When building a robot, selecting the right small gear motor is crucial to the overall performance of your robotics drive motor system. The small gear motor you choose directly impacts your robot’s ability to lift, move, and operate efficiently. It’s important to match the torque, speed, and gear ratio of the small gear motor to the specific requirements of your robotics drive motor application.

When choosing a robotics drive motor, consider key factors such as voltage, shaft size, and mounting options to ensure seamless integration into your design. Opt for small gear motors that are suitable for DIY projects, hobby robots, or advanced robotics systems. Refer to the table below for common specifications to help you select the ideal small gear motor for your robotics drive motor needs.

|

Specification |

Typical Range / Value |

|---|---|

|

Voltage |

|

|

Output Power |

Less than 50 W |

|

Output Speed (RPM) |

5 to 2000 |

|

Gear Ratio |

5 to 1500 |

|

Output Torque |

1.0 gf.cm to 50 kgf.cm |

|

Transmission Precision |

1 to 2 arcminutes |

|

Noise Level |

≤ 45 dB |

Key Takeaways

-

Think about what your robot needs. Look at load, torque, speed, voltage, and size before picking a gear motor.

-

Make sure the gear motor’s torque, speed, and gear ratio fit your project. This helps your robot move well and work smoothly.

-

Pick the right motor type. Choose brushed or brushless DC motors based on your robot’s power, control, and how long you want it to last.

-

Think about things like temperature, dust, and humidity. This helps you choose a gear motor that works well and lasts a long time.

-

Test your gear motor early. Use trusted brands with good support. This helps you avoid mistakes and build a robot you can trust.

Define Robotics Project Needs

Before you select a gear motor for your robot, you need to understand your project needs. Every robot project has unique requirements. You must look at the load, torque, speed, voltage, and size to make the right choice. This step is the foundation for success in robotics and automation.

Load and Torque Requirements

Start by figuring out how much weight your robot must move or lift. The load affects the torque your gear motor must deliver. Torque is the force that makes your robot move or turn. To estimate torque, you can measure the electric current drawn by the motor. Current is proportional to torque. For a robot arm, you can use this method:

-

Calculate the load weight (mass × 9.81 m/s²).

-

Measure the arm length.

-

Find the joint angle.

-

Use the formula: torque = load weight × arm length × sin(joint angle).

Most small robots need torque starting from 0.1 Nm. Remember, stall torque is the maximum force your gear motor can provide. Continuous torque is about 20% of stall torque. Always check both values to match your torque and speed requirements.

Speed and Movement Goals

Think about how fast you want your robot to move. Speed is measured in rpm. The desired speed sets the gear motor’s rpm. Gear motors reduce high rpm from the motor to a lower, usable rpm for your robot. The gear ratio helps you balance speed and high torque. For mobile robots, accurate speed control prevents weaving and keeps movement smooth. Always check the gear motor’s torque-speed curve. Make sure your robot operates within the continuous region, not just at stall torque.

Voltage and Power Source

Your project needs a stable power source. Most small robots use batteries like LiPo, which offer high power-to-weight ratios. Motors often need 6V, 12V, or even 11.1V. Use a buck converter to step down voltage for microcontrollers and sensors. Always match the gear motor’s voltage rating to your power source. Running a motor above its rated voltage increases rpm but shortens lifespan. Too little voltage causes high current, which leads to heat and wear. Stable voltage ensures your gear motor lasts longer and meets your power requirements.

Size and Mounting Constraints

Check the space available in your robot. The gear motor must fit without making the robot too heavy. Mounting options matter. Some gear motors offer flexible mounting hardware. Others need specific orientations. Plan your robot’s dimensions early. Make sure the gear motor’s size and weight match your project needs. This helps avoid overloading your robot and keeps your design efficient.

Tip: Honest offers custom gear motor solutions for robotics and automation in many industries. Whether you build a medical robot, a smart home device, or an industrial automation system, Honest can help you match your project needs with high torque, precise rpm, and reliable performance.

Motor Types for Robotics Drive

Small Gear Motor Options

There are many gear motors you can pick for your robot. The main types are spur, planetary, worm, cycloidal, and helical bevel gear motors. Spur gear motors use simple gears. They work best for light robots. Planetary gear motors are small but strong. They are great for robot joints. Worm gear motors can hold heavy things in place. They have high reduction ratios and self-locking. Cycloidal gear motors are quiet and smooth. They also give high torque. Helical bevel gear motors are precise and flexible. They help transfer power at different angles. Each gear motor type helps your robot move with the right speed and force.

