Water pump motors are crucial across industries and homes, and their consistent operation is essential. Unreliable pump performance causes costly downtime and inefficiencies. Given the high cost of failure in competitive sectors, this comprehensive guide is designed to equip you with the knowledge to understand, diagnose, and prevent common pump faults. By providing a systematic, practical methodology for maintenance and diagnostics, we ensure you can extend the lifespan and maintain the peak performance of your critical pump systems.

Key Takeaways

Focus on electrical (Insulation Resistance Testing), mechanical (Bearings, Vibration), and hydraulic (Cavitation, Seals) fault categories.

High-wear components like mechanical seals and bearings require rigorous inspection and timely replacement.

Use regular checks and advanced tests (like Megohmmeter testing) to prevent failures and ensure longevity.

Upgrade to modern technology like VFDs and BLDC/PMSM motors to save energy and improve performance.

Partnering with a reliable brand ensures long-term efficiency and operational continuity.

Understanding Water Pump Motors

Motor Types and Core Components

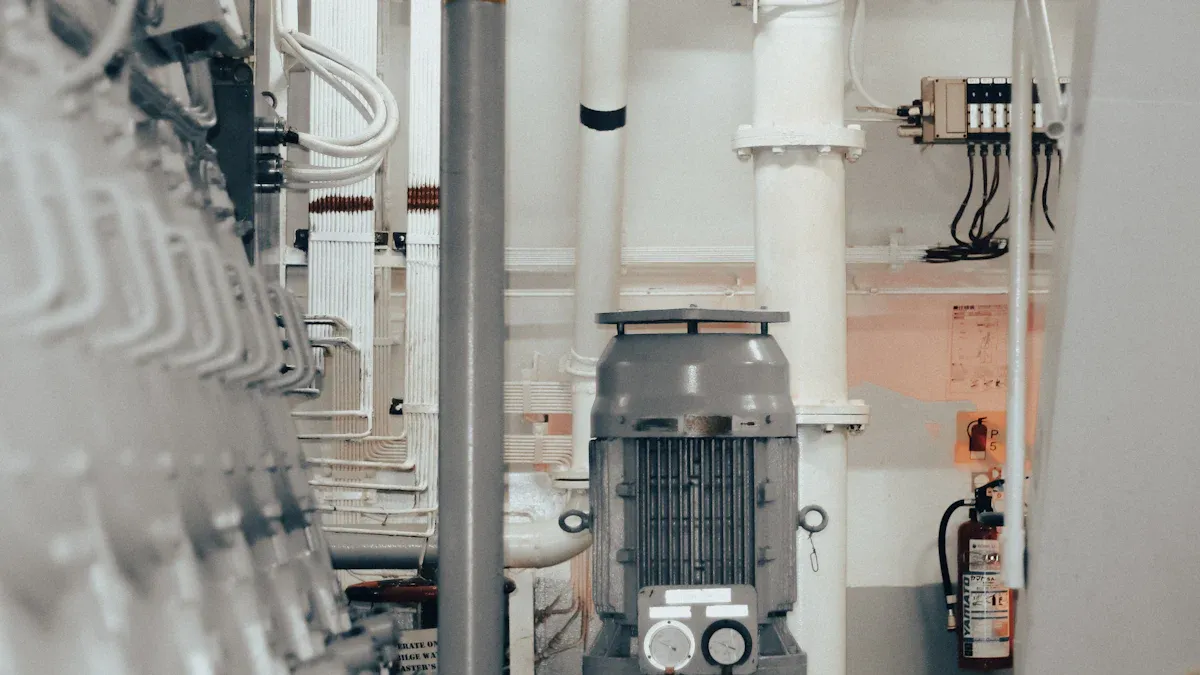

You encounter various water pump motor types in different applications. Centrifugal pumps move water using rotational force. Submersible pumps operate fully immersed in the fluid. Understanding their core components is vital for effective maintenance. A typical water pump motor system includes several essential parts:

Impeller: This core component rotates. It draws in fluid and expels it outwards. This action increases pressure and velocity.

Casing: This houses the impeller. It directs the flow of water.

Motor: This provides power for the impeller’s rotation.

Inlet and Outlet Ports: These allow water to enter and exit the pump.

Seals: These prevent contamination.

Bearings: These ensure smooth operation. Each part plays a critical role in the pump’s function.

