Choosing the right motor affects how well a system works. Motors use about 70% of energy in factories. This makes them very important for saving energy. High-Efficiency Motors help make machines more accurate and reliable. Servo motors use feedback devices to control movement. They also use closed-loop control for exact position control. Honest gives custom, energy-saving solutions. These include synchronous motors, asynchronous motors, gearmotors, and brushless DC motors.

Key Takeaways

-

Select motors that match the speed, torque, and accuracy required for your application to improve performance and longevity.

-

Consider environmental factors such as heat, moisture, dust, and vibration, and take protective measures to extend motor life.

-

Ensure the motor’s voltage and power specifications align with your system to prevent overheating and save energy.

-

Select the motor type that best fits your speed, torque, and accuracy needs, considering common options such as brushless DC, synchronous, asynchronous, or gearmotors.

Performance Needs

Speed and Torque

Motors in precision automation need the right speed and torque for each job. Speed shows how fast the motor spins. Torque is the force the motor uses to move things. If a motor goes faster, it often has less torque. Heavy loads need high torque at slow speeds. Robotic arms and lifting machines need strong torque to move heavy stuff. Assembly lines that move small parts quickly need more speed but less torque.

-

Fast response times help machines finish tasks quickly.

-

High torque helps with tough jobs.

-

Changing speed and torque lets machines handle different loads.

-

Engineers use gearboxes or special motors to get more torque at slow speeds.

-

Advanced controls help motors give the right torque at any speed.

The table below shows common torque and speed ranges for motors in high-precision automation:

|

Motor Series Type |

Torque Range (Nm) |

Speed Range (rpm) |

|---|---|---|

|

Frameless Direct Drive Torque Motors |

0.025 to 50 |

4000 to 5000 |

|

Housed Direct Drive Torque Motors |

0.25 to 200 |

60 to 530 |

Picking the right motor means matching these numbers to the job.

Accuracy and Duty Cycle

Precision automation needs motors that can place parts very accurately. Some motors, like stepper motors, can move as close as 0.001 degrees. This accuracy is important for robotic assembly, CNC machining, and pick-and-place jobs. High accuracy means fewer mistakes and better products.

-

Very accurate positioning, sometimes down to tiny levels.

-

Reliable work even when used a lot.

-

Less noise for quiet places.

-

Small size fits in tight spaces.

Duty cycle tells how long a motor works before resting. If a motor runs too long without stopping, it can get too hot and break faster. Picking a motor with the right duty cycle helps stop overheating and keeps machines working well. Motors made for nonstop work are best for jobs that never stop. Motors made for on-and-off work are good for machines that start and stop often. Matching the duty cycle to the job keeps the motor safe and working right.

Environment Factors

Temperature and Humidity

Temperature and humidity can change how motors work. Hot weather makes motors get even hotter inside. When motors heat up, they lose some power. If the temperature goes up by 5°C, torque can drop by 1–2%. This means the motor does not work as well. It can also break sooner. Heat can hurt the insulation inside the motor. This makes the motor less safe and less strong.

Cold weather can make motor parts hard and easy to break. If parts get brittle, they might crack. Humid air is also a problem for motors. Water in the air can get inside and cause rust. Rust can hurt bearings and electrical parts. This makes the motor less reliable. Engineers use stainless steel and special coatings to help. Sealed motors keep out water and things that cause rust. Cooling systems and strong insulation help motors work in tough places.

Tip: Keeping motors cool and sealed helps them last longer and work better in hot or wet places.

Dust and Vibration

Dust and vibration can cause many problems for motors. Dust can get inside and wear down bearings and gears. It can block cooling paths and make motors too hot. Vibration shakes the motor and can move parts out of place. Over time, this can break the motor. Both dust and vibration make motors less accurate and less reliable.

-

Use motors with tight covers, like TEFC, to keep out dust.

-

Put motors on flat, steady surfaces to stop shaking.

-

Use pads under motors to help with vibration.

-

Keep motors away from big machines that shake a lot.

-

Cover motors to stop dust and dirt from getting in.

-

Use sensors to watch motors and find problems early.

