Industrial Asynchronous Motor technology offers numerous advantages of asynchronous motor systems, making it a preferred choice in modern industry. Industrial asynchronous motors account for more than half of all industrial electric motors used worldwide. The advantages of asynchronous motor include lower costs, long service life, and simple maintenance. Operators appreciate industrial asynchronous motors for their durability and versatility across various applications. Additionally, these motors are easy to control.

Some common advantages of asynchronous motor systems are:

Reliable performance in harsh environments

Simple maintenance requirements

Compatibility with variable frequency drives

High starting torque for demanding tasks

Remanufacturing industrial asynchronous motors contributes to energy savings and environmental sustainability, further highlighting the advantages of asynchronous motor technology for a wide range of industrial applications.

Key Takeaways

Industrial asynchronous motors are very dependable and do not break often. They do not need much fixing, so they save money over time. They last a long time in factories.

These motors use less power, especially with smart controls like variable frequency drives. This helps save money and is better for the earth.

They give strong starting power, so heavy machines can start easily. They help machines work well even when it is hard.

Their simple and strong design lets them work in tough places. They can work in hot, wet, or dusty areas without needing many repairs.

Smart technology and new ideas make asynchronous motors even better. They help with control, checking, and saving energy.

How Asynchronous Motors Work

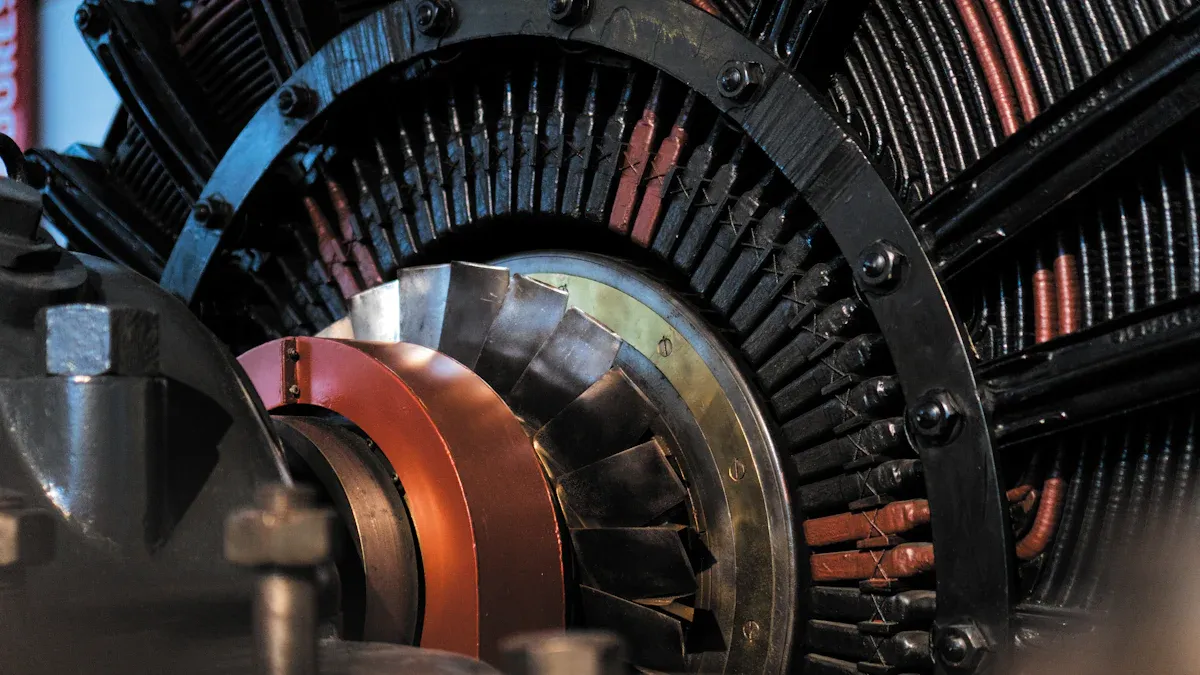

Induction Principle

Asynchronous motors move things using electromagnetic induction. When alternating current goes through the stator windings, it makes a spinning magnetic field. This field crosses the air gap and causes a current in the rotor. The rotor always spins a little slower than the magnetic field. This small speed difference is called slip. Slip is needed to make torque. Torque is the force that turns machines and equipment.

The stator’s magnetic field makes current in the rotor without touching it.

The rotor tries to match the spinning field but never does.

This lets asynchronous ac motors start by themselves and have strong starting torque. They are good for heavy jobs.

Synchronous motors need extra parts to start, but asynchronous motors do not.

Asynchronous motors work well when loads change. This makes them great for many factories.

