Reliability is very important for heavy machines that use Industrial Induction Motors. These machines need motors that work well all the time and do not break often. Honest uses smart engineering and good maintenance to help companies keep their machines running. Their skills make sure each motor works its best, even when things get tough.

Key Takeaways

Pick the right motor that fits what the machine needs. This helps stop breakdowns and makes the motor last longer.

Put in motors with care. Make sure they are lined up right. Use the correct wires and test them first. This stops early damage and keeps things running well.

Check motors often. Look at the bearings, clean them, and watch the heat and shaking. This helps find problems early.

Use smart tools like predictive monitoring and health index dashboards. These tools help you find issues before they break the motor.

Change motor speed with variable frequency drives and soft starters. This saves energy, lowers wear, and keeps machines safe.

Motor Selection

Application Fit

Choosing the right motor starts with knowing what the machine needs. Engineers check things like power, torque, insulation, and protection. Every machine is different. A conveyor system needs steady torque and can handle heavy loads. A pump at a water plant needs good insulation and to stay dry. Honest says to match the motor to the job. This helps stop breakdowns and makes motors last longer.

Tip: Always look at the load profile and duty cycle first. This helps make sure the motor will not get too hot when working hard.

Efficiency & Durability

Efficiency and durability are important for making motors last. Honest’s Industrial Induction Motors save energy and do not get too hot. These motors meet IE3 energy rules. The IP55 rating keeps out dust, water, and oil. Strong bearings and windings help the motor last longer. These features help in tough places. Honest’s motors can handle loads significantly higher than standard motors, which is helpful for machines that start and stop frequently.This helps when machines start and stop a lot.

