Brazil’s industries are growing quickly, but they have new problems from grid instability. Factories and plants often have unstable voltage and low power factor.

Motors and electrical systems can get damaged. This can make them stop working without warning.

Voltage unbalance makes extra current. This can make motors too hot and wear out faster.

Equipment can break down. This costs money and needs expensive repairs.

Honest’s team of experts in advanced motor solutions works hard to help businesses keep their operations safe with strong, high-quality products.

Key Takeaways

Synchronous motors always run at the same speed, even if the load changes. This makes them great for factories that have grid instability.

These motors help make power better by changing their power factor. This helps keep voltage steady and keeps equipment safe.

Using synchronous motors can lower downtime and repair costs a lot. This helps factories work better and faster.

Synchronous condensers are a kind of synchronous motor. They give reactive power to the grid and make it more stable. This is very helpful when using renewable energy.

Picking the right synchronous motor means thinking about speed, power, and the environment. This helps the motor work its best.

The High Cost of Grid Instability

The Silent Threat

Grid instability is a big problem for many factories in Brazil. Power systems can stop working well when supply and demand do not match. This issue can happen suddenly and cause a lot of damage.

Grid instability causes many technical problems:

Temporary overvoltages can make voltage jump up fast.

Undervoltages can leave machines without enough power.

Phase imbalances can mess up electrical system balance.

Frequency and voltage changes often happen with renewable energy.

Transmission lines can get overloaded and shut down during busy times.

When demand and supply do not match, power can be too low when factories need it most.

These issues can hurt equipment and slow down work. For example, frequency changes can break machines and stop jobs. Voltage drops can make machines stop or not work right. Blackouts can cause long breaks and lost work time.

Impact of Grid Instability | Description |

|---|---|

Frequency Fluctuations | Can break equipment and stop work. |

Voltage Drops | Can make machines stop or not work right. |

Blackouts | Cause long breaks and lost work time. |

The blackout in Spain in April 2025 showed why stable grids are important. Factories lost power and could not work. This event shows we need strong ways to protect industrial systems.

Why Traditional Motors Fall Short

Many factories use traditional motors for their machines. These motors have trouble when the grid is unstable. They cannot handle quick changes in voltage or frequency. When power is not steady, traditional motors can get too hot or wear out fast. This means more repairs and higher costs.

Traditional motors also cannot keep a steady speed or power factor. They do not adjust well to phase imbalances or voltage drops. Machines can stop working or make poor quality goods. Factories lose time and money because of these problems.

Honest’s team knows about these challenges. They make synchronous motors that help keep grids stable and improve power quality. Synchronous motors keep a steady speed and work well, even when power changes. These motors help factories by cutting downtime and protecting equipment. Honest’s solutions help businesses stay safe and keep working when the grid is unstable.

