You have a significant challenge in modern farming. You need to save energy to reduce costs, but your machines must also endure the rigors of hard farm work. When it comes to motor selection, efficiency is crucial. New motors utilize superior electrical steels and innovative winding designs. Variable frequency drives enable you to manage power effectively. The table below illustrates how these advancements can benefit you daily.

Aspect | Description |

|---|---|

Efficiency Metrics | Consider power factor, full-load efficiency, and part-load performance under various conditions. |

Impact on Energy Consumption | Enhanced motor efficiency translates to lower electricity usage and reduced expenses. |

Technological Advancements | Implement high-grade electrical steels, improved winding designs, and variable frequency drives (VFDs) for optimal energy management. |

Key Takeaways

Pick motors that use less energy. This helps you save money. Electric motors can work very well. They can make your power bills lower.

Find motors with a high IP rating. These ratings protect motors from dust and water. This makes motors last longer.

Match the motor type to your farm jobs. Each machine needs its own power and speed. Make sure your motor fits your machine. This helps your machines work their best.

Choose motors that are easy to maintain and make sure the manufacturer offers reliable support. Both good maintainability and technical support will save you time and costs in the long run.

Use motors that follow energy rules. This keeps your motors safe and working well. It helps you follow the law. Your farm will run better.

The Dual Imperative: Efficiency & Durability

The Long-Term Return of Efficiency

Picking the right Motor Selection helps your farm save money over time. High-efficiency motors lower your costs and make your machines work better. Electric motors are about 90% efficient. Diesel motors only reach 30-40% efficiency. Using electric motors means you spend less on fuel and repairs. Variable frequency drives let you change motor speed. You only use the energy you need for each job. This helps you save money every month.

Your daily work gets easier, too. High-efficiency motors finish tasks faster and make your job less hard. Permanent magnet motors keep a steady speed. This helps your irrigation stay even. These motors use special materials that waste less energy. You can notice these good things in many ways:

Your electricity bills go down

You spend less time fixing machines

There are fewer breakdowns when you are busy

You make less pollution

You should pick motors that meet the best efficiency standards.

The Non-Negotiable of Durability

Durability is just as important in Motor Selection. Farm motors deal with dust, water, and very hot or cold weather. These things can make motors overheat, rust, or shake. Overheating is the main reason motors break. When insulation fails, motors short-circuit and stop. Dust and chemicals can block cooling fans. This makes motors get too hot.

Cause of Motor Failure | Description |

|---|---|

Low Resistance | Insulation damage causes short circuits. |

Overheating | High heat cuts insulation life in half for every 10°C rise. |

Contamination | Dust and chemicals block cooling and cause shaking. |

You can keep your motors safe by picking strong housing and temperature protection. Better fan designs and liquid cooling help keep motors cool. Special materials help get rid of heat. These things help your motors last longer, even when farm work is tough.

Essential Criteria for Motor Selection

Choosing the right motor for your farm equipment means looking at several important factors. You want your machines to work well, last long, and fit your needs. Let’s break down what you should consider during Motor Selection.

Matching the Application

Every farm machine has its own job. Some need to lift heavy loads, while others run for hours at a steady pace. You must match the motor to the task. Here are the main things to check:

Engine Compatibility and Integration: Make sure the motor fits your machine’s size and mounting points. It should work smoothly with your other parts.

Power and Performance Requirements: Think about how much power and torque you need. A grain auger needs different power than an irrigation pump.

Fuel Efficiency and Operating Costs: Pick motors that use less energy. This saves you money over time.

Maintenance Needs and Aftermarket Support: Choose motors that are easy to maintain. Good support from the manufacturer helps you fix problems fast.

You can see how different machines need different setups. For example, a tractor tire and a sprayer tire have different load and pressure needs. The same goes for motors. Here’s a simple table to show how requirements can change:

Equipment Type | Power Needed (kW) | Speed (RPM) | |

|---|---|---|---|

Grain Auger | 12,350 | 5 | 1,400 |

Irrigation Pump | 17,085 | 7.5 | 2,900 |

Honest offers a wide range of motors, from single-phase to three-phase, and from asynchronous to gearmotors. You can get custom solutions for any farm job. If you need a motor for a feed mixer or a water pump, Honest can match the power, speed, and mounting you need.

Tip: Always check the power and speed ratings on your equipment before Motor Selection. This helps you avoid overloads and keeps your machines running smoothly.

Environmental Protection (IP Rating)

Farm work is tough on motors. Dust, dirt, and water are everywhere. You need motors that can handle these conditions. The IP (Ingress Protection) rating tells you how well a motor resists dust and water.

