High-efficiency motors are transforming how industries use energy, reflecting the latest energy-saving trends. Companies are increasingly adopting motors that meet higher efficiency standards, such as IE3, IE4, and IE5, to reduce operational costs and environmental impact. Studies show that implementing advanced motors across industrial facilities could save hundreds of millions in energy bills and significantly cut carbon emissions.

To support this shift, governments are enforcing stricter energy-efficiency regulations, while automation and smart control technologies are helping factories optimize motor performance. For example, specialized brushless motors combined with intelligent controls can reduce energy consumption while maintaining high output, enabling manufacturers to meet both cost and sustainability goals.

Key Takeaways

High-efficiency motors reduce energy costs and lower carbon emissions.

Smart controls and automation enhance motor performance and can significantly reduce energy consumption.

Governments now have stricter rules for energy-efficient motors. Businesses must follow these rules.

Energy-saving motors can cost a lot at first. Financial help programs can make it easier to buy them.

Picking lightweight and eco-friendly motors helps your business. It also helps the planet stay healthy.

Energy-Saving Trends Shaping 2025

Industry Drivers

The motor industry is undergoing significant transformation, driven by multiple factors.Companies want to spend less money and use less energy. Using motors that need less power helps save money and helps the earth. The market for energy-efficient motors is getting bigger every year. Experts think it could be worth $151 billion by 2034. This means more factories want motors that work better and waste less energy.

There is increasing emphasis on environmental protection. New motors have better lamination and insulation. These features help motors lose less energy as heat. They also have improved fans, so they stay cooler and last longer. Many companies increasingly adopt these motors to improve efficiency and reduce environmental impact.

The initial investment in energy-saving motors can be substantial. Many companies worry about spending so much money. Some governments and groups give help, like loans or subsidies, to make it easier to buy these motors. This support lets more people choose energy-saving options, even if they do not have a lot of money.

Here are some reasons why more people use energy-saving motors:

People want to save money and energy.

Businesses care about the planet.

New technology makes motors work better.

Financial help makes it easier to pay for new motors.

Tip: To save money and help the earth, pick motors with high efficiency ratings and smart controls.

Regulatory Impact

Governments help shape Energy-Saving Trends in a big way. They make rules about how efficient your motors must be. These rules make companies build better motors and help you pick products that use less energy.

Here is a table that shows how different rules affect the motor industry:

Regulation Type | Description |

|---|---|

Energy Efficiency Standards | Countries set rules for how efficient motors must be. You have to use motors that meet these rules. |

Incentive Programs | You can get money back, tax credits, or other help when you buy energy-efficient motors. |

Regulatory Mandates | Public projects must use energy-saving equipment, so more people want efficient motors. |

Environmental Compliance | Rules to lower pollution make you use motors that use less energy and pollute less. |

In North America, strict rules and saving money are important. Europe cares about green solutions and gives rewards for using efficient motors. In Asia-Pacific, energy costs are rising, so more factories use energy-saving motors.

Here is a quick look at what is happening in each region:

Region | Key Drivers | Trends in 2025 |

|---|---|---|

North America | Tough rules, need to save money | More automation and focus on the planet |

Europe | EU rules, green goals | High demand for energy-saving motors, rewards |

Asia-Pacific | Fast growth, higher energy costs | More efficient motors in factories |

Latin America | Need to work better, save energy | Moderate growth, more renewables |

Middle East & Africa | High energy prices, want sustainability | New market for energy-saving motors |

Rules and what people want both matter. They guide the choice of energy-saving motors.

