Motors give power to electric actuators by turning electrical energy into movement. These actuators use this movement to control machines, valves, and other devices in automation systems. Electric actuators are now very important for reliable and exact movement in many industries. The market for actuators has grown fast, with millions of AC and DC motor-based actuators used all over the world. Companies like honest make actuator technology better with advanced electric actuator motors that help save energy and move accurately. As automation gets bigger, actuators help push industry progress.

Key Takeaways

Electric actuators use motors to change electrical energy into movement. This helps control machines and devices in many fields.

There are different motor types like brushed DC, brushless DC, stepper, and servo motors. Each type has special benefits for speed, force, and accuracy.

Electric actuators save energy by using about 80% of their power well. This makes them cheaper to use and better for the environment.

Honest’s advanced electric actuators are strong, reliable, and quiet. They have smart controls for safe and exact movement.

Picking the right actuator depends on the kind of movement, load, speed, accuracy, and place. This helps make sure it works well for a long time.

Electric Actuators and Motors

Energy Conversion

Electric actuators use motors to turn electrical energy into movement. This starts when the actuator gets an electrical signal. The motor inside makes a magnetic field. The magnetic field makes the rotor spin. When the rotor spins, it creates rotary movement. Some actuators use gears, lead screws, or belts to change rotary movement into straight movement. For example, a linear actuator uses a lead screw to push or pull something in a straight line. A rotary actuator uses the motor’s shaft to turn things like valves or levers.

There are different kinds of motors in electric actuators. These include brushed DC motors, brushless DC motors, stepper motors, and servo motors. Each motor type works in its own way. Brushed DC motors are simple and used a lot. Brushless DC motors last longer and need less fixing. Stepper motors move in small steps for careful movement. Servo motors give strong force and very exact control. The motor you pick changes how fast the actuator moves, how much force it has, and how long it works.

Motor Type | Characteristics and Performance Differences |

|---|---|

Brushed DC | Has brushes and commutators; easy to control; wears out faster; needs more fixing; used in many actuators |

Brushless DC | No brushes; works better; more dependable; needs less fixing |

Stepper | Moves in steps; stops at exact spots; best for slow movement |

Servo | Strong force; very exact control; great for careful movement |

Electric actuators are good at saving energy. They use about 80% of the energy they get to do work. Pneumatic actuators use only 10-25%, and hydraulic actuators use about 40%. Because they are efficient, electric actuators help save energy and money over time.

Honest makes advanced electric actuator motors. Their motors are efficient, have strong starting force, and steady power. These things help electric actuators work well in many places, like water treatment and factories.

Motion Control

Motion control is how actuators manage movement. Electric actuators use motors and special parts to control how far, how fast, and how smooth things move. For linear actuators, the motor’s rotary movement turns a lead screw. The lead screw moves a nut or carriage in a straight line. This setup gives careful and repeatable movement. Rotary actuators use gears or the shaft to turn things with control.

Servo actuators use feedback systems. Sensors check the position and speed of movement. The controller changes the motor right away. This feedback lets the actuator move very accurately. Stepper actuators move in set steps. Each step is a certain distance, so the actuator can stop at exact spots.

Electric actuators can also use ballscrews and electronic controls. These parts help the actuator start, speed up, slow down, and stop at the right times. The system can set many stop points along the path. This makes electric actuators great for jobs that need careful and repeatable movement.

Motion control in electric actuators helps lower mistakes and keep things safe. Honest’s advanced motors help with these features. They let actuators respond fast, move with care, and work well. Honest’s actuators can handle hard jobs and heavy loads. Their design helps stop problems like wear, overload, and electrical faults. Regular checks and smart tools, like sensors and diagnostics, keep actuators working well.

Note: Honest’s electric actuators use advanced motors and motion control systems. These features help industries get accurate, safe, and energy-saving movement in their machines.

Types of Actuators

Electric actuators have a few main types. Each type uses a different motor to make things move and control them. The three most common types are linear actuators, rotary actuators, and servo or stepper actuators. Honest has many kinds of these actuators. Each one is made for a special job or need.

