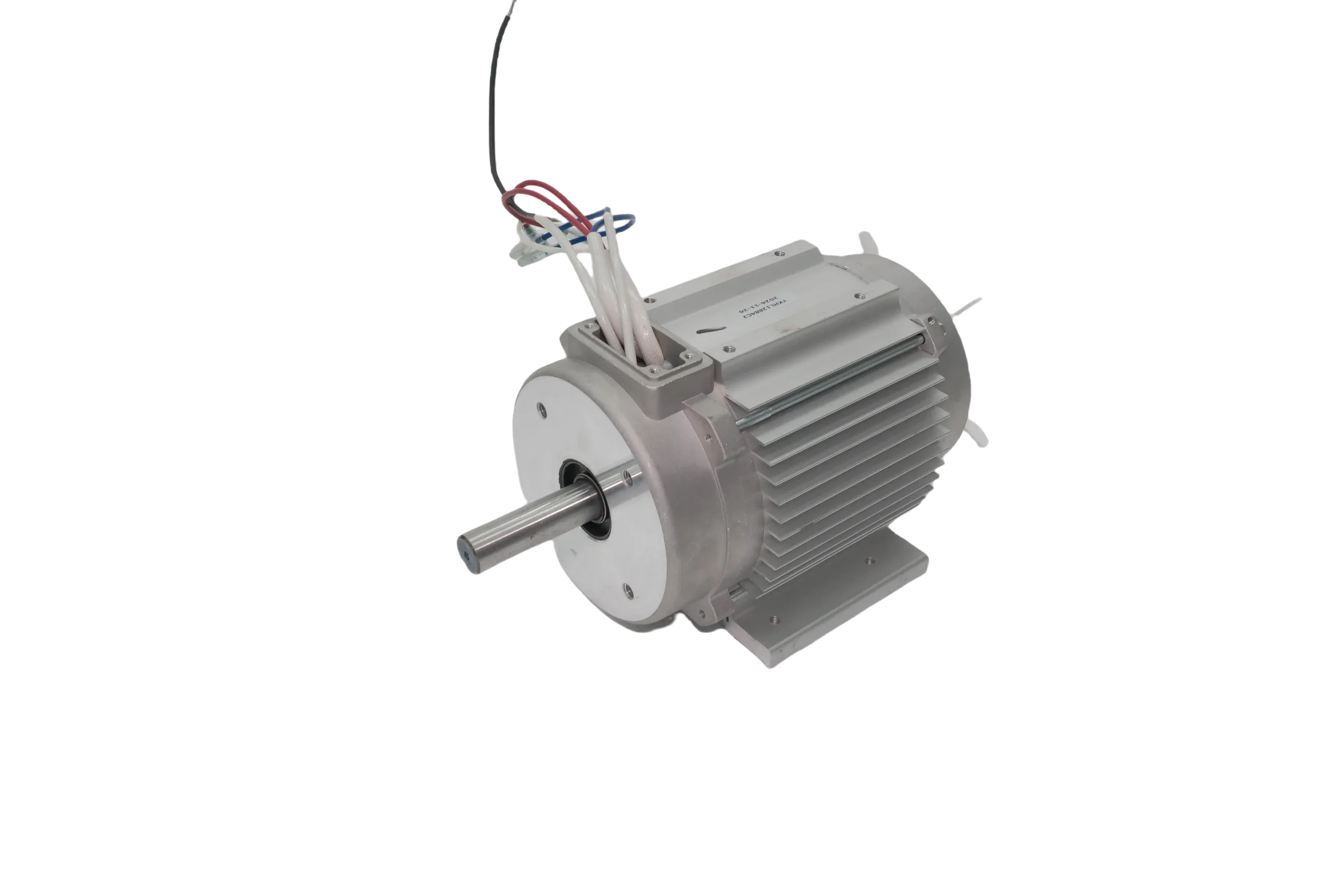

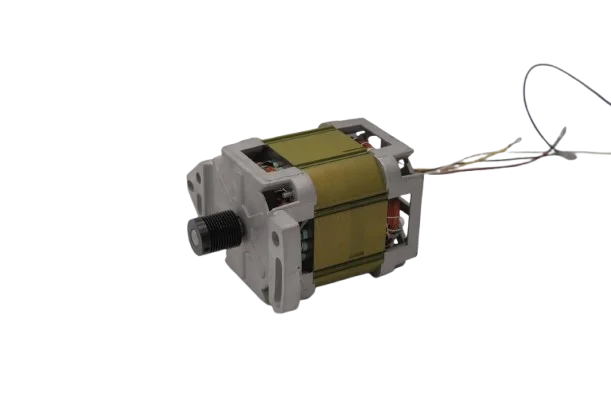

Single-phase asynchronous motors operate by driving the rotor through an alternating magnetic field generated by stator windings, with a rotational speed slightly below synchronous speed. Designed for single-phase AC power supply, these motors feature a compact design, cost-effective manufacturing, stable operation, and easy maintenance. Their lightweight construction and low power consumption make them ideal for household and small-scale commercial applications, particularly in scenarios with variable loads and minimal precision requirements.