Importance of Reliable Pump Performance

Reliable pump performance is paramount. Your operations depend on consistent water flow. This is especially true in critical applications like water treatment and industrial automation. In water treatment, a malfunctioning pump can disrupt essential processes. This affects public health and environmental compliance. Industrial automation relies on pumps for cooling, fluid transfer, and process control. Any pump failure leads to costly production halts. You must monitor key performance metrics to ensure reliability.

Flow and head measurements provide vital data. You extract this directly from motor voltage and current signals. Tracking efficiency levels is also crucial. This helps you operate the pump at its Best Efficiency Point (BEP). This saves energy. You should also monitor for operating deviations. Issues like cavitation, blockages, or wear trigger immediate alerts. This prevents equipment failures. Measuring head pressure against flow rate plots a pump’s performance curve. This verifies capability and identifies inefficiencies. You also measure speed (RPM) with flow and pressure. This allows analysis against OEM requirements. Consistent pump operation ensures system integrity. This proactive monitoring safeguards your investment. It also maintains operational continuity.

Common Water Pump Motor Faults

You must recognise common faults to maintain your water pump motor effectively. These issues fall into electrical, mechanical, and environmental categories. Understanding their causes and symptoms helps you prevent costly downtime.

Electrical Issues and Symptoms

Stress Factor | Key Symptoms & Consequences | Root Causes & Professional Tips |

Voltage Imbalance / Low Voltage | Frequent Breaker Trips, Motor Overload, Reduced Efficiency. | Voltage variations (exceeding ± 10%) or consistently low voltage; a significant cause of irreparable motor failure. |

Transient Power Issues | Burned Contactors/Starters, Electrical Burn Smell. | Power surges, voltage spikes, or frequent starting placing high stress on components. |

Winding Failure | Motor humming but not rotating, Intermittent operation, Severe tripping. | Winding insulation failure (short circuit) or broken internal wires (open circuit). |

Miswiring | Very little water pumped, potential severe pump damage. | Incorrect wiring causes the motor to run in reverse, damaging the impeller and leading to cavitation. |

Tips:Insulation Resistance—— Use a megohmmeter to check insulation resistance against ground; this is the most effective way to detect early water ingress or winding damage.

Mechanical Failures and Indicators

Mechanical failures are equally critical. They often manifest through physical signs.

Fault Type | Symptoms / Physical Indicators | Core Causes (Root Causes) |

Bearing Failure | High Noise (Whining), Excessive Vibration, Bearing housing overheating. | Inadequate/Excessive lubrication, Lubricant contamination (e.g., water), incorrect internal clearance, or operating under sustained overload/fatigue. |

Shaft Misalignment | Severe vibration, accelerated wear on seals and couplings. | Incorrect installation or loose foundation leading to uneven radial loads on rotating components. |

Visible fluid loss, deposit buildup, corrosion, reduced efficiency. | Dry running, improper installation, seal ring misalignment, or material wear. | |

Vibration (General) | Loose bolts, cracking of pump housing, damage to internal components. | Unbalanced rotating components (impeller wear) or loose structural supports. |

Environmental and Hydraulic Challenges for Pumps

Environmental factors and hydraulic issues significantly impact pump longevity and performance. You must consider these external influences.

Challenge Type | Key Impact on System | Prevention Focus |

Cavitation | Noise (popping), Vibration, and pitting damage to the impeller/casing. | Ensure sufficient suction pressure (NPSH); monitor flow deviation and fluid temperature. |

Corrosion & Contamination | Structural failure, chemical degradation of seals, reduced component lifespan. | Exposure to saltwater/acidic fluids or presence of sediment/abrasives (requires material selection and filtration). |

Water/Dust Ingress | Contaminates internal motor components, leading to short circuits and bearing corrosion. | Ensure correct IP rating is maintained; promptly replace worn shaft seals. |

Dry Running | Causes rapid overheating and catastrophic damage to mechanical seals and impellers. | Use low-level sensors and ensure adequate pump priming before startup. |

Systematic Fault Diagnostics

You need a systematic approach to diagnose water pump motor faults effectively. This helps you pinpoint issues quickly and accurately. You minimise downtime and prevent further damage. This section guides you through visual checks, electrical tests, and mechanical assessments. You will also learn about Root Cause Analysis.

