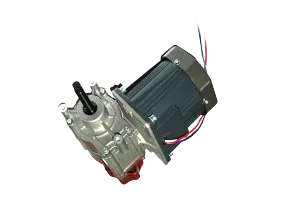

Designed for precision and responsiveness, a gear reduction interaction motor integrates a motor with a gearbox to provide low-speed, high-torque output with fine motion control. It’s perfect for smart automation tasks—such as robotic arms, medical devices, or intelligent valve systems—where precise positioning and torque consistency are critical. Its compact build ensures efficient transmission and smooth, quiet operation in dynamic environments.

Ensures precise, reliable flow regulation in pipelines.

Drives smooth, accurate parcel movement on high-speed conveyors.

Provides dependable opening/closing for secure passenger flow.

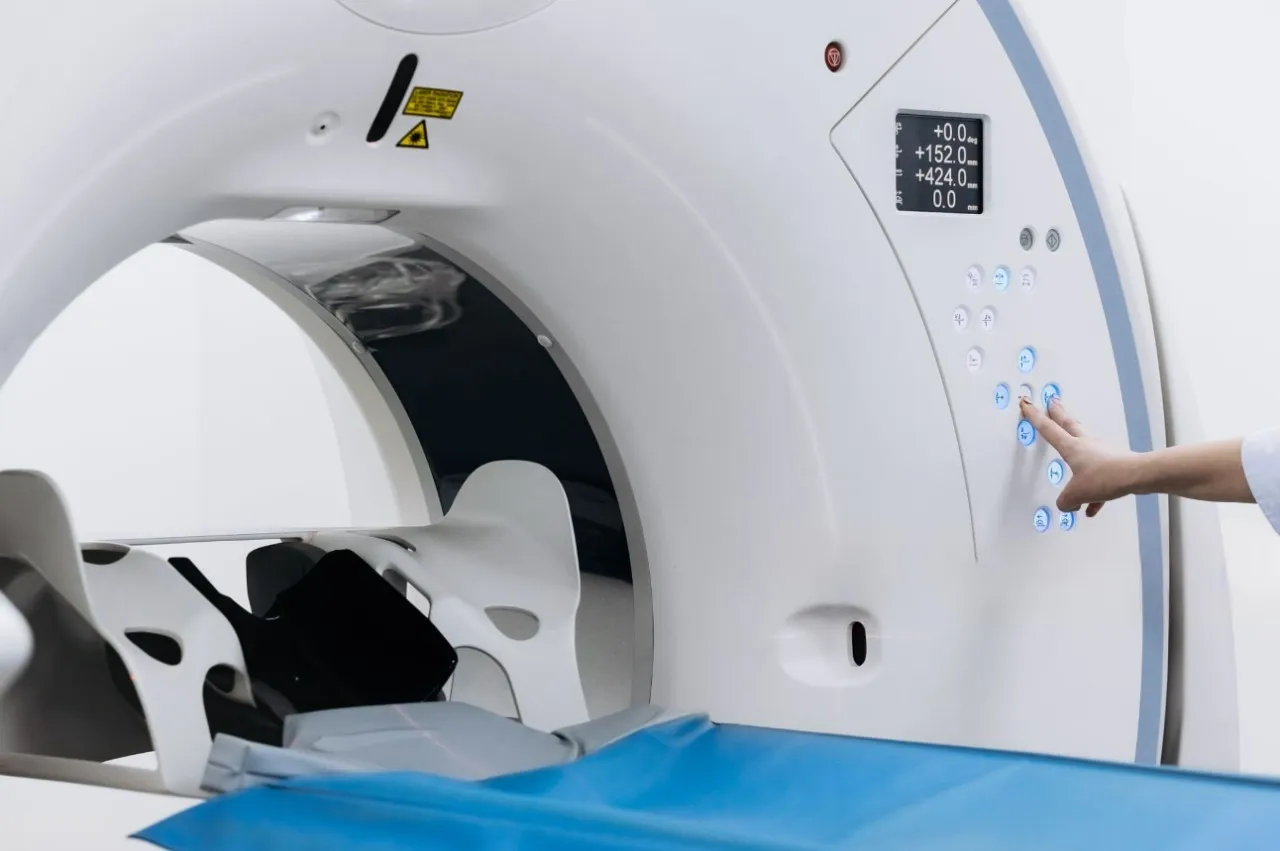

Delivers stable, precise rotation for high-resolution medical imaging.

