You can find induction motors in many modern factories. These motors help machines work better and use less energy. Honest’s new induction motors make factories more steady and save money. If you pick energy-saving induction motors, you use less power and spend less. A food factory in Jordan used 18% less energy with better motors. This helped them pay less each month and make less pollution. Good motors help you reach your factory goals and build smarter systems.

Key Takeaways

Induction motors save energy and cut costs with smart controls like variable frequency drives.

They last long and need little maintenance thanks to strong parts.

Smart sensors and predictive maintenance spot problems early, avoiding breakdowns and repair costs.

They work well in tough factory conditions—dust, heat, or water don’t stop them.

When linked to smart factory systems, they use live data to run machines better, save energy, and boost efficiency.

Induction Motors in Factory Automation

Honest makes reliable induction motors for factories. These motors are widely used to keep machines running smoothly. They work well with pumps, conveyors, and other industrial equipment. Honest’s motors are ideal for factories that require precise operation. They also support testing of other motors and comply with strict industrial standards.

How Induction Motors Work

Induction motors convert electricity into mechanical power for machines. When you supply power to the stator, it creates a magnetic field that makes the rotor spin. They don’t need extra parts to start, making them easy to use while delivering strong torque. These motors are ideal for large machines, fans, and pumps. Honest’s motors can be equipped with smart sensors to monitor temperature, vibration, and current. This helps keep motors running smoothly and prevents problems, saving energy and money. Induction motors also work with smart systems, allowing you to use data to optimize operations and reduce power consumption.

Tip: Induction motors with variable frequency drives let you change speed and torque. You can use less power for different jobs and save energy.

Why Induction Motors Are Preferred

Induction motors are used in most factories. People pick them because they work well and need little fixing. These motors are simple—you don’t need a DC excitation system, and they start on their own. They can handle heavy loads and use energy efficiently. Honest’s motors follow IE3 and IE5 efficiency standards, so you pay lower electricity bills. Three-phase induction motors are the most common, appearing in big machines and automated systems.

Technical Advantage | Explanation |

|---|---|

Fewer parts make fixing easier. | |

No DC Excitation Required | You do not need extra systems and save money. |

Self-Starting Capability | Motors start fast and lift heavy things. |

Cost-Effective | You pay less to set up your factory. |

Higher Efficiency | Motors use less power and stay cool. |

Minimal Maintenance | You spend less time and money fixing things. |

High Overload Capacity | Motors work even when things get tough. |

Induction motors help you reach your factory goals. You get strong power, better efficiency, and use less energy. Honest’s motors help smart factories and automation. You can trust them to keep running smoothly in any factory.

Energy Efficiency with Induction Motors

You want your factory to save energy and money. Induction motors help you do that. Honest’s three-phase asynchronous motors use new materials and smart designs for higher efficiency. Factories choose them to reduce costs and be more environmentally friendly. High-efficiency motors make your factory stronger and greener.

High-Efficiency Motor Design

Induction motors use new designs to work better. Honest’s motors have strong rotors and smart winding systems. These parts lower losses and make motors work well. You get more power from less energy. In factories, motors use most of the energy. High-efficiency induction motors help change this. They turn more electricity into useful work. You see less waste and pay lower bills. IE3 induction motors save energy and last longer. You help your factory follow rules and protect the earth.

Note: If you upgrade to high-efficiency induction motors, you save a lot of energy. You also cut carbon emissions and help your factory go green.

Variable Frequency Drives and Soft Starters

Variable frequency drives (VFDs) and soft starters make motors smarter. You can control speed and torque for each job. This means you only use the energy you need. VFDs help you save up to 40% on energy. They also protect motors from stress and heat. Soft starters help motors start smoothly. You avoid big power spikes and lower wear. These tools help your factory stay efficient and reliable.

VFDs let you change motor speed for each job.

You save energy by matching motor output to the load.

Motors last longer because they run cooler and smoother.

You spend less on repairs and downtime.

VFDs help your factory reach energy goals.

When you use VFDs and soft starters, your motors work better. You save a lot of energy and money.

Predictive Maintenance for Efficiency

Predictive maintenance keeps your motors working well. You use sensors to watch for problems. These sensors check vibration, temperature, and signals. You find issues before they cause trouble. This helps you avoid wasted energy and keep things running.

Aspect | Explanation |

|---|---|

Good motors use less energy and cost less. | |

Real-time Monitoring | Sensors find early signs of motor trouble. |

Advanced Analytics | Smart software tells you when to fix motors. |

Digital Twins | Virtual models help you plan and improve motors. |

IIoT Integration | You manage all motors for better energy use. |

You use vibration checks, circuit checks, and heat checks to watch your motors. These tools help you find problems early. You also use AI and machine learning to study data. This helps you plan repairs and keep motors working. Predictive maintenance lowers energy use and keeps your factory running.

Tip: Predictive maintenance helps you stop sudden breakdowns. You save energy and keep your factory strong.