Visual and Operational Checks

You begin your diagnostic process with thorough visual and operational checks, as these often reveal obvious problems.

First, conduct an Initial Physical Inspection: Look for signs of burning, leaks, or physical damage. Check the seals for visible wear and ensure suction and discharge lines are free of blockages. Observe the water flow for anomalies (such as low flow or water quality degradation). Simultaneously, inspect the electrical wiring for any loose connections, burned insulation, or corrosion.

Next, Monitor Operational Data Trends. Continuous monitoring of vibration, flow, temperature, pressure, and energy consumption provides crucial diagnostic insight. Pay attention to minor variations in runtime, maintenance frequency, and energy use patterns. Fluctuations in metrics like rising motor currents or increased cycle frequency often indicate underlying issues and signal the need for in-depth inspection.

Electrical Testing and Analysis

Electrical testing provides critical data about your water pump motor’s health. You use various tools and techniques for this.

You begin by inspecting wiring and connectors for moisture, loose contacts, or corrosion. You must monitor power readings, checking that voltage and amperage are within the normal range and looking for any voltage imbalances between the various phases (even a 1% imbalance can significantly increase motor temperatures).

Insulation resistance testing is also essential, you use a megohmmeter (‘megger’) to apply voltage and measure the insulation value against ground, comparing it with the standard values provided by the pump manufacturer. This helps you assess the insulation condition and detect water ingress. Further tests include:

Winding Checks: Measuring resistance between motor phase windings (with an ohmmeter) to detect variations that signal impending failure.

Specialized Analysis: Using a Professional Power Quality Analyzer to measure transient voltage, voltage imbalance, and harmonic distortion, which indicates deterioration of winding insulation.

Mechanical and Hydraulic Assessment

Mechanical and hydraulic assessments help you identify physical wear and operational inefficiencies.

Temperature Monitoring: Pay close attention to bearing temperatures (standards suggest these should not exceed 80℃). Trend analysis provides early warnings of issues.

Vibration Analysis: Vibration monitoring and analysis is widely applied for detecting problems early by measuring displacement, velocity, and acceleration. This is a non-intrusive and fast-response method.

Alignment Checks: Laser alignment is crucial for detecting shaft deviations. This prevents issues like reduced bearing life, coupling defects, and excessive vibration.

Hydraulic Health: Monitor flow rate and pressure deviation alerts to ensure the pump operates near its Best Efficiency Point (BEP). Pressure monitoring helps prevent cavitation and identifies impeller issues or blockages.

Load Analysis: Monitor motor load and electrical imbalance; increased power demand often signals mechanical issues.

Root Cause Analysis (RCA)

Root Cause Analysis (RCA) is a structured methodology for pump failures. It helps you understand what happened, how it happened, and why it happened. By moving beyond immediate symptoms to uncover underlying system flaws, RCA ensures that corrective actions prevent recurrence.

RCA Tools in Maintenance: The most commonly applied tools to complete an RCA include Pareto Analysis, 5Ys (Five Whys), Fishbone Diagrams, Fault Tree Analysis (FTA), and Reliability-centred Maintenance (RCM).

Effective Repair and Maintenance

Electrical System Rectification

You must address electrical issues promptly. This ensures your pump system’s reliability. You correct wiring problems. You tighten connections. You also address winding issues. A proactive approach to maintenance is crucial for your pump.

Here are key strategies you should adopt for effective maintenance:

You document operating conditions, machine specifications, and performance tolerance ranges. This establishes a baseline for normal operation of your pump.

You capture and document critical measurements at installation, before and after maintenance, and routinely. This provides data points for comparison.

You create an archive reference of measurements. This facilitates trend analysis. It helps you identify changes in the system’s state. This aids early detection of potential issues.

You plot individual measurements to establish a baseline trend. You investigate any significant deviation (e.g., more than ± 10% to 20%) from this trend. This determines the root cause of the issue.

