Following global regulations is key to a successful export plan. Major trading partners prioritize compliance, as failure to adhere to these rules can lead to significant costs, including product recalls and substantial fines. Honest helps in Mitigating Export Risk in global trade through specialized processes that ensure exceptional quality and assist with specific certifications. This support simplifies navigating complex global regulations, providing confidence in your international dealings.

Key Takeaways

Adhering to global regulations helps you sell products worldwide, effectively mitigating major risks such as fines or product recalls.

Robust quality management systems (like ISO 9001 and IATF 16949) ensure your products meet international standards, building trust and avoiding high-cost issues.

Your products must comply with material regulations such as RoHS and REACH, and secure essential safety approvals like UL, CE, and EMC to penetrate different markets.

Honest specializes in custom motor designs, ensuring your customized products meet all global compliance requirements right from the initial phase.

Comprehensive compliance documentation and rapid professional support help accelerate market entry and significantly lower risks in global trade.

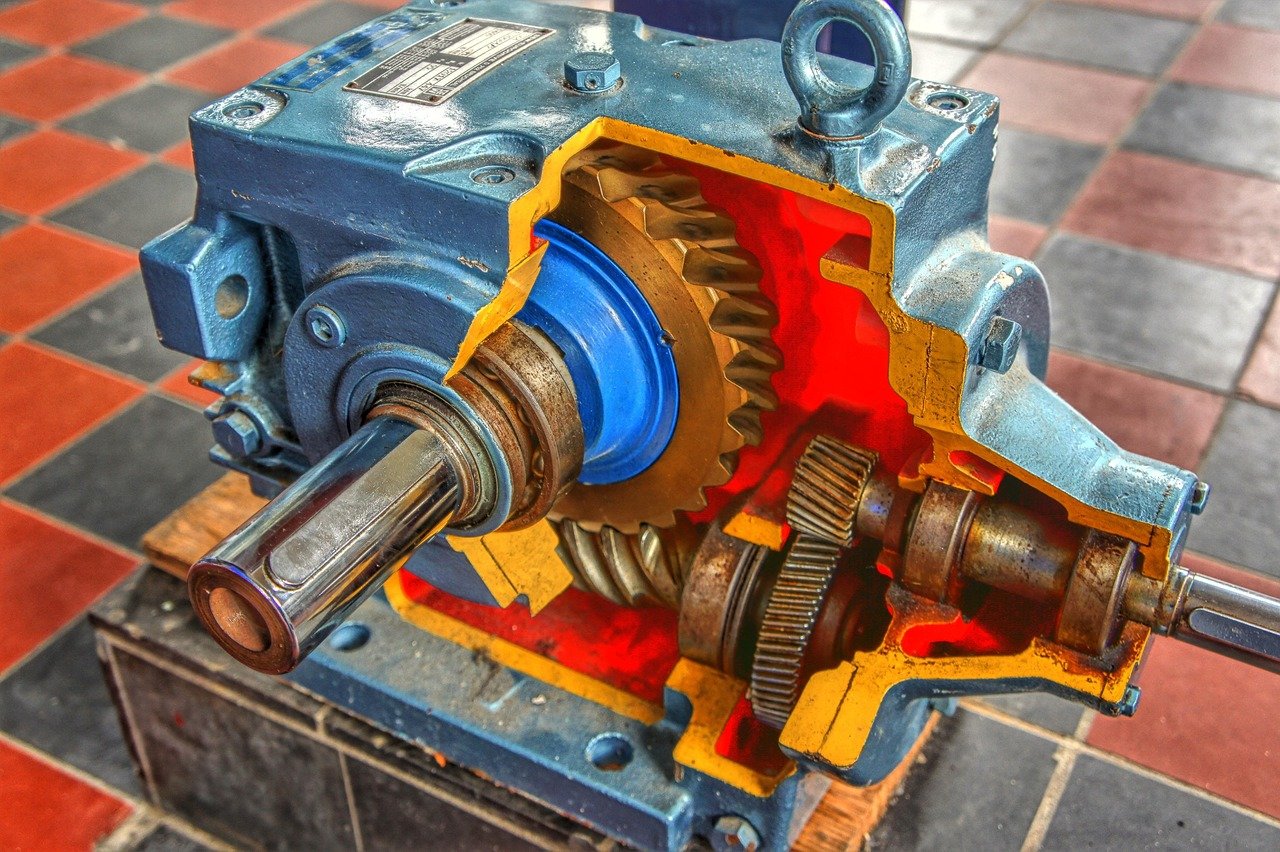

Pillar One: Quality Systems

You must possess a robust quality management system (QMS). This is essential for selling products globally and is fundamental for effectively Mitigating Export Risk. These systems ensure your products consistently comply with global regulations, which builds international trust and avoids costly operational issues. Lacking comprehensive quality assurance can result in financial loss, damage to brand reputation, and potential legal liabilities.