Cleaning and storing motors the right way helps them stay cool and work well. Doing these things keeps motors running, even in tough places.

Power and Compatibility

Voltage and Supply

To pick the right motor, check the voltage and power supply first. Motors work best when their voltage and current match the system. If the voltage is wrong, motors can get too hot or not work well. Engineers look at some important things:

-

Motors need to fit the voltage and current of the power supply.

-

The power rating should be right for the job to stop overload.

-

AC motors need the correct frequency to run well.

-

Motors must handle high power when starting up.

-

The motor should work with control systems for exact jobs.

-

Matching the power supply saves energy and money.

-

Safety matters, especially with high-voltage motors.

Factory power supplies must give steady, clean current. They need to handle sudden power spikes, like when motors start. Many systems use wide voltage ranges, like 100–240 V for single-phase or 100–500 V for three-phase. Good power supplies keep voltage steady and safe. They also protect against too much voltage, short circuits, and overheating. Meeting safety and electromagnetic rules keeps systems safe and strong. Some power supplies, like switched-mode types, are very efficient and react fast to changes.

Note: Keeping voltage steady and having good protection helps motors last longer and work better in hard places.

Integration with Control Systems

Motors in automation must work well with control systems. Smart controllers and relays help run motors and keep equipment safe. Variable Frequency Drives (VFDs) read motor data and help with repairs. These devices must use the same communication rules as the rest of the system.

-

Motor Control Centers (MCCs) use communication buses to make wiring easier and more reliable.

-

Picking the right bus, like Modbus, Profibus, or Ethernet, is important for the system.

-

Using motors and drives from the same brand helps stop wiring and feedback problems.

-

Software from the maker can help match motors and drives, making setup faster and better.

If motors fit with old systems, repairs are easier and cost less. Systems that can grow let you upgrade later without big changes. Fast setup and online editing help keep projects on time and stop long delays.

|

Control System Feature |

Benefit for Motor Integration |

|---|---|

|

Compatible communication |

Reliable data exchange |

|

Easier setup and fewer errors |

|

|

Supports future expansion |

|

|

Online editing |

Reduces downtime during updates |

Tip: Matching motors with control systems helps them run smoothly, makes repairs easier, and gives better results for a long time.

High-Efficiency Motors Selection

Motor Types

Picking the right motor type is very important. Each motor type works best for certain jobs. Here are the main types of high-efficiency motors used in precision automation:

-

Brushless DC (BLDC) Motors use electronic control instead of brushes. They are quiet, last a long time, and need little care. BLDC motors are good for robotics, CNC machines, and 3D printers.

-

Servo Motors give very exact control over speed and position. They are great for robotic arms and machines that need to move just right.

-

Stepper Motors move in tiny steps. They are good for jobs where parts must move to exact spots, like 3D printers and pick-and-place machines.

