The portable device and robotics industries are constantly pushing for higher performance in smaller packages. With consumer demand for products like drones, wearables, and electric tools increasing, conventional motors can no longer meet these strict requirements. For example, the need for extended battery life and compact design is critical, as every millimeter and every minute of run-time directly impacts a product’s success. In this highly competitive market, Custom BLDC Motors are the superior choice. Their specialized features help manufacturers innovate their products, achieve greater efficiency, and easily meet stringent regulatory standards.

Key Takeaways

Custom BLDC Motors help batteries last up to 30% longer. This means portable devices can work longer on one charge.

Their small and light design makes devices like drones and electric tools easier to carry and use.

These motors last between 10,000 and 20,000 hours. This cuts down on how often you need to replace them. They are reliable for important tasks.

Making these motors special lets companies change how they work. This helps save energy and meet rules.

Buying Custom BLDC Motors can save money over time. They lower maintenance costs and make devices work better.

The BLDC Motor Advantage

High Efficiency & Extended Battery Life

Custom BLDC Motors are known for being very efficient. This helps portable devices work better. These motors reduce energy loss. This means devices can run longer on one charge. This efficiency is very important for battery-powered devices. Every bit of energy matters.

Key Efficiency Metrics:

Efficiency

BLDC motors are very efficient because they lose little energy. Other motors lose energy due to friction and sparking.

Torque Control

BLDC motors give exact torque control at many speeds. Other motors have less precision and more torque ripple.

Speed Range

BLDC motors work steadily at many speeds. Other motors are less steady at high speeds.

Noise and Vibration

BLDC motors are quiet and vibrate little. Other motors make noticeable noise and electromagnetic interference.

Maintenance

BLDC motors need little maintenance. Other motors often need brush replacements.

Durability and Lifespan

BLDC motors last longer because they don’t have brushes. Other motors wear out quickly.

Heat Management

BLDC motors spread heat evenly, which helps cooling. Other motors create heat at brushes.

Power Density

BLDC motors give high power in a small design. Other motors have moderate power output.

In devices like smartphones and wearables, using Custom BLDC Motors saves a lot of energy. For example, these motors can make battery life last 30% longer than regular brushed motors. This longer battery life lets you use your devices more without recharging often.

Compact & Lightweight Design

Another big plus of Custom BLDC Motors is their small and light design. These motors use advanced materials and smart engineering. This gives them a high power-to-weight ratio. This small size is very important for portable devices, where space is tight.

Advantages of Compact Design:

Permanent Magnet Synchronous Motors (PMSMs) have even higher power density. They can create more power in a smaller size than BLDC motors.

This means while BLDC motors are compact, PMSMs might be even better for size and efficiency.

The light weight of these motors helps make devices easier to carry. For example, in drones and electric tools, using Custom BLDC Motors can lower the total weight. This improves maneuverability and makes them easier to use.

Long Lifespan & High Reliability

Custom BLDC Motors also last a long time and are very reliable. This makes them great for portable devices. These motors can last from 10,000 to 20,000 hours. This is much longer than brushed motors, which last only 1,000 to 3,000 hours.

Lifespan Comparison:

Brushed motors usually last 1,000 to 3,000 hours.

Brushless motors often last 10,000 to 20,000 hours or more.

The long life of Custom BLDC Motors means you can trust your devices longer. You won’t have to replace them often. This reliability is especially important for critical uses, like medical devices and industrial tools, where consistent performance is key.

The Core Value of OEM Customization

Customizing Custom BLDC Motors gives big benefits for portable devices. You can change the performance to fit your needs. This lets you improve power use, speed, and how the motors handle different environments.

Tailored Performance

When you customize your motors, you control important performance details. Here are some key details to think about:

Description | |

|---|---|

Power requirements | Continuous and peak power ratings based on duty cycle analysis |

Speed characteristics | Operating speed range, acceleration/deceleration rates, and precision needs |

Environmental conditions | Temperature extremes, moisture exposure, and contamination levels |

Mechanical constraints | Mounting requirements, shaft configurations, and space limitations |

Control integration | Communication interfaces, feedback systems, and safety functions |

This custom approach makes sure your devices work well, even in tough situations.

Seamless Integration & Miniaturization

Custom BLDC Motors can fit easily into your portable devices. You can design them to match specific spaces and needs. This often leads to smaller designs, which is very important for today’s electronics.

Benefits of Seamless Integration:

Custom motors offer better design and control, avoiding problems with standard motors.

They can be made to fit special integration needs.

Custom designs can help reduce weight through better magnetic and electrical design.