Advances in Electric Motors

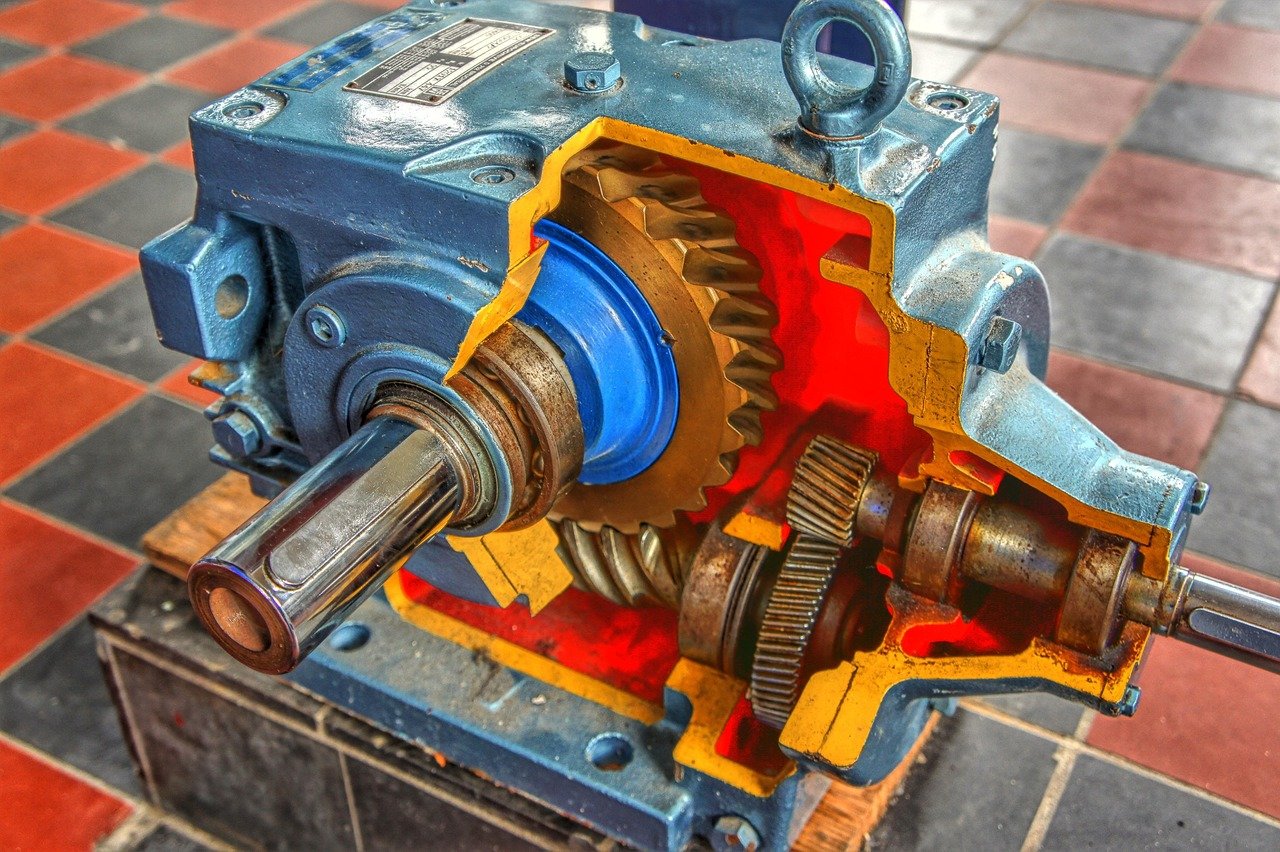

High-Efficiency Gear motors

Gearmotors are now smarter and use less energy. Some manufacturers have developed gearmotors with advanced gear reduction technology, providing higher torque and better speed control. These motors are ideal for applications that demand strong power while saving energy, such as robots, conveyor belts, or medical devices. With sealed designs that extend service life and minimize maintenance, and backed by patented innovations, these gearmotors deliver strong performance while reducing electricity costs.

Some new motors can recover energy that would otherwise be lost.Regenerative braking systems in electric vehicles reuse this energy.

Single-Phase and Three-Phase AC Motors

When picking between single-phase and three-phase AC motors, think about power needs. Here is a quick guide:

Three-phase motors save more energy if used all the time.

Three-phase motors give smoother power and higher torque.

You lose less energy with three-phase motors, so they are good for factories.

Single-phase motors cost less but do not last as long or work as hard.

Three-phase motors are best for big jobs and places with high power needs.

Three-phase motors are generally the preferred option for high-power, continuous operation due to their efficiency and reliability.

AC vs DC Motor Solutions

You may wonder which motor is best for your job. Here is a table to help you choose:

Motor Type | Efficiency Characteristics | Applications |

|---|---|---|

DC Motors | Higher efficiency at variable speeds, easy speed control, lower maintenance costs, less energy use | Variable speed jobs |

AC Motors | Best for constant speed, high power factor with VFDs | Steady speed jobs |

DC motors are better when you need to change speeds a lot.

