The outdoor power equipment (OPE) market is undergoing a profound transformation. The shift towards powerful cordless systems powered by advanced batteries is accelerating, driven by global demand for reduced pollution and enhanced user convenience. This segment of the market is expected to continue its robust growth, with a projected compound annual growth rate (CAGR) exceeding 7% into the foreseeable future.

To capitalize on this electric transition, manufacturers must make strategic component choices, particularly concerning motor technology. While standard options often appear cheaper upfront, a thorough Total Cost of Ownership (TCO) analysis reveals a different financial reality. This article will demonstrate why investing in Custom BLDC Drive Solutions—motors and their integrated electronics—is a smarter long-term plan, leading to significantly lower operational expenditure and maximizing product performance over its entire life cycle.

Key Takeaways

TCO Advantage: Custom BLDC Drive Solutions entail a higher initial investment but deliver substantial long-term savings and superior Total Cost of Ownership (TCO) compared to standard motor options.

Efficiency & Endurance: BLDC motors offer dramatically higher energy efficiency, extending battery run-time and requiring fewer repairs due to their brushless design.

Performance & Durability: Custom-designed BLDC motors ensure optimal fit and performance, incorporating robust IP-rated protection against dust and water, thereby significantly extending product lifespan in harsh outdoor environments.

Supply Chain Resilience: A stable, global supply chain mitigates single-source risks, offering predictable costs and guaranteed availability vital for long-term production planning and financial forecasting.

TCO Analysis: The Hidden Costs of Standard Motors

Total Cost of Ownership (TCO) provides a holistic financial perspective far beyond the initial procurement price. TCO captures all costs—both immediate and long-term, direct and indirect—associated with acquiring and maintaining an asset throughout its operational life. This methodology is crucial for accurately comparing competing technologies and determining true long-term profitability.

True Cost Drivers Beyond Initial Price

The sticker price of a motor is merely one variable. Several hidden cost drivers can rapidly inflate the lifetime expenses of standard motor solutions:

Supply Chain Volatility of Legacy Tech: As the market rapidly transitions to electric, demand for older component technologies (including specific parts for legacy gas and older DC motors) decreases. This reduced production scale can lead to rising per-unit costs and increased sourcing risks for manufacturers committed to outdated platforms.

The Cost of Design Integration: While a standard motor might be cheap to purchase, its suboptimal fit often necessitates expensive, non-standard modifications to the tool housing or assembly process, increasing labor and integration costs—a frequently overlooked component of the initial investment.

The Maintenance Penalty of Brushed DC

Conventional Brushed DC motors carry a significant maintenance burden. Their carbon brushes are subject to continuous friction and wear, requiring frequent, mandatory replacement. Each maintenance cycle incurs:

Downtime Costs: The tool is unavailable to the end-user, leading to lost productivity or service delays.

Labor and Parts Costs: Expense for replacement brushes and the labor required to service the motor.

These cumulative repairs substantially raise the operational expenditure and reduce the overall reliability and readiness of the tool fleet.

The Inefficient Power Drain

Standard motors, including older brushed DC and traditional gas engines, are inherently less efficient, resulting in significant wasted energy (often dissipated as heat).

Higher Running Costs: This inefficiency translates directly into higher energy consumption and, for battery-powered tools, necessitates more frequent and shorter charging cycles.

Regulatory and Market Pressure: Stricter environmental regulations continue to penalize less efficient gas engines through increased compliance costs or taxes. Furthermore, a reliance on outdated, less-efficient technology erodes brand perception in an increasingly eco-conscious and high-performance electric market.

Get More From Batteries With BLDC Motors

Save Energy and Extend Run-Time

BLDC motors are fundamentally more energy efficient than their brushed counterparts, translating raw battery power into mechanical work with minimal waste. This high efficiency directly leads to prolonged battery run-time and optimized power consumption across the tool’s usage cycle.

