The industrial automation market is growing fast. It is expected to rise from USD 217.80 billion in 2023 to USD 434.30 billion by 2031. This growth shows that people want more precision and speed. Synchronous motors are very important for meeting these needs. Their special performance improves the accuracy and efficiency of production lines.

Key Takeaways

Synchronous motors respond faster and control better than asynchronous motors. This makes them great for tasks that need high accuracy.

These motors keep a steady speed even when the load changes. This improves performance in factory automation and boosts production efficiency.

Choosing the right synchronous motor means looking at how it works, its efficiency, and if it fits the application. This helps ensure the best performance.

Driving Precision with Synchronous Motors

Comparison to Asynchronous Motors

When you look at synchronous motors and asynchronous motors, you see big differences in how they work. Synchronous motors are faster and give better control. This makes them perfect for jobs that need high accuracy. Here’s a quick comparison of these two motor types:

Motor Type | Response Speed | Precision Control |

|---|---|---|

Synchronous Motors | Ideal for high-precision applications | |

Asynchronous Motors | Slower response | Great torque output, less precision |

Synchronous motors are great at speed control. They can make precise changes. On the other hand, asynchronous motors have strong torque but may not be as precise.

Technical Principles

Synchronous motors work based on important principles that help with their precision control. Knowing these principles helps you see why they are important in factory automation.

Principle/Feature | Description |

|---|---|

Power Supply | A DC supply powers the rotor’s magnetic coils, while an AC source powers the stator. |

Rotating Magnetic Field (RMF) | The AC supply creates a RMF that works with the rotor’s magnetic field, causing synchronous rotation. |

Magnetic Interlocking Principle | The rotor and stator fields connect, letting the rotor turn at synchronous speed. |

Constant Speed | Synchronous motors keep a steady speed, which helps with accurate performance. |

Leading Power Factor | By changing excitation, these motors can get a leading power factor, improving efficiency. |

Reduced Torque Ripple | They have less torque ripple, which means smoother operation and fewer vibrations. |

Precise Control | The ability to change excitation allows for exact control over speed and torque. |

These features make synchronous motors very useful in high-precision manufacturing. They keep a steady speed no matter the load changes, which is key for jobs needing precise speed control.

Besides their technical benefits, synchronous motors are very efficient. They change electrical energy into mechanical energy well, which means lower energy use and cost savings. This efficiency is very important today, where energy costs can greatly affect overall expenses.

Types of Synchronous Motors

Many types of synchronous motors are used in factory automation, each with special features:

Type of Motor | Features |

|---|---|

Excited Synchronous Motor | Rotor winding powered by DC supply, allowing for greater control. |

Single Phase Synchronous | Works on single-phase AC, used in small jobs like clocks and timers. |

Three Phase Synchronous | Powered by three-phase AC, used in industrial jobs, offers more power and efficiency. |

Unexcited Synchronous Motor | Uses the stator’s magnetic field, no external rotor winding. |

Reluctance Motor | Simple design, high efficiency, torque comes from rotor alignment with stator field. |

Hysteresis Motor | Rotor made of special magnetic material, runs smoothly, used in constant speed jobs. |

Each type is made for specific tasks, so you can find the right motor for your needs. The flexibility of synchronous motors makes them a popular choice in many industries, from manufacturing to renewable energy.