Main Components

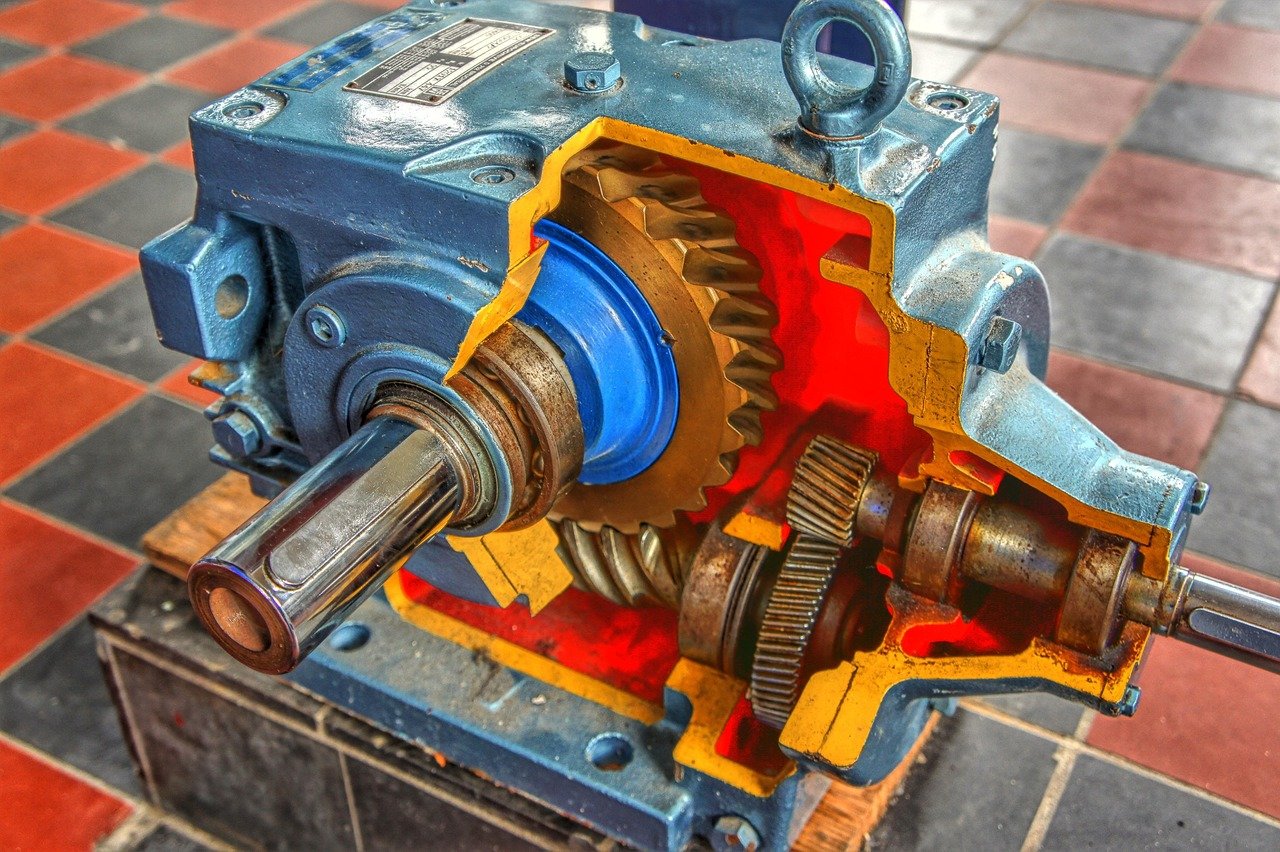

Asynchronous ac motors are simple and tough. This helps them last a long time and work well. The main parts are the stator, rotor, end bells, and shaft.

The stator makes the spinning magnetic field needed for the motor to work.

The rotor, usually a squirrel cage type, gets energy from the stator and spins to give power.

End bells hold the rotor and have bearings to keep it steady and spinning smoothly.

The shaft links the rotor to the machine and sends power to it.

Asynchronous motors have fewer moving parts, so they break less often. They do not have brushes or commutators, so they need less fixing. New materials and cooling help these motors handle strong force and run for a long time. Their strong build lets them work in tough places.

The simple design of asynchronous motors makes them cheaper to make and fix. This is why many factories use them.

