When selecting pump motors for your operations, you have a wide range of choices. Choosing the right pump motors is essential for improving efficiency, saving energy, and reducing downtime.

High-efficiency pump motors can significantly lower your energy consumption, helping you save up to 30% on energy costs.

Monitoring your equipment and selecting the properly sized pump motors extends their lifespan and reduces the need for frequent repairs.

Many industries, such as water treatment, have achieved substantial cost savings by adopting industrial pump motor solutions.

In India, the pump market is expanding rapidly, with the industrial segment accounting for 59% of the market in 2024. This sector is projected to grow at over 6% annually through 2030. Making smart decisions about pump motors and industrial pump motor solutions today will set you up for long-term success.

Key Takeaways

Pick pump motors that match your fluid type, flow rate, and pressure. This helps save energy and stops damage.

Think about where you use the motor and if it fits your system. This helps your motor last longer and work better.

Choose motors that are high-efficiency and reliable. This can cut energy costs and lower repairs and downtime.

Follow simple steps: know what you need, look at different motors, and ask experts for help. This gives you the best results.

Do regular maintenance and avoid common mistakes. This keeps your pump motors working well and saves money.

Pump Motor Basics

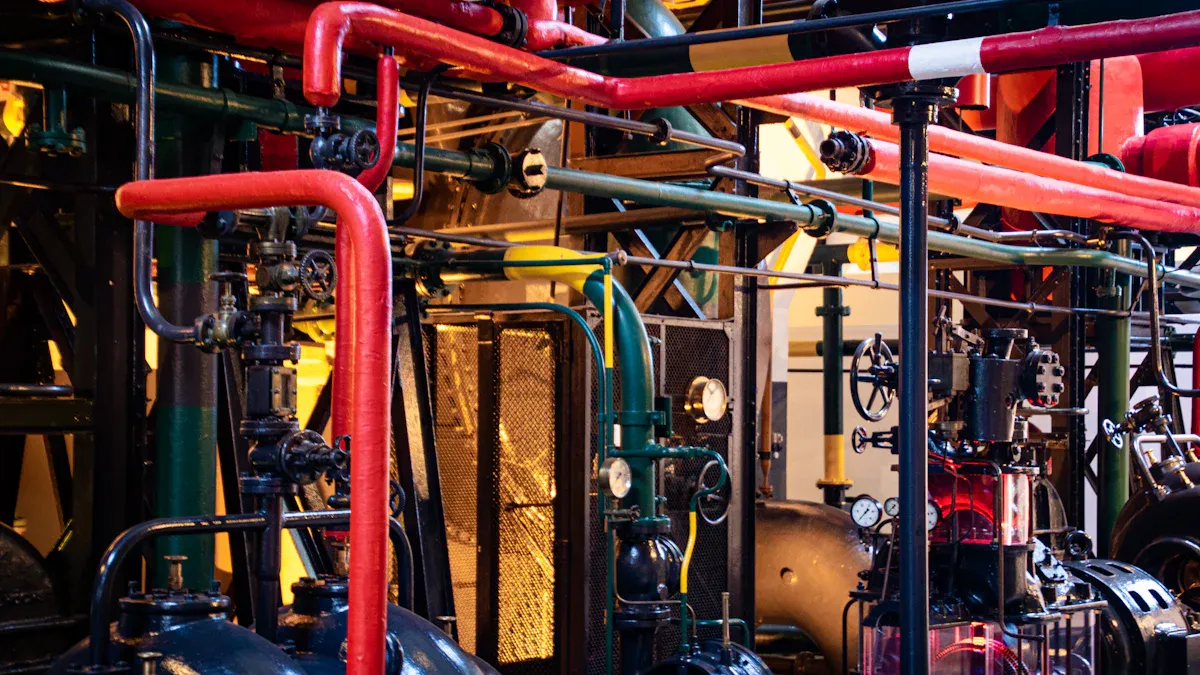

Pump motors help move liquids in many places. You see them in water plants, factories, farms, and pools. These motors change electrical energy into mechanical energy. This makes the pump work and moves liquids to where you want. Picking the right pump motors saves energy and lowers maintenance. It also helps your work go smoothly.

Types of Pump Motors

There are many pump motors for different jobs. Here are some common types and how people use them:

Centrifugal Pumps: These are used the most. They move water and other liquids fast. They are simple to set up. You find them in water plants, farms, and factories.

