Selecting a mining truck fan motor requires careful consideration of several factors. Performance is crucial, as mining operations place significant demands on machinery. Engineers must assess whether the motor, such as the Caterpillar 797F motor, is energy-efficient, durable, and suitable for the intended application. In underground mining, a mining truck fan motor must withstand dust, moisture, and hazardous gases. Therefore, it is essential that the motor is robust enough to cope with these challenging conditions. Certain tasks may also require features such as explosion protection, which not only ensures safety but can also reduce operational costs. The Caterpillar 797F motor exemplifies the necessity for reliable and powerful motors in the mining industry.

Key Takeaways

-

Pick fan motors that give steady airflow and pressure. This helps keep mines safe and engines cool. It stops overheating and expensive breakdowns.

-

Use variable speed drives to change fan speed as needed. This saves energy and makes the motor last longer. It also lowers wear and tear.

-

Choose heavy-duty, sealed motors made from strong materials. These materials resist rust and damage. They can handle dust, wetness, hot or cold, and dangerous gases.

-

Make sure the fan and motor fit together the right way. The mounting and space must be correct. This stops damage, lowers noise and shaking, and helps them work better.

-

Do regular checks, like looking at belts and clamps. This helps find problems early. It keeps fan motors working well and safely.

Performance and Motor Types

Airflow and Pressure

Mining truck fan motors need to give steady airflow and keep the right pressure. This helps with good ventilation in both underground and open-pit mines. At the Borden underground mine, engineers change airflow from 23% to 100% as needed. Airflow is measured in cubic feet per minute (CFM). Each truck type needs a different amount of airflow. Electric and diesel trucks need different airflow to keep air safe to breathe.

-

Ventilation on-demand systems use fans, variable speed drives, and tracking tools. These help send the right airflow to where people and trucks are working.

-

Plastic ducting makes less friction and loses less pressure than steel or fabric ducts. This lets fans run slower or be smaller.

-

Air can travel farther with better airflow and pressure when plastic ducts are used. This can cut energy use by 40-50%.

-

Auxiliary ventilation systems use axial fans and ducting to give the needed airflow in underground mine roads.

-

Fan power and pressure drop depend on duct size and length. Bigger ducts lower pressure drop and save energy.

-

Making duct diameter bigger from 0.6 m to 0.8 m can cut fan power needs by up to 74%.

-

Ducts between 0.6 m and 2.4 m wide and tunnels up to 4000 m long are used to make auxiliary ventilation work better.

-

Choosing the right size for ducts and fans is very important. It helps get the needed airflow at the work area and keeps energy costs low.

How well airflow works affects cooling. Enough airflow keeps air moving and controls temperature. If airflow drops, fans can stall. This can cause motors and parts to overheat and break. Smart control systems change airflow to match cooling needs. This saves energy and works better. Checking airflow like CFM and static pressure often helps find blockages or problems early. This stops fan stalls and keeps cooling going.

In mining trucks, cooling fans are near radiators. They pull in cool air and help get rid of engine heat. If airflow drops or fans stop working, engines can get too hot. This lowers power and uses more fuel. Keeping airflow good by checking fan blades, belts, shrouds, and cleaning the radiator is key. This keeps trucks working well and helps them last longer.

Motor Power and Speed

Motor power and speed are very important in ventilation on-demand systems. Changing fan speed to match real-time needs saves a lot of energy. Fan power use changes a lot with speed. Lowering speed can save much more energy. For example, cutting speed by 10% saves about 30.59 kW. Cutting speed by 50% saves almost 97.03 kW.

|

Aspect |

Relationship / Effect |

Explanation |

|---|---|---|

|

Power use vs. fan speed |

Power ∝ (Speed)^3 |

Lowering fan speed cuts power use a lot |

|

Bearing life vs. load |

Bearing life L ∝ 1 / (Load)^3 |

Small load increases can shorten bearing life a lot |

|

Load vs. fan speed |

Load ∝ Speed |

Faster speed puts more load on bearings |

|

Bearing life vs. fan speed |

Bearing life L ∝ 1 / (Speed)^3 |

Slower speed makes bearings last longer |

|

Wear rate vs. speed |

Wear rate W ∝ (Speed)^3 |

Halving speed cuts wear rate to 12.5% of before |

|

Financial impact |

Energy savings cut costs |

Yearly savings can be big |

Variable speed drive technology lets mining truck fan motors match airflow and ventilation as needed. This saves energy and makes parts last longer. Lower speeds also mean less wear, so there is less fixing and longer life for equipment.

