Industrial blower motors are essential for numerous operations. Selecting the wrong one significantly impacts efficiency, operational costs, and system reliability. Consider a well-chosen motor a strategic investment, not just a component. Navigating the complexities of industrial blower motor selection can be challenging. This guide provides a systematic, practical approach. It ensures optimal performance and longevity for your specific industrial applications.

Key Takeaways

Understand your blower’s needs, like airflow and air type, before choosing a motor. This ensures the motor works well and lasts a long time.

Match the motor’s power, speed, and turning force to your blower’s needs. This makes sure the system runs well and does not waste energy.

Choose motors with high efficiency ratings (IE3 to IE6) and use Variable Frequency Drives (VFDs). This saves a lot of energy and lowers running costs.

Pick strong materials and check protection ratings (IP, ATEX) for harsh places. This makes sure the motor lasts and is safe to use.

Install your motor correctly and follow a regular maintenance plan. This helps prevent problems and makes your motor last longer.

Define Your Application’s Core Needs

Before you select the right motor for your industrial blower, thoroughly understand your application’s specific demands. This foundational step ensures optimal performance and longevity.

Airflow, Pressure, and Runtime Requirements

First, determine the exact airflow your system requires, typically measured in cubic feet per minute (CFM). Next, identify the static pressure needed to move air through your ductwork and equipment. These airflow ratings directly influence the motor’s power and speed. Consider the operational duration; will your blower run continuously for long periods, or intermittently? A high-capacity blower operating constantly demands a more robust motor than one used for short bursts.

Air Type and Environmental Conditions

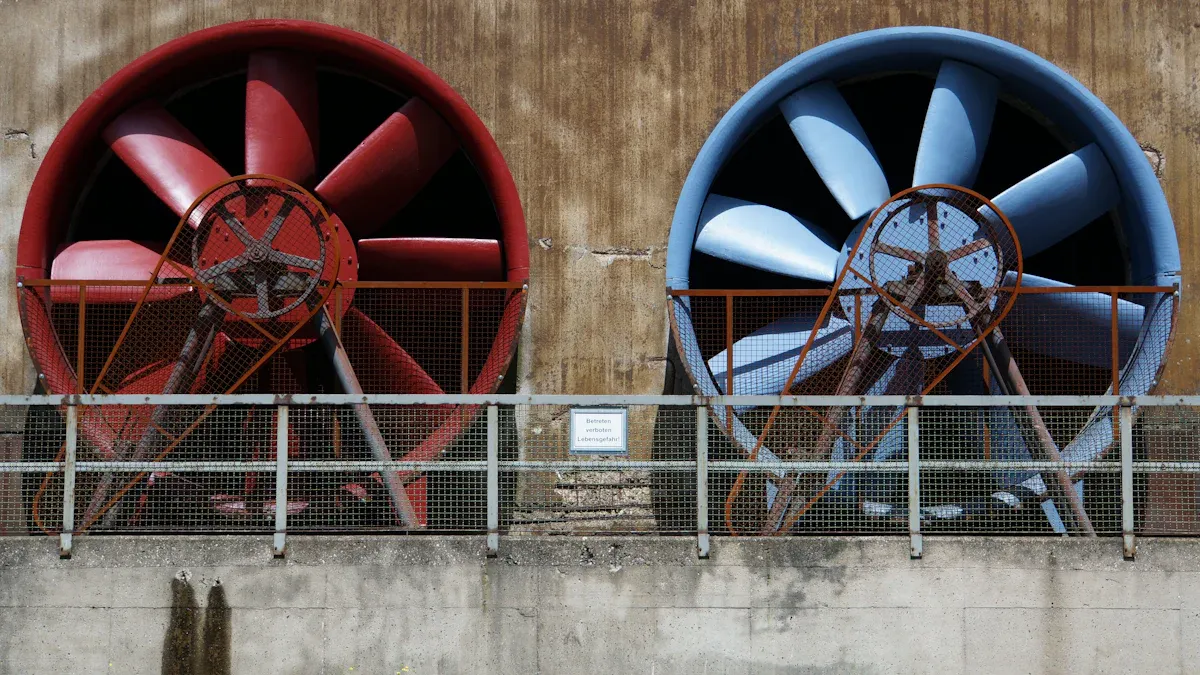

Assess the air your blower handles and its operating environment. Exposure to dirt, dust, debris, or moisture directly impacts motor protection. For instance, Open Drip Proof (ODP) motors are vulnerable to contaminants, while Totally Enclosed Fan Cooled (TEFC) motors offer superior protection. Ingress Protection (IP) ratings define resistance to solids and liquids; higher ratings mean better protection for outdoor or industrial use.