Reciprocating Pumps: These pumps make strong force. They work well with thick or sticky liquids. Mining and farming often use these pumps.

Rotary Pumps: This group has gear, vane, and screw pumps. They give a steady flow. They are good for moving oil or smooth liquids.

Submersible Pumps: These pumps and motors go underwater. They are sealed to stop damage. People use them for stormwater, sewage, and city water.

Gear Pumps: These pumps use gears that turn to move fluids. They work with grease, oils, and fuel.

Honest offers a wide range of pump motors, including asynchronous motors, synchronous motors, DC brushless motors, and gear motors. These are commonly used in various industrial pump solutions, including applications in water plants, factories, and beyond.

Key Terms Explained

Knowing some key words helps you pick pump motors. Here is a table to help you:

Technical Term | What It Means and Why It Matters |

|---|---|

Motors can take small voltage changes. Too much can make them hot or wear out fast. | |

Frequency Variation | Changes in frequency change the motor’s strength. |

Voltage Unbalance | Uneven voltage can make the motor too hot and break early. |

Locked Rotor Torque | The force the motor makes when it starts. This matters for pumps with heavy loads. |

Breakdown Torque | The most force the motor gives before stopping. Needed for hard jobs. |

Motor Speed | Must fit the pump’s needs. Sometimes you need a gearbox or speed changer. |

Insulation Class and Temperature | Shows how much heat the motor can take. Too much heat can hurt the motor. |

Harmonics from VFD | Special drives can make extra heat. Filters help keep the motor safe. |

Abnormal Operating Conditions | Too much work or many starts can hurt the motor. Pick a motor made for your job. |

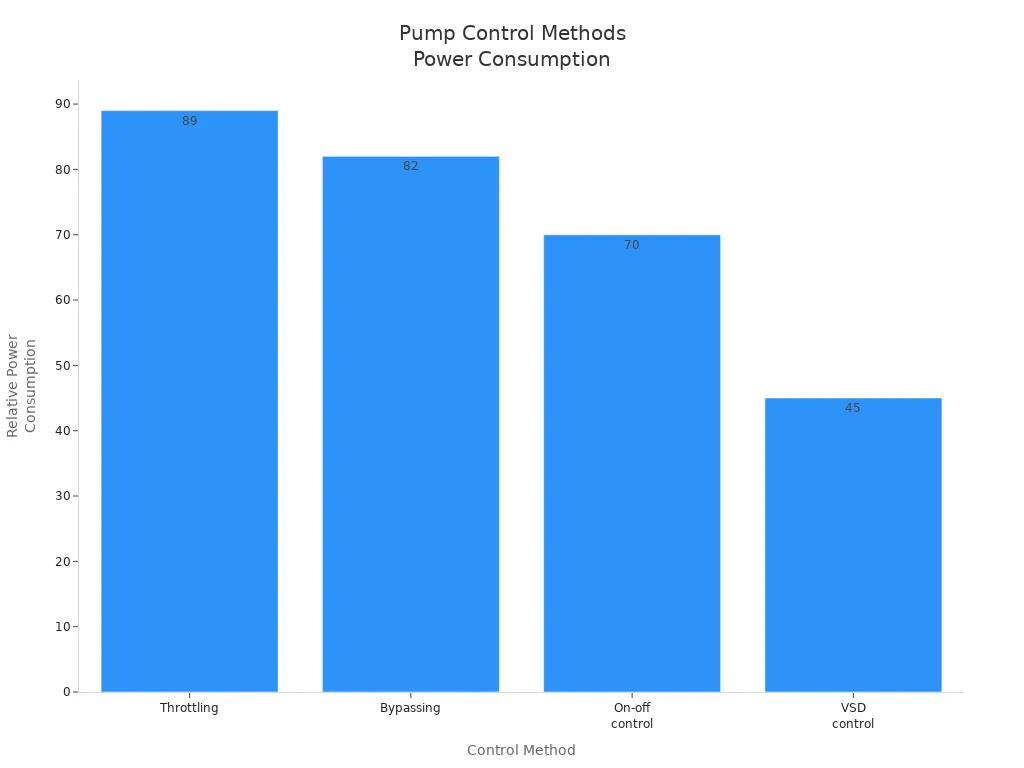

Tip: High-efficiency pump motors and smart controls can save lots of energy. You can save up to 60% on costs. The right industrial pump motor solutions lower your total cost and make your system work better.