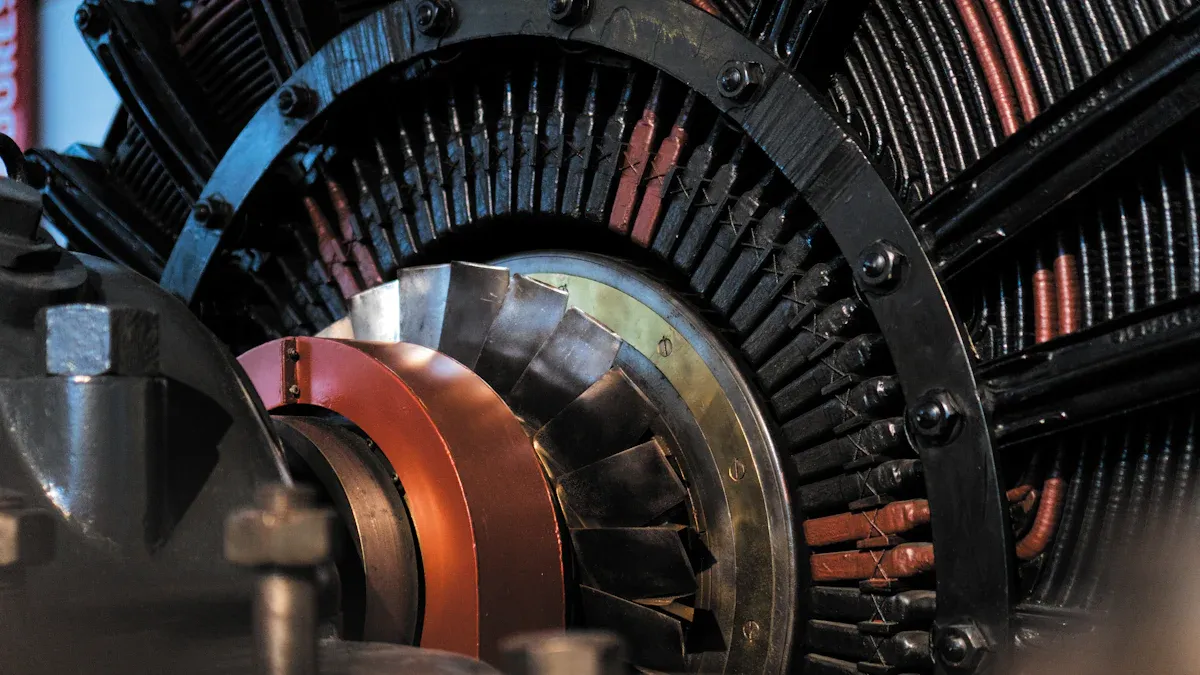

AC vs DC Motors and Variable Speed Control

Picking the right fan for mining trucks means choosing between AC and DC motors. AC motors, especially three-phase induction types, are best for mining truck fans. They work better and need less fixing. They do not have brushes or commutators, so there are fewer parts to change and less downtime. AC motors can change speed smoothly with variable frequency drives. This gives better power and speed control. They also allow for regenerative braking and can be used in trolley systems. This helps lower emissions and save energy.

-

AC motors give up to 7% more work from the same energy and need less fixing, usually just one check a year.

-

Trolley trucks with AC drives can go almost twice as fast on slopes and have fewer moving parts. This helps the environment and saves money.

-

DC motors are good at low speeds and are easy to control by changing voltage, but they need more fixing because of brushes and commutators.

-

DC motors cannot go as fast and have more complex control parts.