Synchronous Motors: The Unsung Heroes of Power Quality

A Quick Look at the Technology

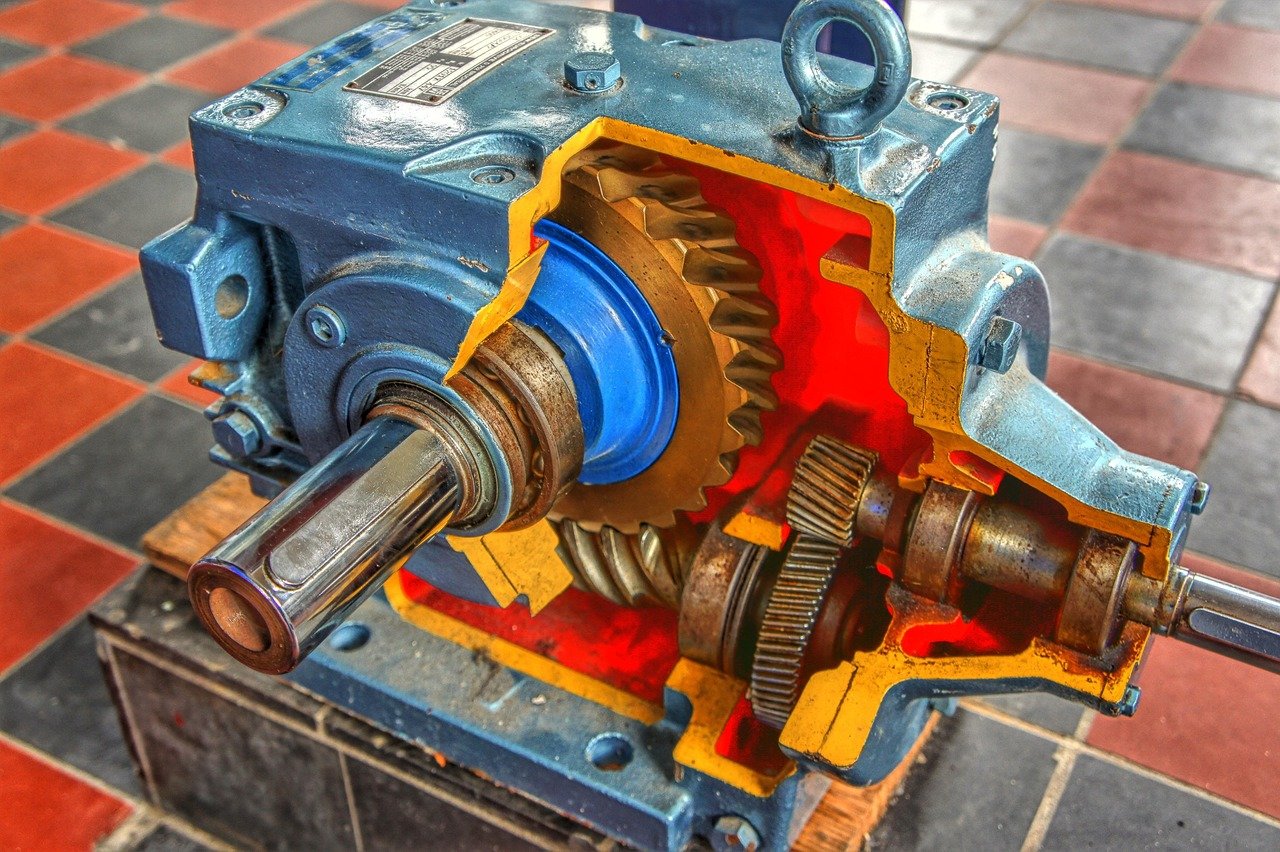

Synchronous motors are special electric motors. They always run at the same speed, even if the load changes. Induction motors slow down when they have more work to do. Synchronous motors use permanent magnets or electromagnets in their rotors. They need a power source called excitation to work. This design helps them save energy and gives better control.

Here is a table that shows how synchronous motors and induction motors are different:

Feature | Synchronous Motors | Induction Motors |

|---|---|---|

Speed | Keeps the same speed | Slows down with more load |

Rotor Type | Uses permanent magnet or electromagnet | Uses squirrel cage or wound rotor |

Excitation | Needs outside excitation | Does not need outside excitation |

Power Factor | Can change (lagging or unity) | Always lagging, cannot change |

Efficiency | Works better, especially at low speeds | Not as good at saving energy |

Key Benefits for the Grid

Synchronous motors help fix grid problems in many ways. They can change their power factor by adjusting the excitation current. This lets them work at lagging, leading, or unity power factor. When the grid needs help, these motors give extra reactive power. This keeps voltage steady and the system balanced.

Synchronous motors give these main benefits:

They fix the power factor by changing excitation.

They keep voltage steady during dips to protect machines.

They can make or take in reactive power when needed.

Synchronous condensers are special synchronous motors that run with no load. They give the grid just the right amount of reactive power. Capacitor banks always give the same amount, but synchronous motors can change their output. This makes them very helpful in today’s power systems.

Factories that use synchronous motors have fewer voltage drops and less downtime. These motors help machines work well, even when the grid changes suddenly. This helps industries avoid losing money from grid problems.