Key Factors for Selection

Picking the right pump motors means thinking about many things. Each thing helps you find a motor that fits your needs. This makes your system work well, saves power, and helps it last longer.

Application Needs

First, you need to know what your system will do. Think about the fluid type, how much you want to move, and the pressure. Some fluid properties are important to check:

Temperature (how hot or cold the fluid gets)

Specific gravity (how heavy the fluid is compared to water)

Vapor pressure (how easily the fluid turns into vapor)

Presence of solids (if the fluid has sand, dirt, or other particles)

Shear sensitivity (if the fluid changes thickness when pumped)

Abrasiveness (if the fluid can wear down parts)

Fluid Property | Importance / Effect on Pump Selection |

|---|---|

You need a different pump for thick fluids. High viscosity means you should use positive-displacement pumps, not centrifugal pumps. | |

Concentration | This changes how hard it is to move the fluid. It also affects how well the pump works, especially with big particles. |

Flammability | You need pumps made from safe materials, like stainless steel, if the fluid can catch fire. |

Specific Gravity | This changes how the pump works. Heavy fluids need more power from the motor. |

Temperature | Hot or cold fluids need special motors and materials. |

You also need to know the flow rate and pressure you want. Flow rate is how much fluid you move in a set time. Pressure is the force needed to push the fluid through pipes. If your motor is too small, it can get too hot or break. If it is too big, you waste energy and money. Variable speed motors let you change flow and pressure, but they cost more. Honest can make custom pump motors for your job, so you get the best fit.

Compatibility & Environment

Your pump motor must work with your current setup. It should fit your pipes, control systems, and power supply. This helps you avoid long stops and extra costs.

The place where you use the motor matters too. Think about these things:

Temperature: High heat can make motors too hot. You may need special cooling or materials.

Humidity: Wet air can hurt motors. Motors with climate protection last longer in wet places.

Air quality: Dust, oil, and dirt can block cooling parts and make motors break sooner.

Enclosure rating: Motors need to be safe from water, dirt, and chemicals. Look for ratings like IP55 or higher for tough places.

Duty cycle: Some motors run all day. Others start and stop a lot. Pick a motor that can handle your work schedule.

Note: Honest makes pump motors with strong covers and special coatings. These help your motor last longer, even in tough places like chemical plants or outside.

Efficiency & Reliability

Efficiency and reliability change how much you spend over time. High-efficiency motors use less power, so you save money. Reliable motors keep working and do not break often.

Efficiency ratings, like IE5, show how well a motor uses energy. IE5 motors are very good and can cut motor losses by 30% compared to old ones. Using variable frequency drives (VFDs) lets you change motor speed to save even more energy.

Reliable motors have strong bearings, good insulation, and smart monitoring. These things help stop common problems, like bearing or winding failures.