-

AC polyphase motors have no brushes, need little fixing, and last a very long time.

-

DC motors might be chosen for portable or trailer-mounted machines if power supply is limited.

Siemens has used three-phase AC drives in mining vehicles for over 30 years. AC motors turn electric fields straight into movement. DC motors need current to stop and start again, which limits speed and means more fixing. AC motors can use regenerative braking and save energy, which is good for mining truck efficiency and the environment.

Variable speed control with variable speed drives in mining truck fan motors saves a lot of energy. This is because of the cubic link between speed and power. Lowering speed makes bearings last much longer and cuts wear. This saves a lot of money. Ventilation on-demand systems work better with variable speed control. They can change airflow and ventilation to match what is needed, saving energy and cutting fixing costs.

Energy Efficiency and Operational Costs

Mining sites need good ventilation to keep people safe. It also helps machines stay cool. The fan motor you pick changes how well the system works. Engineers want motors that give enough airflow but use less power. This helps save money and energy.

Ventilation on-demand systems only use energy when needed. These systems change fan speed and airflow using real-time data. If there are fewer workers or trucks, airflow goes down. This saves energy and makes the fan motor last longer. Many mines now use smart controls to help with this.

Good ventilation keeps the air clean and removes bad gases. It also stops engines from getting too hot. When ventilation works well, the mine uses less power and needs fewer repairs.

The table below shows how ventilation on-demand is different from old systems:

|

Feature |

Traditional Ventilation |

Ventilation On-Demand |

|---|---|---|

|

Airflow Control |

Fixed |

Adjustable |

|

Energy Use |

High |

Lower |

|

Maintenance Needs |

Frequent |

Reduced |

|

Operational Cost |

Higher |

Lower |

Ventilation on-demand has clear advantages. It gives the right airflow for each area. This saves energy and lowers costs for the mine. Good ventilation means fewer breakdowns and less time stopped. Mines with better ventilation systems are safer and make more money over time.

Environment and Durability

Dust, Moisture, and Temperature Extremes

Mining truck fan motors work in places with lots of dust, water, and very hot or cold weather. These tough conditions make motors wear out faster and can cause rust or broken parts. Dust in mines can scratch moving parts and block air paths. Water can make metal rust and damage the motor’s wires. Quick changes in temperature can crack or bend motor parts. Cleaning and checking the motor often helps find problems early. Special sensors can spot strange shaking or heat, so repairs can happen fast. Motors that pass MIL-STD-810G tests are strong against these problems and work well in hard mining jobs.

Hazardous Gases

Underground mines can have dangerous gases. These gases might catch fire if there is a spark or hot part. Fan motors here need explosion-proof parts. ATEX certificates show a motor is safe where there could be explosive gas or dust. These motors have sealed cases to keep sparks inside and controls to stop them getting too hot. Strong materials stop gas from causing rust. All wires and parts must also be explosion-proof. Picking the right fan motor for each ATEX zone keeps people and machines safe.

Safety Tip: Always make sure fan motors and parts in underground mines have the right explosion-proof rating.

Heavy-Duty Construction and Frame Materials

Mining trucks need fan motors that are very strong and last a long time. Heavy-duty motors use hard metals and strong frames to handle bumps, shaking, and rough use. In mines, motors must also stand up to hits and chemicals from dust and gas. Makers often use stainless steel or special coatings to stop rust. A strong frame keeps the motor steady, even on bumpy roads. Mining motors should have extra seals and covers to keep out dust and water. These things help the motor last longer and stop it breaking down.