Feature | Benefit |

|---|---|

IE3 Efficiency | Uses less energy |

IP55 Protection | Keeps out dust and water |

Overload Capacity | Works with heavy loads |

Long Lifespan | Needs less fixing |

Honest Three-Phase Induction Motors

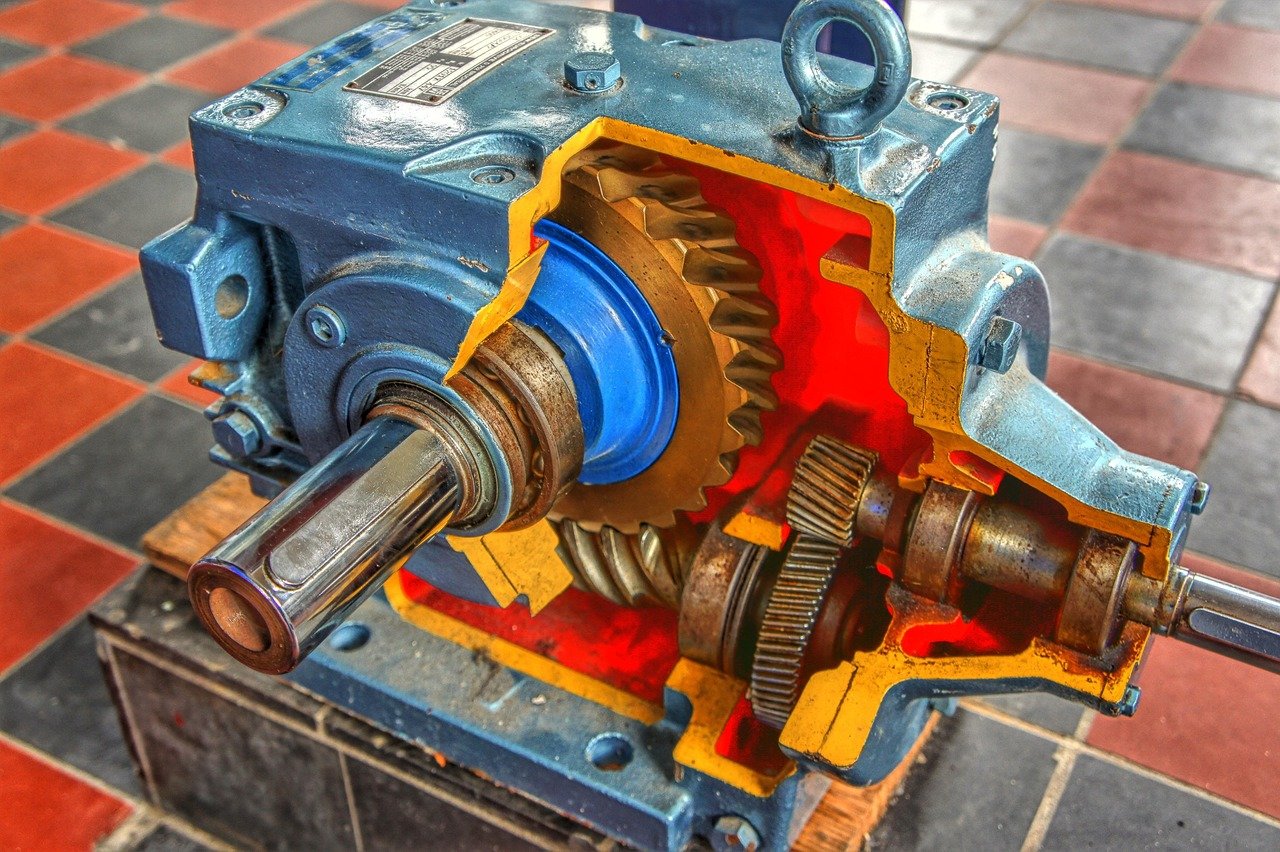

Honest’s three-phase Industrial Induction Motors are great for heavy work. They use cast copper rotors and F-class insulation. This helps them work well with big loads. Honest has motors from 0.12kW to 315kW. These motors work with variable frequency drives for speed control. Synchronous motors give exact speed control. Asynchronous motors, or induction motors, are strong and cost less. Honest has both types, so users can pick what they need.

Note: Honest can customize motors for each job. This helps with pumps, conveyors, or textile machines.

Installation & Commissioning

Alignment & Vibration

Good alignment helps motors work well. Engineers need to line up the motor shaft with the equipment. If it is not lined up, the motor can shake and make noise. This can also break the bearings early. Using laser tools can help achieve the best results, and keeping vibration low is important too. Technicians should look for soft foot problems and tighten all bolts. Vibration should stay at safe levels set by the maker. Checking often stops damage from getting worse.

Tip: Use a vibration meter to check for changes. Finding strange vibration early can save money on repairs.

Electrical Setup

Setting up the motor right keeps it safe and working well. Electricians must check that the power matches the motor’s voltage and frequency. All wires should be tight and clean, and clear terminal labels help make wiring easier. Grounding the motor keeps people and machines safe. Technicians should test insulation resistance before starting the motor. This helps prevent electrical problems.

Checklist for Electrical Setup:

Check voltage and frequency match

Tighten all wire connections

Look for broken wires or insulation

Test insulation resistance

Make sure grounding is done right

Baseline Testing

Baseline testing gives a starting point for future checks. After putting in the motor, technicians should write down things like current, voltage, vibration, and temperature. Honest helps by giving guides and technical help. These records show changes that could mean trouble later. Having a good baseline makes fixing problems faster and easier.

Note: Honest’s team can provide on-site or remote commissioning support, helping ensure every motor starts off in optimal condition.

By doing these steps, companies help their industrial induction motors last longer and work better. Honest’s help during installation and commissioning sets up motors for success.

Maintenance Strategies

Preventive Care

Preventive care helps motors work well for a long time. Technicians follow a plan to check and clean each motor often. They look at bearings, add oil to moving parts, and check for damage. Honest says to check temperature, vibration, and noise often. These steps help find problems before motors stop working. Companies use lists to make sure every job gets done. Feedback from customers shows that Honest’s motors tend to experience fewer breakdowns, thanks to their robust design and high-quality components.

Doing preventive care often stops surprise problems and saves repair money.