ISO 9001: Quality Foundation

ISO 9001 is the foundational QMS standard, applicable to organizations of all types. It provides a framework guiding companies on how to meet both customer and applicable regulatory requirements. Customer focus is a core principle of ISO 9001, requiring companies to identify and consistently satisfy customer needs to enhance satisfaction.

ISO 9001 certification represents a commitment to quality, covering all aspects of a company’s operations. It utilizes the renowned Plan-Do-Check-Act (PDCA) cycle—a four-step iterative model designed for continuous improvement. This mechanism ensures the enterprise remains flexible and responsive to market changes.

Globally, over a million companies use ISO 9001. Certification demonstrates a company’s competence in delivering consistent, high-quality products and services, making it a vital passport for entering the global market.

IATF 16949: Automotive Quality

IATF 16949 is the key Quality Management System technical specification for automotive parts manufacturers and their suppliers. It builds upon ISO 9001 by incorporating more stringent, automotive-specific requirements. This standard places a high emphasis on specific customer requirements, continuous improvement, defect prevention, and the reduction of variation and waste throughout the supply chain.

Understanding the differences between the two standards is crucial. Here is how they compare:

Feature | ISO 9001 | IATF 16949 |

Scope | Applicable to any organization. | Limited to organizations manufacturing automotive parts and their supply chain. |

Foundation | General quality management principles. | Based on ISO 9001, incorporating strict automotive-specific requirements. |

Customer Focus | Meeting customer needs. | Emphasizes meeting specific customer requirements. |

Risk Management | Identifying risks and opportunities. | More stringent requirements for product safety and potential failure analysis (actions for automotive failure modes). |

Process Approach | Uses a process-oriented approach. | Incorporates specific manufacturing processes and core tools (e.g., PPAP, Control Plans). |

Continuous Improvement | Enhancing the QMS. | Focuses on defect prevention and reducing variation and waste (via FMEA, SPC, MSA, etc.). |

Product Safety | Implicitly addressed. | Clear, detailed rules, including traceability and special characteristic management. |

Tools & Techniques | No mandatory specific tools. | Mandatory use of automotive core tools, such as APQP, PPAP, FMEA, SPC, MSA. |

Industry Specificity | General purpose. | Highly automotive-specific. |

Adhering to IATF 16949 demonstrates a commitment to the highest standards of quality and safety, which is a Must-Have for securing and maintaining critical contracts within the automotive industry.

Pillar Two: Product Readiness

Ensuring Product Readiness means your products meet the necessary material regulations and safety certifications for worldwide sale. Companies must establish robust internal risk management plans to integrate compliance requirements into the early design phase, allowing them to proactively identify and resolve potential issues. This forward-looking approach saves significant time and cost. Furthermore, utilizing regulatory tracking software or document management systems is vital for staying updated on the latest global regulatory changes.

RoHS and REACH Material Compliance

Environmental regulations are paramount for motor manufacturers. RoHS, the Restriction of Hazardous Substances Directive, aims to limit certain dangerous substances in Electrical and Electronic Equipment (EEE). The Directive requires that all homogeneous materials within EEE components comply with the restriction thresholds. Even component manufacturers must adhere to RoHS if their parts are integrated into EEE. Honest ensures its motors fully comply with both RoHS and REACH standards, thereby facilitating overseas sales.