|

Feature |

Benefit in Mining Environments |

|---|---|

|

Sealed housings |

Stops dust and water getting in |

|

Reinforced frames |

Handles bumps and shaking |

|

Corrosion-resistant |

Stops rust from water and gas |

|

Stops fires in dangerous places |

Compatibility and Matching

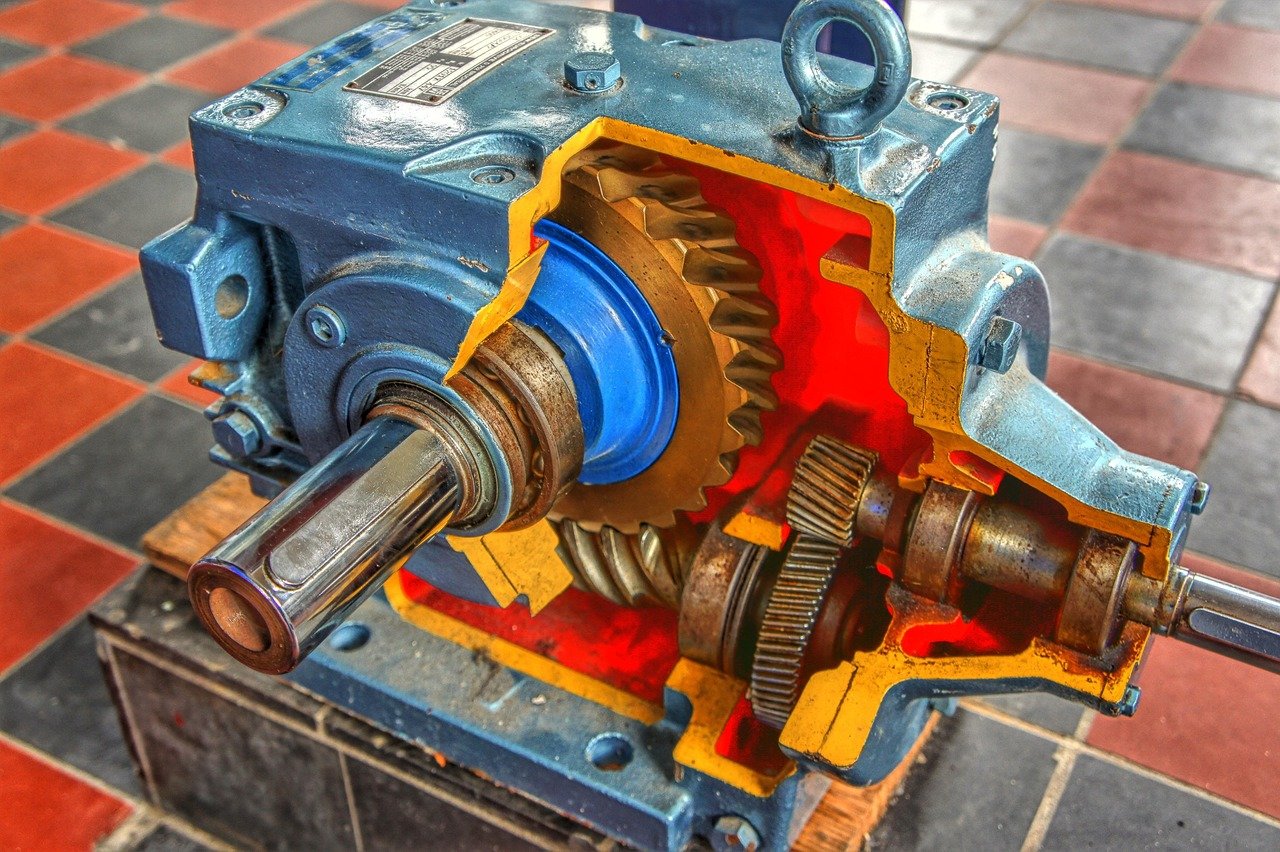

Fit and Mounting

Picking the right fan for a mining truck is not just about power. The fan and motor must fit in the space and be mounted safely. There are different ways to mount fans, like shaft-mounted or fan drive types. Each type needs its own way to be put in and needs certain space around it. The table below shows the main differences:

|

Aspect |

Shaft-Mounted Fans |

Fan Drive / Clutch Mounted Fans |

|---|---|---|

|

Mounting Method |

Direct on motor shaft with a hub |

Uses pilot and bolts on fan drive; pulley links drive to shaft |

|

Common Applications |

Electric or hydraulic motors, engines with gearboxes |

Hydraulic motors, water pumps, better fan speed control |

|

Fan Types |

Metal, fully-moulded, modular |

Metal, fully-moulded, modular |

|

Fit Considerations |

Fan size, things in the way (radiator, brackets, pulleys, shroud), space on radiator side, other side, blade tip |

