In the evolving landscape of AGV and AMR systems, OEMs face a significant challenge. They must strike a balance between the high positioning accuracy offered by permanent magnet synchronous motors (PMSM) and the superior battery efficiency provided by AC induction motors. The selection of the right AGV drive motor is essential for achieving success and operational efficiency. Understanding the specific requirements of each application is crucial. Ultimately, the best choice hinges on the project’s needs and total cost of ownership (TCO) considerations.

Key Takeaways

Pick the right motor type for AGV and AMR systems. Permanent Magnet Synchronous Motors (PMSMs) are very efficient and precise. AC Induction Motors (ACIMs) are reliable and cost less at first.

Think about the total cost of ownership (TCO) when choosing motors. PMSMs might cost more upfront but save money on energy bills later because they are efficient.

Focus on precision and quick response in applications. PMSMs are great at keeping speed and position, which is important for tasks needing high accuracy.

Check battery runtime and efficiency. PMSMs usually let you run longer because they are more efficient, which is important for getting work done.

Customization is important for OEMs. Change motor features like torque ranges and feedback options to fit specific needs, improving performance and reliability.

Motor Fundamentals

PMSM vs Induction Basics

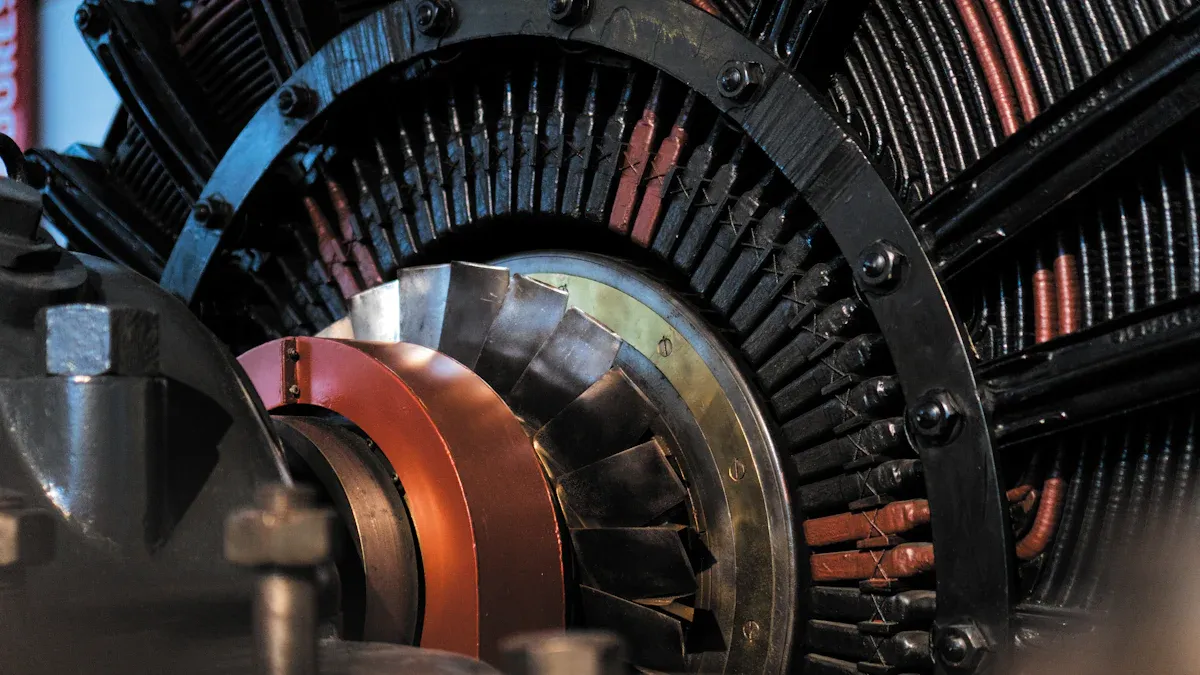

Permanent Magnet Synchronous Motors (PMSMs) and AC Induction Motors (ACIMs) have different jobs in AGV and AMR systems. Knowing how they differ is important for OEMs picking the right motor.

Feature | Permanent Magnet Synchronous Motors (PMSMs) | AC Induction Motors (ACIMs) |

|---|---|---|

Operation | Needs a drive to work | Can work without a VFD |

Efficiency | Higher efficiency at full load | Usually lower efficiency |

Size | Smaller design | Generally bigger size |

Speed Control | Needs precise control with VFD | Can work without VFD |

PMSMs have a rotor with permanent magnets. This helps them run in sync and be very efficient, over 97%. On the other hand, induction motors use electromagnetic induction. This means there is some slip between the rotor and stator. Because of this, they are less efficient, usually reaching only 90-93%. A 50 kW PMSM usually weighs less than 30 lbs, making it lighter than an induction motor.