We have developed countless asynchronous motors, and this is a partial list of them.

Check out their specification and usage scenarios and choose the one that is most similar to what you need, or contact us directly!

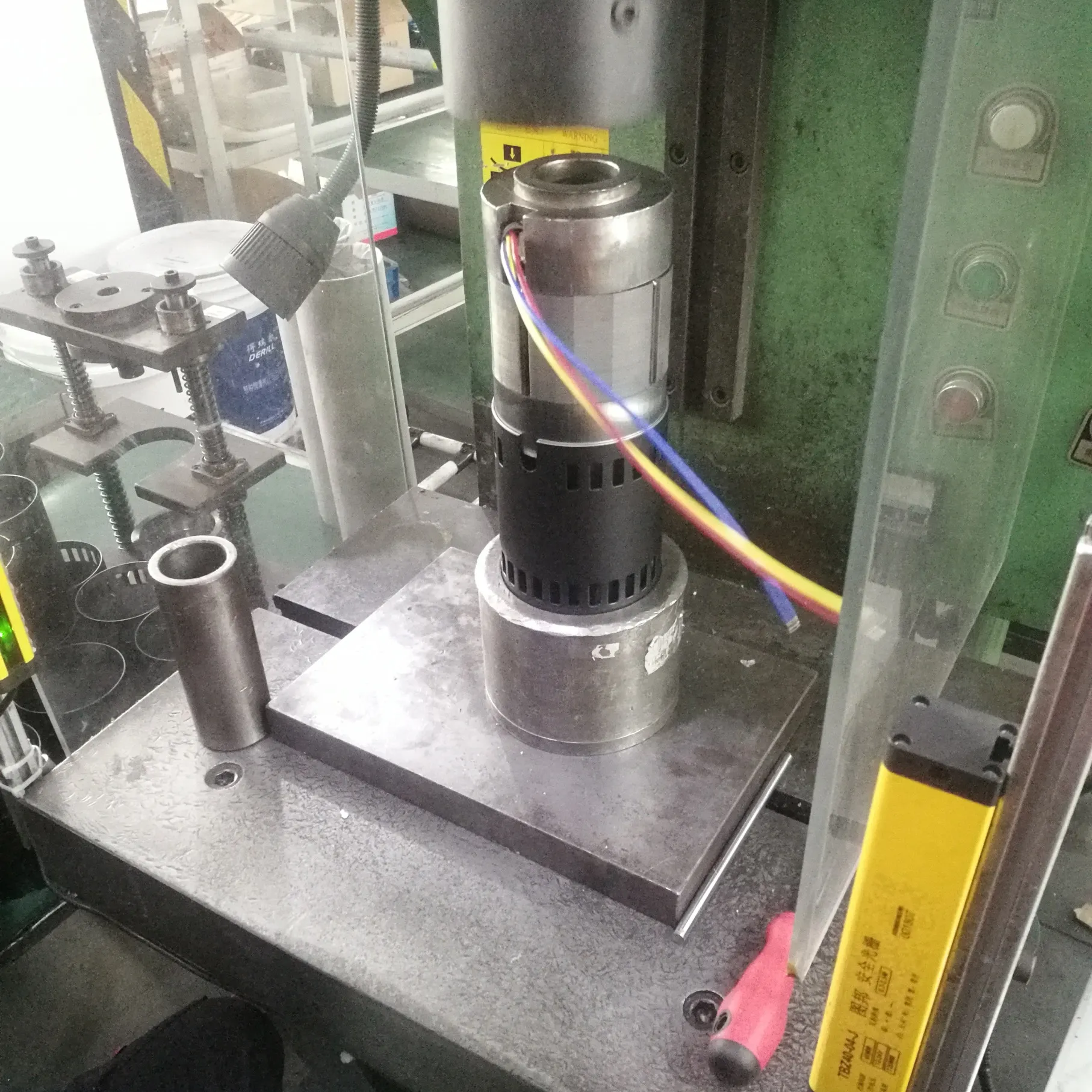

The shaft and end plates are pressed into the core by a hydraulic press.

The front and rear cover blanks are processed through the use of a lathe, drilling machine, and tapping machine.

