Choosing the right pump motor means you should focus on energy efficiency first. Pumps use a lot of energy in factories, about 20% of all motor energy in the world. If you pick efficient pump systems, you can use up to 50% less energy. Using less energy means you pay less money, your equipment lasts longer, and it breaks down less often. Good, energy-efficient pumps also help you reach your sustainability goals and protect the environment. Honest gives trusted pump solutions for many industries. Think about how energy efficiency can help your business grow and save money for a long time.

Key Takeaways

-

Energy-efficient pump motors use up to 50% less energy. This can lower your electricity bills a lot.

-

Picking the right pump size is important. Using variable frequency drives helps pumps work better and last longer.

-

Efficient pumps need less fixing and break down less often. This saves you time and money on repairs.

-

Upgrading to high-efficiency motors cuts greenhouse gas emissions. It also helps you reach your sustainability goals.

-

Honest gives you strong pump motors with smart features. They also offer expert help to meet your needs.

-

Doing regular maintenance keeps pumps working well. This makes sure you save money and get good performance for a long time.

-

Energy-efficient pumps can pay for themselves in a few years. This happens because you save energy and money.

-

Switching to efficient pumps helps your business grow. It also protects the environment for the future.

Pump Motor Energy Efficiency

Why Efficiency Matters

It is important to know why efficiency matters when picking a pump motor. Efficient pumps use less energy to move water or other fluids. This helps you save money on your electric bill and helps the planet. High-efficiency pumps use less energy and lower your carbon footprint.

Here are some main reasons why pump efficiency is important:

-

Using more energy costs more money and harms the environment.

-

Variable frequency drives help you control pump speed and save energy.

-

Picking the right pump and motor helps you reach your sustainability goals.

-

The total cost of owning a pump includes energy, maintenance, and downtime, so efficiency is very important.

-

Efficient pumps last longer and need fewer repairs.

If you use pumps that are not efficient, you waste energy and money. These pumps can be noisy, break down more, and need more repairs. By choosing efficient pumps, you avoid these problems and keep your systems working well.

Impact on Operating Costs

Pump efficiency changes how much you pay to run your equipment. Pumps that are not efficient use more electricity than needed. This makes your energy bills higher and wastes resources. When pumps do not run at their best, they use extra power but do not work better. Oversized pumps also waste energy by slowing down the flow.

You can save a lot of money by using high-efficiency pumps. Studies show that high-efficiency pump motors can use up to 85% less energy than regular ones. For example, if you use a motor with 80% efficiency and a pump with 93% efficiency, you get about 74% combined efficiency. This is much better than the 56% you get from cheaper pumps. These savings add up over time and lower your costs.

You can also use variable frequency drives to change pump speed as needed. Even a small speed drop can save a lot of energy. For example, lowering pump speed by 20% can cut energy use by up to 50%. This saves money and helps your equipment last longer.

Tip: Doing regular maintenance, like checking lubrication and pipe size, keeps your pumps efficient and your costs low.

Honest’s Commitment to Efficient Motors

Honest always puts efficiency first in every pump motor solution. You can find high-efficiency pumps and motors for many uses, like water treatment, factories, and smart homes. Honest makes motors that use less energy, last longer, and need fewer repairs. This helps you save money and reach your sustainability goals.

Honest’s motors have advanced features like variable frequency drives and smart controls. These features let you match pump speed to what you need right now, which saves energy and helps your system work better. Honest also gives expert help to pick the right pump motor for your needs.

You can trust Honest’s products because they meet strict global standards. Here is a table that shows some certifications Honest follows:

|

Certification/Standard |

Description/Scope |

|---|---|

|

CE |

EU safety, health, and environmental compliance for pump motors |

|

UL |

U.S. electrical safety and reliability certification |

|

RoHS |

Restriction of hazardous substances in motor materials |

|

REACH |

Chemical safety compliance for motor components |

|

ISO 9001 |

Quality management system for reliable production |

|

IATF 16949 |

Automotive industry quality standard for motor supply and production |

When you pick Honest, you get high-efficiency pumps that help you use less energy, save money, and support a greener world.

Cost Benefits of Efficient Pump Motors

Lower Energy Bills

If you pick energy-efficient pumps, your energy bills go down. These pumps use less electricity to move water or other fluids. You pay less each month because the pump does not waste power. Many people see savings right after they switch to a better pump motor.