Ensures centralized climate control for high-traffic retail environments.

Drives continuous heavy-load grinding for commercial food prep.

Generates paint-safe pressure for on-demand vehicle renewal.

Maintains consistent water quality through precise water flow.

We have developed countless asynchronous motors, and this is a partial list of them.

Check out their specification and usage scenarios and choose the one that is most similar to what you need, or contact us directly!

Using automatic welding equipment for argon arc welding of laminated iron cores

Precision machining of end cover casing workpieces using CNC machine tools

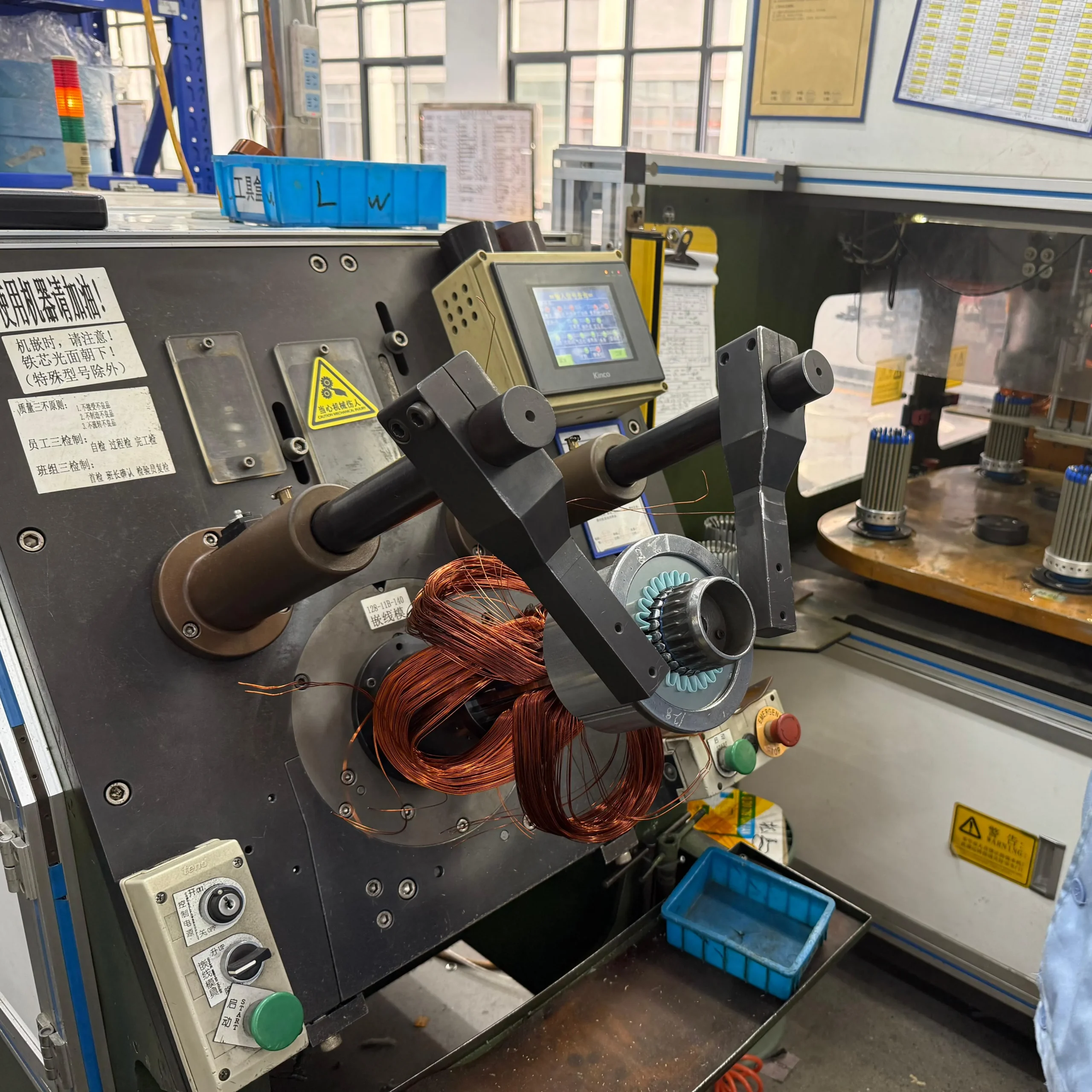