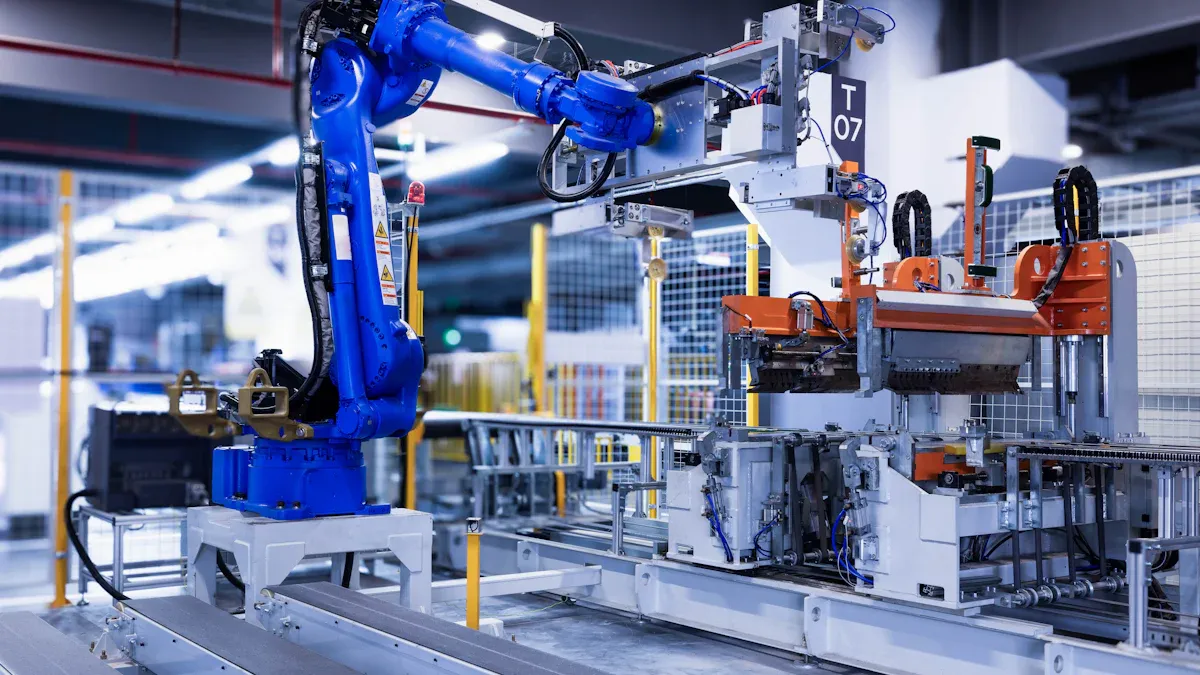

Core Applications and Real-World Impact

Synchronous motors are very important in many industries. They are precise and efficient, making them great for tasks needing high accuracy and reliability. Here are some key areas where you can see how synchronous motors make a difference:

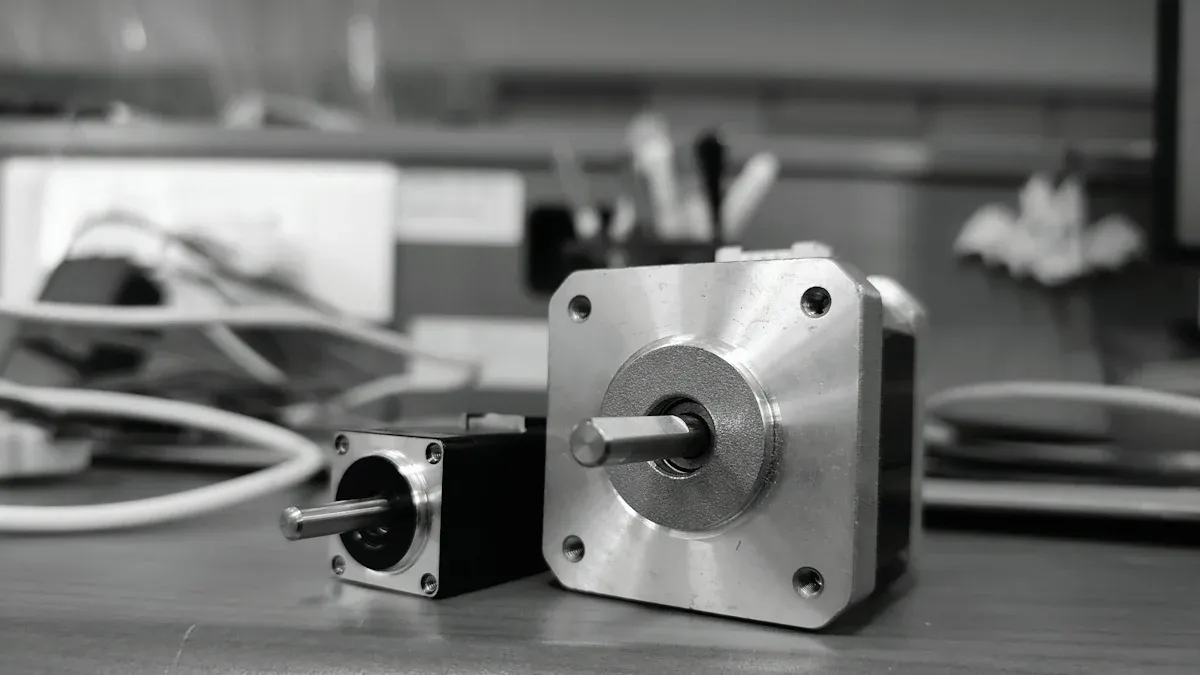

Industrial Robotics and CNC Machines

In industrial robotics and CNC (Computer Numerical Control) machines, precision is key. Synchronous motors improve accuracy and repeatability in these jobs. Here are some benefits you can expect:

Improved Control: A control method called Switching Active Disturbance Rejection Control (SADRC) helps speed controllers in servo systems. This is important for keeping accuracy in robotics and CNC work.

Superior Performance: Studies show that SADRC works better than other control methods like LADRC and NLADRC. This helps keep control effective even with different errors, leading to better repeatability.