|

|

Recommended Clearances |

Sucker fans: about 1× pitch width (radiator side), 3% fan size (other side), 1.25-3% fan size (blade tip) |

|

|

Obstructions |

Radiator and brackets (radiator side), FEAD pulleys and crankshaft parts (other side), shroud and finger guard (blade tip) |

|

|

Performance Impact |

Fan in shroud (best is 65-70%), less stress and shaking with bigger fans turning slower |

|

A good fit helps the fan work well and stops it hitting other parts. Engine fans need enough space so they do not get damaged by shaking or moving. If the fit is right, the fan and motor make less noise and last longer.

Fan and Motor Matching

Getting the fan and motor to match is very important for mining trucks. Engineers look at things like height, heat, wetness, and dust. These things change how the fan and motor work together. Some good tips are:

-

Lower motor power by 3% for every 500 metres above 1,000 metres.

-

Use non-sparking fans made from brass, bronze, or aluminium in risky places.

-

Pick explosion-proof motors if there are dangerous gases or dust.

-

Add more cooling fans if the main fan is slow and cannot cool enough.

-

Keep the motor clean, cool, and dry to stop it breaking.

-

Put heaters in motors to stop water drops in cold or wet places.

-

Use heat sensors to check motor temperature and stop it getting too hot.

-

Think about service factors, shaft grounding, and extra protection to make motors last longer.

Tip: Always make sure engine fans and motors suit the mining truck’s place and how they are put in. This helps stop expensive problems and keeps the truck working.

If the fan and motor are matched well, the system gives the right airflow, keeps the engine cool, and works safely in tough mining places.

Maintenance Considerations

Serviceability

Mining truck fan motors need regular checks to work well. Engineers sometimes hear fan belt squeaks. This means the belt should be changed soon. Old belts or stiff hoses can break without warning. Technicians say it is best to change these parts before they fail. Clamps around the fan and belt must be tight. This stops slipping and lowers shaking. Regular checks help teams find problems early. This stops long and costly repairs.

-

Change old belts and stiff hoses quickly.

-

Make sure clamps are tight on the fan and belt.

It is easier to fix fan motors if you can reach them easily. Mining trucks with open fan housings and clear service spots save time. Good serviceability makes trucks more reliable. It helps trucks keep working in tough places.

