Electric motor solutions now power over 60% of adjustable hospital beds worldwide. This shows a big move toward safer and better care. These solutions give high accuracy and dependability. They help beds move smoothly, quietly, and safely. Hospitals use electric motor solutions because they offer great control and steadiness. This makes things easier and more comfortable for patients and caregivers in busy hospitals.

Key Takeaways

Electric motors help hospital beds move smoothly and quietly. They also make beds move in a very exact way. This helps patients feel more comfortable and safe.

Adjustable beds with electric motors help nurses take care of patients more easily. These beds also help staff not get tired or hurt as much.

Safety features like locks, backup power, and smart controls keep patients safe. These features also help a lot during emergencies.

Smart and energy-saving motor systems help hospitals give better care. They also help save money and protect the environment.

Custom motor solutions let hospitals meet special needs. They also help hospitals follow strict safety rules.

Key Functions

Smooth Positioning

Electric motor solutions help hospital beds move smoothly and quietly. They let beds change positions without sudden stops or loud sounds. Linear actuators make these changes easy and gentle. They turn electrical energy into straight-line movement. This helps adjust the bed’s height, backrest, and leg rest exactly. Each movement is soft and steady, which keeps patients safe and comfortable.

Feature | Contribution to Smooth and Precise Positioning in Medical Beds |

|---|---|

Gives exact height, tilt, and angle changes for patients. | |

Smooth & Silent Operation | Keeps noise and shaking low for a peaceful room. |

High-Speed & Efficient Performance | Allows quick and steady moves during important care. |

Compact & Durable Design | Works well even when used a lot in hospitals. |

Integrated Control Systems | Makes controls easy and accurate with automatic systems. |

Linear actuators with control systems give feedback on position. They also start and stop softly and limit power use. These things make every bed move smooth and safe. In places like ICUs, beds can change fast but gently. This helps patients get better and makes work easier for nurses.

