In today’s tough market, you must balance costs and performance. Choosing the right motor is very important. Brushless motors often get a lot of attention. However, picking between Brushed vs. Brushless motors can significantly impact your budget. Knowing when to choose the more affordable Brushed DC motor is key. This helps improve your product design and save money.

Key Takeaways

Brushed motors cost less to buy and install. This makes them great for projects with tight budgets.

Brushless motors work better and last longer. This can help save money on repairs later.

Use brushed motors for tasks that need easy control. They are good when high efficiency is not very important.

Pick brushless motors for projects that need exact control. They are also quieter and need less maintenance.

Think about all costs, like installation and care, when choosing between brushed and brushless motors.

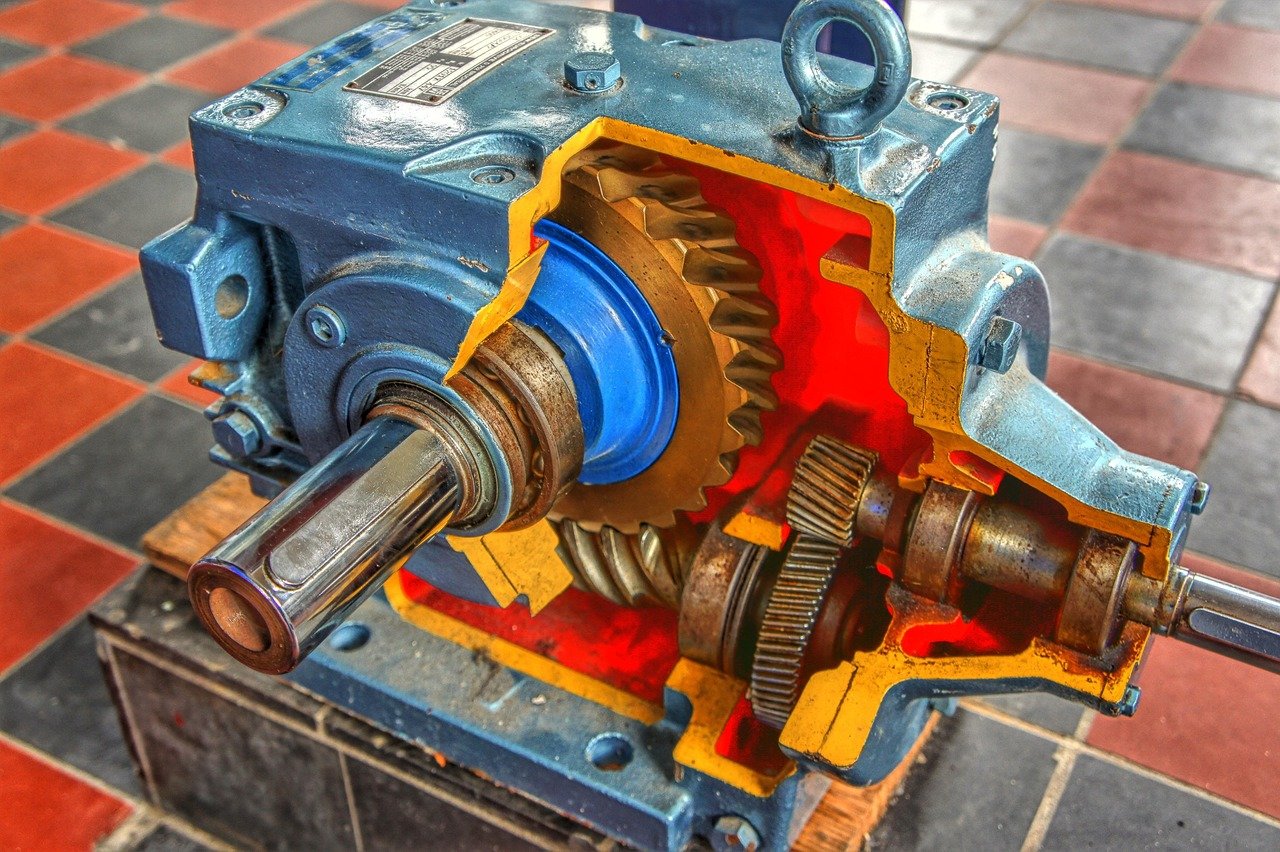

Brushed vs. Brushless: Performance & Cost Comparison

Cost Analysis

When you look at the costs of Brushed vs. Brushless motors, you’ll find that Brushed DC motors are usually cheaper to make and buy, while Brushless DC motors have a higher initial price point. This is because Brushed motors have a lower price at first, but Brushless motors need extra electronic parts, which raise their starting costs.