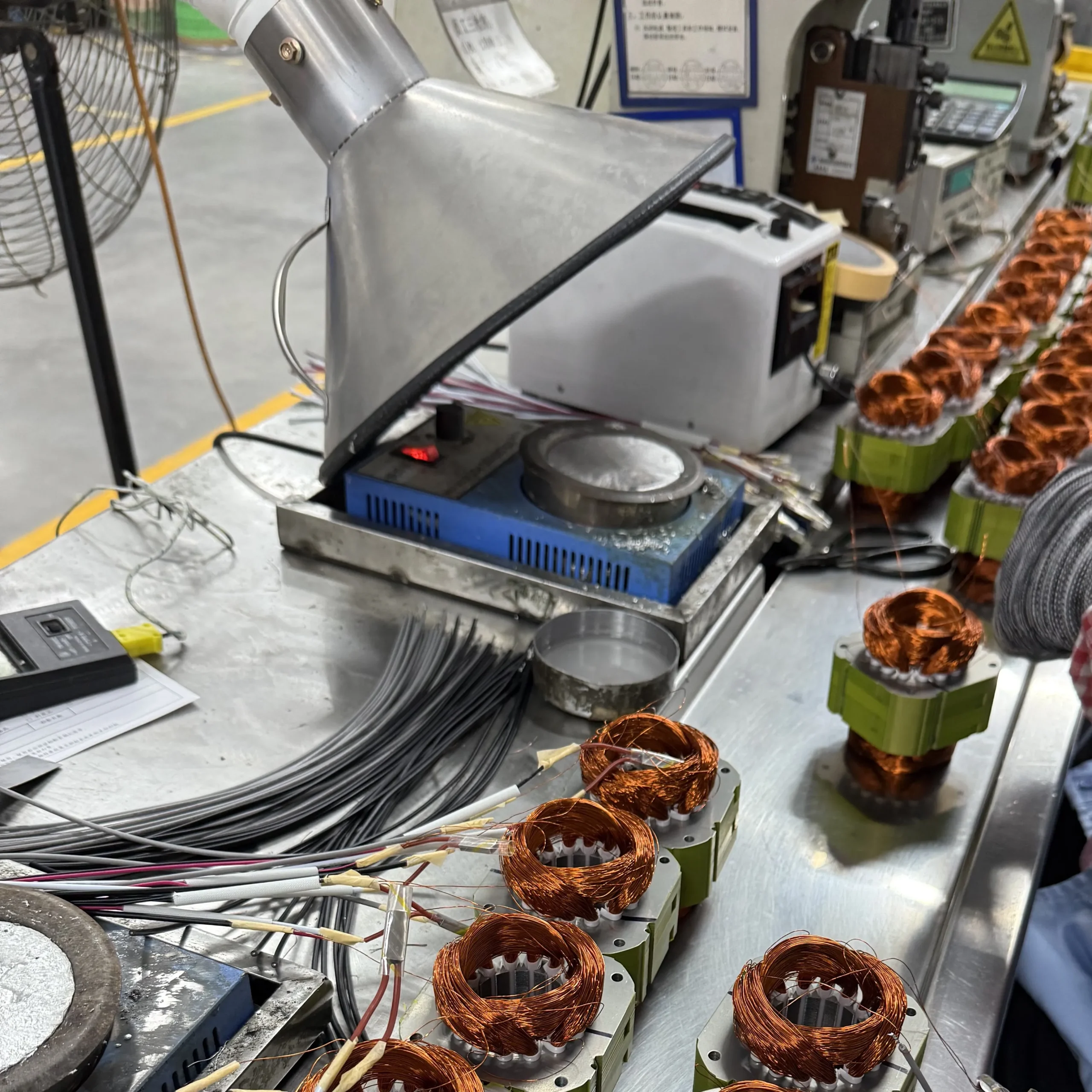

Wrap the enameled wire into the stator coil using a winding machine according to the winding template, ensuring that the coil shape is consistent and there are no crossings or loose wires

Use hydraulic press fit equipment to assemble the rotor core and shaft using specialized fixtures for interference fit

Using a fully automatic wire embedding machine to accurately embed the wound coil into the stator slot

Using CNC precision turning machine to perform precise turning on the outer circle of the rotor, using epoxy adhesive to precisely match the magnetic steel inside the rotor, achieving efficient conversion between electrical energy and mechanical energy