-

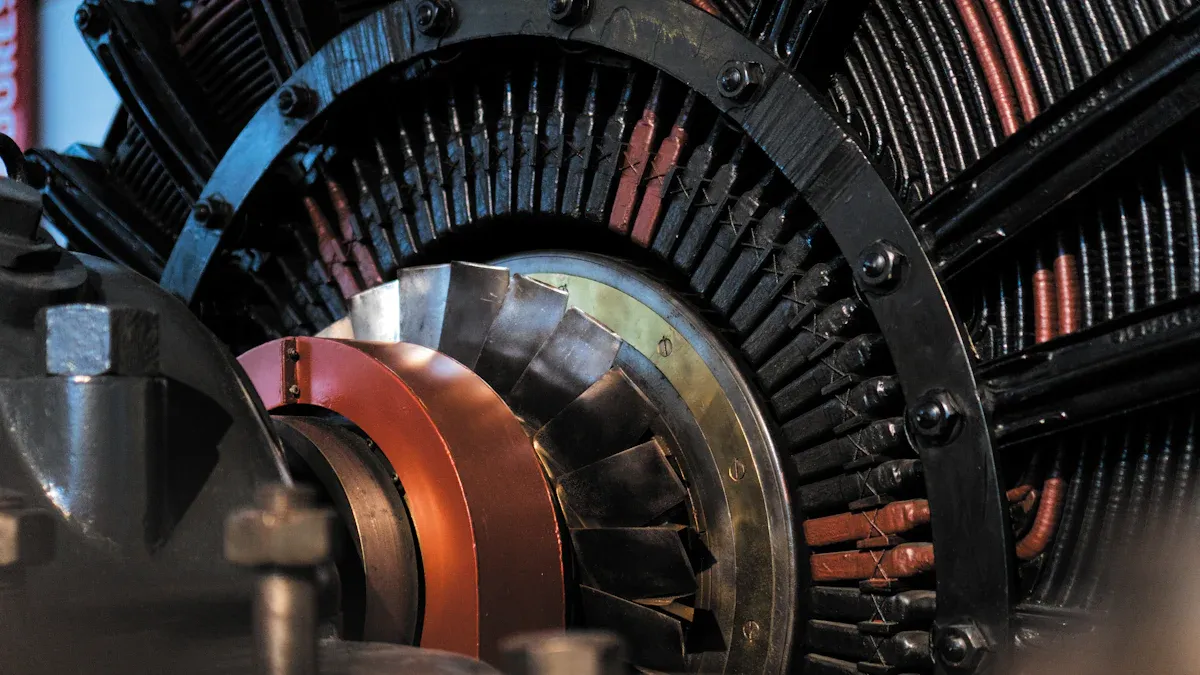

Induction Motors (Asynchronous Motors) are strong and dependable. They work well where lots of power is needed and can handle heavy loads.

-

Synchronous Motors can be very efficient. They keep a steady speed and give strong torque, even at low speeds.