The RoHS Directive restricts ten substances. Your motors must not exceed these maximum allowed concentrations, which apply to the homogeneous material level:

Substance | Maximum Allowed Concentration |

Lead | 0.1% |

Mercury | 0.1% |

Cadmium | 0.01% |

Hexavalent chromium | 0.1% |

Polybrominated biphenyls (PBB) | 0.1% |

Polybrominated diphenyl ethers (PBDE) | 0.1% |

Di(2-ethylhexyl) phthalate (DEHP) | 0.1% |

Butyl benzyl phthalate (BBP) | 0.1% |

Dibutyl phthalate (DBP) | 0.1% |

Diisobutyl phthalate (DIBP) | 0.1% |

To ensure RoHS compliance, various motor components must be tested. This process involves scrutinizing potential materials for the presence of restricted substances:

Plastics and Polymers: Tested for plasticizers (softeners) and flame retardants (e.g., in motor casings and cable covers).

Metal Components: Checked for heavy metals like Lead and Hexavalent Chromium (e.g., in screws, plug contacts, and housing parts).

Electronic Components: Evaluated for RoHS substances in circuit boards, connectors, solder, cables, and coatings.

Coatings and Adhesives: Surface coatings, paints, and sealing materials used for assembly must also be tested.

RoHS testing must adhere to international standards, such as the DIN EN 62321 series. This key methodology establishes the procedures for sample preparation, testing, and reporting, ensuring the accurate measurement of restricted substances in Electrical and Electronic Equipment (EEE).For products sold in Europe, manufacturers must affix the CE mark and prepare an EU Declaration of Conformity.

REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) governs the manufacture and use of chemical substances and their potential impact on human health and the environment. This regulation manages three product categories: substances, mixtures, and “Articles.” An “Article” (the classification that applies to components like electric motors) is defined as an object whose function is determined more by its shape, surface, or design than by its chemical composition. This distinction is crucial for determining regulatory obligations.

For manufacturers supplying these Articles, the primary requirement is information transmission, particularly concerning Substances of Very High Concern (SVHCs). If an Article contains an SVHC above the threshold of 0.1% (w/w), the supplier is legally obligated to inform customers and consumers. Honest continuously monitors and adheres to all REACH Annex XVII (Restriction) requirements, ensuring proactive chemical assessments for custom motors to meet all SVHC reporting obligations.

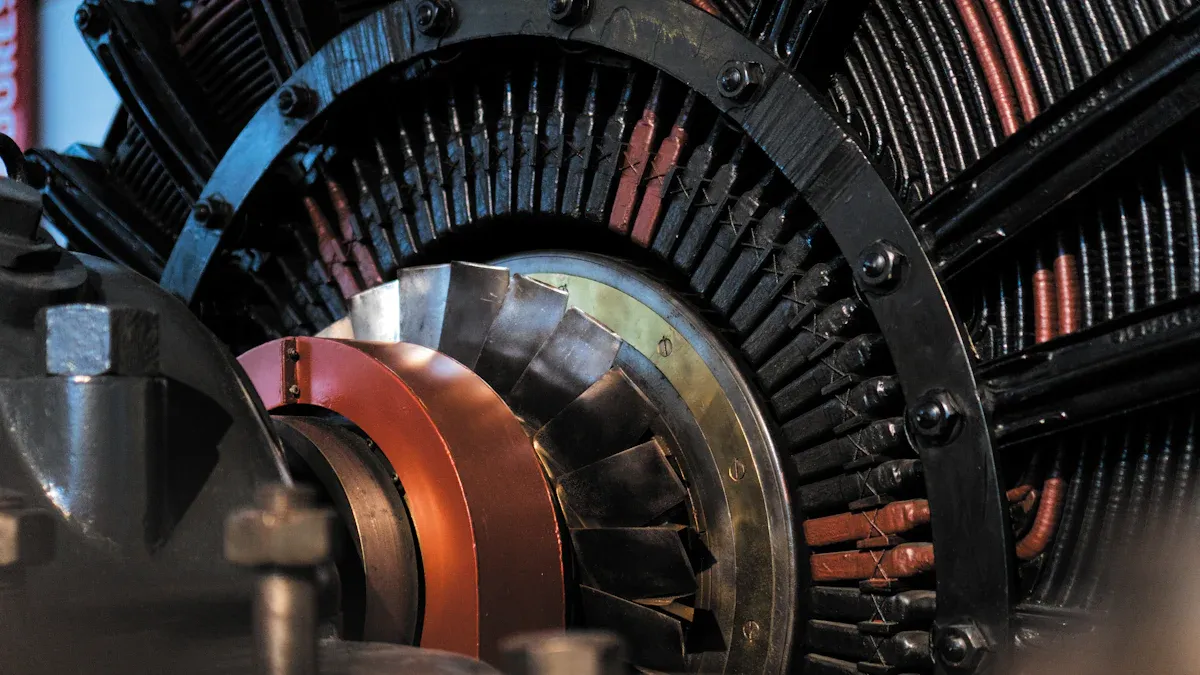

UL, CE & EMC Safety Testing

Beyond material compliance, your motors require essential safety and electrical certifications.