Remove the paint and tin coating from the enameled wire end and connect it to the lead end

Using a dynamic balancing instrument to perform double-sided correction of the unbalanced position of the rotor component, ensuring smooth high-speed rotation of the rotor without vibration through weight removal or balancing

Use an automatic binding machine to wrap the binding tape around the stator winding and cut off excess wire ends for insulation protection

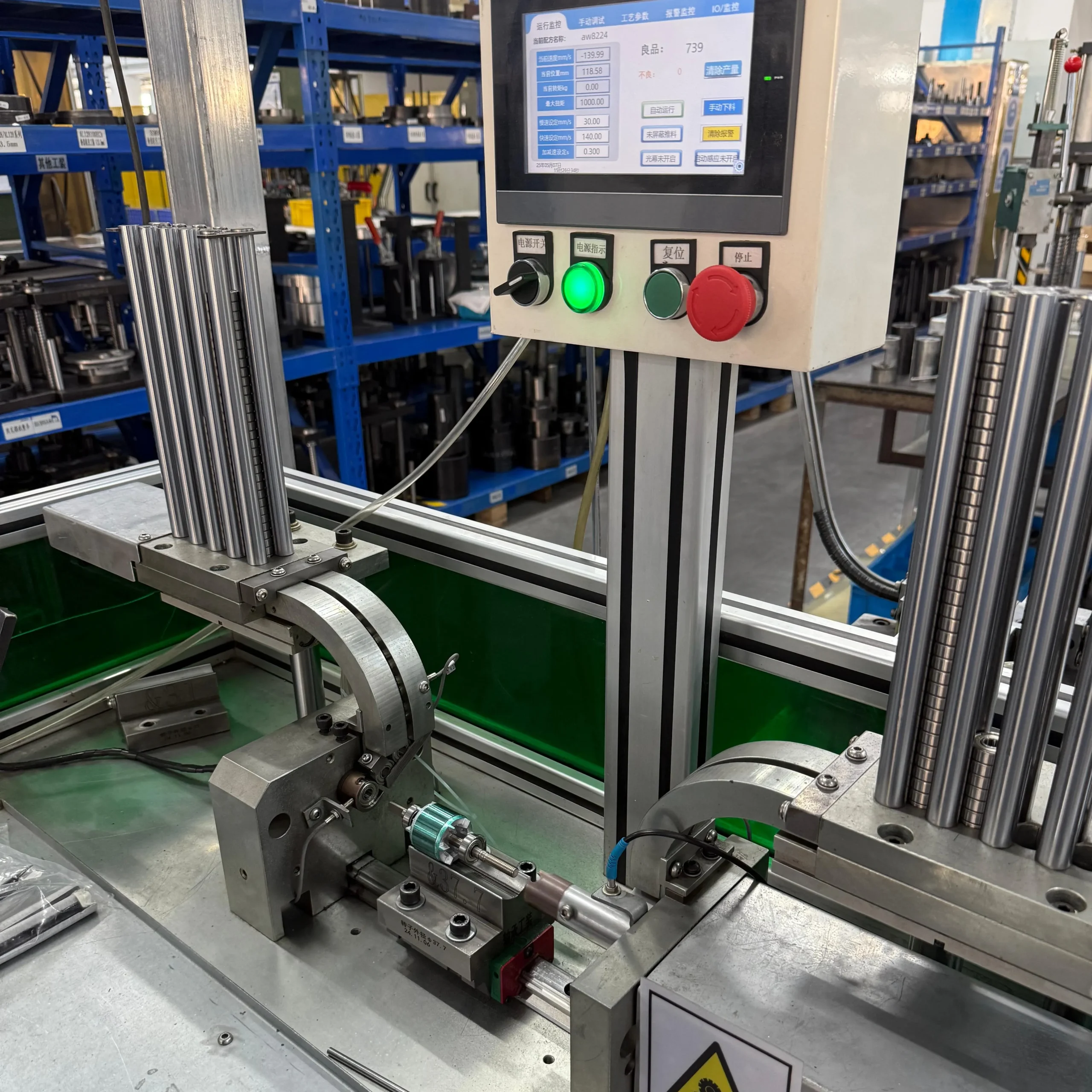

Using a bearing press fitting machine to perform interference fit assembly between the bearing and the shaft, the press fitting curve is monitored in real-time through a pressure sensor to ensure smooth and secure rotation of the bearing inner ring and shaft after assembly

Use a hydraulic shaping machine to press the end of the stator winding to prevent looseness and improve the overall structural strength