-

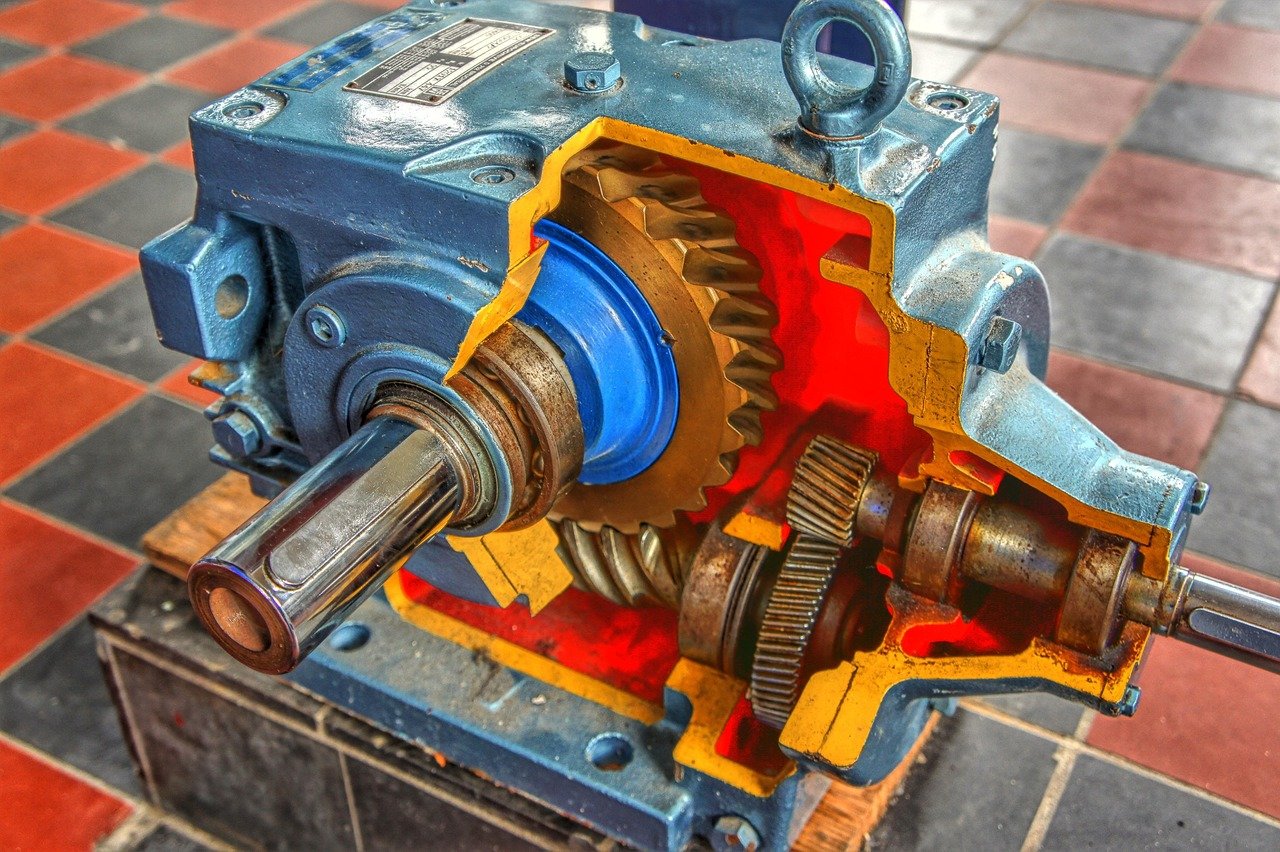

Gearmotors have built-in gears. They help give more torque in small spaces and are useful when machines need more force but less speed.

The table below shows how efficient these motor types are and what makes them special:

|

Motor Type |

Key Characteristics Relevant to Precision Automation |

|

|---|---|---|

|

Brushed DC Motors |

75 – 80 |

Lower efficiency due to brush friction; less suitable for high precision |

|

Brushless DC Motors |

85 – 90 |

High efficiency, low maintenance, precise control, longer lifespan |

|

90 – 93 |

Robust, high torque, commonly used in industrial automation |

|

|

Synchronous Motors |

Up to 99 |

Near-perfect efficiency, compact design, superior torque at low speeds |

Suitability for Precision Automation

The best high-efficiency motors depend on what the job needs. Some jobs need very exact movement. Others need more power or must fit in small spaces. Honest has many motor solutions to fit these needs.

|

Motor Type |

Efficiency Range (%) |

Torque Characteristics |

Speed Control & Precision |

Maintenance Requirements |

Noise Levels |

Size Constraints |

Typical Applications |

|---|---|---|---|---|---|---|---|

|

Brushless DC Motors |

85 – 90 |

Moderate max torque, low ripple |

High precision, smooth motion |

Low maintenance |

Quiet |

Compact |

Robotics, precision automation |

|

Synchronous Motors |

Up to 99 |

High efficiency, precise speed synchronization |

Very precise speed control |

Moderate maintenance |

Moderate |

Moderate |

Energy-saving, precise speed tasks |

|

Asynchronous Motors |

90 – 93 |

Robust, efficient |

Moderate control |

Low maintenance |

Moderate |

Larger |

General industrial automation |

|

Gearmotors |

Varies (depends on motor) |

Torque multiplication in limited space |

Depends on motor type |

Maintenance depends on motor and gearbox |

Varies |

Compact (due to gearing) |

Applications needing high torque in small space |

-

Brushless DC motors are known for being efficient, quiet, and easy to control. They are a top pick for robotics, medical devices, and smart home equipment where smooth and steady motion matters.

-

Synchronous motors save the most energy and keep a steady speed. They are good for machines that need exact speed and strong torque, like textile machines and pumps.

-

Asynchronous (induction) motors are tough and reliable. They are used in factories for jobs that need lots of power but not very exact speed control.

-

Gearmotors are helpful when machines need more torque in a small space. They mix a motor and gearbox, so they work well for conveyor belts and packaging machines.

Honest’s high-efficiency motors meet or beat global standards like IE3 and IE4. Their motors use new technology, like variable frequency drives, to save energy and match speed to what is needed. This can lower energy use by 20-30% or more. Honest also has custom features like protection from rust, explosion-proof design, and quiet running. These features help their motors work well in hard places, from factories to hospitals and smart homes.