Multi-Axis Adjust

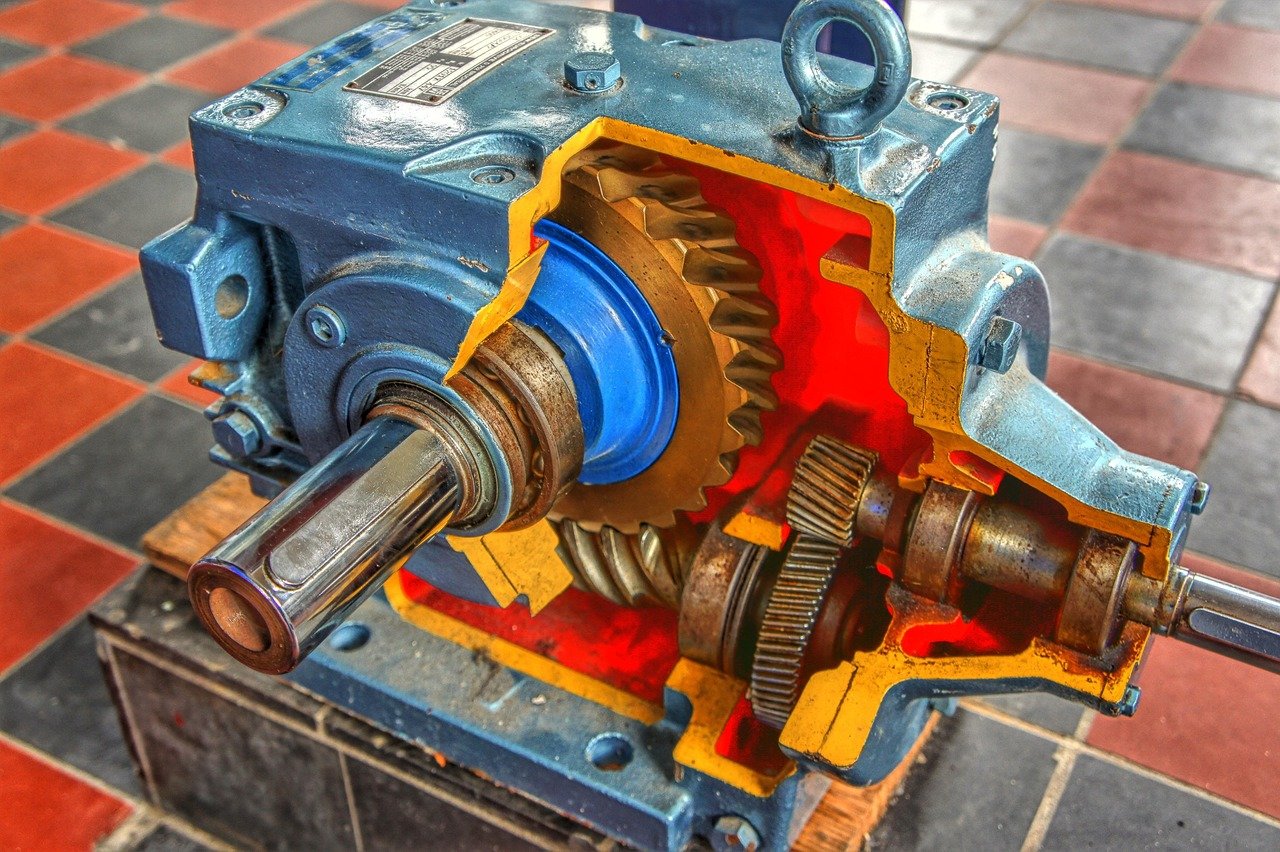

Modern hospital beds can move in many ways to help patients and nurses. Electric motor solutions, like 12v gear motors, power different movements. These include raising the bed, tilting the backrest, bending the knees, and Trendelenburg positions. Each actuator gives strong and steady movement. This helps beds fit many needs and keeps patients comfortable.

Raising the bed helps nurses move patients.

Backrest and knee moves stop sore spots and help blood flow.

Trendelenburg positions help with breathing and drainage.

Side rails, moved by actuators, keep patients safe.

Remote controls let patients adjust beds and save nurses time.

Linear actuators here give strong power and fine control. This lets beds make tiny changes, which is important after surgery. 12v gear motors keep beds working even if the power goes out. Backup batteries or manual controls help in emergencies. For example, during a hospital emergency, 12v gear motors kept beds working. Staff could move patients safely and quickly.

Note: Multi-axis actuator systems help patients feel better and make nurses’ jobs easier. This helps everyone heal faster and work safer.

Consistent Safety

Safety is always most important in hospitals. Electric motor solutions add many safety features to beds. Actuators with locks and quick-release parts keep beds steady. They also let beds move fast if there is an emergency. Side rails powered by actuators stop falls and help move patients.

Electric height and position changes help with care and comfort.

Good locks and moving parts keep beds safe and steady.

Monitoring and smart controls help track patients and move beds automatically.

Strong frames and easy-to-clean surfaces keep beds safe and clean.

All actuator systems follow strict medical safety rules like IEC 60601-1 and ISO. These rules say actuators must be quiet, steady, and waterproof. 12v gear motor backups make beds reliable, even if the power fails. The gearbox in each 12v gear motor cuts down shaking and damage. This helps actuators last longer and keeps beds safe.

