Landscaping presents harsh operating conditions—high vibrations, heavy loads, and constant debris. This environment demands a shift from traditional gas engines to professional-grade High-Torque BLDC motors. By delivering instant response and achieving 63% higher peak torque than a 36cc gas trimmer, these motors redefine efficiency while eliminating maintenance tasks like oil changes and spark plug replacements.

Key Takeaways

High-torque BLDC motors provide instant torque and require less maintenance, saving you time and money.

The outer rotor design enhances performance by preventing stalling, allowing for consistent power delivery during tough tasks.

Custom diameter fittings from 20mm to 260mm enable you to optimize tool design for better performance and ergonomics.

IP-rated sealing protects motors from dust and moisture, ensuring durability and reducing repair needs.

Rapid prototyping service allows for quick design adjustments, helping you bring high-performance tools to market faster.

Mastering Peak Torque Density

Outer Rotor: Anti-Stall Performance

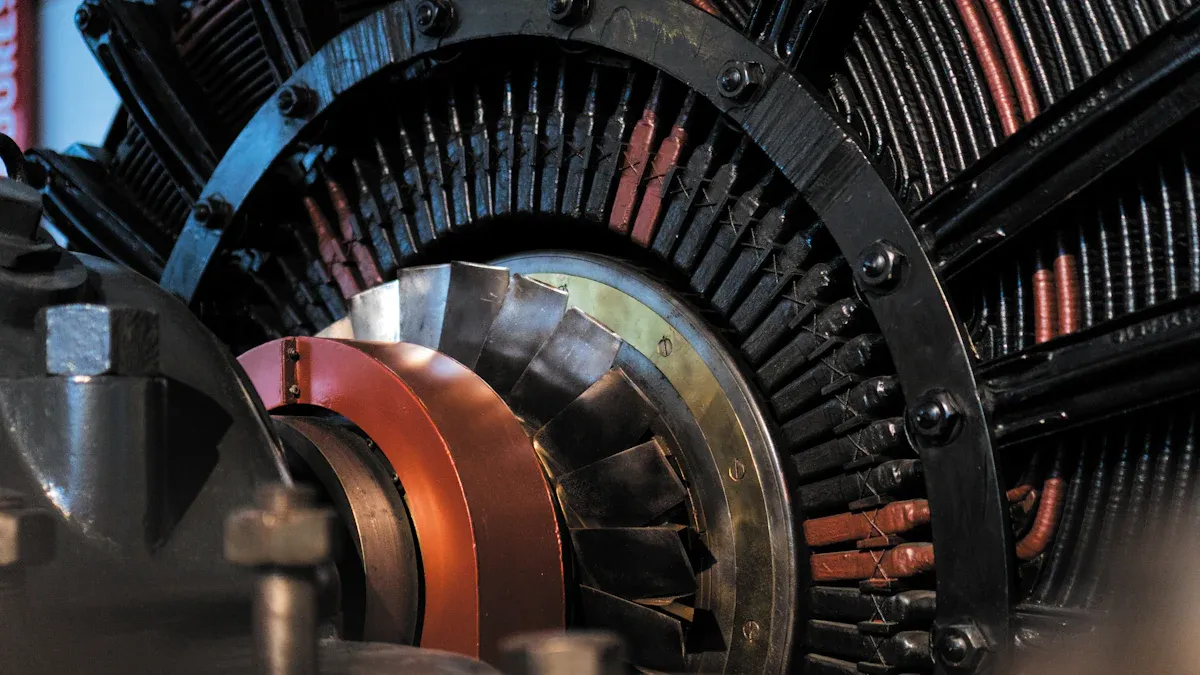

High-torque BLDC motors for gardening tools excel in demanding outdoor environments. By utilizing an outer rotor design, these motors provide a significant mechanical advantage over traditional inner-rotor options, especially when cutting through thick brush or dense branches.

The Flywheel Effect for Consistent Power The primary advantage of the outer rotor structure is its higher rotational inertia. Like a heavy flywheel, the outer rotor stores kinetic energy, allowing the motor to maintain consistent torque even when encountering sudden resistance.

Anti-Stall Capability: Resists stalling under heavy loads, ensuring smooth operation in chainsaws and lawnmowers.

Mechanical Stability: The design minimizes the impact of shock loads, leading to a more stable cutting experience.

Durability: Robust construction reduces mechanical wear, extending the motor’s operational lifespan in high-vibration landscaping tasks.

Feature | Outer Rotor BLDC | Inner Rotor BLDC |

Inertia Level | High (Flywheel Effect) | Low (Quick Accel/Decel) |

Load Stability | Superior (Anti-Stall) | Standard |

Best Application | Heavy-duty cutting/mowing | High-speed precision tools |

Engineering for Shock Resistance

In landscaping, tools often face shocks and vibrations from rough terrain. High-torque BLDC motors are engineered to withstand these conditions. Their robust construction minimizes wear and tear, ensuring that they remain reliable over time. You can trust that these motors will perform consistently, even in challenging environments. The shock-resistant features help prevent damage during operation, which means fewer repairs and lower maintenance costs for you.

The efficiency improvements achieved by using high-torque BLDC motors in gardening tools are noteworthy. Consider the following table that outlines these enhancements:

Efficiency Improvement | Description |

|---|---|

High-speed rotation | High efficiency Brushless DC motors deliver high-speed rotation, enhancing performance in gardening tools. |

Extended battery life | These motors offer extended battery life compared to traditional DC brush motors, improving overall tool efficiency. |

Higher torque at low speeds | BLDC motors can be integrated with gearboxes to provide higher torque at lower speeds, essential for cutting through thick grass in robotic lawn mowers. |

Bespoke Solutions for Slim Design

Custom 20mm-260mm Diameter Fittings

Optimizing tool design requires a motor that fits specific mechanical constraints without sacrificing power. We offers bespoke diameter fittings from 20mm to 260mm, enabling a precise match for diverse landscaping applications.