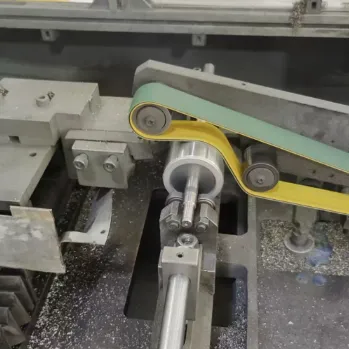

The outer diameter of the rotor is precisely machined to be within the qualifiedrange,resulting in a smooth surface without burrs.

Assemble the stator components, rotor components, casing, and end caps according to the drawings.

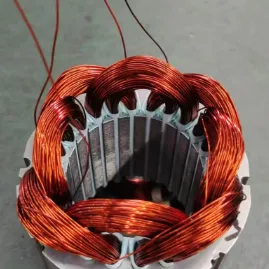

The enameled wire is wound through the winding machine according to thewinding template to complete the winding of the stator coils. Ensure that the coilshapes are consistent, without intersections or loose wires.

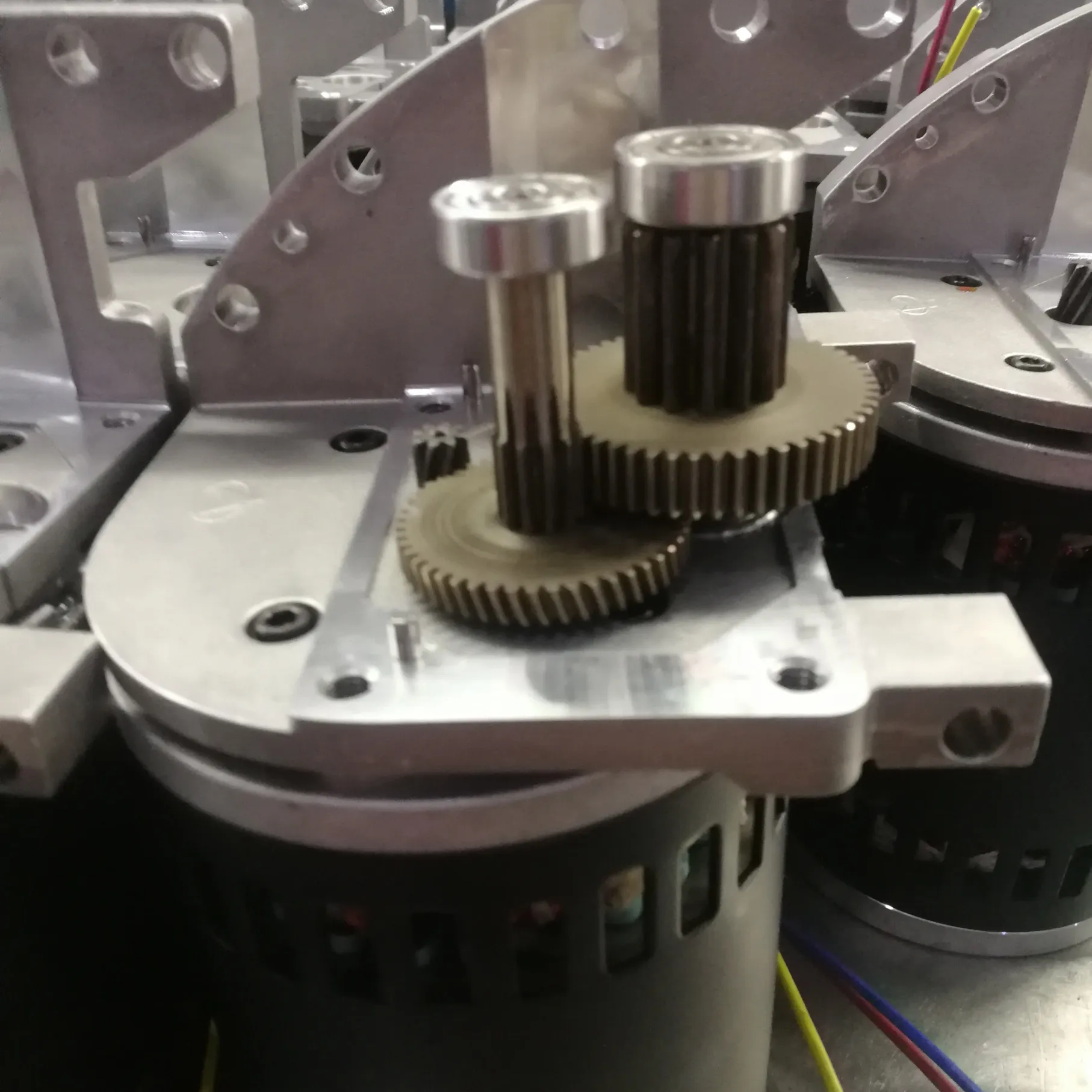

Assemble the single motor and gearbox components together

The quality of the semi-finished product's rotor is determined through thedetection of the comprehensive tester.

