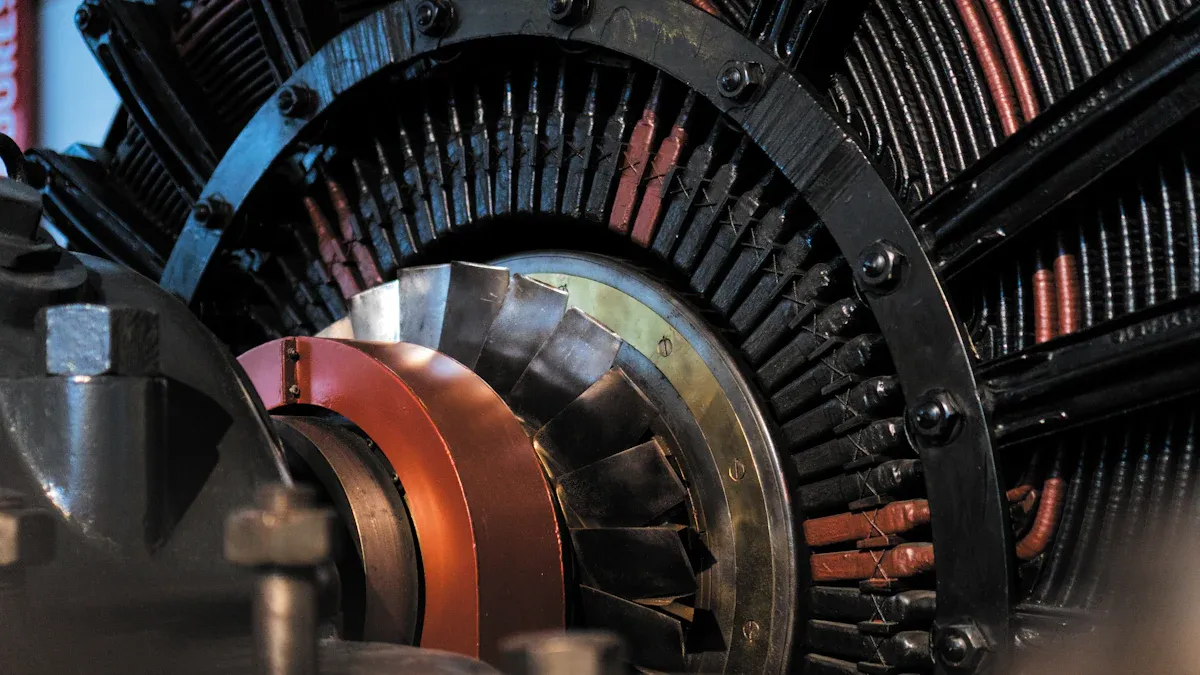

The popularity of RVs continues to grow, driven by the desire for outdoor adventures and flexible, self-directed travel. This trend is increasing the demand for better onboard systems—specifically, those that address the critical needs of energy management, noise reduction, and long-term reliability. In this context, brushless motors stand out as an ideal solution. Their superior efficiency, compact design, and quiet operation perfectly align with the modern RV traveler’s need for high performance and a premium experience. Adopting brushless technology is a key step toward maximizing both your comfort on the road and your vehicle’s overall performance.

Key Takeaways

Brushless motors convert between 80-90% of electrical energy into mechanical power across most operating conditions, resulting in significantly more energy-efficient RV systems.

Their lightweight design facilitates compact installations, which contributes to better fuel economy and handling for your RV.

Working quietly is a critical benefit that reduces noise pollution, making for a more peaceful travel experience, especially in quiet campsites.

These motors require less maintenance and boast a longer lifespan than traditional alternatives, saving RV owners substantial money on repairs and replacements.

Switching to brushless motors can lead to considerable reductions in yearly operating costs compared to older brushed motors, making them a wise long-term investment.

BLDC Power The Three RV Essentials

Lightweight Design & Power Density

When you think about upgrading your RV systems, the weight matters a lot. Brushless motors help make your RV systems much lighter. This lighter weight helps save fuel and makes handling better. These motors are small, which is important in the tight spaces of an RV.

Here’s a comparison of the weight benefits of inner and outer rotor brushless motors from:

Motor Type | Weight Advantage |

|---|---|

Inner Rotor Motor | Small and light, perfect for tight spots. |

Outer Rotor Motor | Strong torque while staying light, good for heavy use. |

Both kinds of brushless motors give strong torque in a small size, boosting performance in many RV uses.