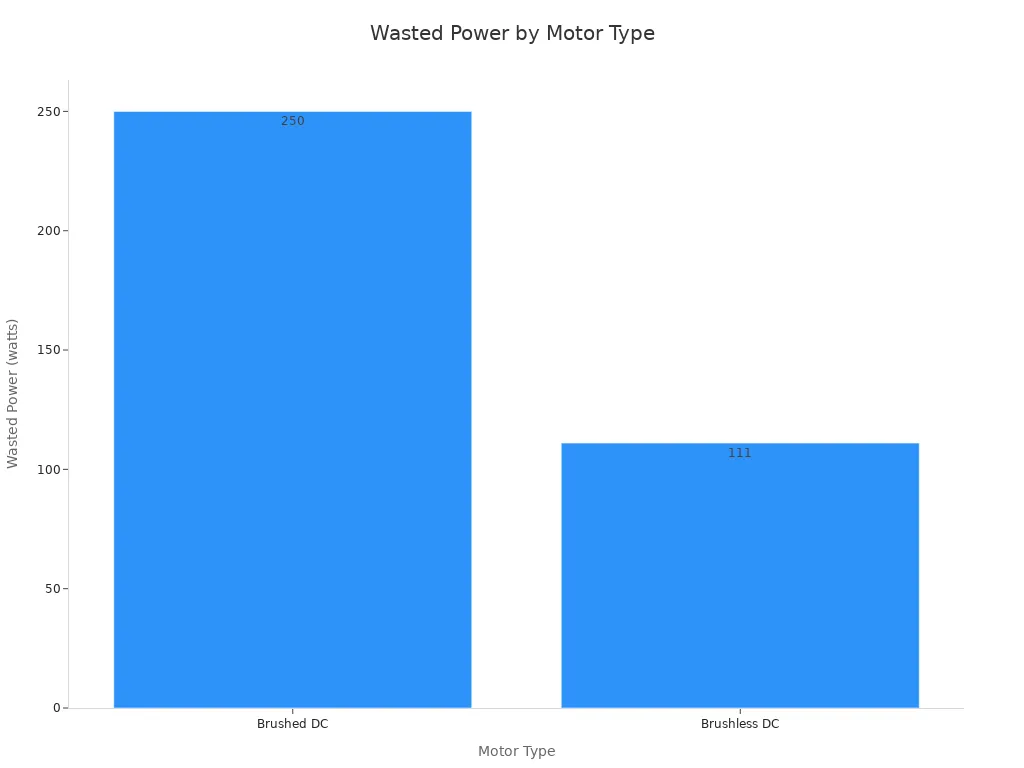

Motor Type | How Well It Works | Power Used (for 1000W work) | Power Wasted |

|---|---|---|---|

Brushed DC | 75% to 80% | 1250 watts | 250 watts |

Brushless DC | 85% to 90% | 1111 watts | 111 watts |

As shown above, BLDC motors require 139 fewer watts to deliver the same performance, enabling tools to run over 10% longer on an identical battery charge.

The TCO Advantage of Thermal Management

less wasted power means significantly less heat generation (111W vs. 250W). Excessive heat is the number one cause of battery degradation and failure. By running cooler, BLDC solutions not only maintain peak performance but also extend the overall operational lifespan of the expensive battery pack, resulting in fewer battery replacements and a major reduction in TCO.

Last Longer and Get Better Warranties

The maintenance penalty of brushed motors—namely the periodic replacement of wearing carbon brushes—is completely eliminated with BLDC technology. The motor’s lifespan is primarily determined by its bearings and thermal management.

Motor Type | Lifespan Limiter | Typical Operation Hours |

Brushed DC | Rapid brush wear | Significantly limited by brush life |

BLDC Motors | Bearings and thermal control |

This inherent durability allows manufacturers to confidently offer a robust warranty (e.g., a 2-year standard motor warranty from the date of use). This strong backing reduces perceived risk for the customer and reinforces the product’s long-term value proposition by demonstrating faith in the motor’s exceptional lifespan (20,000 to 50,000 hours).

Fewer Costly Repairs and Less Downtime

The robust, long-lasting nature of Custom BLDC Motors translates directly into substantial TCO savings. Fewer mechanical failures mean:

Reduced Service Costs: Manufacturers see fewer expensive warranty claims and service calls.

Minimized Downtime: End-users experience less waiting time and maximized productivity, building strong brand trust and customer satisfaction.

Investing in Custom BLDC technology is a strategic decision that drives down lifecycle costs while simultaneously enhancing product reputation and operational readiness.

Maximizing Return Through Engineered Solutions

Custom motors represent a strategic engineering decision for outdoor power tool manufacturers. They guarantee optimal performance and long-term savings, serving as a smart method to mitigate operational risks and ensure robust long-term Return on Investment (ROI).

Balancing Initial Investment and Long-Term Value

It is important to acknowledge that truly custom BLDC solutions require a higher initial commitment, including potential Non-Recurring Engineering (NRE) costs and longer design cycles. However, this upfront investment is crucial for securing the precise performance specifications and durability features that drive long-term TCO benefits. This deliberate approach minimizes risks associated with generic, off-the-shelf components.

Perfect Fit Guarantees Seamless Assembly

A custom-designed motor is engineered to integrate flawlessly into the tool’s existing housing and power train. This perfect fit eliminates expensive setup problems, streamlines the assembly process, and significantly reduces labor costs on the manufacturing floor. This careful design ensures the motor performs exactly as modeled, preventing component misfit issues that often plague standard motor integrations.

Custom IP & Superior Thermal Management

Outdoor tools operate in demanding conditions, where electric motors are constantly exposed to environmental hazards.

Robust Environmental Protection: The ability to specify a custom IP (Ingress Protection) rating is vital. An IP68 rating ensures complete dust ingress protection and capability to withstand immersion in water, guaranteeing longevity in the wettest environments. Even an IP65 motor effectively guards against water jets, making it suitable for heavy rain or cleaning cycles.