Tip: Custom high-efficiency motors from Honest can make machines more accurate, save energy, and need less care. This means better products, lower costs, and less harm to the environment.

Honest’s motors help many industries:

-

Industrial automation: Motors for conveyor systems, valve control, and textile machines give exact control and last a long time.

-

Medical equipment: Quiet, reliable motors run oxygen concentrators, medical beds, and MRI cooling pumps to keep patients safe and comfortable.

-

Smart home applications: Energy-saving motors power air conditioners, dryers, and coffee grinders quietly and efficiently.

By picking the right high-efficiency motors for each job, companies can work faster, save energy, and keep machines running well.

Cost and Efficiency

Total Cost of Ownership

Picking a motor is about more than just the price. Companies need to think about all the costs over time. This is called the total cost of ownership. It includes many things:

-

The first cost is buying and setting up the motor.

-

Maintenance costs mean paying for parts, work, and training.

-

Running the motor uses energy and adds to bills.

-

Some motors let you add more machines later without big costs.

-

Getting and installing the motor can take time and be tricky.

-

Saving energy is important, like using special drives and gears.

High-Efficiency Motors may cost more at first, but they save money later. They work well even when not used at full power, down to 20%. If a motor runs below this, picking the right size helps save energy. Using special drives can cut energy use in half. This lowers the cost to run the motor. These motors also need less fixing. Brushless DC motors last longer and are quieter than brushed ones. They help stop breakdowns and keep work going. Companies spend less on repairs and new motors.

Picking the best motor means paying more at first but saving money later. This makes the system cheaper and more dependable.

Energy Savings

Saving energy is very important in automation. High-Efficiency Motors use less power. This means lower bills and helps the earth. The table below shows why these motors are good:

|

Metric |

Value/Description |

|---|---|

|

Average energy savings |

|

|

Estimated annual energy savings |

67,868 MWh/year |

|

Estimated annual cost savings |

Over US$4 million/year |

|

Payback period |

2-3 years (at ~50% motor load) |

|

Emission reductions |

44,582 tons CO2, 333 tons SO2, 122 tons NOx/year |

High-Efficiency Motors make less heat, so they last longer. They also do not need as much cooling. Special controls keep speed and force steady, so they work better. Some power companies give money back if you buy these motors. This helps with the first cost. These motors often meet tough rules, like NEMA Premium. This helps companies be more green. Using less energy and lasting longer saves money and helps the planet.

Picking High-Efficiency Motors for precision automation takes a few steps. First, engineers need to know how the machine should move. They look at how heavy the load is and how fast it must go. Next, they compare different motor types to see which works best. They also make sure the motor’s inertia matches the job. Engineers check if the motor fits with the rest of the system. They pick the right drivers and think about friction in the system.

Honest’s experts help companies skip mistakes and find special answers for fields like robotics, pumps, and cars.

Quick Checklist for Motor Selection:

-

Know what kind of motion and accuracy you need

-

Look at speed, torque, and how much weight the motor moves

-

Compare motor types and how well they save energy

-

Make sure the motor works with your system

-

Ask Honest for help with custom solutions

FAQ

What is a high-efficiency motor?

A high-efficiency motor uses less energy than a regular motor. It does the same job but saves power. It stays cooler and lasts longer. This helps save money on electric bills.

Tip: Honest’s motors follow world energy rules for top efficiency.

How does Honest help with custom motor solutions?

Honest’s engineers talk to customers about what they need. They make motors that fit special jobs. They give choices for size, power, and protection. This helps machines work better in many industries.

Which motor type works best for robotics?

Brushless DC motors are best for robots. They move smoothly and are very accurate. They are also quiet. Honest’s brushless motors help robots move just right.

|

Motor Type |

Best Use |

|---|---|

|

Brushless DC |

Robotics |

|

Synchronous |

Pumps, textile |

|

Induction |

Factories |

How can companies save energy with motors?

Companies save energy by picking motors with high efficiency. Using variable frequency drives helps too. Choosing the right size motor for the job also saves power. Honest’s motors can cut energy use by up to 30%.

Note: Saving energy means lower costs and helps the planet.