Advantages of Asynchronous Motor

Reliability and Low Maintenance

Industrial asynchronous motor systems are known for being reliable. They do not break down often. Their simple build means there are fewer moving parts. This lowers the chance of something going wrong. Operators can trust these motors to work for a long time. They do not need repairs very often. The table below shows how different motors compare:

Motor Type | Annual Failure Rate | Service Life (years) | Maintenance Frequency (per year) | Maintenance Cost (% of total investment) |

|---|---|---|---|---|

Asynchronous Motors | 2%-3% | 18-20 | 2-3 | 2%-3% |

Synchronous Motors | 5%-6% | ~15 | 4-5 | 4%-6% |

Brushless DC Motors | <0.1% (extreme) | 10+ | N/A | N/A |

Asynchronous motors fail less than synchronous motors by 30%-40%. They last longer and cost less to keep running. This makes them a smart pick for factories.

Asynchronous ac motors do not use brushes or commutators, so they need less repair.

Operators just do simple jobs like oiling bearings and cleaning vents.

These motors keep working even in tough places, showing they are strong.

Cost and Energy Efficiency

Asynchronous motor systems help save money and energy. They are good for factories that want to spend less.

Asynchronous motors use less power, especially with variable frequency drives.

New models can be up to 96% efficient, meeting top standards.

Switching to better motors could save U.S. factories $1.68 billion each year.

Upgrades and voltage control can cut energy use by 10-15.5%.

Fixing and reusing motors helps save money and cuts down on waste.

Using less energy means lower bills and helps the planet.

Motor Type | Notes | |

|---|---|---|

Three-phase Asynchronous | 3% to 5% | Long service life (10-15 years) |

Synchronous | About 5% | Efficient after 15+ years |

Asynchronous ac motors run more than 80% of machines in some places.

Their simple design and low repair needs keep costs low.

Smart control methods, like fuzzy control theory, help save even more energy.

High Starting Torque and Performance

Industrial asynchronous motor systems give strong starting torque. This is important for heavy machines. It helps them start easily and move big loads.

Asynchronous motors have more starting torque than synchronous motors.

They do not need extra parts to start.

Operators use these motors for hard jobs like pumps and conveyors.

High starting torque helps machines work well with heavy loads.

DC motors can give even more torque, but asynchronous motors are easier to use and fix.

With variable frequency drives, asynchronous motors handle changing loads well.

Their tough build means they work steady and need little repair, even when things change.

Other Key Advantages

Simple design means fewer problems and easy fixes.

Long life means you do not need to replace them often, saving money.

These motors can be used in many different jobs.

They work with smart tech and IoT for real-time checks and early repairs.

Operators trust these motors to last in hot, wet, or dusty places.

Asynchronous motor systems are very important in factories. They help save energy, lower costs, and work well for a long time.

Industrial Asynchronous Motor Applications

Asynchronous motors are very important in many industries. They are reliable and work well in different places. Factories, HVAC systems, and machines that move things use them a lot. The next parts show how these motors help different jobs.

Manufacturing

Factories need asynchronous motors for many jobs. These motors run machines that cut, shape, and put things together. Their simple build and strong starting power help with heavy work and many starts.

Factories use asynchronous motors for:

Roll forming and machining like turning, milling, and grinding

Stator making, such as punching, welding, and winding coils

Shaft making, which needs cutting, shaping, and hardening

Asynchronous motors run machines in oil, gas, plastic, and metal jobs. More factories use them because of new rules and growing business. Reports show these motors are getting more popular in factories.

Many factories pick asynchronous motors because they last long and do not break much. This helps keep work going and stops delays.

HVAC and Pumps

Big HVAC and pump systems use asynchronous motors to work well. These motors use almost all the power they get. This saves energy and money.

Main benefits in HVAC and pump systems:

Can work in tough places like water plants

High efficiency helps save energy

Start up smoothly and work well

Three-phase asynchronous motors give steady power to fans, pumps, and compressors. They can change how much power they use when needed. This makes them good for places where work changes fast.

Asynchronous motors help companies spend less and use less energy. This is good for the planet.

Material Handling

Conveyors and cranes need asynchronous motors for their strength. The cast iron body keeps them safe from hits and shaking in busy places.

Good things for material handling:

Strong power for lifting and moving big things

Speed can change for different jobs

Work well even in hard places

Asynchronous motors move belts in car factories and cranes in warehouses. They are tough and can do many jobs, so many factories use them.

Workers trust asynchronous motors to move things safely and quickly, even when work is hard.

Motor Comparison

Synchronous vs Asynchronous

Synchronous motors and asynchronous motors do different jobs in factories. Synchronous motors always run at the same speed as the power supply. This makes them good for jobs that need steady speed, like generators or conveyor belts. Asynchronous motors, also called induction motors, work well when loads change. They are strong and can do many kinds of work.

Synchronous motors cost more because they are more complicated. They need an extra part called an excitation system. Asynchronous motors have a simple design. They cost less and last longer in tough places.

