Selecting the right planetary gearbox is critical for stable, high-performance automation systems. Mismatched components are a leading cause of premature failures and elevated Total Cost of Ownership (TCO), risking High-Dynamic System Instability and catastrophic performance loss.

Crucially, an incorrect gear ratio can lead to insufficient speed or torque, and if too high, may significantly increase thermal losses and friction, resulting in overheating. Operational issues, such as increased vibration and noise, further degrade performance.

This comprehensive guide addresses these common pitfalls by focusing on two essential design elements—inertia mismatch and thermal limits—ensuring your system maintains optimal stability and longevity.

Key Takeaways

Select the right gear ratio to ensure sufficient speed and torque for your automation system.

Avoid inertia mismatch by aiming for an inertia ratio of 10:1 or lower to maintain optimal Closed-Loop Control Performance and system stability.

Incorporate proper thermal management features to prevent overheating, ensuring the lubricant integrity and long-term reliability.

Regularly monitor and maintain lubrication and sealing to prevent contamination and extend the L10 mechanical rating life of the system.

Evaluate environmental factors and load profiles to optimize performance and prevent premature wear.

Motor and Gearbox Fundamentals

Key Motor Specifications

When selecting motors and gearboxes for automation, several key specifications influence system performance. Here’s a summary of the most critical parameters for matching:

Parameter | Description |

Torque Rating | Ensure continuous and peak torque requirements are within the manufacturer’s specified limits, considering the system’s thermal limits. |

Required Reduction Ratio | Match this to your desired output speed and torque, ensuring the ratio also helps achieve the target Inertia Ratio for stable control. |

Backlash | Critical for precision applications; specify low-backlash models (< 3 arcmin or lower) essential for closed-loop systems demanding high repeatability. |

Efficiency | Single-stage units typically achieve ~ 97%, while multi-stage may drop to ~90% overall, directly impacting heat generation. |

Ingress Protection (IP) | For dirty or wet environments, specify IP65 or higher to prevent contamination and safeguard bearing systems. |

Mechanical Rating Life | Look for L10 or B10 life estimates (e.g., 20,000 hours) based on ISO 281 or AGMA standards for reliability prediction. |

Mounting Configuration | Check compatibility with NEMA or IEC motor frames, flange types, and shaft dimensions to ensure proper alignment and rigidity. |

