Choosing the right OEM motor manufacturer helps industrial applications perform reliably over the long term. Effective collaboration with your supplier strengthens partnerships and improves outcomes, as demonstrated in the table below:

Evidence Type | Description |

|---|---|

Correlation | There is a strong link between working together and having a good partnership for a long time. |

Coefficient | The Align number is positive and very important at the 1% level. This means working closely together helps partnerships last longer. |

Performance | Suppliers do better when they work closely with you. This makes them want to keep helping you even when sales go down. |

You may have problems like not enough skilled workers, supply chain issues, and checking quality. Many companies only look at price, but working well together and having a good partnership matter more. OEM motor solutions help you solve these problems and keep your business running well.

Key Takeaways

Decide what technical needs you have before picking a supplier. This helps you find a partner who fits your needs.

Choose suppliers who have worked in your industry before. Their experience can help you avoid problems. It also helps make sure your motors work well.

Make sure the supplier has the right certifications. This shows they follow the rules and make good products.

Good communication with your supplier is important. Talking openly builds trust and makes your partnership stronger.

Think about if the supplier can customize products for you. A supplier who can do this helps your business change and grow.

Defining Technical Requirements

Before you pick a supplier, you must know what you need. This step helps you set clear rules for making choices. It makes sure you find the right partner for your business. Honest gives custom solutions for many industries. This makes it easier to match your needs with the right product.

Technical Needs

Start by writing down your technical needs. Every project is different, so you must know what matters most. Common needs for OEM motors in factories are:

Reliability means less downtime and fewer repairs.

Design flexibility lets you use motors in many ways.

Low noise levels are important in busy places.

Honest’s custom approach lets you get motors that fit your needs. You can work with their team to change features, size, and how the motor works.

Compliance & Certifications

You must make sure your supplier follows all rules. Certifications show a company does things the right way and makes good products. The most important certifications for OEM motor suppliers are:

Certification | Description |

|---|---|

A rule for quality management in car making, made by the International Automotive Task Force. | |

ISO 9001 | Sets rules for a quality system, showing better customer service and relationships. |

ISO 14001 | A global rule for caring for the environment, helping companies do less harm. |

Honest’s factories meet these rules. This helps make motors in a way that is good for the planet and helps you follow the rules.

Volume & Scalability

Think about how much you want to order and if you might need more later. The supplier selection matrix should include volume as a key rule. In car making, order sizes can change fast. Top suppliers use smart systems to track demand and stop shortages. Honest can make more or fewer motors to fit your needs. They offer custom solutions for big and small orders. This helps you avoid problems and find new ways to grow.

Tip: Always check your needs before you talk to suppliers. Clear goals help you choose faster and better.

Identifying OEM Motor Solutions

When you look for oem motor solutions, pick suppliers who know your industry. This helps you avoid mistakes and makes sure your motors work well.

Industry Experience

Find suppliers who have worked with businesses like yours. You want a partner who knows your problems and can help. Honest has helped over 20 industries, like medical equipment and smart home devices. Their team knows how to fix problems in many fields. If you pick oem motor solutions from an experienced supplier, you get motors that fit your needs.

Tip: Ask for stories or references from similar jobs. This shows if the supplier can give you what you need.

Customization Capabilities

Every business is different. Check if the supplier can change motors for your project. Honest can customize gearmotors and AC or DC motor options. Their engineers can change features, size, and how the motor works. With oem motor solutions, you get motors that make your systems better.

Think about how many motors you need

Look at the price and payment rules

See if the supplier can change plans fast

Product Portfolio & Technology

A big product range gives you more choices. Honest has asynchronous motors (single- and three-phase), brushed DC motors, brushless DC motors (inner/outer rotor), synchronous motors, universal motors, geared motors (DC & interaction), and electric actuators. These OEM motor solutions support a wide variety of industrial applications, from precision equipment to heavy-duty machinery.

Building on this diverse product range, Honest integrates the latest technologies into its motors to enhance performance. These advancements significantly improve efficiency, reduce weight, and lower material usage, making the motors suitable for a wide variety of industrial applications, including HVAC systems, robotics, medical devices, and renewable energy solutions.

Feature | Description |

|---|---|

Efficiency | Motors offer significantly improved performance and energyefficiency. |

Weight Reduction | Advanced designs reduce motor weight, improving handlingand installation. |

지속 가능성 | Optimized materials and production methods supportenvironmentally friendly use. |

Versatility | Suitable for a wide range of applications, including HVAC, e-mobility, medical devices, robotics, aerospace, and renewableenergy. |

Choosing Honest for OEM motor solutions gives you access to a wide product range and the latest technology, helping your business stay competitive and meet evolving needs.

Selecting the Right OEM Partner

Picking the right manufacturing partner is very important for your business. You need to follow steps to make a good choice. Honest cares about quality and helps you build a strong partnership that lasts a long time.