Compact Integration (20mm – 45mm): Specifically engineered for lightweight tools like handheld pruning shears, where reducing motor diameter is key to improving ergonomics and reducing user fatigue.

High-Torque Scaling (50mm – 260mm): Larger diameters provide the magnetic volume necessary for heavy-duty chainsaws and lawnmowers, delivering the extra torque required for professional-grade tasks.

Strategic Benefits of Custom Sizing:

Optimized Power-to-Weight Ratio: Achieve maximum efficiency by matching motor size to the tool’s load requirements.

Enhanced Ergonomics: Compact designs lead to lighter tools, a critical factor for professional operators during extended use.

Market Versatility: One platform can be adapted for everything from residential trimmers to industrial robotic mowers.

IP-Rated Sealing Against Sap and Dust

Outdoor operation exposes internal components to corrosive sap, fine dust, and moisture. High-torque BLDC motors featuring IP65/IP67-rated sealing ensure robust protection against these contaminants, preserving performance and extending operational longevity.

Durability: Shields internal windings and magnets from abrasive debris.

Reliability: Maintains consistent electrical output in high-humidity or wet conditions.

Efficiency: Minimizes downtime and repair costs by preventing internal contamination.

Automotive-Grade Reliability

High-torque BLDC motors for gardening tools must meet rigorous standards. We adheres to IATF 16949, which emphasizes zero-defect manufacturing. This commitment ensures that every motor you receive is reliable and performs consistently. You can trust that these motors will withstand the demands of landscaping tasks.

IATF 16949: Zero-Defect Standards

Honest’s manufacturing excellence is anchored in IATF 16949 certification, the global benchmark for automotive quality management. Moving beyond standard consumer-grade quality, our zero-defect strategy ensures that every motor provides the heavy-duty reliability required for professional landscaping.

Zero-Defect Commitment: Rigorous defect prevention and continuous improvement protocols are integrated into every production phase.

Precision Testing: Each high-torque BLDC motor undergoes stress testing for performance, thermal stability, and vibration resistance before delivery.

Mission-Critical Reliability: Engineered to withstand the extreme duty cycles of professional-grade chain saws and robotic mowers, minimizing field failures and unexpected downtime.

Rigorous Testing for Extreme Environments

Honest motors undergo comprehensive environmental stress testing to ensure consistent performance under the most punishing landscaping conditions.

Environmental Simulation: Motors are tested against rapid temperature fluctuations, high-humidity moisture exposure, and salt spray to prevent corrosion and electrical failure.

Mechanical Endurance: High-amplitude vibration and shock-load testing simulate rough terrain and accidental impacts, ensuring structural integrity.

Customized Optimization: Beyond standard testing, Honest provides tailored performance tuning—balancing peak torque and weight to meet the specific duty cycles of your equipment.

Honest’s Agile Supply Chain for OEMs

In the world of landscaping, durability is crucial. You need tools that can withstand harsh environments. We understands this need and has developed an agile supply chain tailored for Original Equipment Manufacturers (OEMs).

15-Day Rapid Prototyping

Accelerating Market Entry Honest provides an agile supply chain specifically optimized for OEMs. We deliver custom motor prototypes in just 15 days from design finalization, allowing you to validate and refine your products without traditional development bottlenecks.

Fast Iteration: Rapidly transition from testing feedback to design adjustments, shortening your R&D lifecycle.

Cost Efficiency: Minimize the financial overhead associated with protracted development phases.

Engineering Collaboration: Direct access to Honest’s technical team ensures your vision is translated into a high-performance reality.

This accelerated prototyping capability empowers you to bring professional-grade gardening tools to market ahead of the competition.

Strategic Partnership for Scalable R&D

We believes in building strong partnerships with OEMs. This collaboration enhances research and development (R&D) efforts. You gain access to:

Tailored Solutions: Customize motors to meet specific gardening tool requirements.

Scalable Production: Easily scale up production as your demand grows.

Innovative Technologies: Leverage the latest advancements in motor technology, including IP-rated sealing and thermal management features.

These features protect your tools from dust, moisture, and extreme temperatures. They ensure reliable performance, even in challenging conditions.

We provides a significant edge in power density and market readiness for electric gardening tools. Our high-torque BLDC motors deliver exceptional performance, ensuring you can tackle any landscaping challenge with confidence.

Ready to elevate your products? Collaborate with us on your next high-performance motor project.

FAQ

What are high-torque BLDC motors?

High-torque BLDC motors provide efficient power delivery and instant torque. They replace traditional gas engines in tools like chain saws and lawnmowers, offering lower maintenance and environmental benefits.

How do I maintain high-torque BLDC motors?

You can maintain these motors by keeping them clean and ensuring proper ventilation. Regularly check for debris and inspect connections to ensure optimal performance.

What is the lifespan of high-torque BLDC motors?

High-torque BLDC motors typically last over 20,000 hours with proper care. Their brushless design reduces wear, leading to longer operational life compared to traditional motors.

Are high-torque BLDC motors suitable for all gardening tools?

Yes, high-torque BLDC motors are versatile and can power various gardening tools, including chain saws, lawnmowers, trimmers, and blowers. They adapt well to different applications.

How do I choose the right motor size for my tool?

Select a motor size based on your tool’s power requirements and design constraints. Honest offers custom diameter fittings from 20mm to 260mm to meet your specific needs.