Experimental Validation: Tests show that Permanent Magnet Synchronous Motors (PMSMs) using SADRC have better control effects. These results support the idea of improved accuracy and repeatability in factories.

Also, synchronous motors help speed up production and improve quality in CNC machining. Here’s how:

Increased Processing Speed: Using AC permanent magnet synchronous linear motors greatly speeds up processing.

Enhanced Accuracy: These motors make CNC machining more accurate, ensuring your products meet high standards.

Better Surface Finish: By removing mechanical parts, synchronous motors cut down on backlash and compliance, improving surface finish quality.

Reduced Non-Cutting Time: High acceleration reduces non-cutting time, increasing overall productivity.

Semiconductor and Electronics Manufacturing

Synchronous motors are also great in semiconductor and electronics manufacturing. Their energy efficiency and precision control make them a top choice in this field. Here are some key points to think about:

Energy Efficiency: Synchronous Reluctance Motors (SynRMs) can be up to 15% more efficient than regular induction motors. This efficiency is important in a field focused on cutting costs.

Market Growth: The global market for SynRMs was about 175.2 million units in 2023. This growth shows the rising need for energy-efficient solutions in electronics.

Overall Energy Consumption: Synchronous motors can cut electricity use by up to 30%. This is due to global energy efficiency policies, making them a green choice.

Evidence Type | Description |

|---|---|

Energy Savings | IBM’s energy management system for PMSMs can save up to 30% energy compared to older methods. |

Efficiency Standards | IEC standards classify PMSMs into efficiency groups, helping to lower energy use. |

Policy Impact | Energy efficiency policies saved over 1.5 billion tons of oil-equivalent energy in 2023. |

By using synchronous motors, you not only improve your production lines but also help create a more sustainable future. Their ability to enhance power factor correction and lower energy use fits well with the growing focus on eco-friendliness in manufacturing.

Your Strategic Partner: From Selection to Implementation

Correct Selection

Picking the right synchronous motor for your job is very important. You should think about several key points to make sure it works well. Here’s a table that lists the main factors to remember:

Criteria | Description |

|---|---|

Operational Characteristics | Synchronous motors work best in jobs needing constant speed, like in textile and paper work. |

Efficiency | They are very efficient, especially for motors over 1000 kW. |

Power Factor Control | These motors can help manage the power factor of your whole plant, fixing lagging power from induction motors. |

Application Suitability | They fit well for big, slow-moving compressors and fast drives, like centrifugal compressors. |

Cost Consideration | They might cost more at first, but can save money compared to adding capacitor banks for power factor fixing. |

By looking at these points, you can make a smart choice that fits your needs.

Drive and Control Systems

Using advanced drive and control systems greatly improves how synchronous motors work. These systems let you control speed and torque precisely, which is key for keeping efficiency in factory automation. Here are some new developments in this area:

Model Predictive Control (MPC) methods for Permanent Magnet Synchronous Motors (PMSMs) make systems respond better.

Hybrid control mixes old methods with artificial intelligence, making them more flexible and able to handle problems.

Techniques like multi-vector Finite-Control-Set MPC (FCS-MPC) lower the computing load while boosting performance.

These improvements help your synchronous motors run at their best, even when loads change. Using Variable Frequency Drives (VFDs) also helps save energy, especially at lower loads.

Beyond the Product: Our Services

At Honest, we know that choosing and using synchronous motors is just the start. We provide many services to help you through the whole process. Here’s a table showing our main services:

Service Type | Description |

|---|---|

3D Scanning & Reverse Engineering | Uses technology for accurate repairs and part replacements. |

Coil Manufacturing | Provides custom coils made for motor needs for quality and reliability. |

Project Management | Makes sure motor projects run smoothly and finish on time. |

In-house Machine Shop | Takes care of all machining needs for motor repairs and custom work quickly. |

Engineering Consultancy | Offers expert advice to make motor systems work at their best. |

These services make sure you get full support, from the first choice to ongoing care. By working with us, you can improve the reliability and efficiency of your operations.

Synchronous motors are very important for the future of automation. They keep a steady speed even when loads change.If you want to improve the accuracy and efficiency of your production lines, reach out to our expert team today. We can help you find the best synchronous motor solutions for your needs!

FAQ

What are the main advantages of synchronous motors?

Synchronous motors provide exact speed control. They are very efficient and have a leading power factor. This makes them great for jobs that need accuracy and dependability.

How do I select the right synchronous motor for my application?

Think about things like how it works, its efficiency, power factor control, and if it fits your job. This will help you pick the best motor for your needs.

Can synchronous motors operate in harsh environments?

Yes, synchronous motors can be made to handle tough conditions. They can work in extreme temperatures and dusty places, ensuring they perform well in hard jobs.