Drive System Essentials

Many reputable motor manufacturers make both synchronous (PMSM) and asynchronous (induction) motors. These suppliers offer a wide range of products tailored for different AGV and AMR applications. Their expertise helps customers secure high-quality solutions for their specific operational needs. By providing both PMSMs and induction motors, these suppliers enable OEMs to choose the best motor type based on a critical balance of performance requirements and total cost considerations. This choice is key for ensuring AGV and AMR systems operate efficiently and reliably.

Performance Selection

Precision and Low Backlash

Precision is very important for AGV and AMR systems. Permanent Magnet Synchronous Motors (PMSMs) are great at this because they keep a steady speed and position. This is key for jobs that need high accuracy, like automated warehouses and assembly lines. PMSMs have low backlash because of their design. This design makes the gap between the rotor and stator smaller. It helps the motor respond better, allowing for exact control while working.

On the other hand, induction motors usually have more backlash. They depend on slip to work. This can cause less accurate positioning, which might not fit the strict needs of some AGV jobs. So, when choosing an AGV drive motor, OEMs should think about how precise their application needs to be and the benefits of using PMSMs.

Torque and Dynamic Response

Torque and dynamic response are key in deciding how well motors work in AGV and AMR uses. Permanent Magnet Synchronous Motors (PMSMs) have a higher torque-to-weight ratio. This means they perform better in acceleration and handling loads compared to AC Induction Motors (ACIMs).

The table below shows typical high-end Permanent Magnet Synchronous Motor (PMSM) specifications, illustrating the performance advantages in dynamic applications:

Specification (High-End PMSM) | Value |

Power Range | 50W to 15kW |

Speed Range | 0-3,000 RPM base speed |

Torque Density | 1.5-3.0 Nm/kg |

Dynamic Response | Excellent (Bandwidth exceeding 1 kHz, Settling Times under 10 ms) |

Torque Characteristics | High torque-to-size ratio; Flat curve from zero to rated speed |

PMSMs have great dynamic response. They can quickly adjust to changes in load and speed. This fast response is important for AGVs that move through complex areas and need quick changes to stay efficient and safe. Induction motors are strong but often respond slower because of how they are designed, relying on slip for torque generation, which inherently limits their dynamic agility.

Power Density Analysis

The small size of Permanent Magnet Synchronous Motors (PMSMs) helps make lighter Automated Guided Vehicles (AGVs). This weight reduction means they need less energy to move. This not only boosts efficiency but also allows for smaller motors and battery packs, improving overall system performance. PMSMs have higher power density, so they can give more power in a smaller space than induction motors. This is especially helpful in places where space is tight and saving weight is important.

Operational Value

Battery Runtime & Efficiency

The type of motor you choose affects battery runtime and efficiency in AGV and AMR systems. Permanent magnet synchronous motors (PMSMs) are great for this because of how they are made. These motors can reach higher efficiencies, often going over 97% when they work best. This means they use less energy, so AGVs can run longer on one charge.

In real-life use, the efficiency of PMSMs can change based on how much load they have. For example, when there is no load, the efficiency can drop to about 45%. But at full load speed, PMSMs keep their high efficiency of 97%. As the load gets lighter, efficiency goes down too, hitting around 89% at 50% load and 82% at 25% load. This shows how important it is to pick the right motor based on the expected load.

On the other hand, induction motors usually work at lower efficiency levels, often between 85% and 90%. They are strong and dependable, but their efficiency is not as good as PMSMs, especially when the load changes. The lower efficiency of induction motors can mean they use more energy, which might require bigger battery packs to get the same runtime as PMSMs.

Reliability and Durability

Reliability and durability are very important for AGV and AMR systems. PMSMs are known for being strong and able to handle tough working conditions. Their design helps reduce wear and tear, leading to a longer life. This durability is key for jobs that need constant operation, like in warehouses or factories.

Induction motors are also reliable, but their performance can be affected by the environment. They can overheat more easily and need good cooling to stay efficient. In contrast, PMSMs usually have better ways to manage heat, making them more reliable in busy situations.

Also, the higher power factor of PMSMs helps with their efficiency and reliability. A higher power factor means that more of the energy used is turned into useful work. This reduces waste and improves how well the motor works over time. This feature is especially helpful in places where saving energy is very important.