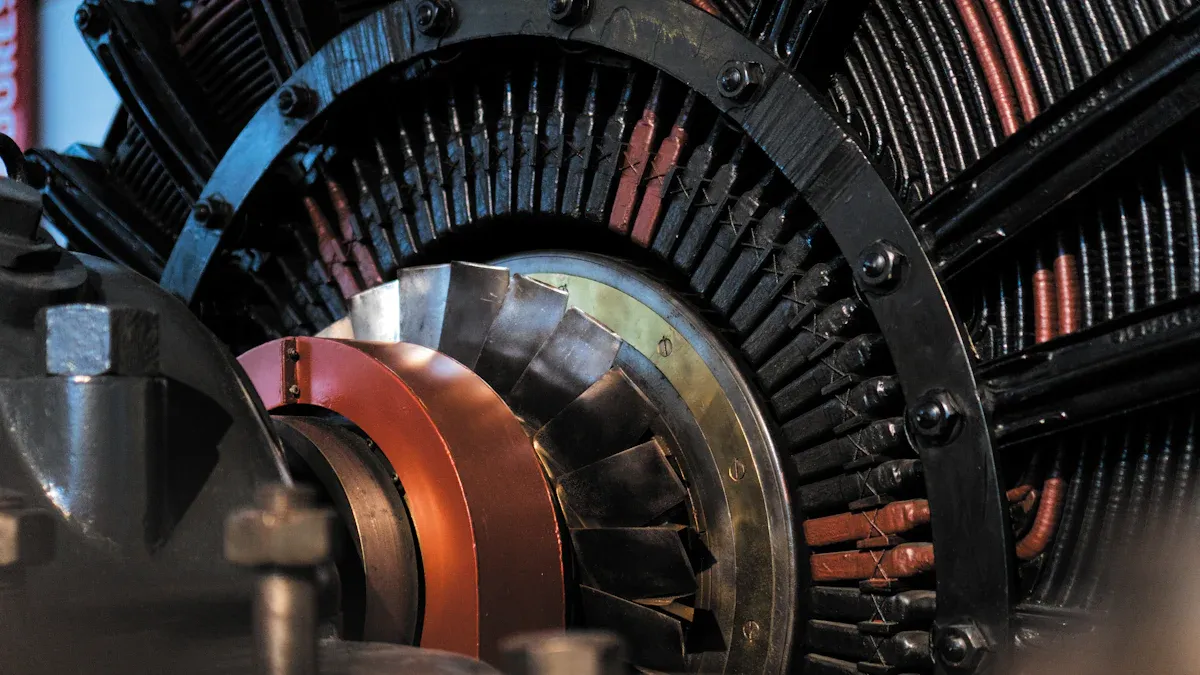

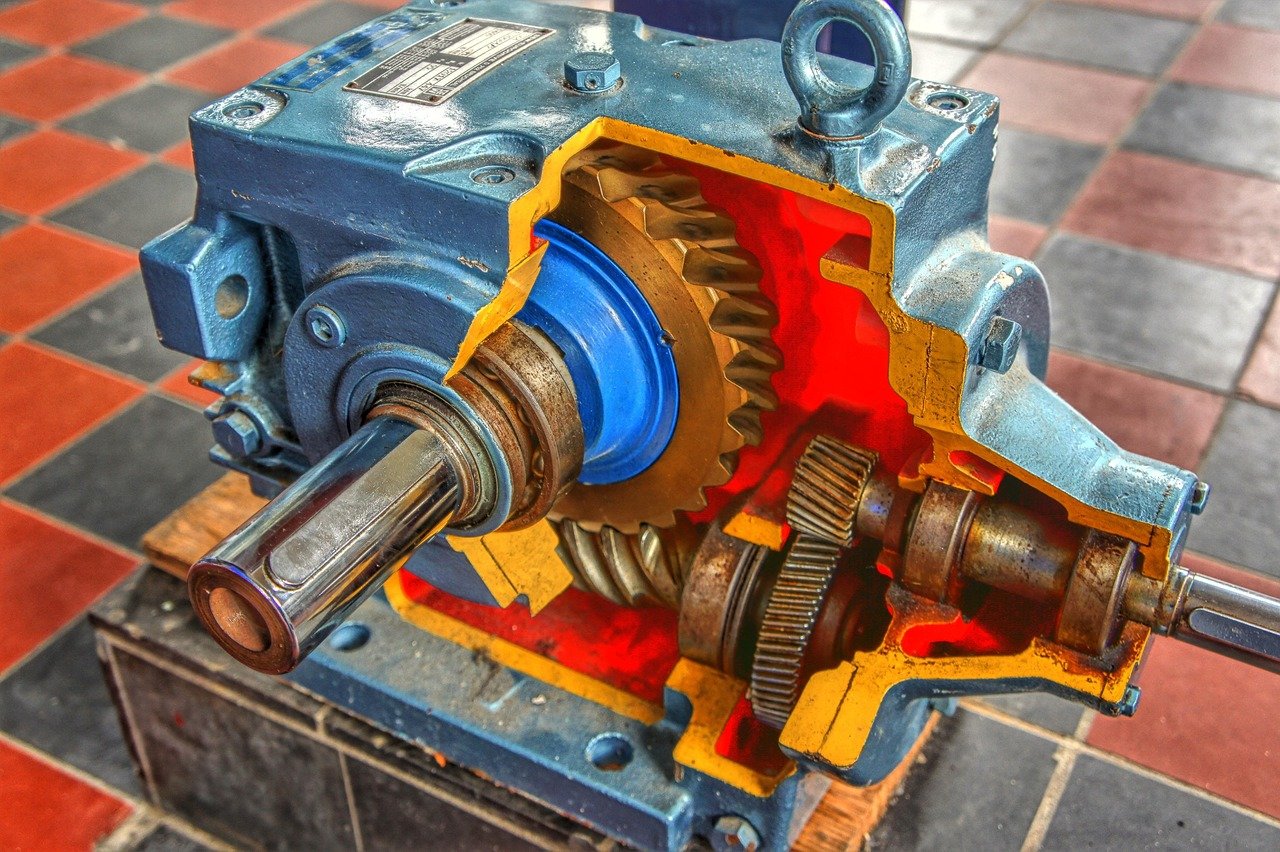

Planetary Gearbox Types and Function

Planetary gearboxes come in various types, each serving unique functions in automation systems. Understanding these types helps you select the right gearbox for your application. Here’s a breakdown of the main types:

Type of Gearbox | Description |

Single-stage planetary gear set | Foundational design, offering high stiffness and efficiency in a compact form factor for moderate torque applications. |

Multi-stage planetary gear set | Incorporates multiple stages for significantly higher torque density and gear ratios, suitable for heavy-duty applications requiring lower output speed. |