Linear Actuators

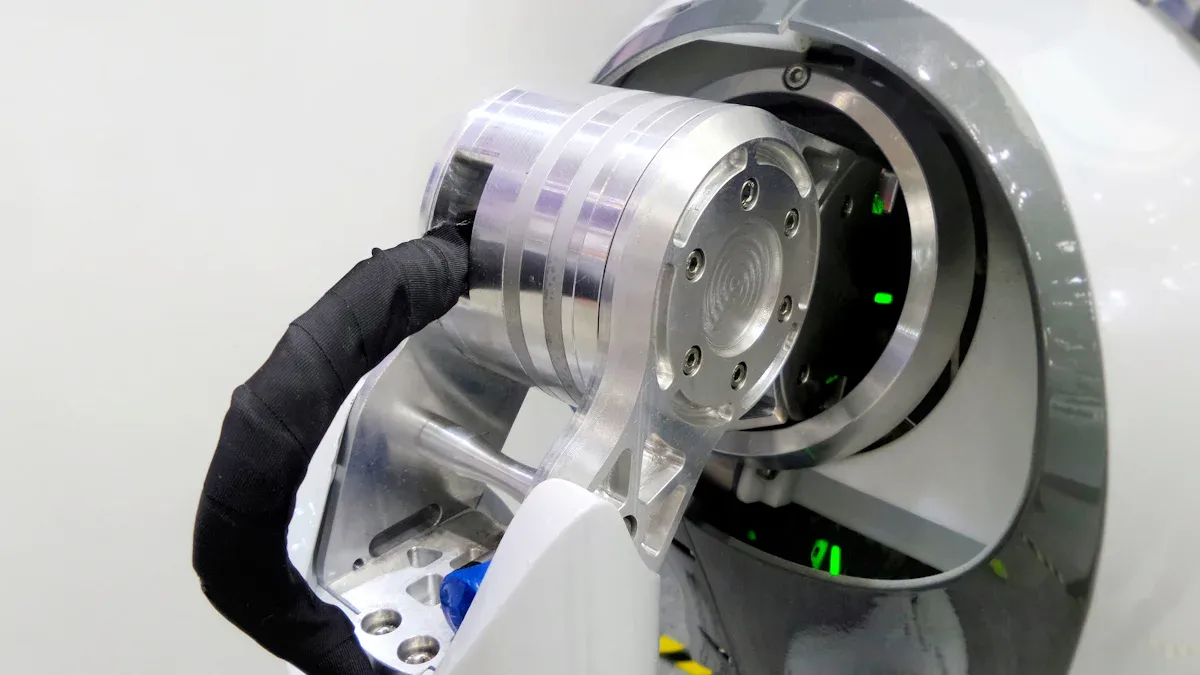

Linear actuators move things in a straight line. They use motors with screws, belts, or gears to push or pull. You can find DC motors, AC motors, stepper motors, and brushless servomotors in linear actuators. Some designs put the motor and actuator together to save space. Some linear actuators use a direct linear motor. This kind does not need screws and moves very smoothly. These actuators work well in CNC machines, medical tools, and robots. Honest makes custom linear actuators for different jobs and places.

Typical Mechanisms for Linear Motion Conversion | Common Applications | |

|---|---|---|

DC Motors (brushed/brushless) | Ball screws, lead screws, belts, rack & pinion | CNC machinery, robotics, medical devices |

AC Motors | Gear assemblies with lead screws | Industrial automation, automotive systems |

Stepper/Servo Motors | Rotary to linear conversion | Valve actuation, material handling |

Linear Motor | Direct electromagnetic drive | Outdoor, harsh environments |

Rotary Actuators

Rotary actuators turn things around. They use motors to spin shafts, levers, or valves. Rotary actuators are measured by torque, speed, how far they turn, and how exact they are. Honest rotary actuators use strong motors and gears for steady movement. They have limit switches, brakes, and manual controls for safety. These actuators are used in valve control, factory lines, and moving materials.

Key features of rotary actuators:

High torque for starting and running

Wide range of angular rotation

Accurate position feedback

Long service life

Servo and Stepper Actuators

Servo and stepper actuators give very exact control. Stepper actuators move in small steps and hold their spot without feedback. Servo actuators use feedback to change how they move right away. Both types help machines move just right in automation.

Aspect | Stepper Motor | Servo Motor |

|---|---|---|

Moves in steps (open-loop) | Continuous rotation (closed-loop) | |

Control Method | No feedback needed | Encoder feedback |

Positioning Accuracy | High due to steps | High with feedback |

Torque | Good at low speeds | High at high speeds, extra bursts possible |

Efficiency | Less efficient | More efficient |

Complexity | Simple | More complex |

Cost | Lower | Higher |

Reliability | Very reliable | Reliable, more maintenance |

Honest electric actuators are easy to use in many ways. The company makes custom actuators for all types. They match the movement, weight, and control for each job.

Actuator Applications

Electric actuators are important in many industries. They help machines move and work better. These examples show how actuators make jobs easier, safer, and faster.