Consider corrosive air streams, which necessitate specific fan materials like expensive alloys or corrosion-resistant coatings. Flammable environments, such as chemical plants or mining operations, require specialised explosion-proof and corrosion-resistant motors for safety and compliance. Temperature extremes, humidity, and corrosive substances all demand appropriate motor enclosures and protection ratings to ensure durability.

Operational Duty Cycle and Load Variations

Understand your blower’s operational duty cycle. For continuous processes, industrial blower motors often operate for many thousands of hours (20,000 to 40,000 or more). This continuous duty (S1) means the motor operates at a constant load long enough to reach thermal equilibrium. To extend operational life, ensure the motor operates within specified temperature limits, receives proper lubrication, and does not exceed its rated load. Operating significantly below the rated load, for example, at 70-80%, minimises stress on components. You must select the right motor capable of handling these specific demands for your industrial applications.

Key Factors in Industrial Blower Motor Selection

You must carefully consider several key factors when making your industrial blower motor selection. This ensures your system operates efficiently and reliably. Honest Motor offers a diverse range of electric motors, including AC and DC options, as well as synchronous and asynchronous choices. We highlight their suitability for various blower applications. Honest Motor provides tailored solutions for your specific power, speed, and torque requirements.

Matching Motor Power, Speed, and Torque

You need to match the motor’s power, speed, and torque precisely to your blower’s demands. Power, measured in kilowatts (kW) or horsepower (HP), indicates the motor’s capacity to perform work. Speed, typically in revolutions per minute (RPM), dictates how fast the blower impeller turns. Torque represents the rotational force the motor produces. A motor with insufficient torque will struggle to start or maintain the required airflow under load. Conversely, an oversized motor wastes energy. You must select the right motor that provides enough power and torque at the correct speed for optimal blower performance.

AC vs. DC Motors: Power Source Compatibility

Your choice between AC and DC electric motors depends heavily on your available power source and control requirements.

AC Motors: Alternating Current (AC) motors are common in industrial settings. They are robust, reliable, and generally easier to maintain. They connect directly to the mains power supply.

DC Motors: Direct Current (DC) motors offer excellent speed control and high starting torque. They are ideal for applications requiring precise speed regulation or frequent starts and stops. Brushless DC (BLDC) motors offer higher efficiency, lower noise, and require less maintenance, making them perfect for precision auxiliary systems.

Synchronous vs. Asynchronous Motors for Blower Drives

You also need to consider the operational characteristics of synchronous versus asynchronous electric motors for your blower drives.

Synchronous Motors: These motors operate at a constant speed, directly proportional to the power supply frequency. They maintain precise speed control, making them ideal for applications where consistent performance is critical. Synchronous motors also offer high power factors and excellent efficiency, especially under high-load conditions. Honest Motor’s synchronous motors can achieve up to IE6 efficiency, providing significant energy savings.

Asynchronous Motors (Induction Motors): Asynchronous motors, also known as induction motors, are robust, simple in design, and cost-effective. Their rotor speed is slightly less than the synchronous speed, a difference known as “slip.” They are versatile and handle fluctuating loads well.

Direct Drive vs. Belt Drive Systems

You have two primary options for connecting your motor to the blower: direct drive or belt drive systems. Each has distinct advantages and maintenance considerations.

Direct Drive Systems: The motor shaft directly connects to the blower impeller. This eliminates belts, pulleys, and associated maintenance. Direct drive systems are generally more efficient because they avoid power losses from belt friction. They also typically produce less noise and vibration.

Belt Drive Systems: A belt connects the motor to the blower impeller, allowing for speed adjustments by changing pulley sizes. This offers flexibility in matching motor speed to blower requirements. However, belt drive systems require more maintenance.

Consider the typical maintenance requirements for each system:

Blower Type | Typical Maintenance Requirements |

|---|---|

Belt-driven | Inspection, adjustment, or replacement of drive belts. |

Direct-coupled | Checking and replacement of coupling alignment if worn. |

Both Types | Inspection of impeller for wear, damage, and dirt collection; monitoring vibration levels during test runs. |

For belt-driven systems, you must:

Check motor alignment.

Inspect belts and pulleys for proper tension and wear.

Address misaligned or worn components to prevent reduced efficiency and increased energy consumption.

For axial and centrifugal belt-driven fans, inspect belts for wear and ensure proper tension to avoid efficiency loss and more significant problems.

How to Select the Right Motor Type for Your Blower

You must carefully select the right motor type for your blower. This ensures optimal performance, energy efficiency, and long-term cost savings. Honest Motor commits to energy efficiency. We design our motors for optimal performance with Variable Frequency Drives (VFDs). This offers precise speed control and significant energy savings.