You should also think about the total costs, like installation and upkeep. The table below shows the starting purchase costs and long-term maintenance costs:

Cost Component | Brushed DC Motor | Brushless DC Motor |

|---|---|---|

Motor Unit | $50-200 | $100-400 |

Controller | Simple ($20-50) | ESC Required ($50-150) |

Installation | Standard | Slightly complex |

$70-250 | $150-550 |

Brushed motors need regular maintenance, like changing brushes every 500-1,000 hours. This can cost between $20-50 each time. On the other hand, Brushless motors do not need this kind of maintenance, which means lower long-term costs.

Performance Comparison

For performance, Brushless motors usually work better than Brushed motors. Brushless motors have higher efficiency ratings, turning 85-90% of electrical energy into mechanical energy. Brushed motors usually have efficiency ratings of 75-80%.

Motor Type | Efficiency Rating |

|---|---|

Brushed DC | 75–80% |

Brushless DC | 85–90% |

Also, Brushless motors last longer, often for tens of thousands of hours. In contrast, Brushed motors usually last between 1,000 to 3,000 hours. This difference in lifespan can greatly affect your total costs and performance over time.

The Practical Guide: Making the Smart Choice

Choosing between a brushed and brushless motor can be tough. Here’s a simple guide to help you decide.

When to Choose a Brushed Motor

Think about a brushed motor when cost is most important. These motors usually cost less to buy and install. They work well where high efficiency is not needed. Common uses are:

ATM machines

Consumer electronics and toys

Electronic locks

Industrial automation

Medical devices and equipment

Small electrical appliances

Recreational electronics

Vending machines

Brushed motors are good for products that need simple control and often change loads. But remember, they need regular maintenance because of brush wear.