Motors in farm equipment face dust, mud, and rain. You should look for motors with an IP rating of at least IP55 for reliable performance.

Higher IP ratings, like IP65 or above, give even better protection. These are best for wet or very dirty places.

Using the right IP rating keeps your motors safe, reduces repairs, and makes your machines more reliable.

With a reliable IP55 rating, Honest’s motors can be used without worry in outdoor, wet, or dusty environments. For instance, their gearmotors have a fully enclosed design that effectively prevents dust and water from getting inside.

Note: Picking the right IP rating means fewer breakdowns and less time spent on repairs.

Compliance and Global Standards

You want your equipment to meet safety and energy rules. Motors must follow certain standards to work safely and efficiently around the world. Here are some of the main standards you should know:

Standard/Certification | Description |

|---|---|

CAN/CSA C22.2 No. 25, 30, 77, 100, 145, 213 | |

UL 1004 Series | U.S. standards for electric motors. |

IEC 60034-5 | International standard for motor performance. |

10 CFR 431 subpart X | U.S. energy efficiency rules for motors. |

CAN/CSA C390-10 | Canadian energy efficiency standard for motors. |

Honest’s motors meet these global standards. You get products that are safe, efficient, and ready for use anywhere. If you need special certifications, Honest can customize motors to fit your needs.

Remember: Motors that meet global standards help you avoid legal trouble and keep your farm running safely.

Motor Technologies for Agriculture

Versatile Asynchronous Motors

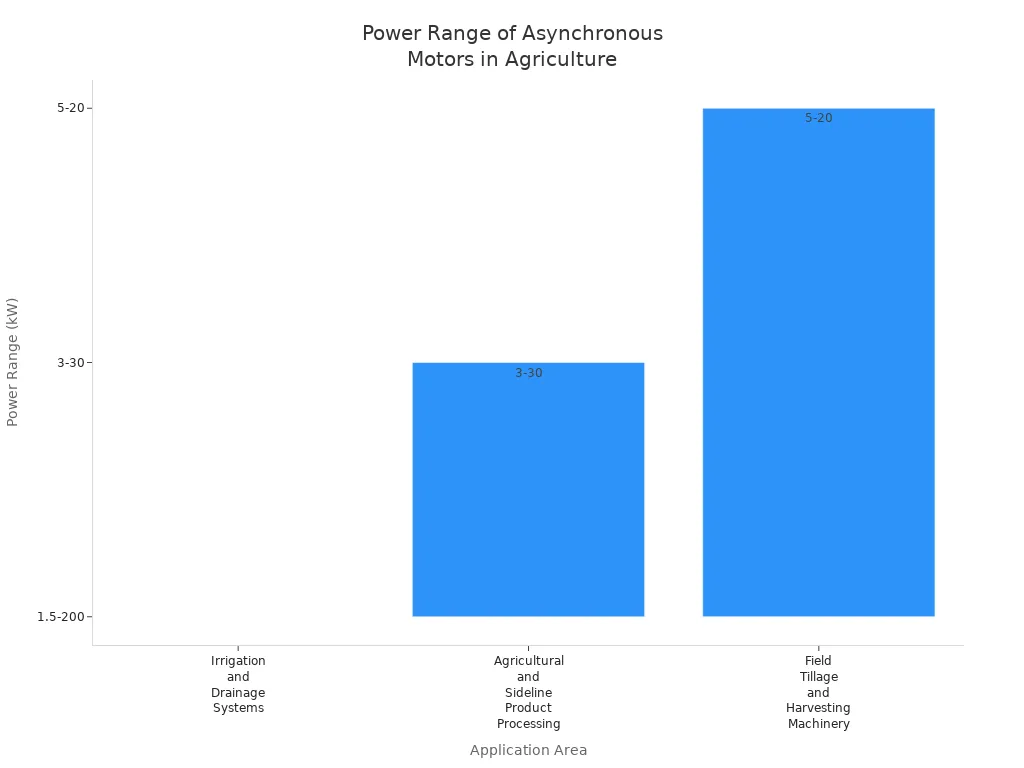

비동기 모터 are used a lot on farms. These motors are strong and simple to fix. You save money because they are cheap to buy and repair. You can change their speed with a frequency converter. This helps you do different jobs. Farmers use these motors in many machines. You see them in irrigation pumps and threshers. They are also in crushers and seed drills. These motors work well in places with dust or water. They keep working even when things get hard.

