Tailored for HVAC Motion Systems — We are your application-specific engineering partner.

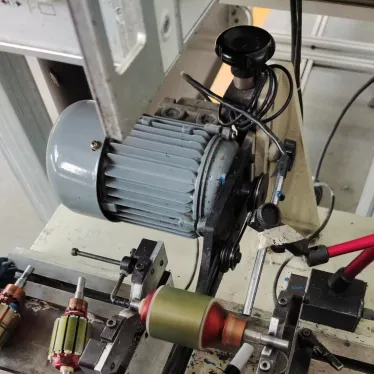

For HVAC fan motors, this includes verifying electrical insulation for high humidity or extreme temperature environments to ensure safe operation.

For HVAC motors, performance is verified under both low and high airflow conditions to ensure efficiency and stability across load variations.

HVAC motors must start quickly and efficiently under varying pressure conditions and sudden load increases without compromising overall performance.

For HVAC motors, simulate fan blade obstructions or irregular air flow to verify the motor’s ability to recover and resume stable operation.

HVAC motors are subjected to thermal validation with varying load cycles and frequent on/off operations to ensure the motor can handle high temperatures without degradation in performance.

HVAC motors undergo repeated start-stop cycles to ensure durability in continuous operational environments, particularly for commercial systems with long runtimes.

HVAC motors undergo noise and vibration testing under continuous duty and varying loads to ensure quiet operation in residential and commercial spaces.

HVAC motors undergo dimensional verification for tight installation requirements, ensuring compatibility with air handling units and HVAC systems.

Get Template

Ensuring consistent motor performance in HVAC systems across varying ambient temperatures (from -20°C to 55°C) while maintaining low noise and vibration during startup and continuous operation.

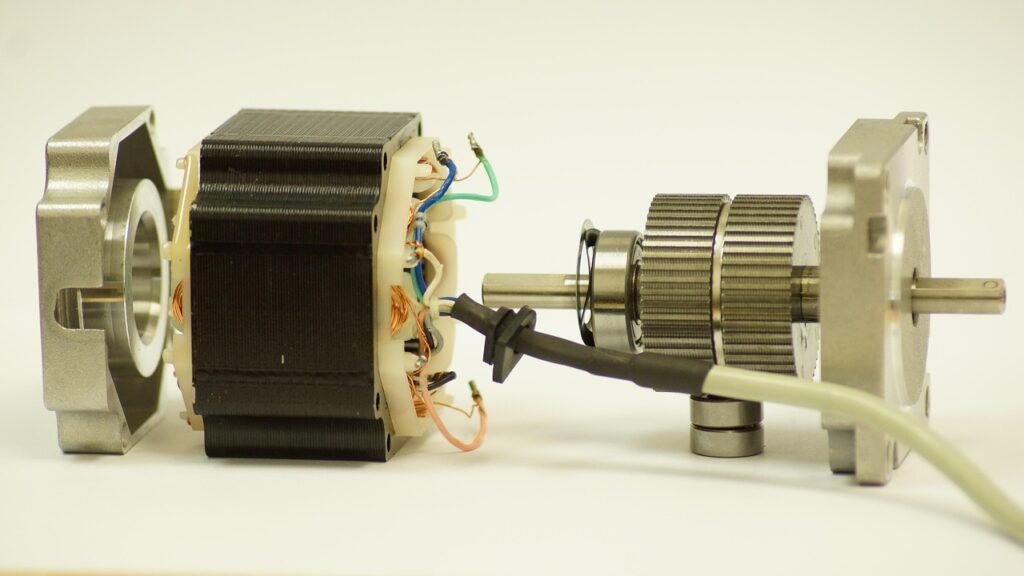

Customized BLDC motor platform with enhanced thermal management, coupled with IP54-rated weatherproof enclosures and vibration-dampening mounts to reduce noise and prevent system instability.

Conducted temperature rise testing under extreme duty cycles; passed 1,000 hours of salt spray resistance testing; verified airflow stability under high-static pressure; nois.

Ideally: Application duty cycle, torque/speed requirements, voltage/frequency, and mechanical interface dimensions. Photos of existing motors help significantly.

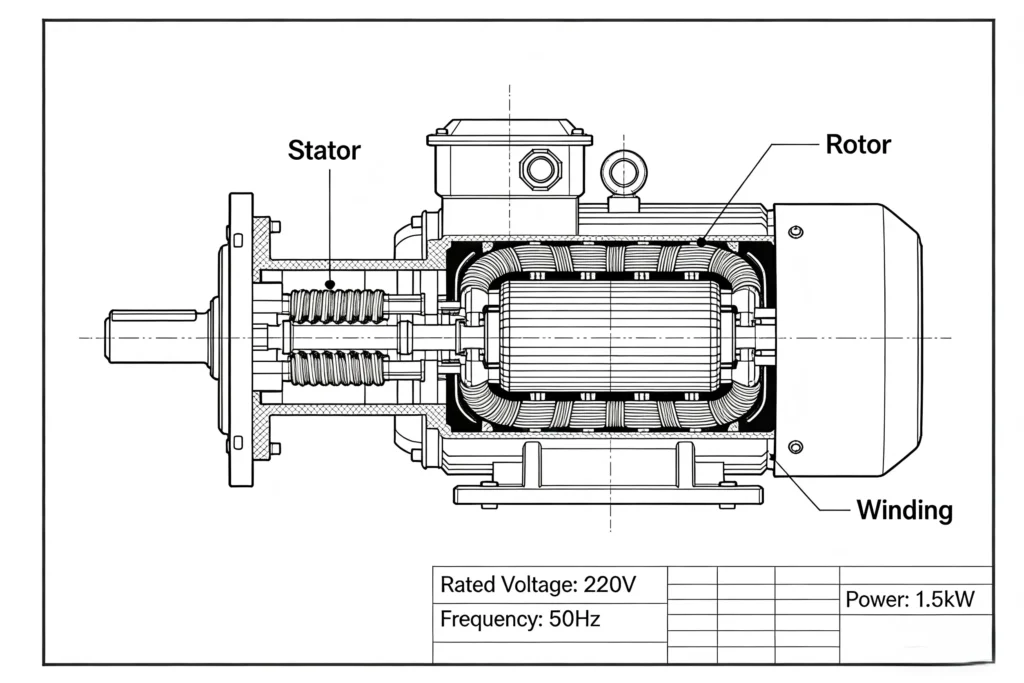

Yes. We configure windings for 100V, 110V, 120V, 220V, 230V, 240V at both 50Hz and 60Hz depending on your target market.

For standard platforms, MOQ is flexible. For highly customized tooling, we typically require 500-1000 units per order after pilot runs.

Our factories are ISO 9001 and IATF 16949 certified. We support component certification for UL, CE, CCC, RoHS, and REACH upon request.

Pro Tip: Uploading a nameplate photo helps us match 50% faster.

Adresse:No.121,Xinlong Road,Zhonglou Xinzha Subdistrict,Changzhou City, Jiangsu Province, China

Telefon: +86-18261152679

Whatsapp: +86-18261152679

E-Mail: sales@honestmotor.cn

Datenschutz / Nutzungsbedingungen / Cookie-Einstellungen / Site Map

© 2025 Honest Alle Rechte vorbehalten.