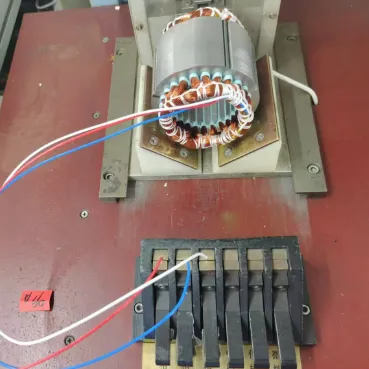

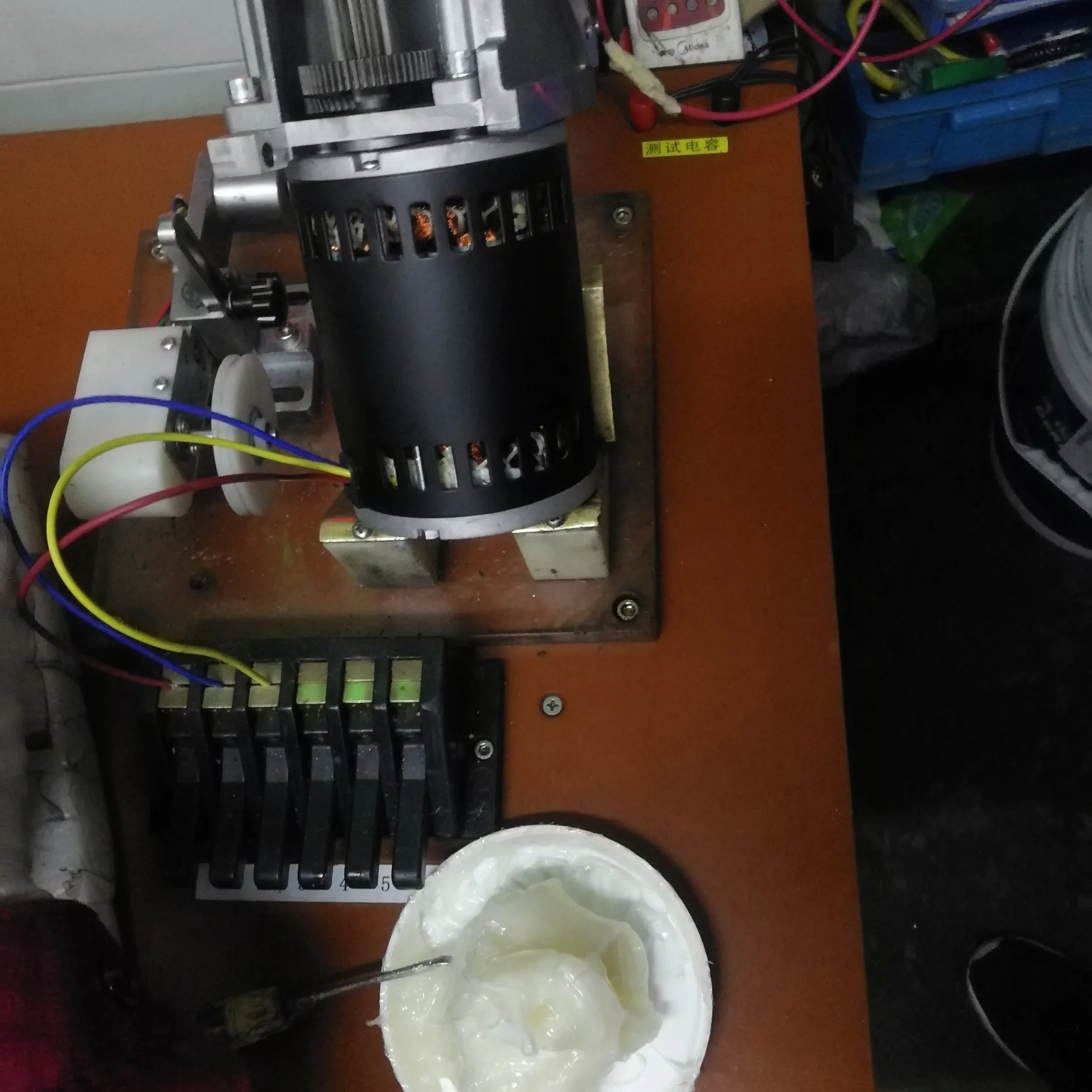

Conduct performance testing on the assembled motor through a comprehensive performance testing platform to ensure stable operation and compliance with efficiency standards.

The stator winding is cured by the stator potting machine to ensure its stabilityand protect the enameled wire, thereby enhancing its insulation properties.

The tested motor products are packaged in dust-proof and moisture-proof materials to provide additional protection during long-distance transportation.

The stator components are pressed into the casing using an oil press.

At Honest, we understand the complexities of international procurement and the importance of reliable partnerships. Our suite of services is designed to provide seamless integration into your supply chain, ensuring efficiency, quality, and adaptability at every stage.

We offer comprehensive product design services, including 3D modeling and simulation, to ensure your concepts are optimized for manufacturability and performance. Our engineering team collaborates closely with clients to refine designs, reducing time-to-market and production costs.

Accelerate your product development with our rapid prototyping capabilities. We provide quick turnaround on prototypes, allowing for iterative testing and refinement before full-scale production. This approach minimizes risks and ensures product quality.

Our lean manufacturing processes are designed for efficiency and adaptability. We can scale production volumes to meet your demand, ensuring timely delivery without compromising on quality. Our facilities are equipped to handle diverse product lines with precision.

Enhance your product’s market readiness with our custom packaging and kitting services. We assemble and package products according to your specifications, improving logistics efficiency and customer satisfaction.

Stay informed with our real-time order tracking system, providing visibility into every stage of the production and delivery process. Our inventory management solutions help prevent stockouts and overstock situations, optimizing your supply chain.

We provide globalized supply chain management, including sourcing, procurement and logistics coordination. Our global network ensures efficient material flow and just-in-time delivery, resulting in shorter lead times and lower costs.