Here is a table that shows how much money you can save by upgrading your pump system:

|

Upgrade Type |

Energy Savings (%) |

Annual Cost Savings ($) |

Notes |

|---|---|---|---|

|

Downsized pump |

40 |

100 |

Smaller pump uses less energy, from 3,000 to 1,800 kWh/year |

|

Reduced run time (60%) |

60 |

140 |

Running pump fewer hours saves more energy |

|

Combination (downsized + time) |

75 |

180 |

Both changes cut costs from $240 to $60 per year |

Even small changes, like using a smaller pump or running it less, can save you up to 75% on energy costs. The U.S. Department of Energy says variable-speed pumps can use up to 80% less energy than single-speed pumps. If you pay $75 each month for a regular pool pump, you could pay only $20 with an energy-efficient pump. That means you save $330 every year, and the pump pays for itself in just a few years.

Energy Star says an average pool pump costs over $450 a year to run. An energy-efficient pump costs less than $200 a year. Over the pump’s life, you can save more than $2,000. Many utility companies give rebates to help you upgrade, so switching is even easier.

Total Cost of Ownership

When you look at pumps, think about more than just the price. The total cost of ownership includes what you spend on energy, repairs, and maintenance over the pump’s life. Energy-efficient pump motors help you save money in all these ways.

-

Energy-efficient motors use advanced designs. They have better insulation, improved bearings, and optimized rotors. These features waste less energy and make less heat.

-

You spend less on electricity because the pump works smarter, not harder.

-

These motors last longer and break down less often. You do not have to pay for repairs as much.

-

If your pump runs all day, every day, the savings add up even faster.

Energy-efficient three-phase motors with soft start technology lower wear and tear on pump parts. They run cooler and smoother, which means less stress on your system. Three-phase motors also make less vibration, so pipes and supports last longer. Brushless DC motors do not need brushes, so you do not have to replace worn parts as often. This means less downtime and fewer repair bills.

Variable speed drives and smart monitoring systems help you keep track of your pump’s health. You can find problems early and fix them before they get worse. This keeps your pump running well and saves you money on big repairs.

Honest Product Examples

Honest has many energy-efficient pump motors that help you lower your costs. Here are some examples:

-

Single-phase AC asynchronous motors: Honest makes these motors to meet strict energy efficiency standards. They work well in homes and small businesses. Even though single-phase motors usually have lower efficiency, Honest uses special designs to boost their performance. You get good energy savings and a motor that lasts longer than most standard options.

-

Three-phase AC asynchronous motors: Honest’s three-phase motors meet IE3 energy efficiency standards. They have certifications from DOE, NRCan, ISO, and ENERGY STAR. These motors give you steady power, high efficiency, and a long lifespan. You can use them in factories, water treatment plants, and other tough jobs. If you add a variable frequency drive, you can control the pump’s speed and save even more energy—sometimes up to 50% in big systems.

-

Brushless DC motors: These motors do not have brushes, so they need less maintenance. They run quietly and efficiently, making them great for places where you want low noise and high performance.

Customers who use Honest’s variable speed pumps save hundreds or even thousands of dollars over the life of their equipment. Some save over $1,000 each year. Lower speeds mean less wear, so the pump lasts longer and needs fewer repairs. Many people also like quieter operation and get rebates from their utility companies, which makes the upgrade even better.

Tip: If you pick an energy-efficient pump motor from Honest, you get more than just lower bills. You get a reliable, long-lasting pump that helps you reach your efficiency and sustainability goals.

Environmental Impact of Pump Efficiency

Reducing Emissions

Picking efficient pump motors helps the environment a lot. High-efficiency pumps use less electricity to move water or fluids. This means power plants do not need to burn as much fuel. When less fuel is burned, fewer greenhouse gases go into the air. In factories, electric motors use most of the electricity. If you switch to energy-efficient pump motors with variable speed drives, you can use 25% to 60% less power. Using less power means much lower carbon emissions.

Studies show that if everyone used new, high-efficiency motors, the world could use up to 10% less electricity. This would help lower greenhouse gases and help with climate goals. When you pick efficient pumps, you help protect the earth for the future.

Note: Even small changes in pump speed can save lots of energy and cut emissions. Every step toward efficiency helps.