In-line planetary gear set | Coaxial arrangement optimized for high precision and maximum torsional rigidity; typically used in BLDC and Servo drives and demanding automation equipment. |

Offset planetary gear sets | Features parallel shafts, enabling unique orientations and providing flexibility in machine design where straight alignment is not possible. |

Right-angle planetary gear sets | Input and output shafts at 90 degrees, crucial for space-constrained layouts where axial length must be minimized. |

Using a planetary gearbox can enhance your system’s efficiency and durability. They distribute torque evenly, which reduces wear and extends the lifespan of both the motor and gearbox. This makes them a preferred choice in many automation applications.

Common Mistakes in Motor-Gearbox Matching

In fact, improper gearbox selection is a leading cause of planetary gearbox failures, significantly contributing to premature wear and system downtime.

Ignoring Inertia Mismatch

One of the most critical mistakes you can make is ignoring inertia mismatch between the motor and the planetary gearbox. When the inertia ratio is too high, it leads to motor instability. This instability will significantly reduce the system’s achievable control bandwidth and dynamic stiffness. To avoid this, aim for an inertia ratio of 10:1 or lower, which is critical for achieving optimal closed-loop system performance and high dynamic stability. Here are some recommended methods to calculate and mitigate inertia mismatch:

Consult the motor manufacturer to assess the inertia ratio for potential issues.If the inertia mismatch is too large, consider:

Moving to a larger motor with higher inertia, despite increased costs.

Reducing the load’s inertia by lowering the overall load, adjusting the center of gravity, adding a prestage between the motor and gearbox, or modifying the gearbox’s reduction ratio.

Maintaining an appropriate inertia ratio is crucial for efficient operation and system stability.

Neglecting Thermal Limits

Another common mistake is neglecting thermal limits. Planetary gearboxes generate heat, and excessive temperature directly causes lubricant viscosity breakdown, which can lead to premature failure. Understanding how design features impact thermal management is essential. Gearbox surface temperature should ideally not exceed 80℃ for optimal synthetic lubricant life. Here’s a table summarizing key features and their effects:

Design Feature | Impact on Thermal Management |

Increased surface area of housing | Enhances heat dissipation through larger contact area |

Use of thermally conductive materials | Improves heat transfer away from critical components |

Incorporation of cooling fins | Aids in passive heat dispersion |

Flow-optimised pathways | Ensures efficient lubricant flow to absorb and transfer heat |

Active cooling elements | Necessary for high-load or high-speed environments to maintain integrity |

By ensuring your gearbox design incorporates these features, you can significantly improve long-term reliability in automation systems.

Overlooking Backlash Requirements

Backlash is another critical factor that you should not overlook. Excessive backlash can lead to inaccuracies in positioning and reduced repeatability, which are crucial for automation systems.

It can destabilize the system, affecting performance in high-precision tasks. Oscillations and vibrations caused by backlash can disrupt operations. The noise generated can create an unpleasant working environment. For high-precision applications, acceptable backlash tolerances vary.

Here’s a quick reference table:

Application Category | Acceptable Backlash (mm) |

|---|---|

Consumer electronics | 0.08-0.12 |

Industrial automation | 0.10-0.15 |

Medical positioning | 0.03-0.08 |

Measurement instruments | 0.05-0.10 |

Improper Lubrication and Sealing

Finally, improper lubrication and sealing can lead to significant issues. Here are some common problems associated with inadequate lubrication:

Inadequate lubricant selection leading to increased friction and wear.

Contaminated lubricants affecting viscosity and lubrication effectiveness.

Insufficient lubricant quantity causing excessive wear and potential failure.

The consequences of these issues include increased wear and tear, noise, vibration, and even gearbox failure. To maximize the lifespan of your planetary gearbox, follow these best practices:

Regular lubrication to minimize wear.

Inspect for leaks to ensure proper sealing.

Monitor operating conditions to maintain optimal performance.

Utilize advanced sealing techniques to prevent contaminants and retain lubricants.

By addressing these common mistakes, you can enhance the performance and longevity of your motor and gearbox system.

Essential Principles for System Longevity

Assessing Load Profiles

Understanding load profiles is vital for selecting the right motor and gearbox combination. Different duty cycles impact the lifespan and reliability of your system. Here’s how various duty cycles affect performance:

Duty Cycle Type | Impact on Lifespan and Reliability |

Continuous Use | Defined by a high RMS (Root Mean Square) torque value, requiring excellent heat dissipation and high-quality lubrication to manage sustained thermal stress. |

Intermittent Use | Characterized by frequent stops/starts, where the peak torque requirement must be strictly monitored to prevent shock loads and gear fatigue. |

You should assess your application’s load profile to ensure that your system can handle the expected demands without premature wear.