This means you can build lighter, smaller devices without losing performance.

Cost-Effectiveness & Project Timelines

Custom motor development might take longer than regular options, but the benefits are worth it. Custom motors need more time because of the initial development, testing, and approvals needed.

Considerations for Project Timelines:

Custom motor development includes engineering, documentation, tooling, and getting materials.

Special features in custom designs take more time and money because of the need for approvals.

However, the long-term performance and reliability of your devices can make this investment worthwhile. With over 20 years of experience, Honest provides high-performance motor solutions that fit many product needs. This ensures your devices work well, even with heavy use and long operation times.

Core Applications & Practical Cases

Electric Tools

Custom BLDC Motors are very important for making electric tools work better. They are light and save energy, which makes them perfect for this area. You can find these motors in many tools like drills, saws, and lawn equipment. Here’s how they help improve how tools work:

Precise Speed and Torque Control: Custom BLDC Motors give great control over speed and torque. This control is key for tasks needing exact movements, like drilling or cutting. The motors can run smoothly at many speeds, so you can change the tool’s performance for each job.

Low Noise Operation: A great thing about Custom BLDC Motors is how quiet they are. For example, the inner rotor brushless DC motor runs at noise levels as low as 45 dB. This quietness is especially good in homes or places where keeping noise down is important.

Feature | Description |

|---|---|

Brushless Design | Removes brushes that create particles, cutting down on contamination in clean areas. |

Integrated Encoders | Gives exact control of motor speed and position, which is key for high-precision tasks. |

Cleanroom-Compliant Housings | Made to meet ISO 14644-1 standards, reducing particle shedding and resisting cleaning agents. |

Particle Generation Requirements | Limited to less than 100 particles per cubic foot of air to meet Class 100 cleanroom rules. |

Outcome | Big drop in particle contamination, better product quality, and higher yield. |

These features make Custom BLDC Motors a top choice for makers wanting to boost the performance and reliability of electric tools.

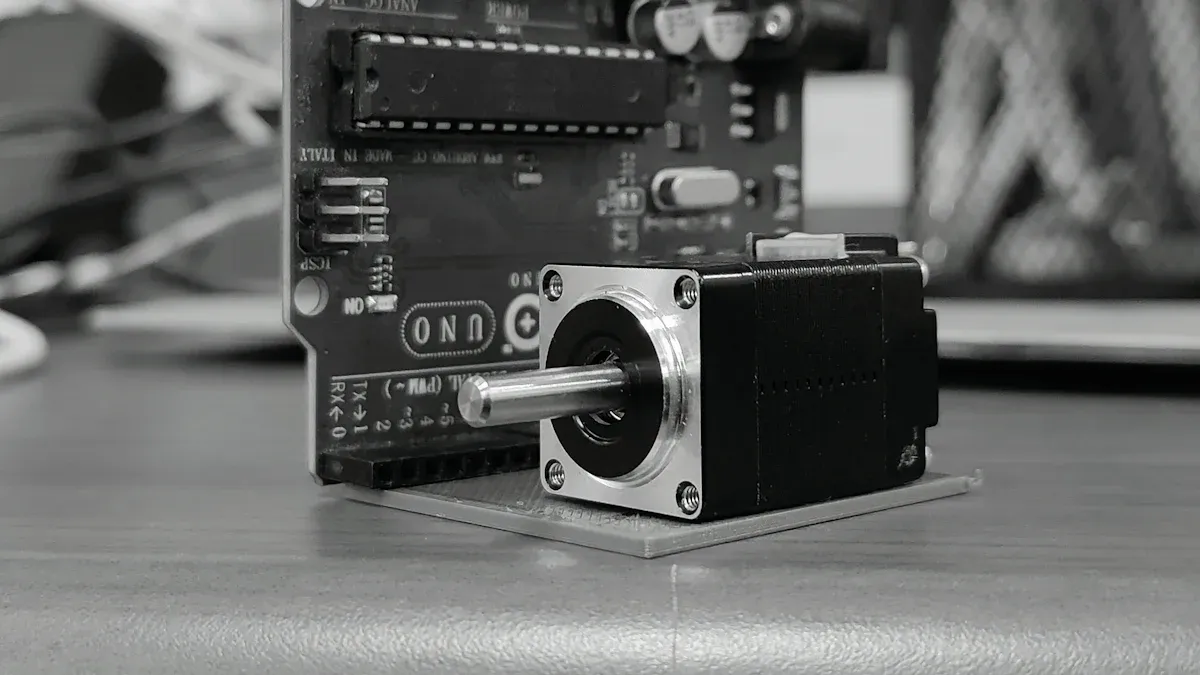

Drones & Robotics

In drones and robotics, Custom BLDC Motors are essential. Their small and light design helps them perform better in tight spaces. Here’s how they improve function in these areas:

Efficiency and Performance: Custom BLDC Motors can be more than 85% efficient, while traditional brushed motors are only 75% efficient. This efficiency helps drones fly longer and carry more weight without losing performance.

