and minimal crevices to prevent contamination. Protection strategies also consider wash-down exposure, drainage paths, and compatibility with food-grade cleaning agents to ensure long-term reliability and compliance.

Pro Tip: Uploading a nameplate photo helps us match 50% faster.

Address:No.121,Xinlong Road,Zhonglou Xinzha Subdistrict,Changzhou City, Jiangsu Province, China

Phone: +86-18261152679

Whatsapp: +86-18261152679

Email: sales@honestmotor.cn

Privacy Policy / Terms of Services / Cookie Settings / Site Map

© 2025 Honest All Rights Reserved.