You can use specific instruments to diagnose electrical problems in your pump:

Electrical Issue | Impact | Diagnostic Instrument |

|---|---|---|

Transient Voltage | Motor winding insulation breakdown, early motor failure, unplanned downtime | Professional Power Quality Analyzer |

Voltage Imbalance | Excessive current flow, increased operating temperatures, insulation breakdown | Professional Power Quality Analyzer |

Harmonic Distortion | Internal energy losses, heat generation, deterioration of winding insulation | Professional Power Quality Analyzer |

Bearing and Shaft Maintenance

Bearing maintenance is vital. Bearing malfunction is a leading cause of servo motor failures. You ensure proper lubrication. You also replace worn-out bearings timely. Proper lubrication practices are essential. They improve electric motor bearing reliability. Inadequate lubrication causes 50-60% of motor failures. This impacts your pump.

You should follow these best practices for pump maintenance:

You avoid over-lubrication. Excess grease can enter windings. This causes insulation deterioration, arcing, shorting, and excessive heat/wear.

You use monitoring during re-greasing. Employ ultrasonic or acoustical monitoring. This detects when bearings are adequately replenished. You stop when the signal indicates sufficient lubricant.

You remove the drain plug during re-greasing. Always remove the bottom drain plug. Re-grease while the motor is running. This allows fresh grease to incorporate fully. It expels excess old grease or equalises pressure.

You use manufacturer-designated lubricant. Select the correct base oil viscosity, NLGI grade, and thickener. Base this on bearing design, speed, and temperature.

You adhere to proper lubrication intervals. Consult manuals or manufacturers for recommended intervals. This is a key aspect of effective maintenance.

For critical, high-temperature, or frequently failing pumps, you should use high-film-strength synthetic oils. Their higher cost is justified. They offer extended replacement intervals. They also provide improved contamination control. Synthetic oils benefit pumps experiencing ongoing problems.

Mechanical Seal Replacement for Pumps

You must replace worn shaft seals, which is crucial for pump longevity. You should address issues like rotor/shaft damage caused by excessive vibration or frequent starts/reversals. Furthermore, you must manage cooling device malfunctions, as dust or coolant leaks are common problems. For applications in polluted environments, seals should be replaced every 3-12 months to prevent fluid loss and contamination. This proactive maintenance extends the life of your pumps and ensures the continuous operation of your pump system.

Optimising Water Pump Motor Performance and Longevity

Proactive Maintenance and Installation

You ensure optimal water pump motor performance and longevity through diligent maintenance and correct installation. Proactive maintenance is key. You must establish a regular maintenance schedule. This ensures reliable operation and reduces downtime.

Key Proactive Maintenance Tasks

Routine inspection for leaks, wear, unusual noises, and overheating.

Proper lubrication of bearings and moving parts.

Checking seals and gaskets, replacing worn ones promptly.

Correct shaft alignment to prevent vibrations and damage.

Cleaning and flushing the pump system, removing debris and contaminants.

Replacing essential parts like impellers and valves when they show wear.

Frequency | Task |

DAILY | Check for overheating, cavitation, bearing noise, motor current, and voltage. |

WEEKLY | Inspect suction and discharge pressures, vibration, noise, visual signs of sealing and pipework leakage, corrosion, or discoloration. |

MONTHLY | Remove safety guards to check shaft and auxiliary devices, verify coupling alignment, and replenish lubrication oil if needed. |

ANNUALLY | If a backup pump is available, run it and check its maintainability. Inspect axial movement of the motor shaft. Remove and clean all auxiliary devices. |

Essential Installation Checks

Position the pump in a dry, stable, and accessible location.

Mount it firmly on a vibration-free foundation.

Shelter the pump from rain and dust.

Ensure adequate ventilation to prevent motor overheating.

Connect suction and discharge pipes carefully, avoiding excessive bends.

Electrical wiring must match the water pump motor’s voltage and current ratings; always ground the motor properly.

Prime the pump by filling the casing with water before operation to prevent dry running.

Advanced Monitoring and Protection

You enhance pump reliability through advanced monitoring and protection systems. These systems provide real-time insights into pump condition.

Advanced systems, such as AI-based sensor-free motor efficiency monitoring technology, perform advanced diagnostics by analyzing electrical signals (current fluctuations, voltage patterns, and power quality) from the motor power supply. They can detect anomalies and predict potential problems in real-time, integrating seamlessly with existing SCADA or IoT platforms. Continuous monitoring of these electrical signals helps you identify early signs of winding and bearing degradation.