|

Gear Motor Type |

Key Features & Advantages |

Typical Robotics Applications |

|---|---|---|

|

Spur Gear Motors |

Simple, cost-effective, moderate torque |

Toy robots, light conveyors |

|

Planetary Gear Motors |

High torque, compact, shock resistant |

Robotic arms, medical robots |

|

Worm Gear Motors |

High reduction, self-locking, compact |

Lifting robots, gate openers |

|

Cycloidal Gearmotors |

High torque, smooth, low noise |

Mixers, conveyors, robotics |

|

Helical Bevel Gearmotors |

Precision, low noise, flexible angles |

Automation, industrial robots |

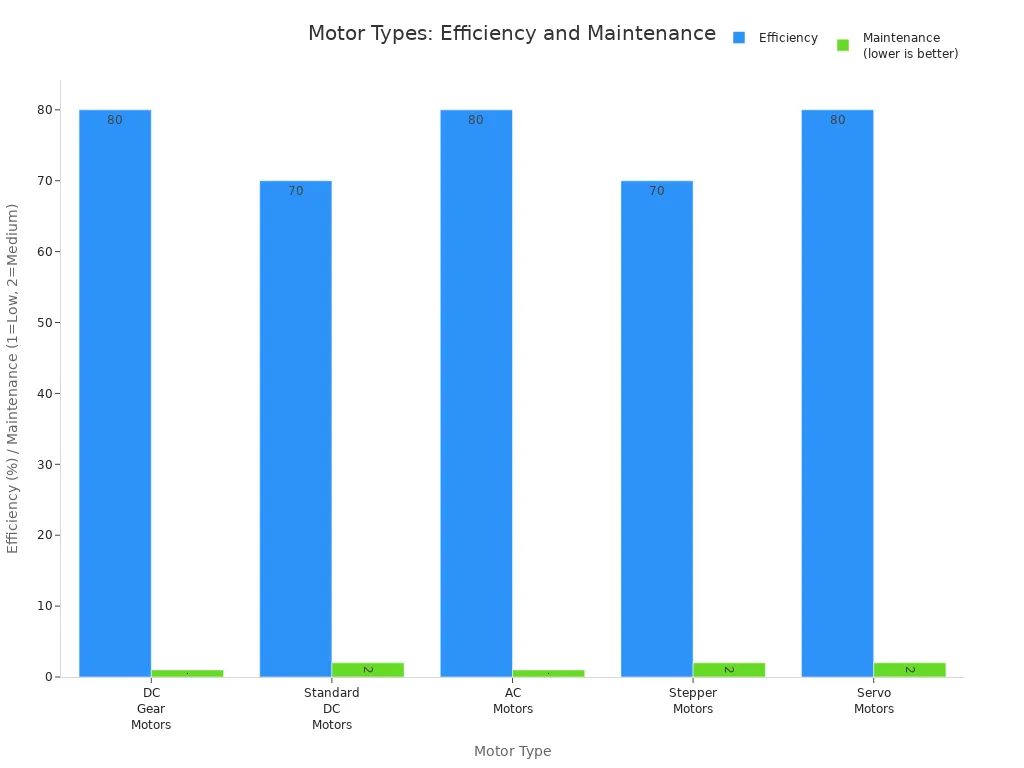

Small DC Motor vs AC Motor

It is important to know how small dc motors and AC motors are different. Small dc motors are small and easy to use. They give high torque at low speeds. This is good for robots that need to move carefully. You can use batteries to power small dc motors. This makes them good for robots that move around. AC motors are bigger and need to be plugged in. They are good for robots that stay in one place. AC motors work well for jobs that need the same speed all the time. But AC motors do not change speed as quickly as small dc motors. Most robots use small dc motors because they are easier to control.

|

Feature |

Small DC Motors |

AC Motors |

|---|---|---|

|

Size |

Compact |

Bulkier |

|

Efficiency |

High for variable speed |

High for constant speed |

|

Torque |

High starting torque |

Lower starting torque |

|

Speed Control |

Easy, quick response |

Slower, less precise |

|

Power Source |

Battery-friendly |

Needs AC power |

|

Maintenance |

Brushed need care, brushless last longer |

Low maintenance |

|

Best Use |

Portable, precise robots |

Large, stationary robots |

Brushed DC Motor Features

Brushed DC motors use brushes and a commutator to make them spin. You can change their speed and torque easily. These motors are simple and strong. They are easy to fix if something breaks. Brushed DC motors give high starting torque. This helps your robot move heavy things right away. You can use simple electronics to control them. They fit in small spaces and work with gearboxes for more torque. Many robots use brushed DC motors. They can start and stop a lot without problems.