Meeting Sustainability Goals

Using energy-efficient pump motors helps your company reach its sustainability goals faster. These motors use less energy and make fewer emissions. Many companies want to lower their carbon footprint and meet standards like the Science-Based Targets initiative (SBTi).

Here are some ways efficient pump motors help you reach your goals:

-

They use less energy and make fewer greenhouse gases.

-

Features like variable speed drives and smart sensors help pumps work better and last longer.

-

You can save 20-30% on energy, which lowers Scope 1 and Scope 2 emissions.

-

Efficient motors use fewer rare materials, which helps lower Scope 3 emissions from making and shipping products.

-

You spend less on energy and repairs, so you save money and help the planet.

-

These changes help your company stay strong and show customers you care about the environment.

Upgrading to efficient pump motors helps your business and the earth.

Honest’s Green Solutions

Honest gives you pump motor solutions that help the environment and save energy. The company uses green technology so every pump works well and lasts a long time. Honest’s motors include brushless DC motors and AC induction motors that use less energy and make less noise. These motors have IP54-rated sealing, so they work in all weather and last longer, which means less waste.

You also get smart features like soft-start, torque staging, and steady speed control. These features help pumps run safely and only use the energy needed. Honest uses energy-saving production and recyclable materials to lower harm to the environment.

-

High-efficiency motors save energy and make less waste.

-

Strong designs mean fewer replacements and less trash.

-

Sustainable manufacturing helps protect natural resources.

When you pick Honest, you get pump motors that help you reach your efficiency and sustainability goals. You also help lower emissions and support a cleaner, greener world.

Reliability and Longevity with Efficient Motors

Less Wear and Tear

Picking an energy-efficient pump motor helps your equipment last longer. These motors work close to their best speed. This means there is less rubbing inside the pump. When motors use less energy, they make less heat. Less heat keeps parts from wearing out fast. You avoid problems like parts getting out of place or off balance. These problems can hurt your pump. If your pump runs smoothly, it works better and lasts longer.

Energy-focused maintenance lets you find problems early. You can fix small issues before they get worse. This way, your pump has less stress and keeps working well. When your pump is efficient, it performs better and lasts longer.

Lower Maintenance Needs

Efficient pump motors last longer and need less fixing. You can use variable frequency drives to set the right speed. This stops the pump from running too fast all the time. Running slower keeps parts from wearing out quickly. Soft starts and stops protect seals and bearings from sudden shocks. This means less rubbing and fewer breakdowns.

Here are some ways energy-efficient pumps need less fixing:

-

Variable speed drives stop the pump from working too hard.

-

Soft starts and stops protect important parts.

-

Smoother running means fewer problems and less downtime.

-

Checking alignment and temperature keeps the pump in good shape.

-

Fewer breakdowns mean you spend less on repairs.

Using these smart features saves you time and money on fixing pumps. Your pump stays strong and gives you more value over time.

Honest’s Durable Motor Designs

Honest makes pump motors that are tough and last a long time. These motors work well even in hard jobs for many years. They use strong materials like aluminum or steel that do not rust. These materials make the motor lighter and able to handle rough places. An alloy radiator and up to 40 fins help the motor stay cool. Staying cool means less heat stress and a longer life.

|

Design Feature |

Description/Specification |

Benefit for Lifetime and Performance |

|---|---|---|

|

Housing Material |

Aluminum/steel, corrosion-resistant option |

Lighter, resists corrosion, lasts longer |

|

Radiator |

Alloy radiator |

Faster heat loss, less thermal stress |

|

Heat Dissipation Fins |

Up to 40 fins |

Cooler operation, less wear |

|

Efficiency Class |

IE2, IE3, IE4 |

Higher efficiency, less energy waste |

|

Mounting Design |

Flange with multiple bolt holes |

Easy to install, less mechanical stress |

|

Reinforced Frame |

Stronger frame, IE4 efficiency |

Safe in high heat, 40% longer service life |

|

Weight |

Up to 18kg for Pro models |

More torque, more durability |

All these features help the pump motor work well for a long time. Honest’s motors can handle heat and tough places better than most. You get a pump that works well, breaks down less, and lasts for years.

Tip: Picking a strong, efficient pump motor from Honest means you get long-lasting performance and less worry for your business.