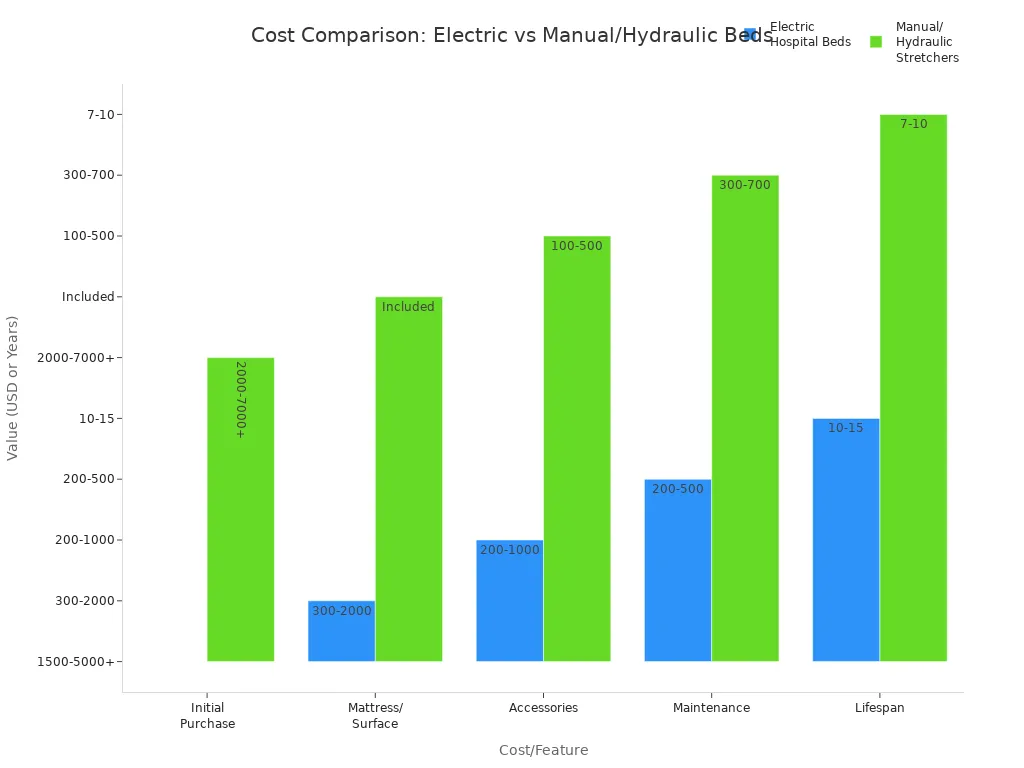

Electric hospital beds with advanced actuators and 12v gear motors are a better choice than manual or hydraulic beds. They move better, last longer, and have more safety features. This makes them best for hospitals and long-term care.

Patient & Caregiver Benefits

Comfort & Recovery

Electric motor-driven hospital beds make patients more comfortable. These beds let people change the backrest, legs, and bed height exactly. Patients can pick the best position for sleep, reading, or therapy. The motors move quietly and smoothly, so they do not wake anyone up. Caregivers say Trendelenburg and side tilt help stop bedsores and make care easier. Patients get gentle moves that help them feel better and heal faster.

“It helps people do things on their own,” a caregiver said, showing how these beds let patients control their comfort.

Staff Strain Relief

Healthcare workers often hurt their backs from lifting and bending. Electric motors help by making it easy to raise or lower the bed. Staff can lift the bed to waist height, so they do not have to bend much. This makes moving patients safer and lines up the bed with lifts or slings. Braked wheels and side rails also make moving patients safer. Workers feel less tired and can spend more time helping patients, which makes their jobs better.

Raising the bed means less heavy lifting.

Easier moves lower the chance of getting hurt.

Staff can use walkers or standing aids more easily.

Safety & Emergency

Safety is very important in hospitals. Electric motors have backup systems for power outages. Beds with both electric and manual CPR controls help in emergencies. Auto-regress and auto-counter features keep patients from sliding and lower belly pressure. Quick-release locks and strong lifts let staff act fast and set the right bed height. These features keep patients safe and help caregivers during emergencies.

Localization for the German Healthcare System

In Germany, hospital beds with electric motors follow strict medical rules like the MDR. Makers add smart tech like IoT sensors to track beds and fix problems before they happen. Energy-saving motors and parts that can be recycled help the country’s green goals. Hospitals get money from the government to upgrade and add digital tools. Top companies spend on research and work together to handle high costs, rules, and training. Using IoT and AI makes beds safer, easier to move, and more efficient, which helps German hospitals keep up with new needs.