Real-World Applications in Brazil’s Industries

Heavy Industry & Mining

Heavy industry and mining need steady power to work well. Synchronous motors are very important in these jobs. Many companies in Acre use synchronous condensers. These help keep voltage steady and lower the need for thermal generation. This technology makes the grid stronger, even far from cities.

Project Description | Location | Results Achieved |

|---|---|---|

Installation of synchronous condensers to stabilize voltage and reduce thermal generation reliance | Acre | Better grid stability, fewer blackouts, and more renewable energy use |

Synchronous condensers keep voltage steady where energy supply changes.

They help lower the need for thermal generation in faraway places.

This technology helps use more solar and wind energy.

Renewable Energy Integration

Brazil’s power grid is changing quickly. Wind and solar energy are growing fast. These sources can make the grid unstable when they change. Synchronous motors, like synchronous condensers, help fix this. They add strength and help keep frequency and voltage steady.

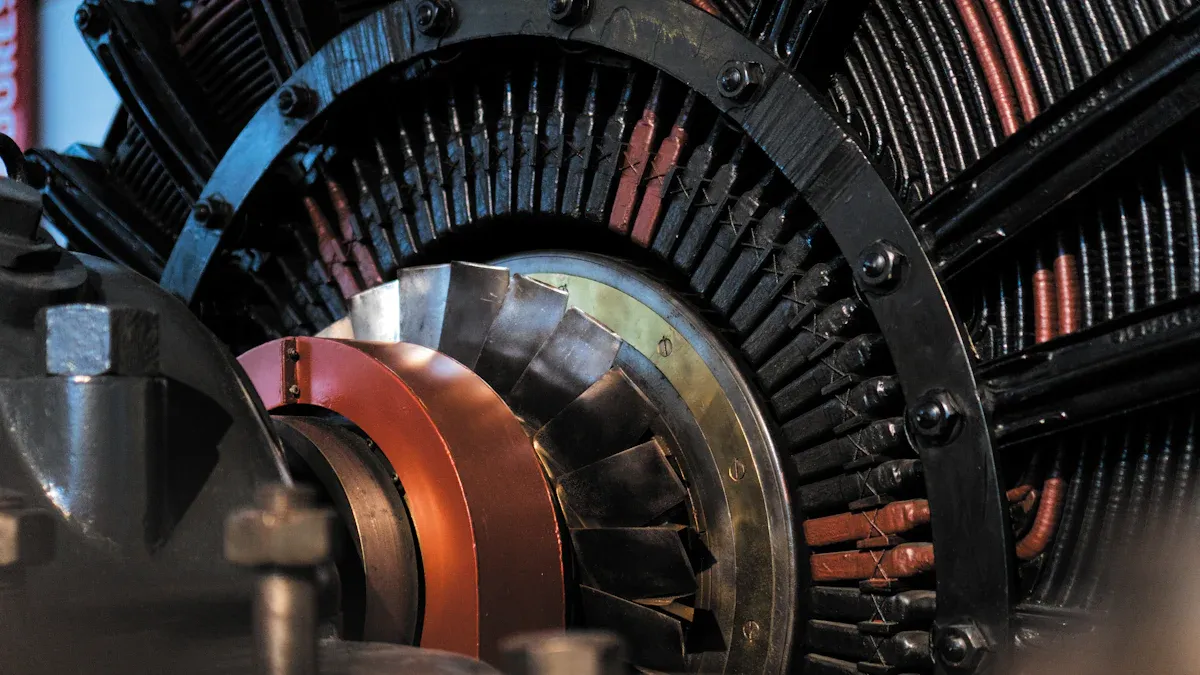

Synchronous motors are used in hydroelectric and wind power plants. These motors act like shock absorbers for the grid. They help keep frequency and voltage at safe levels. This is important as more renewable energy is used. Synchronous condensers have helped the grid since the early 1900s. Their job is even more important now as Brazil uses more inverter-based resources.