Industrial Automation

Factories use actuators to control machines and tools. Actuators move parts and open or close valves. They also help move materials. Here are some ways actuators are used:

Robotics: Actuators help robot arms move with care.

Valve Operation: Actuators open and close valves very exactly in plants.

Food and Beverage Industry: Actuators give clean and steady movement for safe food.

Material Handling: Actuators lift, move, and sort things in warehouses.

Honest electric actuator motors help with these jobs. They give strong force and quick action. They last a long time. Their design helps stop breakdowns and keeps machines working.

Oil & Gas and Water Treatment

Oil and gas plants need actuators to work safely and well. Water treatment plants also use actuators. Actuators control how liquids and gases move by changing valves and pumps. In these places, electric actuators give:

Energy savings because they use power only when moving.

Less fixing needed because there are fewer parts.

Easy to connect to control systems for remote and safe use.

Honest electric actuator motors work well in tough places. They last long and save energy. This helps lower costs and makes them more reliable. These actuators also help the environment by stopping leaks and cutting emissions.

Smart Home and Medical Devices

Actuators make homes and hospitals more comfortable and safe. In smart homes, actuators move beds, sofas, curtains, and lights. In medical devices, actuators move hospital beds and dental chairs. They also help patient lifts and medical robots move just right.

Honest actuators move smoothly, quietly, and with care. Their motors work well and can be changed for different needs.

Actuator uses keep growing as technology gets better. Honest electric actuators help homes and industries get better control, safety, and energy savings.

Selecting Actuators

Key Criteria

Engineers pick actuators by looking at important things. Every job needs a different actuator and motor. Here are the main things to think about:

How heavy the load is and how much force is needed

How fast it should move and how far it should go

How exact and accurate the movement must be

How often and how long it will run

Where it will be used and how it will be set up

What safety rules must be followed

The weight of the load is very important. Heavy loads need actuators with more force or torque. For linear actuators, engineers check the weight, friction, and how fast it speeds up. Rotary actuators must have enough torque to turn things. Safety margins help keep the actuator safe from sudden changes. Engineers also look at how long the actuator will run. This makes sure it does not get too hot.

Tip: Always pick an actuator with the right power and speed. This helps it last longer and work better.

Customization and Control

Every job is different. Honest makes special actuators for unique needs. Their actuators can be made in many sizes and shapes. They also fit different control systems. Advanced controls, like modular design and real-time feedback, help actuators work well with other machines. These features let each actuator work on its own. This makes putting them together and fixing them easier.

Honest actuators have sensors and control systems inside. These give feedback to help control movement better. The actuators react fast and change when needed. This helps factories, robots, and vehicles work better.

Advantages of Honest

Honest Electric Actuator motors have many good points. The table below shows some of their best features:

Key Advantage | Explanation |

|---|---|

Quiet Operation | |

High Efficiency | Motors give strong power and save energy. |

Long Service Life | Fewer moving parts mean less wear and less fixing. |

Precise Control | Sensors and systems help control position and speed. |

Durability | Strong materials help actuators last in tough places. |

Modular Design | Custom actuators fit many different jobs. |

Environmental Sustainability | Electric actuators use less energy and help the environment. |

Honest actuators also follow strict industry rules. They have safety features and good control systems. This makes them a smart pick for important jobs like food plants, water treatment, and automation.

Motors make actuators work, so electric actuator systems are important today. Actuators help smart factories, better repairs, and safer jobs. Honest’s advanced actuators make things more exact, save energy, and work better. These actuators can link with AI and IoT for fast control and data. When picking actuators, people should choose the right one for the job and think about custom options for the best fit. New actuators will keep helping many industries grow.

FAQ

What types of motors do electric actuators use?

Electric actuators can use DC motors, AC motors, stepper motors, or servo motors. Each motor is good for a different job. DC motors are good when you need quick starts. Stepper motors are used for careful, step-by-step moves. Servo motors are best when you need things to be very exact.

Can Honest customize electric actuators for special needs?

Yes, Honest can make actuators for special needs. They can change the size, power, or how the actuator is controlled. This helps them fit many different jobs in many industries.

Where do people use electric actuators most often?

People use electric actuators in many places. You can find them in factories, water plants, oil and gas areas, smart homes, and medical machines. These actuators help run machines, open valves, and move tools.

How do electric actuators help save energy?

Electric actuators use most of their energy to do work. This means they waste less power and help save money as time goes on.

Are Honest electric actuators safe for harsh environments?

Honest makes actuators with strong materials. These actuators can handle dust, water, and chemicals. They work well in hard places like factories or outside.