Assemble the stator components, rotor components, casing, and end caps according to the drawings

Using a vacuum withstand voltage testing system to conduct safety performance testing on stator components

Conduct performance testing on the assembled motor through a comprehensive performance testing platform to ensure stable operation and compliance with efficiency standards

Place the assembled stator in a vacuum impregnation equipment to ensure insulation strengthening, structural curing, and improved lifespan of the stator

The tested motor products are packaged in dust-proof and moisture-proof materials to provide additional protection during long-distance transportation

At Honest, we understand the complexities of international procurement and the importance of reliable partnerships. Our suite of services is designed to provide seamless integration into your supply chain, ensuring efficiency, quality, and adaptability at every stage.

We offer comprehensive product design services, including 3D modeling and simulation, to ensure your concepts are optimized for manufacturability and performance. Our engineering team collaborates closely with clients to refine designs, reducing time-to-market and production costs.

Accelerate your product development with our rapid prototyping capabilities. We provide quick turnaround on prototypes, allowing for iterative testing and refinement before full-scale production. This approach minimizes risks and ensures product quality.

Our lean manufacturing processes are designed for efficiency and adaptability. We can scale production volumes to meet your demand, ensuring timely delivery without compromising on quality. Our facilities are equipped to handle diverse product lines with precision.

Enhance your product’s market readiness with our custom packaging and kitting services. We assemble and package products according to your specifications, improving logistics efficiency and customer satisfaction.

Stay informed with our real-time order tracking system, providing visibility into every stage of the production and delivery process. Our inventory management solutions help prevent stockouts and overstock situations, optimizing your supply chain.

We provide globalized supply chain management, including sourcing, procurement and logistics coordination. Our global network ensures efficient material flow and just-in-time delivery, resulting in shorter lead times and lower costs.

With over 21 years of experience in the electric motor industry, Honest has established itself as a dependable partner for businesses worldwide. Our commitment to quality, innovation, and customer satisfaction has enabled us to build lasting relationships with clients across various industries.

Proven Track Record: Successfully delivered 1000+ projects across 30+ countries.

Global Reach: Serving clients in North America, Europe, Asia, and beyond.

Customer-Centric Approach: Tailored solutions to meet specific client needs.

Основанная в 2004 году, компания Honest занимается исследованиями, разработкой и производством двигателей и приводных систем, стремясь стать мировым эталоном в области прецизионной передачи промышленного класса и интеллектуальных приводных решений. Используя принцип "глубокая адаптация + интеграция технологий" в качестве нашей основной компетенции, мы предоставляем энергоэффективные системы двигателей и прецизионные компоненты приводов для 20+ отраслей промышленности, включая промышленную автоматизацию, новое энергетическое оборудование, "умный дом" и медицинское оборудование, помогая клиентам достичь интеллектуальной модернизации их продукции.

Honest Motor provides one-on-one technical customization based on equipment host requirements. Customizable aspects include motor power, performance parameters, insulation level, installation method, specifications, and appearance color. Voltage range is AC single-phase 100V-240V, power range 10W-10kW, core outer diameter 20mm-260mm, suitable for industrial and civilian scenarios.

The MOQ is 500 units. Samples are chargeable and can be delivered within 15 days; sample cost is refundable upon batch order. Batch delivery time is 25-30 days. We offer expedited communication and production for urgent projects.

All products meet CE and UL certifications. Materials comply with RoHS and REACH. Our factories hold ISO9001 and IATF16949 certifications. Every motor undergoes rigorous electrical safety, mechanical performance, appearance, and dimensional inspections before shipment. Batch sampling includes load characteristics, temperature rise, and life expectancy tests, accompanied by certification and test reports.

We provide 2 years warranty and lifetime maintenance service, with engineers available online for rapid response within 12 hours. After-sales include technical consultation, troubleshooting, and spare parts supply to ensure stable operation under various conditions.

Honest Motor has multiple factories , enabling flexible small-batch production across sites. This reduces lead times and allows quick adaptation to varied production demands.

We have a great deal of experience and case studies in the industry and are equally well aware of the trends in the industry. If you would like to learn more about the industry, including trends within the industry, please click below.

Адрес:No.121, Xinlong Road, Zhonglou Xinzha Subdistrict, Changzhou City, Jiangsu Province, China

Телефон: +86-18261152679

Whatsapp: +86-18261152679

Электронная почта: sales@honestmotor.cn

Политика конфиденциальности / Условия предоставления услуг / Настройки файлов cookie / Карта сайта

© 2025 Honest Все права защищены.