Energy-saving motors, VFDs, and predictive maintenance work together. You get better motor performance, use less energy, and help the planet. Honest’s solutions help you reach your energy goals and improve your factory every day.

Reliability of Induction Motor Solutions

If you pick induction motors for your factory, you want them to last. Honest makes motors that work well and keep your machines running. These motors give strong power and last a long time. You get less downtime and fewer problems. Let’s see how these motors help your factory stay reliable.

Robust Construction and Longevity

You need motors that work for many years. Honest uses special materials and smart designs to make motors strong. Epoxy glue holds the magnetic steel inside the rotor. CNC machines shape the rotor and casing so they fit well. Each rotor is balanced to stop shaking. Automatic machines put in the stator windings. The windings are wrapped and pressed to make them stronger. Vacuum painting protects the windings and helps the motor last longer. Sensors help press the bearings in so they fit right.

All these steps make motors that can handle heavy work and quick changes. You see less damage and fewer breakdowns. Honest’s motors use cast iron or steel cases. These materials stop vibration and shocks. The motors keep working even when things get hard.

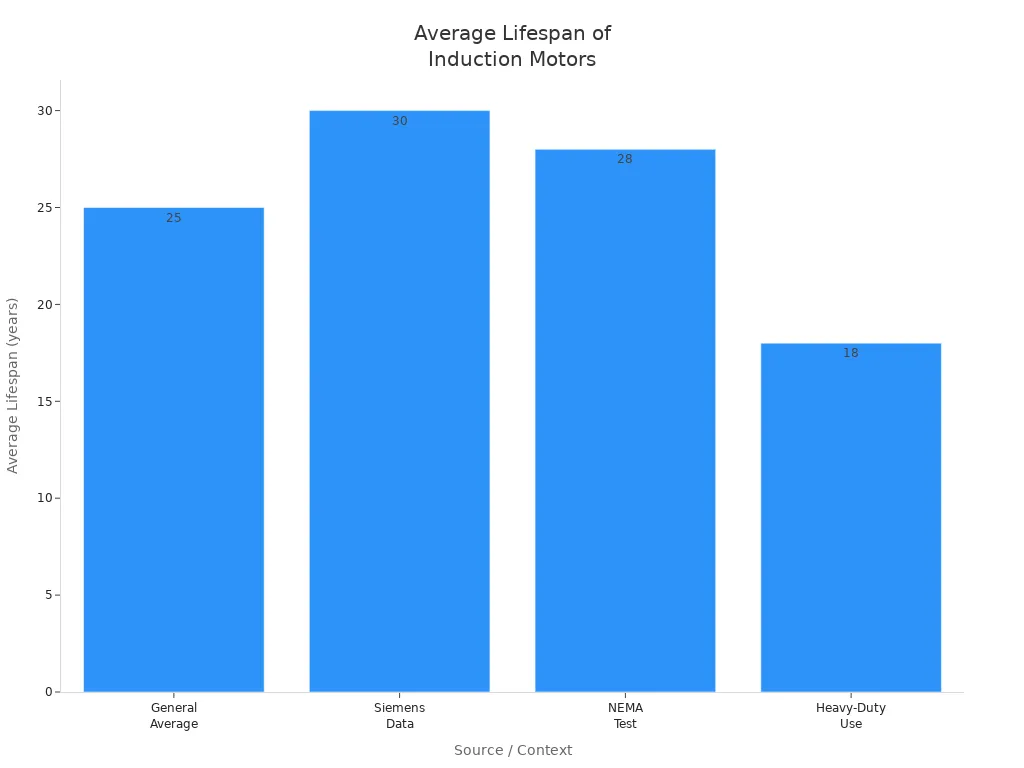

Here is how induction motors last compared to others:

Aspect | Details |

|---|---|

Average Lifespan | Usually 20 to 30 years; some last up to 40 years with good care |

Comparison with DC Motors | Induction motors last 30% to 40% longer than DC motors (which last 10-20 years) |

Manufacturer Data (Siemens) | Most last over 30 years; up to 40 years with good care |

NEMA Test Results | Most last about 25 to 30 years |

Industrial Applications | Used in water pumps, sewage plants, oil platforms, mining machines |

Durability Features | Resist shaking, rust, heat, and hard hits |

Maintenance | Need little fixing, which helps them last longer |

Load Adaptability | Can handle quick changes in work without breaking |

Typical Heavy-Duty Lifespan | About 15 to 20 years with regular care |

You can see induction motors last longer than most others. This means you buy fewer new motors and keep your machines working.

Condition Monitoring and Maintenance

Keeping motors healthy is important for your factory. Honest’s induction motors use sensors to watch for trouble. These sensors check shaking, heat, power, and speed. If something changes, you get a warning. You can fix small problems before they get big.

Watching your motors helps you plan repairs only when needed. You avoid sudden stops and keep machines working. Studies show 99% of problems show up in sensor data before a breakdown. With smart care, you can:

Make machines work 9% more

Help motors last 20% longer

Spend 30% less on spare parts

Check your motors every 3 to 6 months. Clean dust and oil every month. Tighten wires every six months. Use shaking checks, heat pictures, and oil tests to find early problems.