AC motors are good for jobs that need the same speed always.

DC motors have a better power factor, so you lose less power.

In 2025, motors are getting even smarter. Artificial intelligence helps you watch motors in real time. It can tell you when they need fixing. This means your motors last longer and use less energy. You get more control and fewer problems.

Smart and Connected Motor Systems

Intelligent Controls

Motors are increasingly integrated with digital technologies, enabling remote monitoring and control via connected platforms. Smart drive solutions make managing machines easy—you only need a few clicks. These systems use special algorithms, so motors run only when needed. You get data instantly and always know how much energy your motors use.

Here’s what smart controls can do for you:

They save energy by changing motor speed and power when needed.

Digital drives have tools to find problems early.

You can connect to IoT platforms for quick updates and remote control.

You can link all your devices together to work better.

Smart motor management can help you achieve significant energy savings.You also spend less money fixing things. The system warns you before something breaks. Many factories save 20% on investment with smart systems. You help the planet and save money too. These changes are part of Energy-Saving Trends everywhere.

Tip: If you want to save money and keep machines working well, try motors with intelligent controls.

Predictive Maintenance

Predictive maintenance eliminates the need to wait for failures before taking action.Predictive maintenance uses sensors and AI to watch motors all the time. The system tells you when something needs fixing before it fails. This means less downtime and fewer surprises.

Check out how predictive maintenance helps you:

Benefit | Percentage Change |

|---|---|

Overall costs | 10% to 20% less |

Unplanned downtime | 50% less |

Diagnostic time for breakdown | |

Repair time | 25% less |

Maintenance costs | 8-12% less |

Machine downtime | 30-50% less |

Production increase | 20-25% more |

You get alerts on your phone or computer. Technicians fix problems faster. Sometimes they do not need to visit the site. Companies using predictive maintenance see up to 50% less downtime. Your machines work longer. You spend less money fixing them.

Note: Smart motors with predictive maintenance help you avoid expensive breakdowns and keep your business strong.

Sustainable Manufacturing and Materials

Eco-Friendly Production

Sustainable motor design benefits both businesses and the environment.More companies use smart sensors and connected devices in their factories. These tools watch how much energy is used and find waste. They also help lower emissions. Digital technology helps you make better choices. It also helps improve how motors are made.

Companies now care more about carbon. They look at the energy they buy and the parts from suppliers. Nissan wants to cut CO2 from its factories by half for each car by 2030. Ford’s Cologne plant uses only solar power. More companies use wind, solar, and biogas to run their factories. Selecting motors from environmentally responsible manufacturers supports broader sustainability goals.

Selecting motors from environmentally responsible factories contributes to emission reduction and promotes a sustainable future.

Lightweighting Strategies

Motors are becoming lighter across the industry. Lighter motors consume less energy and enhance machine performance. Advances in materials and smart designs allow motors to remain strong while reducing weight. Many companies are increasingly using aluminum and plastic components instead of steel, improving efficiency and ease of handling.

Here are some innovative strategies for lightweight motor design:

Strategy | What It Does | Why It Matters |

|---|---|---|

Aluminum MMCs with SiC and Al2O3 | Mixes aluminum with special particles | Cuts weight and boosts efficiency |

Hybrid aluminum composites | Uses tough materials that last longer | Handles stress and keeps motors running |

Aluminum MMC rotors | Replaces steel in motor rotors | Saves up to 73% weight, raises power density |

Plastic parts | Swaps metal for recyclable plastic | Drops weight by half, helps recycling |

You see these materials in electric cars, robots, and smart machines. Lighter motors waste less energy and give more power where needed. Manufacturers are continually testing new materials, which means motors last longer and work smarter.

Energy-Saving Motors in Water and Industrial Systems

Our high-efficiency motors are applied in water treatment and industrial systems, demonstrating the practical benefits of energy-saving designs.

Water Treatment Pump Solutions

In water treatment, these motors help pool pumps and large treatment plants operate more efficiently while reducing energy consumption and lowering greenhouse gas emissions. Designed to endure tough environments, they feature strong seals and special coatings that protect against water, dust, and chemicals, ensuring longer service life with minimal maintenance. Moreover, versatile power and smart control options, including single-phase and three-phase configurations, allow precise adjustment of speed and output to match system requirements.