Features of Electric Motor Solutions

Precision Control

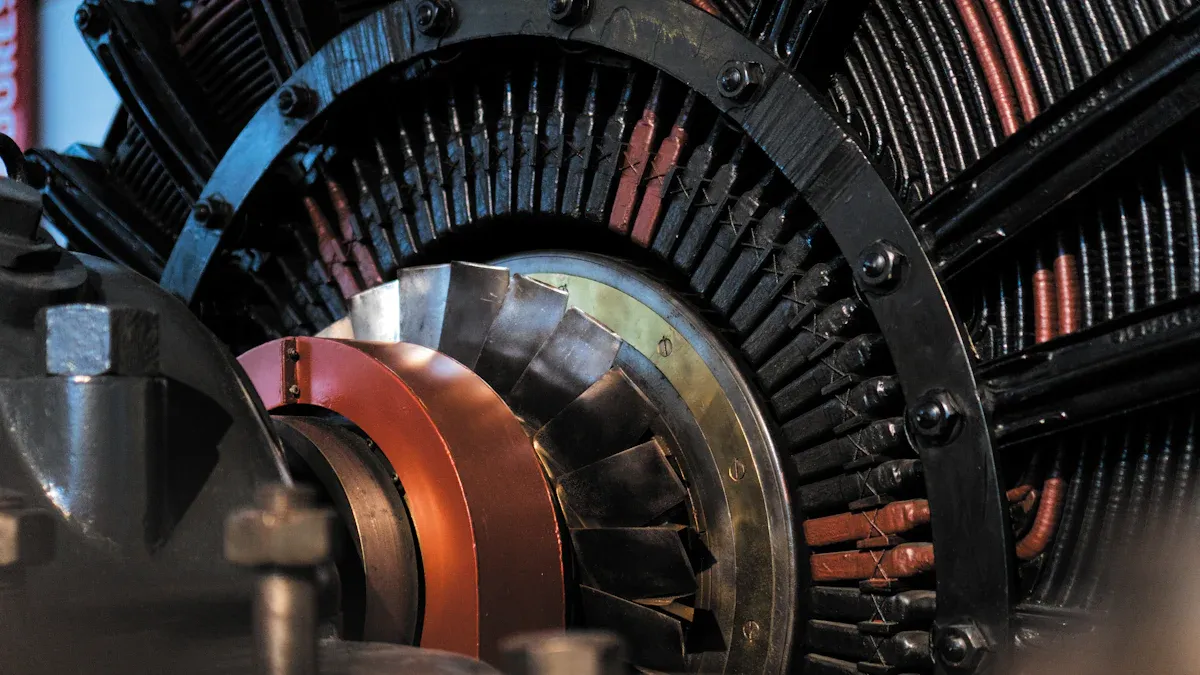

Electric hospital beds use special actuator technology for exact movements. Linear actuators change spinning motion into straight movement. This helps adjust the bed’s height, headrest, and leg rest. The straight movement lets nurses put patients in the right spot. This is important for comfort and safety. Stepper motors with encoder feedback make positions even more accurate. These motors check where things are in real time and fix mistakes. Octupolar motor designs and high-inertia rotors keep speed steady and control torque well. This helps beds move smoothly every time. Actuator systems must handle different weights, so torque stays strong and steady. Hospitals pick these solutions because they meet strict rules and help give great care.

Feature/Component | Description |

|---|---|

Linear actuators make smooth, exact, and quiet straight movement | |

Motion Types | Changes include height, headrest, leg rest, and side tilt |

Control System | Control box sends power and keeps actuators working together; may have programmable controls |

Power Supply | Stays reliable with backup options like a 12v gear motor |

Quiet & Reliable

Quiet beds are very important in hospitals. Electric beds with linear actuators and 12v gear motors make little noise. This keeps patients and staff from being disturbed. These actuator systems use smart drive parts to lower shaking and only make soft sounds. Patients can sleep well, and caregivers can move beds easily. The 12v gear motor gives backup power if the lights go out. This is very important in emergencies when beds must keep working. Hospitals like these actuators because they are easy to clean and help stop germs. The actuator case keeps out liquids, and safe cleaners keep touch spots clean.

Less noise comes from good oil and smart placement.