Common Preventive Tasks:

Look at bearings and add oil if needed

Check for dust and water near the motor

Measure how hot and shaky the motor is

Tighten bolts and wires

Clean fans and air paths

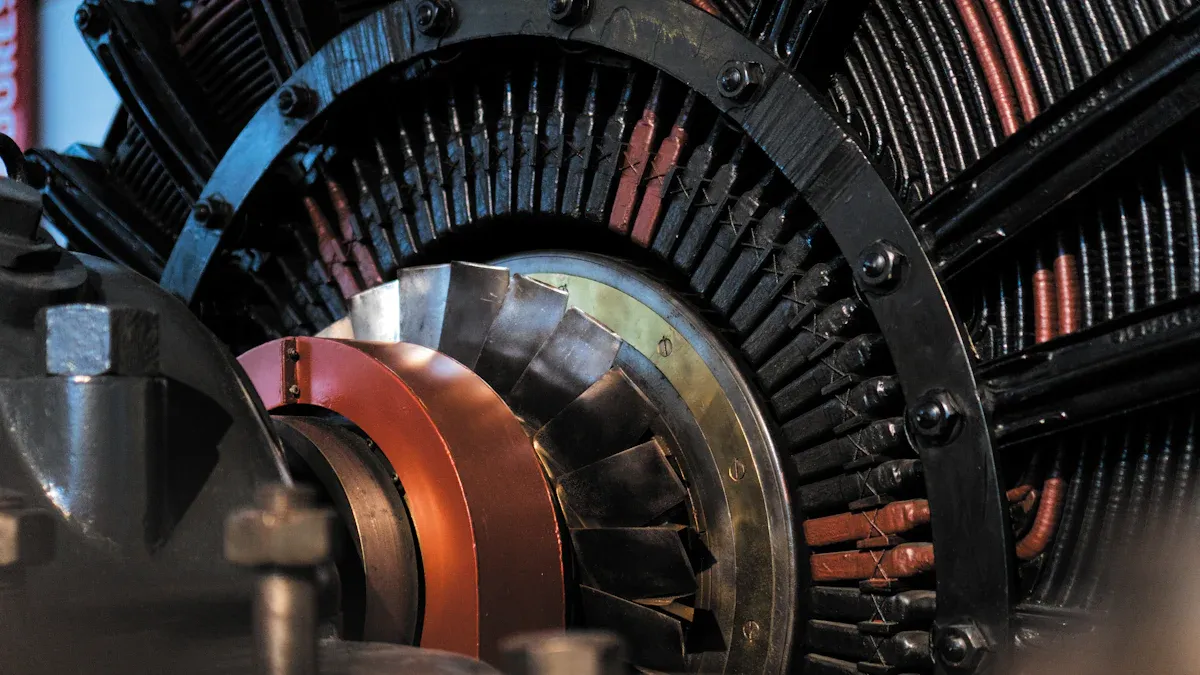

Predictive Monitoring

Predictive monitoring uses smart tools to track motor performance. Sensors measure vibration, temperature, and electrical current, while AI analyzes the data to detect early warning signs. Techniques like Principal Component Analysis, decision trees, and neural networks can help identify potential issues before they become serious. This approach allows industrial induction motors to be maintained more proactively, reducing unplanned downtime and enhancing operational safety.

Predictive monitoring helps address potential motor problems early, keeping machines running more reliably and safely.

Health Index Tools

Health index tools provide a score representing each motor’s condition, based on sensor data and historical maintenance records. Dashboards can display these health scores in real time, alerting technicians if a motor may need attention. Monitoring trends over time helps plan maintenance and prevent emergency shutdowns.

Health index features typically include:

Health Index Feature | What It Does |

|---|---|

Real-Time Dashboard | Shows motor health right now |

Alert System | Warns about problems |

History Tracking | Keeps records over time |

Maintenance Planner | Plans when to fix things |

Using predictive monitoring and health index tools, companies can better plan maintenance and keep motors running efficiently with less unplanned downtime.

Operating Conditions

Voltage & Harmonics

Voltage quality is very important for motor reliability. Motors need steady voltage to work well. If voltage goes up and down, motors can get too hot. This can make motors not last as long. Harmonics are extra frequencies in the power supply. Harmonics can hurt motors by making more heat and shaking. This can cause motors to fail early. Honest’s motors have strong insulation and windings. These help motors handle voltage changes and block bad harmonics. Their IP55 protection keeps out dust and water. This helps motors work well even in tough places.