Stable and Precise Control: These motors offer stable and precise control, which is very important for things like aerial photography. You can take clear pictures without the shakes that come from less stable systems.

Low Maintenance Needs: Since Custom BLDC Motors don’t have brushes, they need less maintenance. This reliability is key for remote work where getting to equipment can be hard.

High Torque at Low Speeds: In robotics, Custom BLDC Motors can create high torque even at low speeds. This is important for tasks needing precision, like those done by robotic arms.

Heat Management: These motors handle heat well, keeping performance steady during long use. This is especially important in jobs where you use them for a long time.

Feature | Description |

|---|---|

Speed Range | Runs from about 0.025 rpm to about 7000 rpm, allowing for exact control across many speeds. |

Precision | High precision in speed control, great for tasks needing exact motion control. |

Application | Can be used in surgical robots and other advanced robotics needing precision. |

Using Custom BLDC Motors in drones and robotics not only boosts performance but also opens new chances for innovation in these fast-changing fields.

From Concept to Mass Production

Design & Prototyping

When you go from an idea to making many Custom BLDC Motors, there are important steps in design and prototyping. Here’s how the process works:

Define Application Requirements: Know the specific needs like torque, speed, and size limits.

Choose Motor Topology: Pick between inrunner and outrunner types based on what you need.

Electromagnetic Design: Work on the stator and rotor design, including winding methods and magnet types.

Thermal Management: Make sure the motor stays within safe temperature limits to avoid damage.

Mechanical Design: Choose the right materials and designs for strength and performance.

Simulation and Prototyping: Use simulation tools to check designs and create prototypes for real-world testing.

Controller Integration: Pair the motor with a good electronic speed controller for the best performance.

This organized method helps you make motors that fit your needs well.

Manufacturing & Quality

After you finish the design, the next step is making the motors. Custom BLDC Motors go through strict quality checks to make sure they work well. Here are some ways these motors improve device performance:

In smartphones, Custom BLDC Motors act as vibration motors. They improve haptic feedback, making user interactions more fun.

In drones, these motors give the power and efficiency needed for flying, leading to longer battery life and better control.

Also, these motors are very important in wearable technology. They provide special solutions that meet needs like size and power. Their small design allows them to fit into tiny devices without losing functionality. Plus, they improve energy efficiency, which is crucial for battery-powered wearables. The precise control they offer boosts the accuracy of these devices.

As you move from idea to mass production, you might face challenges. These include complex control systems, choosing the right motors, sensor integration, and managing heat. Solving these challenges makes sure your Custom BLDC Motors work reliably in different uses.

Custom BLDC Motors are very important in the car and portable device industries. They are efficient and reliable, which makes them necessary for today’s uses. Here are some important points to think about:

The market for automotive BLDC motors is expected to grow at a CAGR of 8.25% from 2026 to 2033. This growth is due to the rising demand for electric vehicles (EVs).

In the portable device area, there is a growing need for energy-saving solutions. This supports the use of BLDC motors.

Customization is key for staying competitive in the future. It helps improve performance, energy efficiency, and meeting rules.

If you want to see how a custom BLDC motor solution can improve your product’s performance and help you compete in the market, contact our expert team today!

FAQ

What are Custom BLDC Motors?

Custom BLDC Motors are special electric motors made for specific needs. They are very efficient, small, and last a long time. This makes them perfect for portable devices.

How do Custom BLDC Motors improve battery life?

These motors help save energy. This means devices can work longer on one charge. They can make battery life last up to 30% longer than regular brushed motors.

What applications benefit from Custom BLDC Motors?

You can use these motors in many places, like smartphones, drones, electric tools, and medical devices. They are flexible and work well in any portable device that needs reliable performance.

How do I choose the right Custom BLDC Motor?

Think about things like power needs, size limits, and environmental factors. Work with a manufacturer to make sure the motor fits your needs and works well in your device.

Are Custom BLDC Motors cost-effective?

Even though making them might take more time at first, the long-term benefits like efficiency, reliability, and lower maintenance costs make Custom BLDC Motors a smart choice for manufacturers.