How to Choose an Energy-Efficient Pump Motor

Right Sizing for Pump Efficiency

Start by picking the right size pump for your system. The correct size helps your pump and motor work their best. If the pump is too big, it wastes energy. If it is too small, it can get too hot and break. This means you will need more repairs and have more downtime. Always match the pump’s flow rate, pressure, and load to what you really need.

Here are some steps to help you pick the right size:

-

Check what flow rate and pressure your system needs.

-

Look at the fluid’s properties, like how thick it is and its temperature.

-

Make sure the pump can handle the suction lift and Net Positive Suction Head (NPSH).

-

Use good load calculations so you do not pick a pump that is too big or too small.

When pumps run close to their best point, they use less energy. This saves money and helps your equipment last longer. It also means you will not need as much maintenance. Picking the right size pump is important for making your system work better.

Tip: Do regular maintenance and check your system for changes. This helps your pump keep working well.

Using Variable Frequency Drives

Variable frequency drives, or VFDs, help you control your pump’s speed. If your system needs different flow rates, VFDs let you change the speed to match. This saves energy and makes your pump work better. VFDs are great for systems that do not always need full power.

Here is a table that shows the main benefits of using VFDs:

|

Benefit |

How It Helps Your Pump System |

|---|---|

|

Energy Savings |

|

|

Improved Pump Control |

Matches speed to demand, protects equipment |

|

Flow Rate Control |

Adjusts flow for different needs |

|

Reduced Maintenance |

Lowers wear and tear, extends motor life |

|

Overload Protection |

Prevents unsafe speeds and damage |

|

Eliminates Water Hammer |

Smooth starts and stops protect pipes |

|

Equipment Reduction |

Fewer control valves needed |

VFDs work best if your system needs different speeds at different times. If your pump always runs at one speed, a VFD might not help. Always check what your system needs before adding a VFD. This way, you get the most energy savings and better pump performance.

Evaluating Efficiency Ratings

When you pick a pump motor, check its efficiency ratings. The Hydraulic Institute’s Energy Rating (ER) Label is a helpful tool. This label shows how much energy the pump saves compared to others. You can use this rating to compare pumps and pick the one that saves the most energy.

Look for pumps with high efficiency ratings, like IE3 or IE4. These pumps use less energy and cost less to run. Many utility companies use these ratings to give rebates and rewards. Think about the total cost of owning the pump, not just the price. Energy and maintenance costs are a big part of what you will spend over time.

Note: Smart pump technologies with factory-set VFDs help you avoid mistakes when installing and save more energy.

By focusing on efficiency ratings and using tools like the ER Label, you can make better choices. This helps your pump work better and saves you money in the long run.

Honest’s Expert Support

Choosing the right energy-efficient pump motor can feel confusing. You might wonder which motor fits your needs best or how to make sure you get the most savings. Honest makes this process simple for you. The company gives you expert support at every step, so you never have to guess.

Here is how Honest helps you:

-

Personal Consultation

You can talk to Honest’s technical team about your project. They listen to your needs and ask about your system. You share details like flow rate, pressure, and the type of fluid you move. Honest uses this information to suggest the best motor for your job. -

Custom Solutions

Every system is different. Honest offers custom motor solutions for your unique requirements. You can get motors with special features, such as corrosion resistance, explosion-proof design, or extra-quiet operation. Honest can match motors to your voltage, power, and size needs. You get a motor that fits your system perfectly. -

Efficiency Analysis

Honest helps you understand how much energy you can save. The team can compare your current setup with new, efficient options. You see real numbers for energy use, cost savings, and payback time. This makes it easy to see the value of upgrading. -

Installation Guidance

You do not have to worry about setup. Honest provides clear instructions and support during installation. If you have questions, you can contact their team for help. This ensures your motor works right from the start. -

Ongoing Technical Support

After installation, Honest stays with you. You can reach out for help with maintenance, troubleshooting, or upgrades. The support team answers quickly and solves problems fast. You keep your system running smoothly.

Tip: Honest’s experts can help you choose motors that meet global standards like CE, UL, and ISO. This means your equipment will work safely and reliably anywhere in the world.

Why choose Honest’s expert support?

-

You save time by getting the right advice.

-

You avoid costly mistakes.

-

You get a motor that matches your needs and saves energy.

-

You have a partner who cares about your success.