Tip: Use power quality analyzers to find voltage dips and harmonics. Finding problems early can stop expensive repairs.

Temperature Control

Keeping motors cool is important for their health. High heat can break insulation and damage bearings. To prevent this, F-class insulation and effective cooling systems help motors stay cool during heavy-duty operation. Technicians should keep air vents open and check fans. In hot places, additional cooling or airflow may be needed. Honest’s motors incorporate these features to perform reliably in hot environments.

Temperature Issue | Solution |

|---|---|

Overheating | Improve ventilation |

Blocked airflow | Clean air passages |

High ambient temp | Use heat shields |

Load Management

Managing load helps motors run well and not get overloaded. Dynamic Load Management (DLM) has many good points:

Watches power use all the time and changes loads to stop spikes.

Sends power to the most important machines first so they keep working.

Works with Building Energy Management Systems to balance loads.

Uses the power system better so upgrades are not needed.

Helps use renewable energy and batteries for better efficiency.

Saves money by lowering peak demand costs and helps the environment.

Honest’s motors have overload protection to stop damage from sudden load jumps. Their strong build keeps motors working well, even with lots of starts and stops. Using smart load management and strong motors helps companies make machines last longer and stop less.

Control Technologies

VFD Integration

Variable Frequency Drives help control how fast motors spin. Operators use VFDs to change motor speed for each job. This saves energy and makes motors last longer. Honest makes motors that work well with VFDs. Their motors can change speed smoothly and keep working well. VFDs help motors start and stop without sudden shakes. This keeps machines safe and means less fixing is needed.

Tip: VFDs can help save money and make motors last longer in big machines.

Soft Start & Protection

Soft starters help motors start slowly. They stop big power jumps when turning on. This keeps gears and belts from getting hurt. Honest puts overload protection in their motors. Their motors can start and stop many times without breaking. Soft start keeps machines safe and helps stop breakdowns.

Protection Feature | Benefit |

|---|---|

Soft Start | Less mechanical stress |

Overload Guard | Stops overheating |

IP55 Sealing | Blocks dust and water |

Remote Monitoring

Remote monitoring lets workers check motors from a distance. Sensors track temperature, vibration, and power usage. Smart dashboards provide quick updates, and warnings alert workers to potential problems before they get worse. This helps plan maintenance and prevents unexpected shutdowns. Motors can also be integrated with modern monitoring tools for enhanced safety.

Industrial Induction Motors in Automation

Industrial Induction Motors are important in smart factories. Automation uses these motors for belts, pumps, and machines. Honest makes motors that connect easily to control systems. Their motors help with data and flexible work lines. Honest’s ideas help factories work better and more safely. Workers trust these motors to run all the time in hard jobs.

Industrial Induction Motors work well if you do a few things. Pick a motor that matches the job. Install it carefully so nothing goes wrong. Use smart tools to keep it working right. Advanced controls help motors last longer and work better. Good companies make special motors that save energy and keep people safe. Honest gives help and custom motors for big machines. Many companies trust Honest to keep their machines working for a long time.

To keep motors working well for years, ask Honest for help with high-efficiency motors and expert advice.

FAQ

What makes Honest’s Industrial Induction Motors reliable for heavy machinery?

Honest builds motors with strong bearings and F-class insulation. They also use IP55 protection to keep out dust and water. These things help motors work in hard jobs and rough places. Their motors meet IE3 efficiency rules, so they use less energy and last longer.

How often should technicians perform preventive maintenance?

Technicians should check motors every three to six months. They need to look at bearings and clean air passages. They also measure vibration to spot problems early. Regular checks help machines run well and avoid big issues.

Can Honest’s motors work with variable frequency drives (VFDs)?

Yes, Honest’s motors can work with VFDs. Operators can change motor speed for each job. This saves energy, lowers wear, and helps motors last longer.

What should engineers do if a motor shows high vibration or heat?

Engineers should turn off the motor and check its alignment and load. They should also inspect the cooling system and airflow. Using available monitoring tools or diagnostics can help identify the problem. Acting quickly prevents further damage and keeps the motor operating safely.