-

High starting torque for quick moves

-

Smooth speed changes

-

Cheap and easy to buy

-

Fits well in small robots

Brushless DC Motor Advantages –

Brushless DC motors have many good points for robots. They are very efficient, up to 90%. You get more torque for the same size. This helps your robot lift and move better. Brushless motors last longer because they have no brushes to wear out. They are quiet and do not make much interference. This is good for robots with sensitive electronics. You can control their speed and position very well. Brushless motors can go faster and move smoothly. They are reliable for your robotics drive motor.

|

Performance Benefit |

Description |

|---|---|

|

Higher Efficiency |

Up to 90% efficient |

|

Longer Lifespan |

No brushes, less wear |

|

Low Maintenance |

No brush replacement needed |

|

High Torque-to-Weight Ratio |

More torque in a smaller package |

|

Precise Control |

Accurate speed and position for robot arms |

|

Quiet Operation |

Less noise, better for sensitive environments |

|

Reduced EMI |

Less interference with robot sensors |

|

Smoother Motion |

Consistent, reliable movement |

Honest Gearmotors Overview

Honest has many gear motors for robots. These motors provide high torque and precise speed control. They are reliable and built to last, making them suitable for robot arms, mobile robots, medical robots, and automated guided vehicles. Honest gear motors are available in both brushed and brushless DC types, giving you flexibility for any robotics project. Compact, efficient, and easy to use, can be trusted for demanding robotic applications.

Tip: Honest gear motors help your robot move smoothly, lift heavy things, and work well in many places.

Gear Motor Selection Guide

Picking the right gear motor for your robot can be hard. You need a simple guide to help you choose well. This part shows you how to pick a gear motor, match specs, think about the environment, and use online tools.

How to Choose a Gear Motor

You want your robot to move well and not break. Follow these steps to get the best gear motor:

-

Write down what your project needs. Include load, where it works, and how often it runs. This helps you know what the gear motor must do.

-

Figure out the output power. For example, a lifter motor may need 1.28W. Use graphs to find the right rpm and torque.

-

Pick a gear ratio. Match the motor speed to the output rpm you need. For example, you might need a ratio of 1/37.

-

Find the torque at the gearbox output shaft. Start with perfect efficiency, then change for real efficiency (usually 50%–70%).

-

Choose a gearbox from catalogs. Look for the closest gear ratio and check its efficiency.

-

Recalculate rpm and torque with the gearbox ratio and efficiency.

-

Add safety margins. Think about extra losses like friction between wheels and ground.

-

Repeat for other motors in your robot. Each motor may need a different gear ratio and efficiency.

-

Test motor samples. Run tests to check fit and performance.

-

Finish your gear motor and gearbox choice. Make sure you can get them and they work for your needs.

Tip: Always check voltage with your power supply. Using too much voltage makes rpm go up but shortens life. Too little voltage causes high current, heat, and wear.

Matching Specs to Application

Matching gear motor specs to your project is very important. Here’s how you do it:

-

List what your robot needs. Include load, how often it runs, speed control, and environment.

-

Figure out the torque you need. Think about total load, lever arm distances, and extra forces like friction or sudden loads.

-

Match gear motor speed and gear ratio to your needs. This helps your robot move smoothly and saves energy.

-

Check power source compatibility. Make sure voltage and type match your gear motor.

-

Think about size and mounting style. The gear motor must fit your robot and be easy to fix.

-

Pick what matters most. Don’t choose a gear motor that misses key needs.

-

Use online tools or checklists. These help you remember and check all important details.

You should also look at duty cycle. Make sure your gear motor runs within its heat limits. The right gear ratio helps you balance torque and speed. Different gear types have trade-offs in efficiency, noise, load, and precision. Check manufacturer specs and charts to make sure they work with your load, rpm, and environment. Test and build prototypes to see how gear motors work in real life.

Note: Honest has many gear motors with high torque, precise rpm, and reliable performance. You can find choices for medical robots, smart home devices, and industrial automation.

Environmental and Operational Factors

Your gear motor must work in tough places. Temperature, dust, and humidity can change how it works. Use this table to see how these things affect gear motor choice:

|

Impact on Gear Motor Selection and Performance |

|

|---|---|

|

High Temperature |

Causes overheating, reduces insulation life, lowers efficiency |

|

Low Temperature |

Affects lubricant, may impair gearbox operation |

|

High Humidity |

Degrades insulation, increases corrosion and short circuit risk |

|

Low Humidity |

Generates static electricity, disrupts control systems |

|

Dust and Pollution |

Damages encoders and bearings, needs better sealing |

|

Corrosive Environments |

Needs special coatings or materials for protection |

High temperatures lower torque and efficiency. Grease breaks down faster, bearings wear out, and electronic parts age quickly. Low temperatures make lubricants less useful, risking system failure. Humidity and corrosion hurt insulation and bearings. Dust harms sensitive parts, so you need sealed gear motors. Always pick gear motors with the right protection rating, like IP65, for your robot.