Noise and Vibration

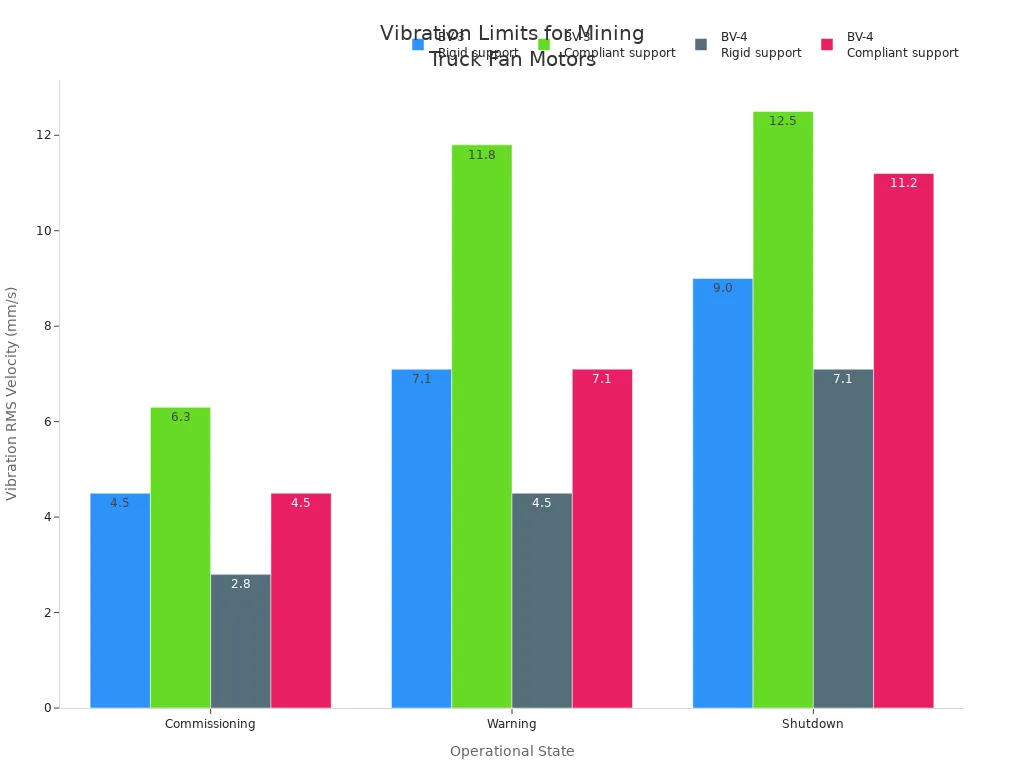

Noise and vibration control are very important when picking a mining truck fan motor. Too much shaking can harm the fan, motor, and other parts. Fans are put into BV-3 and BV-4 groups. Each group has its own vibration speed limits. These limits help engineers check fan health. They can plan repairs before things get worse.

|

Fan Category |

Application Example |

Power Range (kW) |

Vibration Limit RMS Velocity (mm/s) at Operating Site (Commissioning) |

|---|---|---|---|

|

BV-3 |

Industrial processes including mining trucks |

≤15 |

4.5 (rigid support), 6.3 (compliant support) |

|

BV-4 |

Transport fans >15 kW (e.g., larger trucks) |

>15 |

2.8 (rigid support), 4.5 (compliant support) |

|

Fan Vibrational State |

BV-3 Limit RMS Velocity (mm/s) |

BV-4 Limit RMS Velocity (mm/s) |

|---|---|---|

|

Commissioning |

4.5 (rigid), 6.3 (compliant) |

2.8 (rigid), 4.5 (compliant) |

|

Warning |

7.1 (rigid), 11.8 (compliant) |

4.5 (rigid), 7.1 (compliant) |

|

Shutdown |

9.0 (rigid), 12.5 (compliant) |

7.1 (rigid), 11.2 (compliant) |

The Cat 793F Mining Truck cab uses special sound blocks and strong mounts. These help lower noise and shaking. This makes drivers feel less tired and keeps them safe. Strong mounts also protect the truck frame and fan motor. This helps the equipment last longer. Good noise and vibration control make the truck safer and more comfortable for drivers.

Caterpillar 797F Motor Comparison

The caterpillar 797f motor is a top choice for mining trucks. Engineers like it because it is easy to reach. Maintenance teams can get to the mining truck fan motor fast. This means trucks do not stop working for long. The caterpillar 797f motor has a modular design. Technicians can take out and swap the mining truck fan motor easily. They do not need to move other parts. The motor sits in an open space, so cleaning is simple. Dust and dirt do not pile up quickly. This helps the mining truck fan motor work well for a longer time.

Noise and vibration control are very important for the caterpillar 797f motor. Drivers spend many hours in the cab. Too much noise or shaking can make them tired and lose focus. The caterpillar 797f motor has special mounts and dampers. These help soak up shocks and lower vibrations from the mining truck fan motor. The cab stays quieter and more pleasant. The mining truck fan motor also lasts longer because it gets less stress.

Note: A mining truck fan motor with good vibration control keeps both the driver and the truck safe.

The table below shows how the caterpillar 797f motor compares to a normal mining truck fan motor:

|

Feature |

Caterpillar 797F Motor |

Standard Mining Truck Fan Motor |

|---|---|---|

|

Ease of Access |

Excellent |

Moderate |

|

Replacement Time |

Short |

Longer |

|

Cleaning Simplicity |

High |

Medium |

|

Noise and Vibration Control |

Advanced |

Basic |

|

Operator Comfort |

Superior |

Standard |

The caterpillar 797f motor shows that smart design helps with both fixing and using the truck every day. Mining companies save time on repairs and keep workers safer. Drivers feel less tired, and the mining truck fan motor works well even in tough places.