Tip: Regular checks and smart watching help you stop costly stops and keep your factory strong.

Handling Harsh Environments

Factories have dust, water, heat, and chemicals. You need motors that keep working in tough places. Honest’s induction motors have high IP ratings like IP65. This means they block dust and water. The motors use rust-proof materials and sealed cases. Food-safe seals and oils are ready for special jobs.

You can use these motors in places that need lots of cleaning or face strong chemicals. Honest gives custom choices for your needs. The motors work in textile plants, mines, water plants, and food factories. They keep running in hot places and dusty rooms.

Honest’s gearmotors and asynchronous motors are made for nonstop work. They use sealed, self-oiling parts and dust-proof designs. You get less damage and fewer fixes. These motors have world safety marks like UL, CE, and ISO. You can trust them for important jobs in your factory.

Feature | Description |

|---|---|

Motor Type | AC three-phase induction motor, strong and reliable for factories |

Construction | Tough cast iron or steel case stops shaking and damage |

Environmental Resistance | Works well in heat, wet, and rusty places |

Maintenance | Simple design with good ball bearings that need little oil |

Performance Stability | Keeps steady power when work changes, good for factory lines |

Typical Lifespan | About 15 to 20 years in hard jobs with regular care |

Maintenance Impact | Regular checks and oiling help motors last longer and stop early breaks |

Note: Honest’s induction motors meet strict world rules for saving energy and working well. You get motors that save power and keep your factory safe.

When you use Honest’s induction motors, you get strong, steady work in every part of your factory. You spend less on fixing, avoid stops, and keep your machines working their best.

Smart Automation and Integration

IIoT and Data Analytics

You can make your factory smarter with IIoT. Induction motors connect to the Industrial Internet of Things. Smart sensors go on the motors. These sensors give you live data about heat, shaking, and power. You can see if something is wrong right away. This helps you fix things before they break. Your machines keep working and do not stop for long.

Here is what you get when you use IIoT and data analytics with induction motors:

You notice damage early and fix motors before they stop.

You set the motor’s speed and power for each job. This saves energy and keeps things running well.

You use heat sensors to stop motors from getting too hot. This helps motors last longer.

You control energy use in your whole factory. You can move loads and lower high power use.

You make digital twins, which are computer models of your motors. You test and improve how motors work.

You use variable frequency drives to control speed and power better. This cuts waste.

Live checks help you watch how well motors work. You can see patterns and plan repairs only when needed. This is called predictive maintenance. It lowers stops and saves money. Your factory stays strong and works well.

Tip: Live data from induction motors helps you act fast. You can fix problems early and keep your factory running well.

Automation System Compatibility

You want your induction motors to work with your factory’s systems. Honest’s motors use common ways to talk to other machines, like Modbus and Ethernet. This makes wiring and sharing data simple. You can use motors and drives from the same brand. This helps you set up faster and have fewer problems.

Control System Feature | Benefit for Motor Integration |

|---|---|

Common communication buses | Easy wiring and data exchange |

Motors and drives from one brand | Simple setup and fewer problems |

Software support | Fast and accurate motor control |

Legacy system compatibility | Easy repairs and lower costs |

Scalable design | Ready for future expansion |

Online editing | Update systems with less downtime |

You can also use these motors with old systems. This saves money because you do not need new parts. The system can grow as your factory gets bigger. You can add more motors or update your setup. Live checks and predictive maintenance work together. They help your machines stay reliable and efficient.

You can make your factory better with Honest’s induction motors and drives. These motors are reliable and perform well in any factory setting. They help you save energy and prevent breakdowns, which saves money and benefits the planet. Check the table to see how much you can save:

Aspect | Fluid Coupling System | Honest’s VFD Induction Motor System |

|---|---|---|

90,422 MWh/year | 78,716 MWh/year | |

Annual Cost Savings | N/A | 702,000 EUR/year |

Good motors can last up to 20 years and save about 15% on costs each year.

Use good parts, keep motors cool, and check them often to keep your factory running well.

Pick honest’s special motor solutions to get the best results and help your factory become smarter and save more energy.

FAQ

What makes induction motors reliable for factory use?

Induction motors have strong parts and are built simply. This means they break down less and last longer. Honest’s motors use tough materials and smart sensors. These help your machines keep running and avoid costly stops.

How do induction motors help you save energy?

Induction motors use less power because they work well. You can add variable frequency drives to control speed. Honest’s motors meet high energy rules. This helps you pay lower bills and protect the environment.

Can you use induction motors with smart factory systems?

Honest’s induction motors connect easily to smart systems. You use sensors and IIoT platforms for live data and control. This helps you plan repairs and make your factory work better.

How often should you check and maintain induction motors?

Check your motors every 3 to 6 months. Clean off dust and oil each month. Tighten wires two times a year. Honest’s motors let you use sensors to watch them in real time. You find problems early and keep motors working longer.