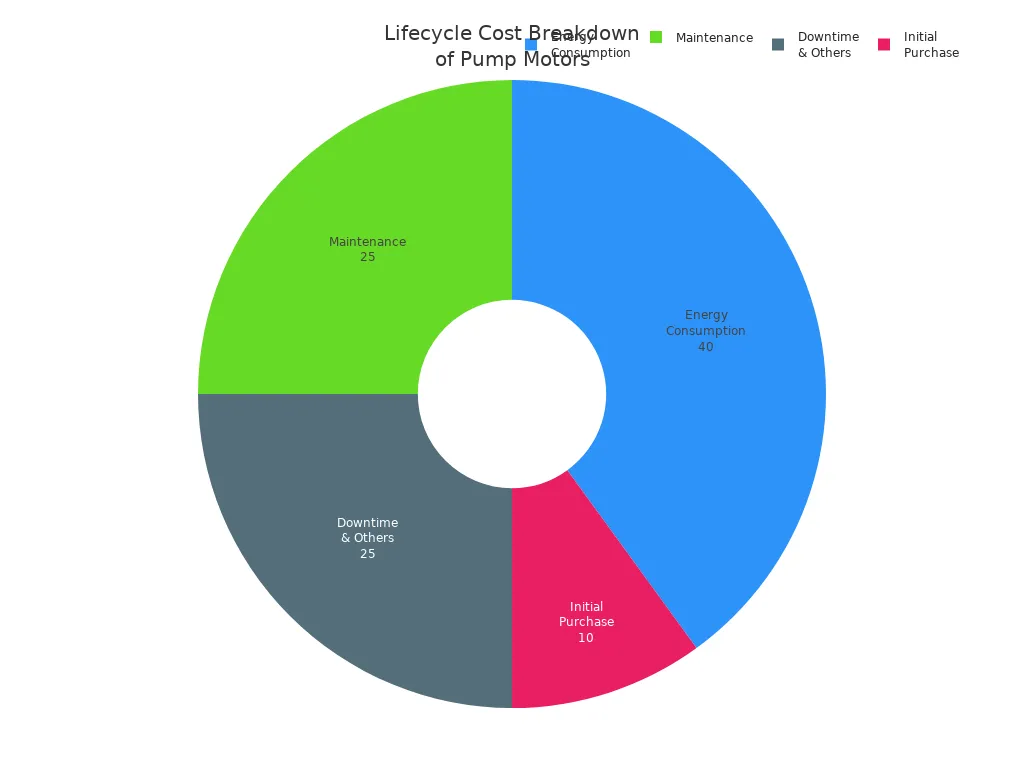

The total cost of owning a motor is more than just buying it. Most costs come from energy, fixing, and downtime—not just the first price.

Cost Component | |

|---|---|

Initial Purchase | 10% |

Energy Consumption | 40% |

Maintenance | 25% |

Downtime & Others | 25% |

Energy use is the largest cost, so choosing efficient and reliable industrial pump motor solutions is key to saving money and avoiding future issues. Honest provides custom options and durable materials to ensure your system operates smoothly.

Selection Steps

Choosing the right pump motors for your application takes careful planning. You want to make sure your system runs smoothly, saves energy, and lasts a long time. Follow these steps to make the best choice.

Define Requirements

Start by understanding exactly what you need. This step helps you avoid mistakes and makes sure your pump motors fit your job. Here is a step-by-step guide:

Learn about your application. Write down what the process does and what kind of fluid you need to move.

Check the fluid’s properties. Look at things like chemical makeup, thickness, temperature, if it has solids, and if it is toxic.

Figure out how much fluid you need to move and how much pressure you need. This helps you match the pump’s size and power.

Pick the right pump type. Centrifugal, positive displacement, or specialty pumps all work best for different jobs.

Choose the best materials for your pump. Think about corrosion, abrasion, and how hot or cold the fluid gets.

Look at where you will install the pump. Measure the space, check the air and temperature, and think about noise and vibration.

Focus on energy efficiency and total cost. Check how efficient the pump is, what kind of drive system it uses, and how much maintenance it needs.

Make sure your pump meets safety rules and has the right certifications.

Think about support and service. Good support keeps your system running and cuts down on downtime.

Write down all your choices and reasons. This helps you later if you need to fix or change something.

Tip: Honest’s team can help you define your requirements. They offer expert advice and custom solutions for many industries, making sure your pump motors fit your needs.