Mining Truck Fan Motor Selection Tips

Picking the right fan motor for mining trucks takes good planning. Mining experts say every choice should match the special problems in mining. As mines get deeper, the environment changes. The fan motor must handle new airflow needs and more resistance.

Tip: Always pick a fan with 30–40% more capacity than you need now. This helps if you need more airflow later and stops expensive upgrades.

When choosing a fan motor, engineers should look at these main points:

-

Assess the Environment

-

Check the temperature and humidity in the mine.

-

Look for toxic gases in the air.

-

Pick fans and motors that can handle dust and water.

-

Make sure they work in very hot or cold places.

-

-

Choose the Right Fan Type

-

Metal fans are strong but heavier.

-

Fully-moulded fans are quiet and use less energy.

-

Modular fans can be changed to fit special needs.

-

-

Optimise Airflow Configuration

-

Sucker fans pull air over the engine to help it work better.

-

Blower fans push air out and keep radiators cleaner.

-

-

Ensure Proper Fit and Mounting

-

Keep the right space around the fan to stop blockages.

-

Use shaft-mounted or clutch-mounted fans for different jobs.

-

-

Prioritise Reliability and Certification

-

Use strong materials like T6-6061 aluminium with hard anodising.

-

Do not use motors or clutches without certificates.

-

Uncertified parts break faster and cost more.

-

-

Avoid Common Mistakes

-

Always pick the right size; 280mm clutches work best for most mining jobs.

-

Do not skip tests for heat and dust.

-

Change clutches after many repairs instead of fixing them again and again.

-

|

Mistake to Avoid |

Why It Matters |

|---|---|

|

Low-quality materials |

Can rust or crack easily |

|

Incorrect sizing |

Blocks airflow or wastes fuel |

|

Poor installation |

Makes leaks and shaking worse |

|

Ignoring durability tests |

Makes motors less reliable in tough mines |

|

Uncertified components |

Means more breakdowns and higher costs |

A strong ventilation plan, good setup, and regular checks help the fan motor work well and safely. Watching the system all the time helps control heat and keeps workers safe in every job.

Picking the best mining truck fan motor needs you to think about many things. You should look at what type of fan is used, how air moves, and how the fan is put in. It is important to check if the fan fits well and works in tough places. The fan must be strong and easy to fix. Some fans need special safety parts for dangerous jobs, like explosion-proof designs. Fans made from tough materials do not rust and last longer in hard places.

Talking to makers or experts gives you better ideas and helps you find the right fan motor. They can help you choose designs that work well and are safe. Their advice helps mines save money and keep workers safe. This is very useful when picking special motors like the Caterpillar 797F.

FAQ

What makes a mining truck fan motor suitable for harsh environments?

A mining truck fan motor needs sealed housings and strong frames. It should use materials that do not rust easily. These things help keep out dust and water. They also protect the motor from very hot or cold weather. Heavy-duty motors last longer in tough mining places.

How often should engineers inspect mining truck fan motors?

Engineers should check fan motors at least once every month. Regular checks help find worn belts and loose clamps. They also spot dust build-up early. Finding problems early stops breakdowns. This keeps the truck working well.

Why is explosion protection important for underground mining fan motors?

Underground mines can have gases that catch fire. Explosion-proof motors stop sparks from lighting these gases. This keeps workers and machines safe. Always pick motors with the right explosion protection for the mine.

Can variable speed drives reduce operational costs?

Variable speed drives change fan speed to match airflow needs. This saves energy and makes parts last longer. Mines spend less money on power and fixing things. Variable speed drives also help the fan motor work for more years.

What should engineers consider when matching a fan and motor?

Engineers must check how much airflow is needed. They should look at the space for mounting. They must think about the mine’s conditions. The fan and motor must fit together well. Good matching keeps the engine cool and the truck safe.