Evidence Type | Description |

|---|---|

Increasing Adoption | Synchronous motors are used a lot in hydroelectric and wind power plants in Brazil. These are big parts of the country’s energy system. |

Manufacturing & Automation

Factories in Brazil use synchronous motors for accuracy and dependability. Places like São Paulo and Santa Catarina use many encoders. Lots of factories and good digital systems help this happen.

Manufacturing, healthcare, and energy are very creative.

More people in cities and higher demand mean better motor solutions are needed.

The government helps with new technology and supports sustainability.

Synchronous motors help factories work better. They make products better and cut down on stops. These motors help with automation and smart factories, making Brazil’s industries stronger.

Choosing the Right Solution

What to Look For

Picking a synchronous motor for a factory needs careful thinking. Engineers and managers look at many things before choosing.

The motor speed should fit what the job needs.

Power needs help pick the right size motor.

Voltage and current ratings keep things safe.

Load details show how the motor works in different cases.

Efficiency and power factor help save energy and support the grid.

The motor type, like surface or salient pole, is for special jobs.

The environment matters, like heat, wetness, and dust.

Good care and long life help the motor last many years.

Synchronous motors and asynchronous motors are good at different things. The table below shows how they help with grid stability and power quality:

Feature | Synchronous Motor | Asynchronous Motor |

|---|---|---|

Speed Regulation | Constant at all loads | Decreases with load |

Power Factor | Adjustable (leading/lagging) | Lagging only |

Synchronous motors are best for places that need steady speed and good power quality. They keep working well when voltage drops and help the power factor. Asynchronous motors cost less and are easier to fix, but their electric energy is not as good. Synchronous motors are better for jobs that last a long time and help keep the grid strong.

The Value of Customization

Making motors fit the job helps factories get more from them. Companies can upgrade old systems to save money and time. Special upgrades work for pumps, compressors, and motor generator sets. Choices include brush and brushless systems and AC motor protection relays.

Custom motors help make the grid stronger. The table below shows important features and what they do:

Feature | Benefit |

|---|---|

High Efficiency | Reduces losses in energy transition |

Reactive Power Production | Stabilizes renewable-heavy electrical grids |

Inherent Short-Circuit Power | Provides stability during faults |

Controlled Reactive Power | Enhances grid reliability |

Motors with custom parts work better and last longer. They help the grid by making reactive power and keeping voltage steady. Factories that use custom motors have fewer power problems and better results. Custom motors make sure each job gets what it needs, so the system is stronger and more reliable.

Synchronous motors are very important for keeping Brazil’s power grid steady. They also help factories work better. These motors give the grid strong support and help save energy. They have high inertia and can give or take reactive power.

Recommendation | Benefits |

|---|---|

Use of synchronous condensers | Helps keep the grid steady and gives reactive power |

Integration with renewables | Keeps the grid stable when fossil plants close |

Industries can get up to 99% efficiency with these motors. They also lose less energy. Some people think the grid has endless energy, but that is not true. Companies should talk to experts to find the best synchronous motor for their needs. This helps them do well for a long time.For a tailored solution, contact the experts at Honest today.

FAQ

What is grid instability?

Grid instability happens when power supply and demand do not match. This can make voltage go up or down. Sometimes, it causes blackouts. Machines and equipment can get damaged. Factories need steady grids to keep machines safe.

How do synchronous motors improve power quality?

Synchronous motors control speed and power factor. They help keep voltage balanced. These motors lower energy loss. Factories use them to protect equipment. They also help cut down on downtime.

Where are synchronous motors used in Brazil?

Heavy industry and mining use synchronous motors. Renewable energy and manufacturing use them too. These motors help keep power steady. They also support automation in factories.

Can synchronous motors work with renewable energy?

Yes. Synchronous motors help grids with wind and solar power. They give reactive power when needed. These motors keep voltage steady when energy changes.

What should companies consider when choosing a synchronous motor?

Companies should look at speed and power needs. They should check voltage ratings and the environment. Custom motors work better for special jobs. They give more efficiency and reliability.

Tip: Honest’s experts help businesses pick the best motor for their needs.