The table below shows the main differences:

Performance Aspect | Synchronous Motors | Asynchronous Motors |

|---|---|---|

Speed Control | Constant, precise | Varies with load, always less than synchronous speed |

Structure | Complex, needs excitation system | Simple, stator and rotor only |

Load Adaptability | Needs precise matching, less tolerant | Handles variable loads well |

Efficiency | High at rated loads, higher cost | Efficient, cost-effective |

Typical Use | Precision tasks, generators, compressors | Pumps, fans, wind power, heavy machinery |

Synchronous motors react quickly and are good for jobs that need exact speed.

Asynchronous motors can handle changing loads and work in more places.

DC vs Asynchronous

DC motors and asynchronous motors are different in important ways. DC motors use brushes and commutators. These parts wear out and must be replaced often. Asynchronous motors do not use brushes. They need oil for bearings and checks for cooling.

Motor Type | Maintenance Needs | Extra Notes | |

|---|---|---|---|

DC Brushed Motor | Brushes | Frequent brush replacement | Brush wear causes downtime |

Asynchronous Motor | Bearings | Lubrication and replacement | Cooling system checks needed |

Brushless DC motors stay cooler and are easier to control. They can be up to 30% more efficient than AC motors. Asynchronous motors can reach 90-95% efficiency in big factories. They work best at steady speeds and high power.

DC motors give strong control and work well at many speeds.

Asynchronous motors are tougher and cost less to keep running.

Most factories use asynchronous motors for hard jobs and long life.

Asynchronous motors are still the best pick for big factories. They save money, work well, and are easy to take care of.

Innovations and Trends

Variable Frequency Drives

Variable frequency drives, or VFDs, have changed how factories use asynchronous motors. New VFDs have smart features that help control motors better. Operators notice quicker changes and stronger torque at fast speeds. These drives let machines do different jobs without costing more.

Advanced VFDs make motor control up to 40% better than old ones.

They let workers watch motors in real time and fix problems before they happen using IIoT platforms.

QR codes and remote access help with setting up and fixing motors.

Smart load systems use digital twins and cybersecurity to keep things safe and working well.

VFDs help asynchronous motors work smoothly and save energy. They are important for making factories run automatically.

Smart Technologies

Smart motor technology gives workers more control and information. These systems use sensors and digital tools to check motors all the time. Workers get alerts if there is too much load or if the current drops. Remote monitoring helps staff check motors in places that are hard to reach.

Condition-based monitoring finds problems early, like short windings or odd shaking.

Early warning systems let workers fix things before they break, so machines stop less.

Online monitoring collects data while motors run, helping find issues before they get worse.

Diagnostic tools, like LEDs on starters, show when parts need fixing.

Smart technology helps workers stop problems before they happen. This makes motors safer and more reliable in factories.

Sustainability

Factories want to use less energy and make less pollution. New motor designs, like switched reluctance and brushless DC motors, use up to 50% less electricity. Magnet-free motors do not need rare earth materials, which helps the planet and makes supply easier.

Lighter motors use fewer materials, so making and moving them hurts the planet less.

Recycling and reusing motor parts helps keep resources in use longer.

Upgrading to better motors saves energy and cuts down on pollution.

Smart sensors and Industry 4.0 tools help manage energy and plan repairs.

Asynchronous motors help factories be greener. Their strong build and high efficiency save money and help protect the earth.

Asynchronous motors give big help to today’s factories. They are very reliable and do not need much fixing. They also have strong starting torque, so machines can keep working. The table below shows how they help:

Impact Area | Benefit for Industry |

|---|---|

Reliability | High uptime, fewer failures |

Energy Efficiency | Lower power use, cost savings |

Adaptability | Handles heavy and changing loads |

Wide Applicability | Used in many industrial applications |

New ideas, like smart sensors and variable frequency drives, make these motors even better. People who pick motors should think about these things for their factories.

FAQ

What is the main difference between asynchronous and synchronous motors?

Asynchronous motors do not run as fast as the power supply. Synchronous motors always match the supply speed. This helps asynchronous motors work better when loads change.

Why do factories choose asynchronous motors for heavy-duty work?

Factories use asynchronous motors because they have strong starting torque. These motors start heavy machines without trouble. Their simple design means fewer problems and less stopping.

Can asynchronous motors save energy in industrial settings?

Yes. Asynchronous motors use less energy with variable frequency drives. Many factories buy high-efficiency models to save money and help the environment.

How often do asynchronous motors need maintenance?

Operators check bearings and clean vents a few times each year. These motors do not have brushes, so they need less fixing than other types.

Are asynchronous motors suitable for harsh environments?

Asynchronous motors work well in hot, wet, or dusty places. Their strong build and simple parts help them last longer, even in tough spots.