1. UL Certification for North America

UL (Underwriters Laboratories) is a global leader in safety science, primarily providing product safety testing and certification for the North American market (USA and Canada). UL approval is often a mandatory or crucial market acceptance standard.

UL certification evaluates electrical products comprehensively, including:

Electrical Safety

Fire Protection

Explosion-Proof Requirements (for hazardous locations)

Compliance with Recognized Standards (e.g., UL 508 for Industrial Control Equipment; UL 61010)

2. CE Mark for Europe

The CE mark is the manufacturer’s self-declaration that a product complies with EU health, safety, and environmental requirements. This includes compliance with key directives such as:

Low Voltage Directive (Electrical Safety)

Machinery Directive

EMC Directive (Electromagnetic Compatibility)

Manufacturers must affix the CE mark and prepare an EU Declaration of Conformity.

3. EMC (Electromagnetic Compatibility) Requirements

EMC is critical. It ensures your motors do not interfere with other electronic devices in their operational environment while maintaining their own functionality. Different jurisdictions have strict EMC regulations (e.g., EN 61800-3 and IEC 60034-5 for factory motors).

Global EMC Testing & Certification Requirements:

Market | EMC Testing/Certification Requirement |

|---|---|

USA | FCC Part 15 Testing & Certification |

Europe | CE Mark (EMC Directive 2014/30/EU) |

Canada | Industry Canada EMC testing |

Japan | VCCI EMC testing & Certification |

S. Korea | KCC EMC testing & Certification |

Australia | ACMA Registration |

Brazil | Anatel testing & certification |

China | CCC Testing & Certification Technical Assessment |

Adherence to these certification requirements is a prerequisite for ensuring your motors are safe, reliable, and capable of operating efficiently anywhere in the world. Honest complies with UL, CE, and EMC standards, guaranteeing your motors are ready for immediate market entry into your target regions.

The Honest Advantage: Custom Support

Customized support is Honest’s core competency. Unlike standardized motors with clear regulations, custom motor designs often involve unique specifications and operational environments, making the certification process complex and requiring tailored compliance solutions.

Honest provides specialized solutions across various motor types (including three-phase AC, DC, universal, and pump motors). We understand these unique demands and utilize a “Design-in Compliance” approach, ensuring your custom motor fully satisfies global regulations right from the conceptual stage, thereby saving significant time and cost.

Engineering for Extreme Compliance

You require motors that perform excellently while adhering to stringent global regulations. Honest’s engineering excels in this area, focusing on “Comprehensive Compliance.” Our engineers meticulously check every detail to ensure your custom motor achieves all necessary approvals, covering material, safety, and electrical regulations.

Consider compliance requirements across different regions:

CE for Europe: Motors must meet multiple EU directives, including the Low Voltage Directive (electrical safety), the EMC Directive (electrical compatibility), the Machinery Directive (if integrated into machinery), and RoHS and REACH (material compliance). A Declaration of Conformity and risk assessment are mandatory.

UL for North America: UL approval is often crucial for the USA and Canada, checking product safety, adherence to standards like UL 1004 (‘Rotating Electrical Machines’) and UL 508 (‘Industrial Control Equipment’), and fire/shock hazards through rigorous electrical, mechanical, and thermal testing.

CCC for China: Required for many products entering China. For motors, compliance with specific GB standards covers safety, performance, and energy efficiency. The process includes product testing and factory inspections.

EAC for the Eurasian Economic Union: This mark confirms compliance with EAEU regulations, covering machinery safety and electrical compatibility, and requires a Declaration or Certificate of Conformity.

Honest’s engineering team collaborates with you to integrate all these rules into the motor’s design early on. By carefully selecting materials, optimizing electrical components, and managing insulation and thermal properties, this early intervention eliminates costly late-stage modifications and accelerates your time-to-market.