Optimal Cooling: Custom BLDC motors are designed with advanced cooling pathways. Managing heat prevents performance degradation and component damage, thus extending the tool’s effective lifespan. The inherent efficiency of brushless motors means less energy is converted to heat, further contributing to system longevity and reliability.

Steady Supply Means Clear Costs and Mitigated Risk

While customization can introduce single-source supply risks, strategically partnering with a supplier that maintains a steady, globally distributed supply chain provides a critical counterbalance. This global manufacturing reach ensures consistent motor availability, mitigating the risks associated with dependency on a single manufacturing region or geopolitical event. This supply chain stability allows manufacturers to accurately forecast costs, avoid production delays, and enhance long-term financial planning.

Honest mitigates custom component supply risk through a globally distributed manufacturing network. For instance, maintaining factories in diverse regions (e.g., Vietnam and Malaysia) ensures resilience and cost clarity across different market conditions.

Figuring Out ROI: Making the Case for Spending Money

The Simple TCO Math

The core of a strategic component decision lies in the Total Cost of Ownership (TCO). This framework moves beyond the simple purchase price to forecast the entire financial impact over the product’s lifespan.

TCO = Initial Costs(I)+ Operating Costs(O)+ Maintenance Costs(M)- Salvage

Key components captured by the TCO framework include:

Initial Costs (I): Procurement price, shipping, design integration (including NRE costs for customization), and setup/training.

Operating Costs (O): Energy consumption (power use), consumables, and labor required to operate the tool.

Maintenance Costs (M): Routine care, unscheduled repairs, spare parts (e.g., brushes, bearings), and associated labor wages.

Hidden Costs: Crucially includes Downtime Costs (lost productivity due to tool failure) and Disposal Costs (end-of-life recycling/decommissioning).

Salvage Value (R): The monetary value recovered at the end of the tool’s life.

Quantifying the TCO Difference: BLDC vs. Brushed

The data clearly demonstrates that while brushed DC motors offer a lower I, their high M and O costs rapidly inflate their total TCO over time. Conversely, the investment in a Custom BLDC Drive System dramatically reduces lifecycle costs.

TCO Comparison: 5-Year Financial Projection (Illustrative Example)

Cost Component | Brushed DC Motor (Standard) | Custom BLDC System (Premium) | TCO Reduction with BLDC |

Initial Cost (I) | $20 (Motor) | $60 (Motor + Controller) | Higher Initial Cost |

Maintenance (M): | |||

Brush Replacements (x5) | $50 | $0 | -$50 |

Service Labor/Downtime | $150 | $30 | -$120 |

Operating Cost (O): | |||

Power/Battery Life (Equivalent) | $100 | $60 | -$40 (Energy/Batteries) |

5-Year Estimated TCO | $320 | $150 | ~53% Savings |

Note: This projection is illustrative, demonstrating the TCO advantage primarily derived from eliminating brush wear and maximizing battery efficiency.

Market Confidence and Long-Term ROI

The industry’s confidence in this technology confirms the TCO analysis. The global BLDC motor market is robust, valued at $5.8 billion in 2024. Furthermore, the market for BLDC motor drivers—the essential electronic controls—is forecast to reach $5.9 billion by 2030, reflecting a strong growth rate of 8.3% from 2024. This rapid adoption signifies that Custom BLDC solutions are not just a component purchase, but a strategically aligned investment that delivers verifiable Return on Investment (ROI).

By cutting out the maintenance penalty of brushes, slashing energy waste, and extending battery life, Custom BLDC Motors secure lower operational costs and enhance brand reputation.

Custom BLDC Motors carry a higher initial cost, but they represent a strategic decision to optimize lifetime ROI. Talk to our team to fully quantify your specific TCO savings and see how a custom solution can elevate your product line.

FAQ

Why are custom BLDC motors more costly at first?

Custom BLDC motors need special design. They need special engineering. They use better materials. They use new ways to build them. This makes them work best. They last a long time. These things make them cost more at first.

How do BLDC motors lower repair costs?

BLDC motors have no brushes. Brushes often wear out. This means fewer changes. It means fewer fixes. Their strong build helps. They last longer. This means less time tools are off. This saves money on repairs.

What good comes from custom IP and heat control?

Custom IP keeps motors safe. It stops dust. It stops water. This is for tough outdoor use. Heat control stops motors from getting too hot. This makes them last longer. These things make them work well. They make them stronger.

How does a worldwide supply chain help predict costs?

A worldwide supply chain helps. Honest has one. It means motors are always there. It lowers risks. It stops relying on one place. This makes things steady. It stops surprise delays. It stops cost changes. This helps plan money for a long time.

Do BLDC motors really make batteries last longer?

Yes, BLDC motors work very well. They change more power into work. Less power turns into heat. This good use of power helps. Tools run longer on one battery charge.