Industrial Automation Solutions

In industrial automation, high-efficiency motors play a key role in valve actuation and custom machinery, providing fast and precise control. They can be tailored to specific machines, ensuring optimal operation. Material handling and logistics systems also benefit from these motors, as they provide strong torque and smooth operation for conveyor belts and sorting lines, enabling higher throughput with less energy. In textile machinery, asynchronous motors operate quietly and stay cool, maintaining production quality while saving power.

Motor Categories and Applications:

Asynchronous Motors: Commonly used in medical devices, valve control systems, and textile machinery.

Synchronous Motors: Suitable for household appliances and swimming pool circulation pumps.

DC Brushed Motors: Applied in automotive components and gardening tools.

DC Brushless Motors: Ideal for medical equipment and industrial pumps.

Universal Motors: Used in commercial appliances and office automation systems.

Geared Motors: Provide precise torque for industrial manufacturing and other high-precision applications.

Tip: If your operations require further support or specialized motor solutions, Honest can provide guidance and customized options across these motor categories.

Overcoming Challenges and Seizing Opportunities

Adoption Barriers

Switching to energy-saving motors is not always simple. Many manufacturers face problems when they try to change. Here are some common barriers:

Technological Challenges: New motor designs sometimes need special materials. They may also need tricky steps to make them. This can slow down how fast motors are built. Engineers may find these steps hard.

Regulatory and Compliance Challenges: Every new motor must follow strict rules before selling. These rules can change often. It is hard for companies to keep up with all the changes.

Economic Factors: Making new motors costs a lot of money. Prices for materials can go up or down. This makes it tough to plan how much money you need.

You can beat these problems by using smart plans. Many companies succeed when they evaluate all aspects of energy use, consider technical improvements, and monitor market trends. Consulting with experts can help in selecting the best motor. Gradual upgrades and advanced materials also support smoother transitions.

Some suppliers provide end-to-end support, from motor selection to testing and installation. They also offer tailored options to fit specific operational needs, such as:

Two-in-One Motor: Combines motor and gearbox to save space in vehicles.

Three-in-One Motor: Simplifies layouts and wiring while making systems more compact.

Motor Assembly Equipment: Enables efficient, automated production of various motor types.

Additionally, support with winding, assembly, and stator testing ensures reliable performance and longer service life.

Growth Opportunities

There are many opportunities emerging in the energy-saving motor market. Here are some key trends:

Regulations are pushing companies to adopt higher-efficiency motors.

Governments provide incentives for replacing outdated equipment.

Robots and automation require more efficient motors to perform effectively.

Energy-saving motors reduce costs for both energy and maintenance.

Compact, high-efficiency motors are becoming essential in modern automation.

To stay ahead, businesses should choose motors that align with operational needs while meeting efficiency standards. Manufacturers that provide customized solutions can help companies grow, comply with new rules, and adopt reliable technologies that support long-term sustainability.

In the future, the growing adoption of smart motors, IIoT, and renewable energy will provide new opportunities for efficiency. System upgrades can significantly reduce energy use and support global sustainability goals.

FAQ

What makes an energy-saving motor different from a regular motor?

Energy-saving motors use better materials and smarter designs. You get more work done with less electricity. These motors also run cooler and last longer. You save money and help the planet at the same time.

How do I choose the right motor for my application?

Start by checking your power needs and how often you use the motor. Look for high-efficiency ratings like IE3 or IE4. If you need help, ask an expert or use this quick guide:

Need | Best Motor Type |

|---|---|

Constant speed | AC Induction Motor |

Variable speed | DC or Brushless DC |

Can smart controls really lower my energy bills?

Yes! Smart controls adjust motor speed and power based on what you need. You only use energy when you need it. Many people see up to 30% savings on their bills.

Tip: Try motors with smart controls for the biggest savings.

What support does Honest offer if I have questions or need custom solutions?

You can reach out to Honest’s team for advice, custom motor designs, or troubleshooting. They help you pick, install, and maintain your motors. You get expert support every step of the way.