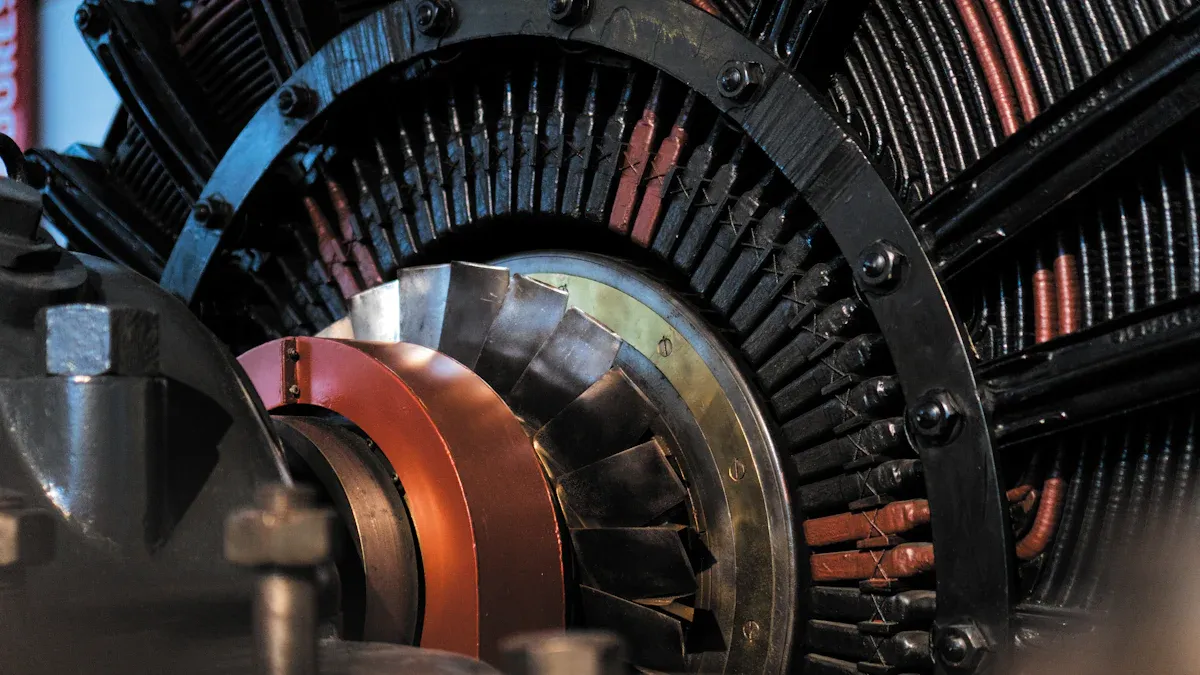

When to Choose a Brushless Motor

Choose a brushless motor when you want high efficiency and a longer lifespan. These motors are great for applications needing precise control and little maintenance. They are best for:

Medical devices (like surgical tools)

Consumer electronics (such as electric toothbrushes)

Automotive applications (including hybrid and electric cars)

Industrial automation (robotic arms and 3D printers)

Brushless motors run quietly and efficiently, making them great for sensitive places. They also lower electromagnetic noise, which helps equipment work better.

Application Examples

Here are some examples of how each motor type fits into different uses:

Brushed DC Motors: Often used in vending machines and ticket dispensers, these motors give reliable performance at a lower cost.

Brushless DC Motors: The Inner Rotor Brushless DC Motor is great for drones and fans, where quick speed changes are needed. The Outer Rotor Brushless DC Motor is good for high torque uses, like electric bikes and industrial machines.

By knowing the strengths of each motor type, you can make smart choices that fit your product’s needs and budget.

From Selection to Implementation

Choosing a motor for your product is very important. At Honest, we aim to give you the best solutions for your needs. We make sure you get the right motor, whether it is brushed or brushless.

Our Professional Expertise

Motor Selection Assessment

Our R&D team works closely with you to create custom solutions. This teamwork is key for picking the right motor for your projects. Here’s how we do it:

We listen to what you need.

We look at the application to find the best motor type.

We focus on being flexible and adaptable in our products.

This way, we can create solutions that fit your unique needs.

Professional Project Analysis

We carefully analyze your project to ensure it works well. This includes:

Checking voltage needs to match your appliance.

Looking at speed and torque to handle expected loads.

Considering size and weight to fit your appliance design.

Reviewing the duty cycle to make sure the motor meets your needs.

By focusing on these points, we help you avoid common mistakes in motor selection.

Optimal Business Decisions

Making smart choices is important for your business. Our knowledge helps you balance cost and reliability. We guide you to think about the total cost of ownership, which includes energy use, maintenance, and possible downtime costs. Efficient motors can lower electricity bills, while regular maintenance helps them last longer.

A Seamless Partnership

At Honest, we believe in working together with you from selection to implementation. Our promise to provide custom solutions means you get support throughout the process.

Clients value our expertise and support, saying we are with them every step.

Many clients thank us for our clear communication, which helps the selection process go smoothly.

Our teamwork helps you handle the challenges of motor selection and implementation.

By choosing Honest, you get a partner who cares about your success. Our custom motor solutions use advanced technologies, improving power density and cooling efficiency. This leads to motors that are smaller, lighter, and quieter, giving better performance than traditional motors.

Choosing the right motor for your project is very important, as there’s no one “best” motor for everyone; you must weigh what works best for your specific needs. This choice requires balancing efficiency, maintenance, noise, cost, and control capabilities.

For help ensuring you select the motor that fits your budget and technical requirements best, reach out to our expert team. We can assist you in finding the right solution.

FAQ

What is the main difference between brushed and brushless motors?

Brushed motors use carbon brushes to work, while brushless motors use electronic controllers. This change affects how well they work, how much care they need, and how long they last.

How do I choose the right motor for my application?

Think about things like cost, efficiency, maintenance needs, and what you need the motor for. Look at your specific needs to see if a brushed or brushless motor is better.

Are brushed motors more affordable than brushless motors?

Yes, brushed motors usually cost less at first. But, think about long-term maintenance costs because brushed motors need more care than brushless ones.

How long do brushed and brushless motors last?

Brushed motors last about 1,000 to 3,000 hours. On the other hand, brushless motors can last for tens of thousands of hours because they do not have brushes.

Can I use a brushless motor in place of a brushed motor?

You can, but make sure your application can support the electronic controller that brushless motors need. Check if it works with your current systems before switching.