Ultra-Quiet Operation (NVH Focus)

Noise, vibration, and harshness (NVH) can really change your RV experience. Brushless motors do a great job here. They make less noise than brushed motors. Without brushes and a commutator, they don’t create the usual mechanical noise. This means quieter operation, so you can enjoy nature without loud sounds.

Noise, vibration, and harshness (NVH) can really change your RV experience. Brushless motors excel here by eliminating mechanical noise caused by brushes and commutators. While traditional brushed motors typically operate in the 50-65 dB range, brushless DC motors can be as quiet as 38 dB. This dramatic reduction in noise pollution makes for a more peaceful travel experience.

Maximum Energy Efficiency & Battery Life

Energy efficiency is very important for RV owners. Brushless motors typically achieve 80% to 90% peak efficiency. This high conversion rate means they use less energy and help batteries last longer. This means they use less energy and help batteries last longer. Here are some main benefits of using brushless motors in your RV systems:

High Overall Efficiency: This means less power use, so you can travel farther without needing to recharge often.

Smart Battery Management via CANBUS: The CANBUS communication protocol allows the BLDC motor controller to intelligently coordinate with the RV’s Battery Management System (BMS). This coordinated control precisely limits inrush and surge currents, resulting in enhanced battery protection and extended lifespan.

Also, brushless motors have less wear and tear since they don’t have brushes. This leads to lower maintenance costs and a longer life. You can enjoy your trips without worrying about repairs or replacements.

Tailored BLDC Power For Every RV System

Keeping noise low is very important in RVs. You want to enjoy nature without loud sounds. Brushless motors are great for this. They run quietly and make your experience better.

Exhaust Fans: Outer Rotor for Quiet Airflow

For exhaust fans, outer rotor brushless motors are the best choice. This design places the magnets on the rotor’s exterior, which provides higher inertia and greater torque density. This allows the motor to operate smoothly at lower, more stable RPMs, ensuring quiet, continuous airflow to remove cooking smells and humidity from your RV.

Air Pumps: Inner Rotor for High-Pressure Output

Inner rotor brushless motors are perfect for air pumps. With a smaller rotor diameter, this design features lower inertia, enabling higher operating speeds and faster acceleration. This high power-density is ideal for creating the high-pressure output needed for quickly inflating air mattresses and other gear. Their small size makes them easy to install in tight spots.

Auxiliary Pumps: Durability & Corrosion Resistance

Auxiliary pumps are very important in RV systems. They must handle tough conditions, like moisture and chemicals. Brushless motors use strong materials that help them last longer. Here’s how different materials help with durability and corrosion resistance:

Material Type | Role in Durability and Corrosion Resistance |

|---|---|

Plastic | Light and resists corrosion |

Brass | Good strength and resists corrosion |

Stainless Steel | Very strong and excellent against corrosion |

These materials help your auxiliary pumps work well, even in hard conditions. With brushless motors, you can feel good knowing your RV systems will last.

The OEM Advantage Customization At Scale

When you think about upgrading your RV systems, brushless motors offer many customization choices. These options can really improve performance. Brushless motors are very energy efficient in the RV market. They change a lot of electrical energy into mechanical power. This means you can take longer trips without needing to recharge often.

Optimized 12V/24V Power Interface

Most RV systems use 12V or 24V power. Brushless motors work well with these systems. This makes it easy to add them to your RV without big changes. Here are some customization choices that can boost the performance of brushless motors in RVs:

Customization Option | Description |

|---|---|

High-strength magnets | Improve motor efficiency by giving more magnetic force and torque. |

Optimized winding configurations | Help magnetic connection, lower resistance loss, and make torque smoother. |

Advanced thermal management techniques | Reduce energy loss as heat, making the motor last longer. |

Soft magnetic alloys | Use new materials to improve performance and cut down energy loss. |

These choices let you adjust the motor’s performance to fit your needs, making sure your RV runs well and reliably.

Shock Resistance & Road Vibration Mitigation

RVs deal with special challenges on the road, like shocks and vibrations. Brushless motors are made to handle these issues. They go through tough testing to make sure they can manage RV travel. Here are some standards used to check shock resistance and vibration control:

Standard | Description |

|---|---|

IEC 60068-2-27 | A test to see if a product can handle certain levels of shocks. |

IEC 60068-2-57 | A test to check if a product can deal with specific vibrations. |

IEC 60068-2-64 | Shows how well products resist dynamic loads without losing function. |

IEC 60068-2-80 | Tests if products can handle mixed mode excitement without losing performance. |

SAE J1211 | Looks at how strong electrical parts are for car use, also good for sensors and switches. |

These standards make sure your brushless motors can take the bumps of RV travel, giving you peace of mind on your trips.