Assessing Motor Efficiency Ratings

Motor efficiency ratings are crucial for reducing operational costs. These ratings, from IE2 to IE6, indicate how effectively a motor converts electrical energy into mechanical energy. Higher IE ratings mean less energy waste. You should always aim for the highest possible efficiency rating for your industrial blower motor.

Here is a breakdown of efficiency improvements across different motor classes:

Motor Class | Efficiency Improvement |

|---|---|

IE2 | High efficiency standard (The standard baseline for many modern industrial motors) |

IE3 | ~96% efficiency, 20% fewer energy losses than previous level |

IE4 | ~97% efficiency, 20% fewer energy losses than previous level |

IE5 | 20% fewer energy losses than previous level |

IE6 | Understood to offer 20% lower losses than IE5 |

Choosing a motor with a higher IE rating directly translates to lower electricity bills. This makes a significant difference over the motor’s lifespan.

Integrating Variable Frequency Drives (VFDs) for Control

Integrating Variable Frequency Drives (VFDs) with your industrial blower motor offers superior control and substantial energy savings. VFDs adjust the motor’s speed to match the exact demand of your application. This avoids the energy waste associated with running a motor at full speed when it is not necessary.

Integrating VFDs with fan motors, such as those in HVAC systems, can lead to energy savings of up to 50%. When an industrial motor operates at 80% of its full RPM, its power consumption reduces to 51.2% of the full power. This demonstrates the cubed relationship between fan impeller revolutions and consumed power. VFDs achieve significant energy savings by reducing motor speed. This precise control not only saves energy but also extends the life of your equipment.

Honest Motor’s Ultra-High Efficiency Synchronous Motors

Honest Motor provides advanced synchronous motor technology designed for superior energy efficiency. Our synchronous motors achieve up to IE6 efficiency, representing the highest standard currently available for energy conservation. These high-efficiency motors offer precise speed control and highly consistent performance for demanding blower applications.

Our synchronous motors are engineered for optimal integration with Variable Frequency Drives (VFDs). This pairing results in superior system controllability, allowing you to finely tune the motor’s speed to meet exact operational requirements. This maximizes energy savings, ensures measurable performance benefits, and supports long-term sustainability goals.

Calculating Total Cost of Ownership and Energy Savings

When you choose an industrial blower motor, you must look beyond the initial purchase price. You need to calculate the Total Cost of Ownership (TCO). This provides a complete picture of the motor’s financial impact over its entire lifespan.

The key components of TCO for industrial blower motors include:

Owning Costs:

Purchase price

Taxes

Cost of borrowing

Other financing costs

Insurance

Residual value at the end of its life

Operating Costs:

Fuel (energy for electric motors)

Maintenance

Repairs

Tires and wear parts

A significant component of an electric motor’s lifetime cost is its energy consumption. This accounts for 96% of the total. This underscores the critical importance of overall efficiency over the initial purchase cost. Investing in ultra-high efficiency IE5 synchronous motors can lead to payback periods of less than one year. This is because IE5 motors offer a 40% reduction in energy losses compared to commonly used IE3 motors. This significantly lowers the total cost of ownership. A specific example of an 8-month payback period was observed for pump upgrades in a building after switching to high-efficiency IE5 equivalent motors. This upgrade resulted in an 81% reduction in electricity consumption. This demonstrates rapid return on investment for such high-efficiency motor installations. The payback time for choosing an IE5 motor over an IE3 motor is frequently less than one year. This is attributed to the IE5 motors having 40% lower energy losses. You must select the right motor to achieve these savings.

Durability, Compliance, and Customisation for Harsh Environments

You must ensure your industrial blower motor withstands its operating environment. This guarantees longevity and reliable performance. Honest Motor offers advanced customisation capabilities for extreme conditions.

Material Selection for Longevity and Compatibility

Selecting the correct materials is vital for motor durability, especially in challenging settings. For industrial blower motors operating in corrosive environments, stainless steel, particularly 304 and 316 grades, comes highly recommended. Stainless steel offers excellent corrosion resistance due to its chromium content. This forms a protective oxide layer. This material is robust, low-maintenance, and withstands high temperatures. It is ideal for demanding industrial applications where plastic alternatives might be unsuitable. You choose between 304 and 316 stainless steel based on specific corrosive agents. Another effective approach involves using bifurcated fans. Here, the motor is completely isolated from the corrosive airflow. This allows for broader material choices for the motor itself. For the fan’s casings and impellers exposed to corrosive air, materials like polypropylene or stainless steel are recommended. They resist aggressive or contaminated airstreams.