Tip: Honest gear motors have IP65 protection. They resist dust, oil, and moisture. This helps your robot work in tough places.

Using Online Tools and Calculators

Online motor selection tools make picking gear motors easier. You enter your project details like weight, rpm, and environment. The tool figures out torque, speed, and power needs. It suggests motors and gearbox ratios that fit your robot.

-

Use tools with graphs and charts. These help you see how changes in rpm or torque affect performance.

-

Always check datasheets and specs. Look for voltage, current, torque, rpm, gearbox ratio, efficiency, and environmental ratings.

-

Read expert reviews to find good gear motors. Trusted brands like Honest offer quality and support.

-

Test motors in real life. Check speed, torque, heat, noise, and durability.

-

Write down your test results. Compare motors and make smart choices.

A good gear motor selection guide saves time and stops mistakes. Matching torque, rpm, and power to your robot makes it work better. Thinking about the environment and how it runs stops problems. Testing and checking catch issues early. Using performance curves and torque calculators helps you pick the best motor, save energy, and make motors last longer.

Note: Honest gives technical support to help you pick the best gear motor for your robot. You can trust their help and products.

Avoiding Common Mistakes

Over/Under-Specifying Motors

It is important to pick the right gear motor. If you choose a motor that is too big, your robot can have problems. Big motors make your robot heavy and cost more money. They also get hotter and can hurt gears or electronics. Heavy motors slow down how fast your robot moves. You might need to buy expensive parts to use them. Sometimes, big motors do not fit in your robot. If your motor is too small, your robot will not have enough power. It may not lift or move things well. Small motors can make your robot hard to control. The robot may not move smoothly or be precise. Using the wrong gear ratio wastes energy or makes your robot slow. Always try to balance power, speed, size, and price. Picking carefully helps your robot work safely and last longer.

Testing and Optimization Tips

You should test your gear motor before finishing your robot. Here are some easy tips:

-

Use charts and calculators to check torque and speed.

-

Make a test area like your robot’s real home. Think about heat, dust, and water.

-

Use tools to check shaking, noise, and how it moves. Write down what you find for later.

-

Make sure the motor’s voltage matches your battery or power. Watch out for too much heat.

-

Try to match the motor’s weight to what it moves for smooth action.

-

Do not just buy the cheapest motor. Good quality means fewer problems.

-

Take care of your motor and mount it the right way.

Tip: Honest gives you help and ready-to-use gear motors. You can ask their experts for advice and finish your project faster.

Reliable Brands and Support

Picking a good brand helps you feel safe. Many brands give strong help and good gear motors for robots. Here is a table with some famous brands:

|

Brand |

Strengths and Support Features |

Robotics Applications |

|---|---|---|

|

Fast delivery, custom design, quick technical support |

Custom gear motor solutions |

|

|

Maxon Motor |

Swiss precision, high efficiency, long lifespan |

Robotics, prosthetics, aerospace |

|

Portescap |

Miniature, low-noise, brushless and coreless motors |

Robotics, medical, industrial control |

|

Nidec |

Large-scale, strong R&D, cost-effective |

Automation, industrial robotics |

|

Faulhaber |

Compact, high torque, innovative drive technology |

Precision robotics, aerospace |

Honest is known for making precise and energy-saving gear motors. They give great help after you buy. You can get custom motors, expert advice, and products you can trust. Honest has world certificates and good service. This makes them a smart pick for your robot project.

Begin your robotics project by knowing what you need. Think about torque, speed, size, and voltage. Look at datasheets and charts to match gear motor specs. Test sample motors so you do not pick ones too big or too small. Always check how much force is needed to start moving. Use sizing tools to help you choose the best motor. Precision gearmotors make your robot work better and last longer. Honest gives advice and support so you can finish your project and feel sure about it.

FAQ

What is the difference between brushed and brushless gear motors?

Brushed gear motors use brushes to switch current. Brushless gear motors use electronics instead. Brushless motors last longer and run quieter. You get less maintenance with brushless motors.

How do I know what torque my robot needs?

You need to measure the weight your robot moves. Use a torque calculator or ask your motor supplier for help. Always add a safety margin to your calculation.

Can I use any gear motor with my battery?

No. You must match the motor’s voltage to your battery. Using the wrong voltage can damage the motor or make it run poorly. Always check the datasheet.

Why does my gear motor get hot during use?

Motors get hot if you overload them or use the wrong voltage. Too much heat can shorten motor life. Make sure you use the right size motor for your robot.

Tip: If you have more questions, Honest’s experts can help you choose the best gear motor for your project.