If you want to make your pump system more efficient, Honest’s expert support gives you confidence. You get clear answers, smart solutions, and friendly help every step of the way. Visit honestmotor.com to connect with their team and start your journey toward better energy efficiency today.

Real-World Pump Motor Efficiency Cases

Industry Applications

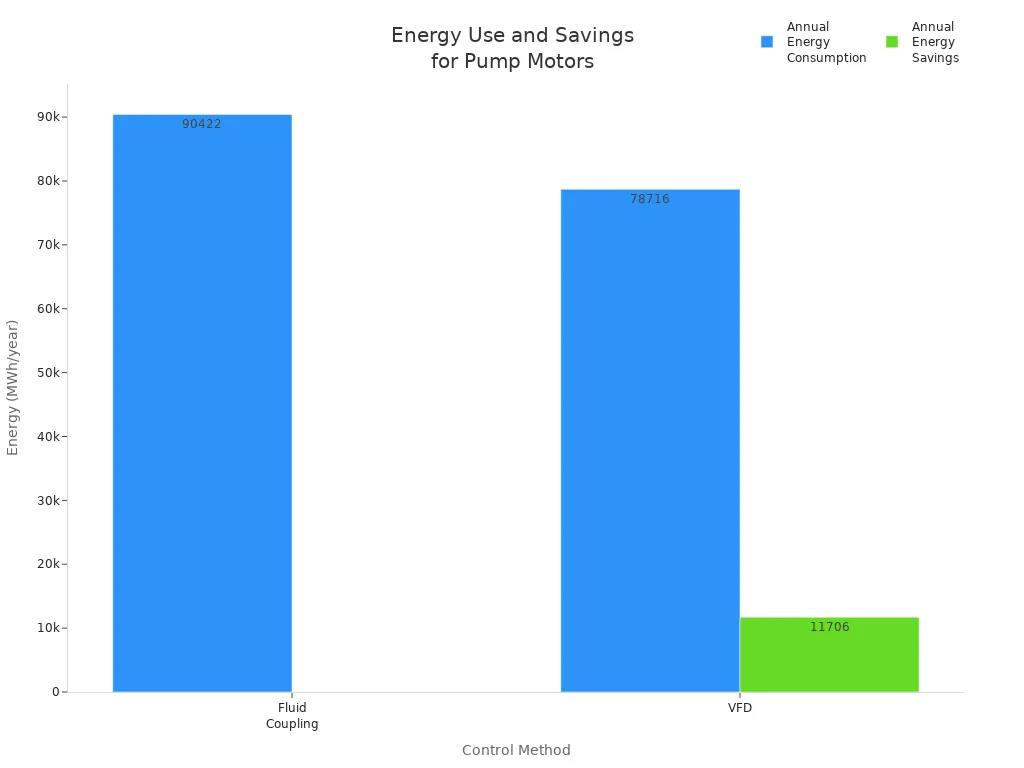

Energy-efficient pump motors help many industries save money and energy. Using the right pump means you do not waste power. In a thermal power plant, engineers tested two ways to control a boiler feedwater pump. One way used a fluid coupling. The other way used a variable frequency drive, or VFD. Both pumps moved the same amount of water and worked just as well. But the VFD system used much less energy every year.

Here is a table that shows how they compare:

|

Aspect |

Fluid Coupling (Base Case) |

Variable Frequency Drive (VFD) |

|---|---|---|

|

Industry |

Thermal power plant (boiler feedwater pump) |

Thermal power plant (boiler feedwater pump) |

|

Pump nominal flow rate |

1,405 m³/h |

1,405 m³/h |

|

Pump efficiency at design point |

85.3% |

85.3% |

|

Motor nominal efficiency |

97.3% |

97.0% |

|

Flow control method |

Geared hydrodynamic fluid coupling |

Variable frequency drive (VFD) |

|

Annual energy consumption |

90,422 MWh/year |

78,716 MWh/year |

|

Annual energy savings |

N/A |

11,706 MWh/year |

|

Annual cost savings |

N/A |

702,000 EUR/year |

|

Estimated CO2 reduction |

N/A |

9,873 tons/year |

|

Additional benefits |

N/A |

Soft start reduces inrush current, extends motor and shaft component life |

|

Payback time |

N/A |

Less than 2 years (estimated) |

You can see the difference in this chart:

Many factories use these ideas to make pumps work better:

-

Change old pumps for high-efficiency models.