With over 21 years of experience in the electric motor industry, Honest has established itself as a dependable partner for businesses worldwide. Our commitment to quality, innovation, and customer satisfaction has enabled us to build lasting relationships with clients across various industries.

Proven Track Record: Successfully delivered 1000+ projects across 30+ countries.

Global Reach: Serving clients in North America, Europe, Asia, and beyond.

Customer-Centric Approach: Tailored solutions to meet specific client needs.

Founded in 2004, Honest has been committed to the research, development, and manufacturing of motor and drive systems, striving to become a global benchmark in industrial-grade precision transmission and intelligent drive solutions. With “in-depth customization + technology integration” as our core competitiveness, we provide energy-efficient motor systems and precision drive components for 20+ industries, including industrial automation, new energy equipment, smart home, and medical equipment, helping customers achieve intelligent upgrades of their products.

We design gear ratios and torque curves based on grid frequency, pole count, and load conditions. Custom flange types and mounting orientations (horizontal/vertical) are available for diverse industrial needs.

Our standard MOQ is 500 units. For OEM projects, we support voltage and structure customization, with controlled production scheduling and phased deliveries.

Yes, we offer IP55 or higher protection ratings. Our motors also undergo heat, humidity, and continuous load testing to ensure long-term durability.

We provide standard spare parts kits, remote support, and maintenance plans to help clients quickly service gearboxes and drivetrain components.

Parallel production lines and regional partnerships enable us to scale efficiently, supporting synchronized delivery and deployment across multiple OEM sites worldwide.

We have a great deal of experience and case studies in the industry and are equally well aware of the trends in the industry. If you would like to learn more about the industry, including trends within the industry, please click below.

Address:No.121,Xinlong Road,Zhonglou Xinzha Subdistrict,Changzhou City, Jiangsu Province, China

Phone: +86-18261152679

Whatsapp: +86-18261152679

Email: sales@honestmotor.cn

Privacy Policy / Terms of Services / Cookie Settings / Site Map

© 2025 Honest All Rights Reserved.