Manufacturing at Scale for OEM Supply

For RV manufacturers (OEMs), the key to translating the technological advantages of brushless motors into actual products lies in securing a reliable and efficient supply chain. Honest deeply understands the importance of manufacturing at scale and is dedicated to providing customers with swift delivery and guaranteed quality.

Our supply commitment is backed by tangible promises of efficiency and certified quality:

Fast Turnaround: Samples are delivered within 15 days, and mass production cycles require only 25 to 30 days, ensuring your schedule stays on track.

Global Certification: Products comply with CE, UL, RoHS, and REACH standards; our factory holds ISO 9001 and IATF 16949 certifications.

Quality Assurance: Every motor undergoes complete testing before shipment and is provided with a detailed test report.

Comprehensive Support: We offer a 2-year warranty, lifetime service, and a guaranteed 12-hour quick response from our engineers.

Seamless Logistics: We support major trade terms (FOB, CIF, DAP) and utilize key ports like Shanghai and Cat Lai for efficient global delivery.

Choosing Honest means partnering with a stable, highly efficient, and certified supplier to reliably meet your large-scale supply needs.

Common Challenges in Transitioning to Brushless DC Motor Technology

Switching to brushless DC motor technology can have challenges for RV makers. Here are some common problems you might face:

Challenge | Description |

|---|---|

Complex Control Systems | Needs advanced algorithms and a lot of processing power for the best performance. |

Motor Selection | Involves picking the right motor type based on what you need and making sure it fits. |

Sensor Integration | Means choosing sensor types for rotor position detection while balancing cost and performance. |

Heat Management | Focuses on getting rid of heat to keep performance and life under different conditions. |

By knowing these challenges, you can get ready for a smooth switch to brushless motor technology in your RV systems.

Brushed Motors The True Cost of Old Tech

Maintenance & Replacement Costs

Brushed motors might look cheap at first. But their costs can grow fast over time. You will have to pay more for maintenance and replacements with these motors. Here’s a look at the usual costs for brushed motors compared to brushless motors:

Cost Factor | Brushless Motor | Brushed Motor | Annual Difference |

|---|---|---|---|

Energy consumption | $2,400 (90% efficiency) | $3,000 (75% efficiency) | $600 savings |

Maintenance labor | $200 (minimal service) | $800 (brush replacement) | $600 savings |

Replacement parts | $50 (bearings only) | $300 (brushes, commutator) | $250 savings |

Failure-Related Downtime & Service | $400 (5 hours) | $1,600 (20 hours) | $1,200 savings |

Total Annual Costs | $5,700 | $2,650 savings |

Note: Efficiency figures (90% and 75%) represent rated efficiency under typical operating loads for the purpose of annual cost comparison.

Switching to brushless motors can save you a lot of money over time. You will have lower energy costs, less maintenance, and fewer parts to replace.

Inrush Current: Protecting the RV Battery

Another problem with brushed motors is their inrush current. When you start a brushed motor, it pulls a lot of current. This sudden surge can hurt your RV battery. It might cause early battery failure or lower performance.

On the other hand, brushless motors start smoothly. They use less inrush current, which helps protect your battery. This means you can trust your RV systems without worrying about battery problems.

In short, brushless motors fundamentally improve the RV experience. Their small size fits easily into tight spots, and the lack of brushes eliminates mechanical wear, dramatically cutting down on downtime and labor costs. With their steady torque across a wide range of speeds, these motors consistently operate with maximum efficiency under different loads.

When upgrading your RV, remember the core benefits: quieter operation, higher energy efficiency, better power-to-weight ratio, and a significantly longer lifespan.Enjoy the benefits of brushless technology for your next RV upgrade. You’ll gain a quieter, more efficient, and dependable travel experience.

FAQ

How do BLDC motors improve RV battery life?

BLDC motors work very efficiently. They change more electrical energy into mechanical power. This means they use less energy, helping your RV battery last longer between charges.

Are BLDC motors easy to install in RV systems?

Yes! BLDC motors are small and light. This makes them easy to fit into tight spaces in RV systems. They also work well with standard 12V or 24V power systems.

How do I maintain BLDC motors?

BLDC motors need very little maintenance because they don’t have brushes. Just check for dust and dirt regularly. Make sure all connections are tight. This simple care helps the motor last longer.

Can I use BLDC motors for other applications?

Yes! BLDC motors are very flexible. You can use them in many places, like home appliances, medical devices, and industrial machines. Their efficiency and quiet running make them great for many settings.