Applicable Equipment | Suitability | Power Range | |

|---|---|---|---|

Irrigation and Drainage Systems | Centrifugal pumps, submersible pumps, axial-flow pumps, mixed-flow pumps | They run all the time and do not break often. | 1.5-200 kW |

Agricultural Product Processing | Threshers, crushers, rice mills, oil presses, hay cutters | They can handle heavy loads and start and stop a lot. | 3-30 kW |

Field Tillage and Harvesting Machinery | Electric rotary tillers, seed drills, small combine harvesters | Their closed design keeps out dust and protects them. | 5-20 kW |

Facility Agriculture Equipment | Greenhouse roller shutters, ventilation fans, irrigation pumps | They work very well and do not fail much. | N/A |

Livestock Farming Machinery | Feed mixers, silage choppers, manure cleaners | They do not rust easily and give steady power. | N/A |

Tip: Asynchronous motors help you keep your farm running without stopping.

Precision with Gearmotors

Gearmotors help you control your machines better. You use them in planters to plant seeds in the right spot. This means each row gets the right amount of seeds. Gearmotors help you plant seeds even on turns. They also help move power and control speed. Gearmotors make more torque for hard jobs. This is good for mixing feed or lifting heavy things. When you pick gearmotors, check the torque. This makes sure your machines work well.

Gearmotors let you control each row in planters.

They help you plant the right number of seeds.

Gearmotors give more power for tough jobs.

You can change speed to fit the job.

The Power of Customization

Farming has many problems to solve. Custom motors help you fix these problems. You use motors in self-driving vehicles and seeders. Motors also help control water for crops. Some machines use motors to change their height. Electric actuators help tractors move and turn by themselves. Gearboxes help machines work more accurately. New ideas like solar power and smart sensors are used more now. These things make your machines work better and last longer. Smart farming uses special motors for better results. Picking motors is easier when you can choose what fits your needs.

Note: Custom motors help you use new tools and ways to farm. You can keep up with changes and do your work better.

Case Studies & Practical Selection Checklist

A Farmer’s Story: How High-Efficiency Motors Changed Their Business

The Efficient Pump: Lowering Farm Electricity Bills

You have a big vegetable farm. Your old irrigation pump used lots of electricity. It broke down many times. You wanted something better. You picked a high-efficiency asynchronous motor with an IP55 rating. This motor can handle dust and water well. You added a variable frequency drive. Now, you change the pump speed when you need more or less water. Your electricity bill went down by 20%. The new motor is quiet. It does not need much fixing. You spend more time growing vegetables. You do not fix your equipment as much.

The Rugged Harvester: Powering Through Tough Fields

A company wanted to make a harvester for muddy fields and dusty weather. You helped them pick a gearmotor with a sealed IP65 enclosure. This motor gives strong torque for heavy work. The harvester works for many hours and does not get too hot. Farmers say their machines break down less during harvest. The gearmotor helps collect crops better. The company now uses this motor in all their new harvesters.

Your Motor Selection Checklist

Use this checklist to help you pick motors for your farm:

Check what power and speed your machine needs.

Pick the motor type that fits your job (asynchronous, gearmotor, or custom).

Look for the right IP rating to protect against dust and water.

Make sure the motor follows safety and energy rules.

Ask about how to fix it and if you get help from the supplier.

Think about if you need to change the speed.

Look at the warranty and after-sales service.

Tip: Print this checklist and keep it in your workshop. It will help you every time you pick a motor.

Getting both efficiency and durability is important for your farm. The right motor helps your machines work better and last longer.

Machines that use motors help you do jobs the same way every time. This can help you grow more crops.

New machines help you use water, seeds, and power carefully.

You do not waste as much and you lose less when you work.

This guide can help you figure out what you need. If you work with a good motor company, you get help from people who know a lot. They give you strong and safe motors. This teamwork helps you pick the best motor for your farm now and later.

FAQ

What is the best motor type for farm irrigation systems?

Pick a high-efficiency asynchronous motor with IP55 or higher. This motor works well with pumps. It can handle dust and water. You save energy and have fewer breakdowns.

How do I know if a motor is energy efficient?

Check for IE3 or NEMA Premium labels. These labels mean the motor saves energy. Look at the efficiency rating on the nameplate. Bigger numbers mean you save more energy.

Why does the IP rating matter for farm motors?

The IP rating tells you how well a motor keeps out dust and water. Higher numbers mean better protection. Your equipment lasts longer and needs fewer repairs.

Can I use the same motor for different machines?

Match each motor to the job you need. Different machines need different power, speed, and torque. Using the wrong motor can break your machine or waste energy.

What support does Honest offer after I buy a motor?

Honest gives you technical support and tips for maintenance. They offer warranty service too. You can ask their team for help with installation or fixing problems. This support helps your equipment work well.