Commercial Decisions

TCO and Initial Cost

When choosing between PMSM and induction motors, total cost of ownership (TCO) is very important. OEMs need to think about the first purchase price and the long-term costs. PMSMs usually cost more at first because they use advanced technology and are more efficient. But, their better energy efficiency can save a lot of money on energy bills over time. On the other hand, induction motors often have a lower initial cost but can lead to higher operating costs because they are less efficient.

Key Considerations:

First purchase price

Energy use during operation

Maintenance costs over the motor’s life

Quality Assurance and Reliability

Quality assurance is paramount when selecting a motor. Honest follows IATF 16949 standards, which include all quality rules of ISO9001. This commitment ensures a foundational level of quality management. The table below shows how these rules affect reliability:

IATF 16949 Requirement | Impact on Reliability |

|---|---|

Covers all quality rules of ISO9001 | Ensures a basic level of quality management. |

Adds extra automotive-specific quality issues | Deals with unique challenges in automotive supply chains. |

Requires ongoing leadership and management review | Encourages a constant focus on quality and reliability. |

Requires planning for possible supply problems | Improves readiness for disruptions, boosting reliability. |

Requires checking for raw material supply chain issues | Finds risks in the supply chain, ensuring steady quality. |

Includes ongoing monitoring and improvement | Helps keep improving product reliability. |

By adhering to these standards, We ensures that both PMSM and induction motors perform reliably in AGV and AMR applications.

Supply Chain and Project Speed

The aggressive timelines of AGV/AMR development require a supply partner committed to rapid prototyping and favorable commercial terms. Honest Motor addresses this by guaranteeing a technical consultation followed by sample motor delivery in just 15 days. Furthermore, we offer flexible procurement options, including highly competitive 90-Day Payment Terms (T/T), allowing OEMs to manage cash flow effectively and accelerate time-to-market.