12v gear motor backup keeps beds working all the time.

Smart Integration

New hospital beds have smart features that help patients and nurses. Actuator systems link to control units, so patients can move beds with switches or sensors. Nurses can watch patient positions and health signs in real time. These smart tools help busy hospitals work better and let nurses help faster. The 12v gear motor also helps smart systems by giving emergency power when needed. Many beds save energy with low-power standby and smart actuator use. Hospitals get better results, use less energy, and help patients more.

Tip: Smart actuator systems help patients do things alone and make nurses’ jobs easier, so every use works better.

Choosing the Right Solution

Selection Criteria

Picking the best electric motor solution for a hospital bed takes careful thought. Hospitals need to make sure each linear actuator can lift what is needed. The motor must have enough torque to lift patients and bed parts without trouble. Speed matters too. The linear actuator should move at a speed that works for both patients and caregivers. Adjustable speed settings help beds lift smoothly and safely during different tasks.

Durability is very important for every use. Motors and actuators must handle lots of lifting and many changes. Hospitals should pick motors that last a long time and do not need much fixing. The duty cycle, or how long the motor works before resting, is important. Motors made for lots of lifting will last longer in busy hospitals.

Other things to think about are:

The kind of linear actuator (AC or DC) and its control features.

The enclosure rating, which keeps dust and water out of the actuator.

Low noise, which helps keep patients comfortable.

How well the actuator fits in the bed’s design, so it is small and easy to add.

Custom changes can help a lot. Honest gives custom linear actuator solutions for special hospital needs. These custom choices can change shaft size, connectors, and add sensors for better control. Hospitals can ask for custom changes for voltage, how things talk to each other, and heat control. This makes sure each use gets the best lifting and works well.

Compliance & Standards

Hospitals must pick solutions that follow strict safety and quality rules. For medical beds, following IEC 60601 is very important. This rule covers electrical safety and keeps patients safe. Power supplies must have strong isolation and protection to stop electrical problems during lifting. There is no special certificate for just electric motors, but the whole actuator system must meet these rules.

UL and ISO certificates are important too. Honest’s custom linear actuator solutions for medical beds meet ISO 13485 and UL rules. These certificates show they care about quality and safety in every use. Hospitals get custom solutions that pass hard tests and checks. Honest’s local making and custom changes help lower wait times and costs, so hospitals can upgrade their lifting systems more easily.

Tip: Always make sure each linear actuator and lifting solution fits the job and meets all the needed rules. Custom options from Honest help every hospital get what they need.

Electric motor solutions from honest help beds move exactly right. They also make beds more comfortable and safe for patients. Hospitals use these systems to give better care and help staff do less heavy work. In Germany, new ideas include motors you can change, smart beds, and ways to fix problems before they happen. Hospitals like motors that save energy because they help the planet and cost less to run. In the future, hospital beds will have built-in sensors, ways to check problems from far away, and parts you can recycle. Hospitals will follow new rules for care and add more helpful services to do well for a long time.

Modular motor designs let beds move just how patients need.

Smart platforms link beds to health records and hospital systems.

Predictive maintenance helps stop problems and saves money.

Energy-efficient actuators help hospitals be green and strong.

Hospitals that pick advanced motor solutions can give better care and work better every day.

FAQ

What makes electric motors in hospital beds reliable?

Electric motors from honest are made with strong materials. They are built using smart engineering. These motors work well for a long time. Hospitals trust them because they follow tough safety rules. They also meet high standards for how they work.

How do electric motors improve patient safety?

Electric motors let beds move in exact ways. They have safety locks and backup systems for emergencies. These things help stop accidents. They also keep patients safe while getting care.

Can hospitals customize electric motor solutions for special needs?

Yes. Honest gives custom motor solutions. Hospitals can ask for different voltages or control systems. They can also change the actuator size. This helps each bed fit what patients and caregivers need.

What maintenance do electric motor systems require?

Regular checks help motors work well. Staff should look for loose wires and clean the surfaces. They should also test the backup systems. Honest makes motors that are easy to care for and last a long time.