Evaluating Environmental Factors

Environmental conditions significantly influence the performance of planetary gearboxes. Here are some factors to consider:

Environmental Factor | Description |

Material Selection | Crucial for ensuring corrosion resistance against harsh chemicals or moisture, and maintaining housing rigidity under load. |

Lubrication | Selecting lubricants based on the operating temperature range ensures stable viscosity and film strength, maximizing component separation and minimizing wear. |

Operational Conditions | Performance varies with temperature and load fluctuations; ensure the gearbox’s IP Rating is suitable for preventing ingress of contaminants. |

Extreme temperatures can lead to lubricant breakdown, increasing friction and wear. You must monitor these conditions to maintain optimal performance.

Maintenance and Inspection Tips

Regular maintenance is crucial for preventing premature failure. Here are best practices to follow:

Best Practice | Description |

Proper Lubrication | Regular checks and use of high-quality lubricants ensure adequate lubrication. |

Alignment and Installation | Use laser tools for precise alignment and follow manufacturer installation guidelines. |

Load Management | Monitor load conditions and implement soft start mechanisms to prevent shock loads. |

Regular Maintenance | Schedule inspections and use predictive maintenance techniques (e.g., vibration analysis and oil sampling) to identify potential issues early. |

Environmental Control | Maintain optimal temperatures and apply corrosion protection measures. |

Advanced Strategies | Integrate IoT for real-time monitoring and data analytics to predict failures. |

By following these principles, you can enhance the longevity of your motor and gearbox systems. This planetary gearbox selection guide for automation will help you make informed decisions and avoid costly errors.

Final Selection Checklist and Guidance

Key Performance Metrics Review

When finalizing your selection of a planetary gearbox, ensure that the detailed metrics covered in this guide (Torque, Speed, Backlash, Efficiency, and Mechanical Life) have been thoroughly reviewed against your application requirements.

Final Considerations for TCO

Total Cost of Ownership (TCO) is a crucial aspect of your gearbox selection process. It encompasses not just the initial purchase price but also the long-term costs associated with operation and maintenance. When analyzing TCO, focus on mitigating the highest risks: system downtime and premature component failure.

Operational Lifespan and Reliability:

Gearbox service life is heavily dependent on the quality of its construction and the alignment of the motor interface. While maintenance intervals vary significantly based on load and temperature, selecting a system that minimizes wear (through optimal load distribution) will directly reduce costs associated with:

Oil Change frequency

Bearing and seal replacement cycles

Costly alignment checks

In addition to maintenance activities, consider the following aspects of TCO:

Initial acquisition costs

Installation costs

Operational energy consumption

Maintenance cost projections

Lifecycle costs

Proper motor and gearbox matching can significantly reduce long-term maintenance and replacement costs. By ensuring optimal load distribution, you enhance system lifespan and performance under high-torque conditions. Customization options for gear ratios allow you to meet specific application needs, improving efficiency and reducing wear.

In summary, avoiding common matching mistakes is essential for reducing your long-term Total Cost of Ownership (TCO). Expert gearbox matching significantly improves performance and system reliability. For optimal system longevity and to validate your TCO projections, customized gearbox matching is often required. Consult our specialized engineers today to ensure the precision and longevity of your next automation system.

FAQ

What is the importance of matching motors and gearboxes?

Matching motors and gearboxes ensures optimal performance in automation systems. Proper alignment enhances efficiency, reduces wear, and prevents system failures, leading to longer equipment lifespan.

How do I calculate the required torque for my application?

To calculate torque, use the formula: Torque (Nm) = Force (N) × Distance (m). Assess your load requirements and consider safety factors for accurate results.

What factors affect the thermal limits of a gearbox?

Thermal limits depend on factors like load conditions, ambient temperature, lubrication quality, and gearbox design. Proper thermal management ensures reliable operation and prevents premature failure.

How often should I perform maintenance on my motor and gearbox?

Regular maintenance should occur every 4,000 to 8,000 hours of operation. Check lubrication levels, inspect for wear, and ensure proper alignment to maintain optimal performance.

Can I use a planetary gearbox with any motor type?

Not all motors are compatible with planetary gearboxes. Ensure that the motor’s torque, speed, and mounting configuration match the gearbox specifications for effective operation.