Technical Fit & Support

First, check if the manufacturing partner can meet your technical needs. Honest works with you to learn about your problems and goals. Their team listens and answers fast, so your motors fit what you want.

Honest gives special service packages based on your business.

You get digital support, so help is always there.

Honest links after-sale services to your brand, making things better.

Sharing data between Honest and your team makes work easier.

An experienced OEM motor partner helps you design and optimize products, providing solutions that enhance performance, reliability, and efficiency.

Quality Systems & Reliability

Quality systems are very important for a good manufacturing partner. Honest uses strong quality checks to make sure every motor is great. You can see this in the certifications they have.

Key Components and Standards | Purpose | |

|---|---|---|

IATF 16949 | Risk-based thinking, FMEA, control plans | Make quality systems better and stop defects |

ISO 9001 | Risk management, CAPA | Follow rules and keep getting better |

Automotive QMS Software | Standardize workflows, detect defects early | Make work better and follow rules |

Honest’s risk checks and improvement plans help stop problems and make motors more reliable. You get motors that pass tough tests. This means fewer failures and smoother work.

When picking a manufacturing partner, look for these things:

Criteria | Description |

|---|---|

Strong quality checks, like ISO 9001 certification. | |

Production Capabilities | Can make enough products and handle special jobs. |

Financial Stability | Important for long partnerships and fewer problems. |

Technological Expertise | Needed for hard or new technology jobs. |

Legal and Regulatory Compliance | Follows all rules to avoid legal trouble. |

Communication Strategies | Good ways to talk for a smooth partnership. |

Honest’s way of handling quality and support makes them a good partner. Their systems help you get motors that work well and last longer.

Communication & Collaboration

Good communication and collaboration are key to successful OEM partnerships. Honest listens to your technical needs, aligns goals, and handles potential risks proactively. Their engineering and supply chain teams work with you to review designs, track progress, and solve issues before they affect production. Sharing information openly, solving problems together, and keeping regular updates help prevent delays, maintain quality, and build a strong long-term partnership.

Tip: When choosing a manufacturing partner, focus on clear communication, managing risks, and aligning goals. Make sure your partner provides technical support, timely updates, and flexible solutions to keep operations running smoothly.

OEM Custom Motor Solutions

Innovation & Co-Engineering

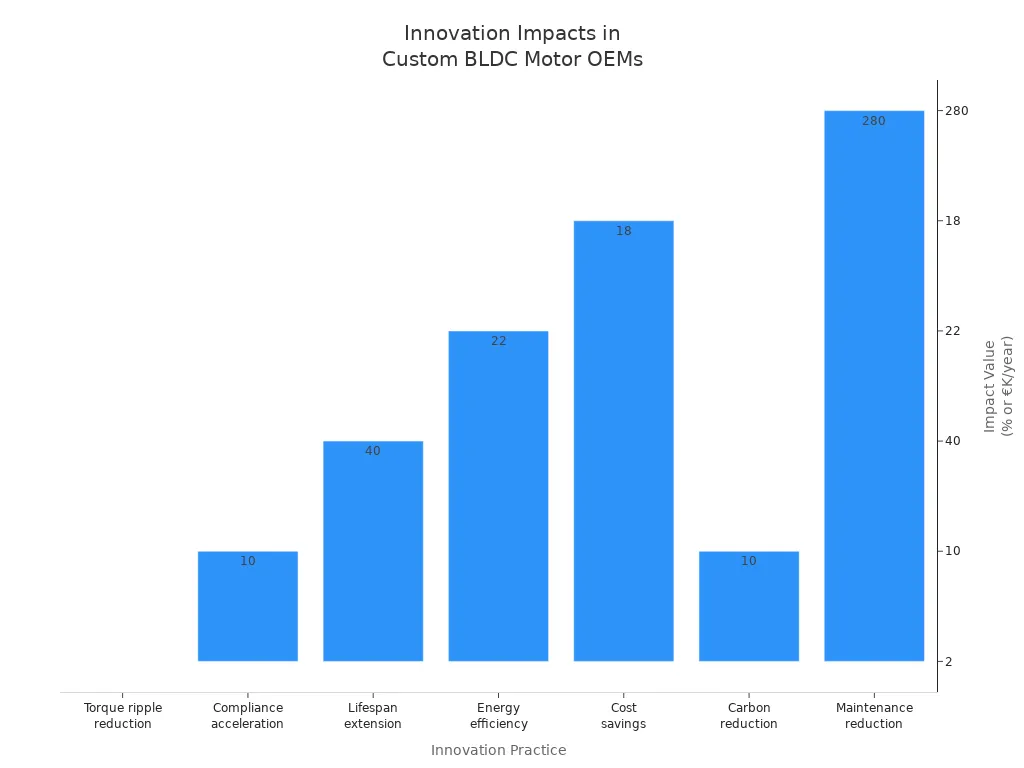

Picking an OEM custom motor manufacturer helps your business grow. You work with experts who want to reach the same goals as you. Together, you design motors that fit your needs. This teamwork brings many good things:

Advantage | Benefit |

|---|---|

Sharing research makes designs better and changes faster. | |

Risk Mitigation | Checking designs early helps you avoid problems and follow rules. |

Lifecycle Value | Special tools help your motors last longer. |

Torque-Speed Customization | Motors are made for special jobs, like robots or electric cars. |

Thermal Resilience | Motors can handle heat, so they work in tough places. |

Certification Bundling | Motors come with needed papers, so you can use them in many fields. |

Material Traceability | Using recycled parts helps you meet green rules. |

Embedded Intelligence | Smart controllers let your motors work with new systems. |

Sensorless Optimization | Fewer parts make motors work better, good for drones and robots. |

You can work closely with your OEM custom motor manufacturer by sharing ideas and using smart tools. For example, computer simulations can help improve motor performance, pre-checked certification documents speed up compliance, and specialized tools can extend motor lifespan. Taking BLDC motors as an example, you can also select specific design parameters to optimize performance for your application.

Supply Chain & Scalability Solutions

Selecting the right OEM custom motor manufacturer ensures your business can scale efficiently. Honest’s supply chain is designed to handle varying order volumes while maintaining consistent quality and on-time delivery. This flexibility helps clients respond to market fluctuations and meet production targets without disruption.

Key strategies for scalable operations include:

Strategy | Description |

|---|---|

Capable of quickly producing large quantities tomeet demand spikes. | |

Cost Optimization Through Scale | Economies of scale reduce unit costs and improveoverall project ROl. |

Supply Chain Stability | Strong supplier relationships and proactive planningminimize delays. |

Advanced Production Systems | Modern equipment ensures consistent quality evenfor large batches. |

Lean Manufacturing Excellence | Streamlined processes reduce waste and acceleratedelivery times. |

Quality at Scale | Rigorous inspections ensure every motor meetsperformance standards. |

By partnering with Honest, you gain more than just motors—you gain a supply chain capable of supporting business growth, handling order variability, and ensuring reliable, high-quality production. Their coordinated production and logistics approach provide clients with a practical advantage in complex industrial projects.

Honest Industrial OEM Motor Solutions

Honest provides tailored OEM motor solutions for a wide range of industrial applications. From automation systems to precision machinery, their motors deliver reliable performance, long service life, and smooth operation, even in demanding environments. Honest’s proven experience in industrial automation, logistics, and textile machinery ensures that solutions are practical and scalable for real-world factory settings.

Industrial Automation Solutions

Honest’s motors power conveyor belts, robotic arms, AGVs, and other factory equipment. Typical benefits include:

Seamless integration with existing machinery, reducing modification needs

Durable materials and robust design, extending motor lifespan

Smooth operation that minimizes downtime and maintenance

Efficient performance that improves overall production output

Application Showcase:

Valve Control Solutions: Explosion-proof motors from 10W to 500W, implemented for Rotork and FLOWSERVE, ensuring reliable operation in demanding environments.

Logistics & Material Handling: Over 2 million motors delivered for Interroll warehouse systems, enabling high-throughput automated operations.

Precision Motor Solutions

For high-tech or specialized machines, Honest delivers custom motors suitable for medical devices, packaging equipment, laboratory automation, and robotics. Key advantages include:

Precise speed and torque for critical operations

Reduced machine breakdowns, maintaining production schedules

Long-lasting materials and careful design for reliability

Smooth operation, lowering maintenance and replacement costs

Application Showcase:

Textile Machinery Applications: Dust-resistant motors developed for Rieter, SSM, and Barmag, engineered to withstand harsh production conditions while delivering precise, reliable performance.

By choosing Honest as your custom machinery partner, you gain a team experienced in industrial automation, logistics, and precision machinery. Their expertise ensures motors meet technical requirements, integrate seamlessly, and support long-term operational efficiency, helping your business stay productive and prepared for future challenges.

FAQ

What should you look for in a potential ems provider?

Check if they have experience and the right certificates. See if they can make custom products for you. Ask how they keep quality high and handle more orders. A good potential ems provider will help your business grow.

How does an electronic manufacturing services provider differ from a contract manufacturer?

An electronic manufacturing services provider does design, assembly, and testing. A contract manufacturer mostly makes things from your designs. You get more help and choices from an electronic manufacturing services provider.

Why is communication important with potential ems providers?

Talking clearly helps stop mistakes and delays. You can tell them what you need and get updates. Good potential ems providers listen and change their work to fit your goals.

How do you ensure quality when working with a contract manufacturer?

Check their certificates and ask about their quality checks. If you can, visit their factory. A good contract manufacturer will show test results and explain how they stop problems.