Noise, Vibration, and Protection Ratings (IP, ATEX)

You need to consider noise, vibration, and protection ratings for operational safety and comfort. Ingress Protection (IP) ratings indicate a motor’s resistance to dust and liquids. Higher IP ratings mean better protection. For hazardous environments, ATEX certification is crucial. This ensures your electric motors meet strict safety standards for potentially explosive atmospheres.

UKCA and International Regulatory Compliance

Adhering to regulatory compliance is non-negotiable for global operations. Honest Motor ensures its electric motors meet international standards. This includes CE, UL, RoHS, and REACH. Our factories hold ISO 9001 and IATF16949 certifications. This guarantees product quality and safety.

Honest Motor’s Explosion-Proof and Custom Solutions

Honest Motor excels in providing custom solutions for the harshest environments. We offer motors for high/low temperature, explosion-proof, nuclear, and subsea applications. Our explosion-proof electric motors feature robust construction with cast-iron frames and sealed components. They prevent the ignition of explosive materials. These designs include flameproof (Ex d) features with robust housings and and increased safety (Ex ec & Ex eb) designs that avoid sparks or hot surfaces. They are rigorously tested and certified to major international safety standards, ensuring compliance for hazardous regions globally. Our solutions for the Oil and Gas industry exemplify these robust, compliant motors.

Installation, Maintenance, and Long-Term Reliability

You must prioritise proper installation, regular maintenance, and reliable support for your industrial blower motor. This ensures optimal performance and extends its operational life.

Best Practices for Motor Installation

The installation phase of a new industrial blower motor demands precision and expertise. You must guarantee the motor is securely mounted, properly aligned, and ready for operation. Always adhere to the manufacturer’s installation guide. This ensures the fan and motor are correctly positioned. Verify the fan is installed according to the manufacturer’s specifications. This ensures the orientation of the fan blades and motor aligns with the required airflow direction.

Developing a Proactive Maintenance Schedule

You need a proactive maintenance schedule to prevent unexpected downtime. Common causes of motor failure include electrical overload, low resistance from insulation degradation, and overheating. Overheating accounts for about 55% of insulation failures. A 10°C temperature rise can reduce insulation life by 50%. Contamination from dust, dirt, and chemicals can damage bearings and block cooling fans. Vibration, often caused by uneven surfaces or loose components, also leads to premature failure. For belt-driven systems, regularly inspect belts for wear, proper tension, and alignment. Bearing wear is also common; timely replacement is crucial.

Troubleshooting Common Blower Motor Issues

You can troubleshoot common issues to maintain efficiency. If your motor overheats, check for overload conditions. Ensure the motor is not working harder than its rated capacity. Consider installing an overload protection device. Insufficient ventilation or a malfunctioning cooling fan can also cause overheating. Ensure adequate airflow and clean openings. Check the cooling fan’s function. For AC motors, incorrect voltage or phase imbalance can lead to overheating. Verify the voltage and phase balance. Electrical faults or short circuits in windings require checking for insulation breakdown. Repair or replace damaged wiring. Finally, ensure the motor size and type are compatible with the application. Upgrade if necessary.

Honest Motor’s After-Sales Support and Warranty

Honest Motor stands by the quality of its products. We offer a 2-year warranty on our motors. We also provide lifetime service. Our engineers respond within 12 hours, reinforcing our commitment to customer support and long-term reliability.

Selecting an industrial blower motor is a multifaceted decision. It requires careful thought about application specifics, motor technology, efficiency, regulatory compliance, and long-term operational factors. A diligent industrial blower motor selection process offers many benefits. These include enhanced efficiency, reduced operational costs, improved safety, and extended equipment lifespan. The right blower moves your entire operation forward. You must select the right motor for your unique industrial needs. Leverage expert advice and comprehensive product information to select the right motor.

For custom solutions, specialized technical advice, or to schedule an engineering consultation, partner with Honest Motor today.

FAQ

What do motor efficiency ratings (IE2 to IE6) mean for my blower?

These ratings show how well a motor converts electricity into mechanical power. Higher IE ratings mean less energy waste. You save money on electricity bills. Honest Motor’s synchronous motors achieve up to IE6 efficiency.

Should I choose an AC or DC motor for my industrial blower?

Your power source and control needs determine this. AC motors are robust and common in industrial settings. DC motors offer excellent speed control and high starting torque. Honest Motor provides both types.

How do Variable Frequency Drives (VFDs) benefit my blower motor?

VFDs adjust motor speed to match demand. This saves significant energy by avoiding full-speed operation when unnecessary. You gain precise control and extend equipment life. Honest Motor designs motors for optimal VFD integration.

What maintenance do belt-driven blower systems require?

You must regularly inspect and adjust drive belts. Check for proper tension and wear. Address misaligned or worn components. This prevents reduced efficiency and increased energy consumption. You ensure optimal performance.