Furthermore, to ensure system safety, professional motor protection systems (such as integrated protective relays) offer comprehensive control functions. These systems often include built-in dry-run detection that monitors active power input, protecting the pump when fluid flow is interrupted without the need for additional sensors. Remote condition monitoring units also play a vital role, capturing peripheral data like vibration, flow, and current draw, and providing immediate alerts to ensure you can effectively implement condition-based preventive maintenance programs.

Enhancing Efficiency with Honest Motor Technology

You significantly improve efficiency and reduce operational costs by choosing the right motor technology.

VFD Integration and the Cubic Law

Variable Frequency Drives (VFDs) are crucial for energy savings because they exploit the Affinity Law (or Cubic Law), which states that pump power consumption is proportional to the cube of the speed (P α N³).

VFD Function: VFDs adjust the motor’s speed to match real-time system requirements. This allows precise control over flow and pressure, avoiding energy waste associated with constant full-speed operation when flow demand is low.

Savings Impact: A small reduction in speed yields massive power savings (e.g., a 10% speed reduction cuts power use by approximately 27%). VFDs stop the pump when there is zero demand, preventing idling and conserving energy.

Example: A 7.5kW motor running at 90% of full speed consumes approximately 73% of the power, leading to potential annual savings.

Feature | Fixed Speed Drive | Variable Speed Drive |

Motor speed | Constant | Adjustable |

Energy efficiency | Low | High |

Flow control | Manual | Automated |

Ideal applications | Simple, consistent load | Variable demand systems |

Honest offers advanced motor technologies for superior efficiency. Permanent Magnet Synchronous Motors (PMSMs) generally offer a significant energy efficiency advantage over standard AC induction motors. PMSM motor losses are typically 15%–20% lower than those of induction motors, resulting in substantial savings. Honest provides synchronous motors up to IE6 efficiency and DC motors up to 93%. This commitment to high efficiency ensures your pumps operate with minimal energy consumption.

Honest Motor’s Solutions for Reliable Pump Systems

Custom Engineering and Global Compliance

Honest Motor specializes in providing reliable, customized solutions engineered to address the most rigorous industrial requirements and complex operating environments where standard pump motors typically fail.

Our customization capabilities include explosion-proof and corrosion-resistant options for demanding sectors like oil and gas, as well as high-starting-torque models. We ensure comprehensive compliance, adhering to strict quality management systems such as ISO 9001:2015 and IATF 16949 (Automotive Quality System), which guarantees manufacturing excellence and product consistency. Furthermore, our solutions comply with UL, CSA, and CE certifications, alongside RoHS and REACH material regulations, ensuring regulatory adherence across global markets.

Dedicated Support and Service from Honest

Securing the continuous operation of your pump systems requires robust, reliable support. You will receive dedicated assurance directly from Honest Motor:

Warranty and Longevity: We provide a comprehensive 2-year warranty on all pump products, backed by lifetime service support.

Rapid Response: Our expert engineers commit to responding to your queries within 12 hours, drastically minimizing downtime for critical operations.

Logistics Network: We maintain a global delivery network and international freight partnerships, ensuring efficient, traceable, and reliable product delivery and supply chain management.

A proactive approach to water pump motor fault analysis and prevention is indispensable. Regular maintenance, proper diagnostics, and investing in quality components are crucial for every pump. Understanding these principles, combined with reliable support from brands like Honest, guarantees the long-term efficiency and reliability of your water pumping systems.

For custom solutions, high-efficiency motor options, or to schedule an engineering consultation, please visit Honest.

FAQ

What are the most common causes of water pump failure?

You often find electrical issues, mechanical wear, and environmental factors cause pump failure. Overheating, bearing failure, and water ingress are frequent culprits. Regular checks help you identify these problems early for your pump.

How can I prevent my water pump from overheating?

You prevent overheating by ensuring proper ventilation around your pump motor. Avoid overloading the pump. Maintain correct lubrication for bearings. Clean cooling fins regularly. These actions protect your pump from thermal damage.

What is cavitation and how does it affect my pump?

Cavitation occurs when vapour bubbles form and collapse in your pump due to low pressure. This causes noise, vibration, and damage to the impeller. You must address this to protect your pump’s lifespan.

How often should I perform maintenance on my water pump?

You should perform daily visual checks on your pump. Conduct weekly inspections of pressures and vibrations. Annually, you should thoroughly inspect and clean your pump. This schedule ensures your pump remains reliable.