Compare Pump Motors

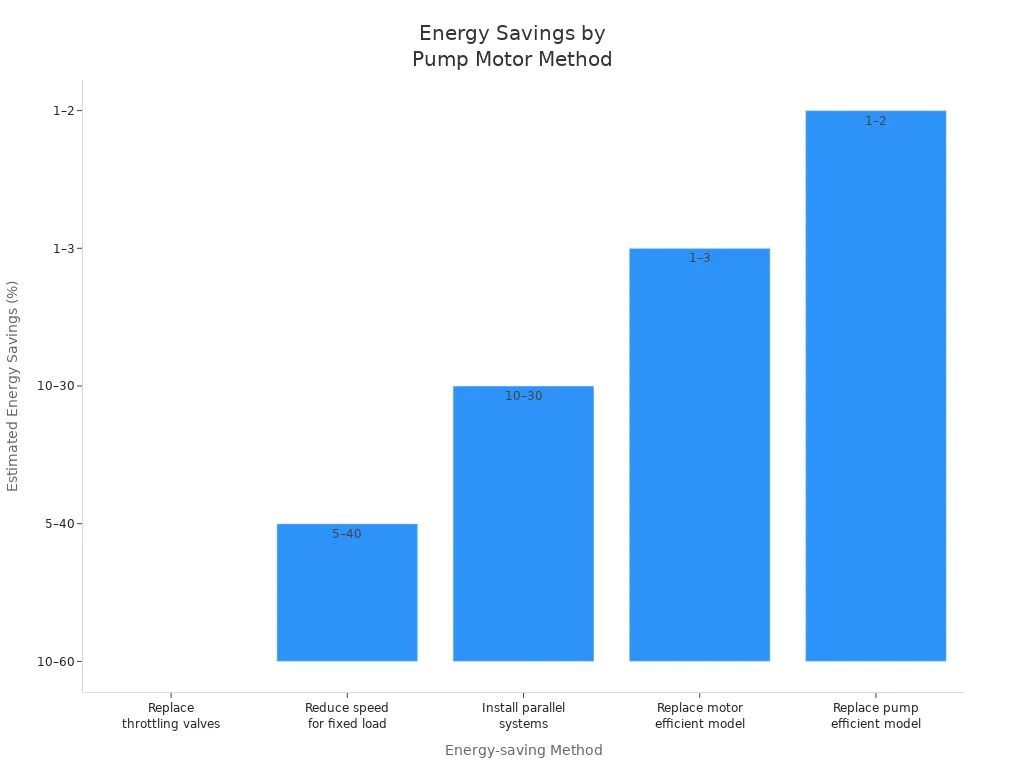

Once you know your requirements, compare different pump motors to find the best match. You can look at control methods, energy use, and how well each motor fits your system. Here is a table that shows how different control methods affect power use:

Control Method | Relative Power Consumption |

|---|---|

Throttling | 89 |

Bypassing | 82 |

On-off control | 70 |

VSD control |

You can see that variable speed drive (VSD) control uses the least power. This method lets you change the pump’s speed to match what you need, which saves a lot of energy. If you want to lower your energy bills, VSD control is a smart choice.

When you compare pump motors, also look at things like efficiency ratings, protection levels, and how easy they are to maintain. Honest offers a wide range of industrial pump motor solutions, including high-efficiency motors and custom options for tough environments.

Note: Always check if the motor can handle your system’s voltage, temperature, and duty cycle. Honest’s experts can help you compare options and pick the best one.

Consult Experts

Talking to pump motor experts can save you time and money. Experts help you avoid common mistakes and make sure your system works well. Here is how they help:

Experts add safety features like relief valves and strong seals to protect your pump.

They help you pick the right motor size and type, which saves energy and lowers costs.

Experts watch system details like oil temperature and pressure. They can stop problems before they cause damage.

They design systems with smart features, like saving energy when the pump is not running but still keeping pressure.

Experts make sure your pump and motor work well together and fit your exact needs.

You should also include the people who will use the system in the decision. This makes sure the pump motors match what you need now and in the future. Experts help you plan for changes in load, duty cycle, and torque, so your system stays reliable.

Honest provides full support, from helping you choose the right motor to offering after-sales service. Their team gives you advice, helps with installation, and offers 24/7 support. Good after-sales support means your pump motors keep working well, with less downtime and lower costs. Honest’s global service network helps you with maintenance, repairs, and upgrades, so your business keeps running smoothly.

Industrial Pump Motor Solutions

honest Product Features

When you pick honest pump motors, you get more than a simple motor. These motors are made to work well and last a long time. Here are some reasons why honest is different:

They use less energy because of special motor types. These motors help you save power and are good for running all day.

They’re incredibly quiet, thanks to special technology that minimizes noise, making your workplace more comfortable.

They are tough. Special seals and materials stop rust and damage. This helps the motors last up to 40% longer, even in hard places.

They are made for rough jobs. Explosion-proof and high-torque features let them run all day in factories and chemical plants.

They have safety and quality certificates from around the world, like CE, UL, CCC and ISO. You can trust these motors to be safe and high quality.

Every motor is made the same way with careful checks. This means you get a motor you can count on every time.

You can get custom motors. Honest’s R&D team can make motors that fit your project, so you have more choices.

These things make honest a good pick if you want strong and reliable industrial pump motor solutions.