System Integration

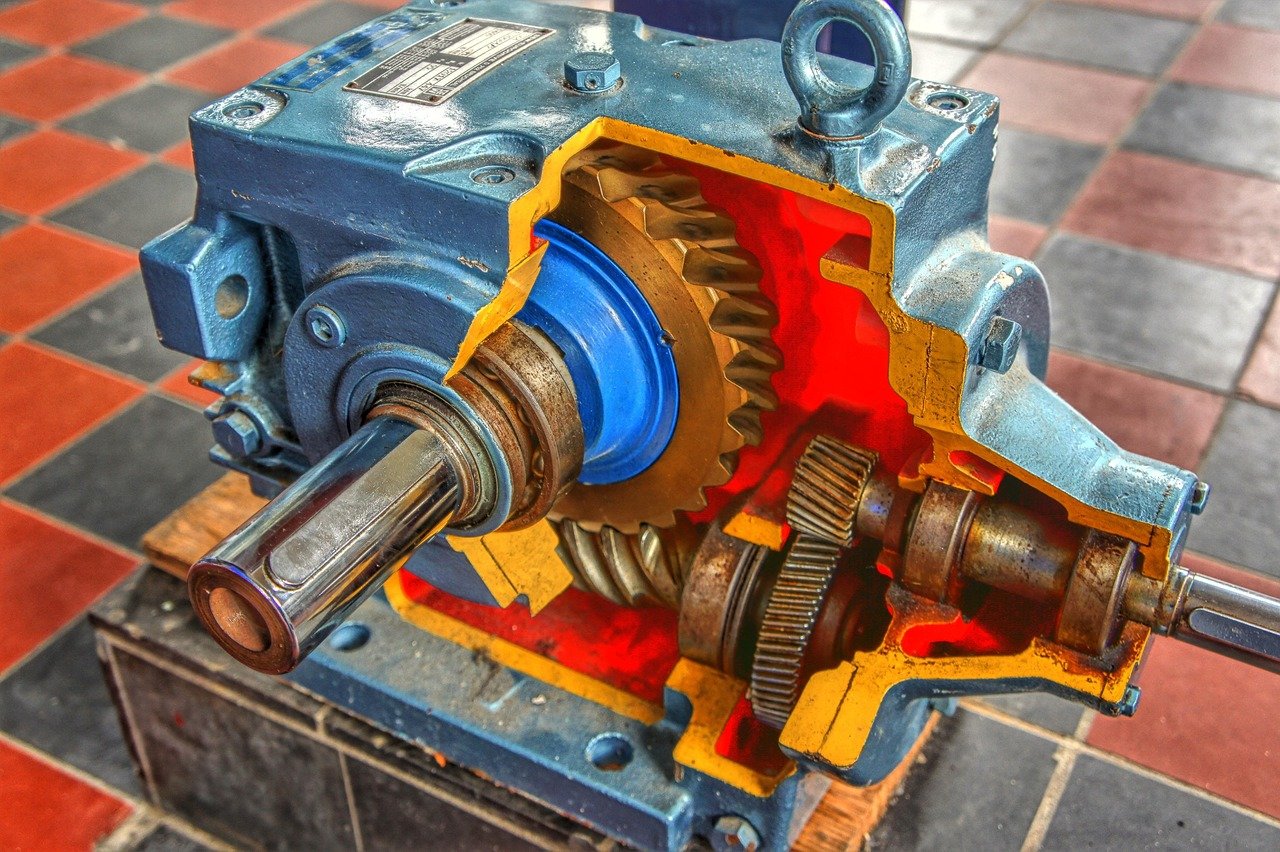

Geared Drive Integration

Adding geared drive systems to AGV and AMR applications improves how well they work. Gear reduction motors are very important in these systems because they increase torque. This is key for jobs that need a lot of torque. When speed goes down, torque goes up. This makes gear reducers very helpful for moving heavy loads.

Gear reduction motors provide:

More torque for high-output jobs.

Higher torque at lower speeds, which helps efficiency.

A reduction ratio that shows how speed decreases and torque increases.

Gearmotors work by using the benefits of gear reduction. When power stays the same, torque goes down as speed goes up. This idea shows how gear reduction helps AGV and AMR systems work better in many situations.

Customization Requirements

Customization is very important for OEMs when choosing motors for AGV and AMR applications. OEMs often ask for special features to fit their needs. The table below lists common customization options:

Customization Options | Description |

|---|---|

Torque Ranges | Different ranges for various application needs |

Speeds | Choices for different working speeds |

Feedback Options | Different types of feedback systems available |

Connector Types | Many connector types for compatibility |

Mounting Options | Various mounting setups to fit different designs |

These customization choices help OEMs adjust their motor solutions, making sure they work well in their specific applications. By meeting these needs, manufacturers can improve the performance and reliability of their AGV and AMR systems.

In conclusion, permanent magnet synchronous motors (PMSMs) and AC Induction Motors (ACIMs) each have their own pros and cons for AGV and AMR uses. The ideal choice hinges on a careful balance between initial investment, long-term efficiency needs, and required application performance.

The following table summarizes the key trade-offs between the two motor types:

Feature | Permanent Magnet Synchronous Motor (PMSM) | AC Induction Motor (ACIM) |

Initial Cost | Higher (Due to magnet materials and complex drive) | Lower (Simpler construction) |

Energy Efficiency | Very High (Typically 90-97%), leading to better battery runtime. | Lower (Typically 85-90%), leading to higher operating costs. |

Precision & Response | Excellent (Fast dynamic response, low backlash, ideal for high-accuracy tasks). | Good, but limited by ‘slip’; slower response compared to PMSM. |

Power Density & Size | High (Smaller and lighter for the same power output). | Lower (Generally larger and heavier). |

Complexity & Reliability | Requires a more sophisticated/precise Variable Frequency Drive (VFD). | High Reliability due to rugged, simpler construction. |

TCO Impact | Higher initial cost, but lower long-term energy cost. | Lower initial cost, but higher long-term energy cost. |

The best motor choice depends entirely on the application. OEMs need to balance performance needs, like accuracy and quick response, with commercial considerations such as total cost of ownership (TCO) and battery efficiency. Selecting a supplier that ensures quality by following stringent standards, such as IATF 16949, builds confidence in the supply chain for these critical drive components.

To ensure your AGV/AMR system achieves the optimal balance of efficiency and cost, you are welcome to consult Honest Motor today for a technical consultation and tailored motor selection advice.

FAQ

What are the main advantages of PMSM over induction motors?

PMSMs are more efficient. They also have better torque-to-weight ratios and precise speed control. These traits make them great for jobs that need high accuracy and energy savings.

How do induction motors perform in variable-speed applications?

Induction motors work well at different speeds. But, they can be less efficient at lower speeds. In contrast, PMSMs keep their high efficiency across a wider range.

What factors should OEMs consider when choosing between PMSM and induction motors?

OEMs need to think about efficiency, cost, application needs, and expected load conditions. Each motor type has special strengths for different jobs.

Are PMSMs more expensive than induction motors?

Yes, PMSMs usually cost more at first because of their advanced technology. But, their energy efficiency can save money on operating costs later.

How does the choice of motor affect battery runtime in AGVs?

The type of motor greatly affects battery runtime. PMSMs usually allow for longer runtimes because they are more efficient. Induction motors might need bigger batteries to match the same performance.