-

Fix pumps when they lose efficiency.

-

Use motors with the right amount of power.

-

Add variable speed drives to control pump speed.

-

Solve cavitation problems to help pumps work better.

These steps help you save energy and spend less money every day.

Honest Solutions in Action

Honest gives you real results with your pump systems. Their energy-efficient motors help you spend less, lower your carbon footprint, and make your equipment last longer. You can see these good changes in many ways.

|

Benefit |

Explanation |

|---|---|

|

High-efficiency pumps reduce wasted energy, saving thousands of dollars annually. |

|

|

Reduced Environmental Impact |

Less electricity use means lower greenhouse gas emissions. |

|

Longer Equipment Lifespan |

Efficient operation minimizes wear, reducing maintenance and replacement frequency. |

|

High Efficiency Levels |

Pumps achieving 89%+ efficiency move more water with less energy, improving operational output. |

You can use these pumps in places like water treatment, heating, cooling, and renewable energy systems. Honest’s motors use adaptive speed control to match what you need. This saves a lot of energy. You also get digital monitoring, so you can check your pump’s health anytime. This helps you stop problems before they get big.

|

Improvement Aspect |

Description |

|---|---|

|

Energy Savings |

Adaptive and variable speed operation leads to substantial energy savings by matching demand. |

|

Cost Reduction |

Lower energy consumption results in significant operating cost savings. |

|

Equipment Lifespan |

Efficient operation reduces wear and tear, extending pump service life. |

|

Reliability |

Enhanced reliability reduces system failures and downtime. |

|

Hydraulic Performance |

Optimized hydraulic design improves overall pump efficiency. |

|

Versatile Applications |

Effective in heating, cooling, ventilation, water treatment, and renewable energy systems. |

|

Environmental Impact |

Reduced energy use lowers carbon footprint, supporting sustainability goals. |

|

Return on Investment |

Upgrading to high-efficiency pumps typically pays off within 3-4 years. |

You can make your pump system better by using variable speed drives, picking the right size pump, and using digital monitoring. These ways help you save energy and keep your system working well.

When you switch to Honest’s high-efficiency pump motors, you save money and get better results. You help your business and the planet at the same time.

Picking energy-efficient pump motors gives you many real benefits. You spend less money, help the earth, and get equipment that works well for a long time. Here’s how these benefits add up:

|

Aspect |

Key Benefit |

|---|---|

|

Cost |

20–30% less energy use, quick payback |

|

Reliability |

Lasts longer, less time stopped |

|

Sustainability |

Fewer emissions, helps climate goals |

-

You can save even more by picking the right pump size and using variable speed drives.

-

Upgrading now helps you follow new rules and keeps your savings going for years.

-

Honest offers trusted, efficient choices for every kind of business.

Always put energy efficiency first when picking a pump motor. This helps your business and the earth.

FAQ

What is an energy-efficient pump motor?

An energy-efficient pump motor uses less electricity to move water or fluids. You save money on your power bill. You also help the environment by using less energy.

How do I know if my pump motor is efficient?

You can check the efficiency rating on the motor label. Look for IE2, IE3, or IE4 ratings. Higher numbers mean better efficiency. You can also ask Honest’s experts for help.

Why should I upgrade my old pump motor?

Old motors waste energy and cost more to run. New energy-efficient motors lower your bills and last longer. You also get quieter operation and fewer repairs.

Can I use a variable frequency drive (VFD) with any pump motor?

Most modern motors work with VFDs. You should check your motor’s manual or ask Honest’s team. VFDs help you control speed and save energy.

How much money can I save with an efficient pump motor?

You can save up to 30% or more on your energy bills. The exact amount depends on your system and how much you use the pump. Many users see payback in just a few years.

What industries benefit most from energy-efficient pump motors?

Many industries benefit, such as water treatment, factories, smart homes, and medical equipment. Any place that uses pumps can save money and energy.

Does Honest offer custom pump motor solutions?

Yes! Honest provides custom motors for your needs. You can get special features like corrosion resistance, quiet operation, or unique sizes. Honest’s experts help you choose the best fit.

How do I get support if I have questions about my pump motor?

You can contact Honest’s support team by phone, email, or through their website. The team answers quickly and helps you solve any problem.

Tip: Always check your pump system regularly. Regular checks help you catch problems early and keep your system running smoothly.