Real-World Applications

You can find honest pump motors in many jobs. In water treatment plants, these motors move clean water, handle dirty water, and control stormwater. Submersible motors with strong waterproofing and rust protection keep working even when underwater. They help stop floods and water crops.

In factories, honest motors help machines work by themselves. They control valves and move conveyor belts exactly. Their explosion-proof and dust-proof designs are great for textile factories and shipping centers. You can count on these motors to keep working, even if the power changes or the place is tough.

Honest’s industrial pump motor solutions also help in farming, mining, and building services. The motors work well even if the power is not steady or the place is rough. They are easy to set up and do not need much fixing, so you spend less time on repairs and more time working.

Tip: If you need pump motors that can handle tough jobs, honest gives you what you need to do well.

Tips & Mistakes to Avoid

Practical Tips

You can keep your industrial pump motors working well by doing a few easy things. First, pick the right motor for your job. Induction motors and variable frequency drives (VFDs) are good for many uses. Smart control systems help you watch how your motor works and find problems early.

Here are some simple tips to help your pump motors last longer and work better:

Put oil or grease on bearings and moving parts often. Always use the kind the maker says is best.

Look at seals and gaskets a lot. Change them if you see leaks or damage.

Keep extra spare parts ready. This helps you fix things fast and stop long waits.

Follow a good plan for taking care of your pump. Check it every day, week, and month.

Clean strainers and filters so nothing blocks the pump. A clean pump works better and lasts longer.

Watch for shaking, pressure changes, and flow problems. These checks help you find trouble before it gets worse.

Use smart sensors and tools that can warn you early. These can tell you about problems before they break your pump.

Doing regular care and using smart tools helps you stop big repairs. Honest gives you good support and checks, so you can trust your pump motors in hard places.

Common Pitfalls

Many people make mistakes when picking or taking care of pump motors. Try not to make these mistakes so you save time and money:

Picking a motor just because it is cheap. Cheap motors may not work well and can break soon.

Not checking your pump often. If you skip checks, you might miss signs of trouble and have sudden stops.

Using too much or too little oil or grease. This can hurt the bearings.

Running pumps outside the right flow or pressure. This puts stress on the motor and makes it wear out faster.

Not lining up the pump and motor shafts right. Bad alignment causes shaking and can break the motor early.

Forgetting to think about all the costs. Look at energy use, care, and help, not just the price you pay at first.

Mistake | How to Avoid It |

|---|---|

Improper pump sizing | Make sure the pump fits what your system needs |

Skipping maintenance | Set a plan and follow it to take care of pumps |

Ignoring energy efficiency | Pick motors that use less energy |

Poor system integration | Ask experts to help set up your system |

Honest’s team can help you not make these mistakes. Their help and checks make sure your pump motors work well, even in tough places.

Picking the right pump motors means you need to know your fluid type, as well as how fast and how much fluid you need to move. You should also consider which materials work best with your fluid. Energy efficiency is key, so you want motors that are easy to maintain and repair. Good industrial pump motor solutions save you money by using less energy and preventing system breakdowns. In regions like India, where power supply can be inconsistent and environments are tough, reliable motors help your system keep running smoothly, saving you money in the long run. Honest offers custom solutions tailored to your needs.

Figure out what your job needs and how much fluid you move.

Pick materials that work with your fluid and where you use them.

Think about saving energy and how much the motor costs over time.

Choose suppliers who give good help and have extra parts.

FAQ

What is the best way to choose the right pump motor size?

You should match the motor size to your flow rate and pressure needs. Oversized motors waste energy. Undersized motors overheat and fail. Honest’s experts can help you calculate the right size for your job.

How often should you maintain your pump motor?

You should check your pump motor every month. Clean filters and inspect seals. Lubricate bearings as needed. Regular maintenance helps your motor last longer and prevents breakdowns.

Can you use the same pump motor for different fluids?

You need to choose a motor that matches your fluid type. Some motors work with water. Others handle chemicals or thick liquids. Honest offers custom motors for many fluids.

What certifications do honest pump motors have?

Honest pump motors carry global certifications like CE, UL, CCC and ISO. These certificates show that your motor meets safety and quality standards for industrial use.

How do you know if your pump motor is energy efficient?

Look for efficiency ratings like IE4 or IE5. High ratings mean your motor uses less power. Honest’s motors offer top efficiency, helping you save money on energy bills.