Certification Acquisition Key Steps:

Initial Design Review: Our engineers assess and verify your motor specifications against required approvals to identify problems early.

Pre-Compliance Testing: Early testing conducted in our labs to predict formal results and allow for timely design adjustments.

Formal Testing: Official compliance testing conducted at accredited third-party laboratories.

Documentation Submission: We compile all required documentation, including test reports, design drawings, and risk assessments, for submission to the approval body.

Factory Inspection: Inspections (e.g., CCC) ensure consistent quality assurance throughout production.

Certification Issuance: Official approval granted upon meeting all requirements.

Ongoing Surveillance: Required for many approvals to maintain continuous compliance.

Establishing Strategic Partnerships is crucial. Honest maintains close cooperation with reputable third-party laboratories and certification bodies to ensure smooth and swift approval processes. We manage these relationships for you, simplifying the process and significantly reducing your administrative burden.

Documentation for Fast Market Entry

Complete compliance documentation is paramount for rapid market entry. Honest’s documentation support is designed to effectively prevent customs delays and satisfy regulatory authorities.

Our documentation support includes:

Technical Files: Detailed technical files containing design specifications, material declarations, and test reports, tailored to each approval body’s needs.

Declarations of Conformity: Assistance in preparing these crucial documents, formally declaring the motor’s adherence to relevant regulations.

User Manuals and Safety Instructions: Ensuring product literature contains all necessary warnings and guides compliant with local regulations.

Certificates of Origin: Providing accurate documentation required for customs clearance and international trade agreements.

Export Licenses and Permits: Guiding you through obtaining necessary export licenses for smooth shipment logistics.

Honest’s team is proficient in global trade documentation requirements, ensuring every document is accurate and complete. This meticulous documentation management prevents customs holds, accelerating your product’s journey to the buyer, which provides a significant competitive edge and faster capital turnover. We integrate our documentation service with engineering expertise, offering a reliable path to selling your custom motors quickly and compliantly.

Logistics and Risk Mitigation

Supply Chain Integration and Quality Assurance

Adhering to the “Design-in Compliance” principle from the outset is the most effective strategic approach to lower export risk and realize significant time and cost savings. This strategy extends critically into the supply chain: Honest focuses on building strong, reliable relationships with its supply partners to ensure component consistency, reduce material variability, and enhance product traceability across the entire manufacturing flow. This proactive management of the supplier network is essential for robust global trade and optimizing overall production efficiency.

Financial Assurance and Agile Response

Honest provides robust assurance through a standard 2-year warranty and lifetime technical support, offering long-term financial stability for your export operations. Furthermore, rapid technical assistance is vital: Honest promises a 12-hour online rapid response. Our engineers can quickly diagnose and resolve issues, minimizing production downtime and effectively mitigating export risk through prompt, reliable service.

Selecting the right motor supplier is key to achieving global sales success. Compliance should be viewed not merely as a cost, but as a decisive competitive advantage. A professional supplier should leverage comprehensive quality processes and expert documentation support to systematically eliminate potential trade hazards, thereby helping you achieve significant export risk reduction early in the product lifecycle.

Should you require further consultation on compliant motor solutions designed for rapid global market entry, our Quality and Trade Support team is ready to assist.

FAQ

Why is following global rules important for your motors sold to other countries?

Following global rules stops big problems. You will not have recalls. You will not get fines. You can sell your motors everywhere. It builds trust with other countries. It keeps your company’s good name safe. Meeting rules helps your products sell around the world.

How do UL and CE approvals help your products?

UL and CE approvals show your products are safe. UL is very important for North America. CE is needed for Europe. These marks mean your motors are safe. They are also dependable. They let you sell in these big markets.

What makes Honest’s special motor approval help different?

Honest puts rules into your motor design. We do this from the start. We handle hard approvals. These include CE, UL, and CCC. Our engineers make sure your special motor meets all global rules. This helps you sell your product faster.

How does IATF 16949 help your car motor projects?

IATF 16949 makes sure car parts are top quality. It works to stop mistakes. It also cuts down on waste. This approval shows you care about being the best. It helps you get big car company deals. It helps you keep them.

Why are material rules like RoHS and REACH important for your motors?

RoHS and REACH rules limit bad stuff in your motors. This keeps people safe. It also protects nature. It makes sure your products meet strict European rules. Honest promises its motors follow these key material rules.