Selecting the right motor—BLDC or PMSM—is a critical decision for electric vehicles in South Korea. Both motor types offer distinct advantages, but PMSM motors generally provide higher power density and greater efficiency for high-speed EV applications. This choice directly impacts vehicle performance, system costs, and motor longevity.

Key Takeaways

BLDC motors: cost-effective, low-maintenance, suitable for city vehicles.

PMSM motors: high power and efficiency, suitable for high-speed EVs.

Motor choice affects vehicle performance, system cost, and lifespan.

Advances in motor technology improve reliability and energy efficiency.

Technical Profiles of EV Motors

Electric vehicles need special motors to work well. These motors help cars use energy better and run smoothly. It is important to know how BLDC and PMSM motors work. This helps you see why they are used in electric vehicles.

BLDC Motor Key Characteristics

A BLDC motor does not use brushes. It uses electronics to control the current. This makes the motor last longer and need less fixing. BLDC motors are very efficient and change energy well. They use Ampere’s Law and Faraday’s Law to make the car move. The rotor turns because of the magnetic field and current. Sensors tell the motor where it is. This helps the motor change speed and torque fast.

Here is a table that shows why BLDC motors are good for electric vehicles:

Performance Characteristic | Description |

|---|---|

Often above 90%. This saves energy and lets cars go farther. | |

Good speed-torque characteristics | Gives strong torque for many driving needs. |

Greater lifespan | Has fewer parts, so it lasts longer. |

Improved heat dissipation | The windings touch the case, so the motor stays cool. |

Low noise and interference | No sparks or brush noise, so rides are quieter. |

BLDC motors deliver high torque relative to size and operate quietly, enhancing EV safety and performance. The brushless design keeps them cool and saves energy.

PMSM Motor Key Characteristics

A PMSM motor uses permanent magnets and a controller. This makes the car move. PMSM motors have high power in a small size. They give steady torque and use less energy. They react fast and help save space and weight in cars.

Here is a table that shows PMSM motor features:

Feature | Description |

|---|---|

High power in a small size, great for electric cars. | |

Output Torque | Gives steady torque for smooth driving. |

Noise Level | Makes little noise for a nicer ride. |

Speed Regulation | Controls speed well for different roads. |

Reliability | Strong build for hard use and long life. |

PMSM motors are reliable, light, and use energy well. They react quickly and can recover energy. This makes them great for new electric cars.

Technical Advancements in BLDC Motor

Efficiency Improvements

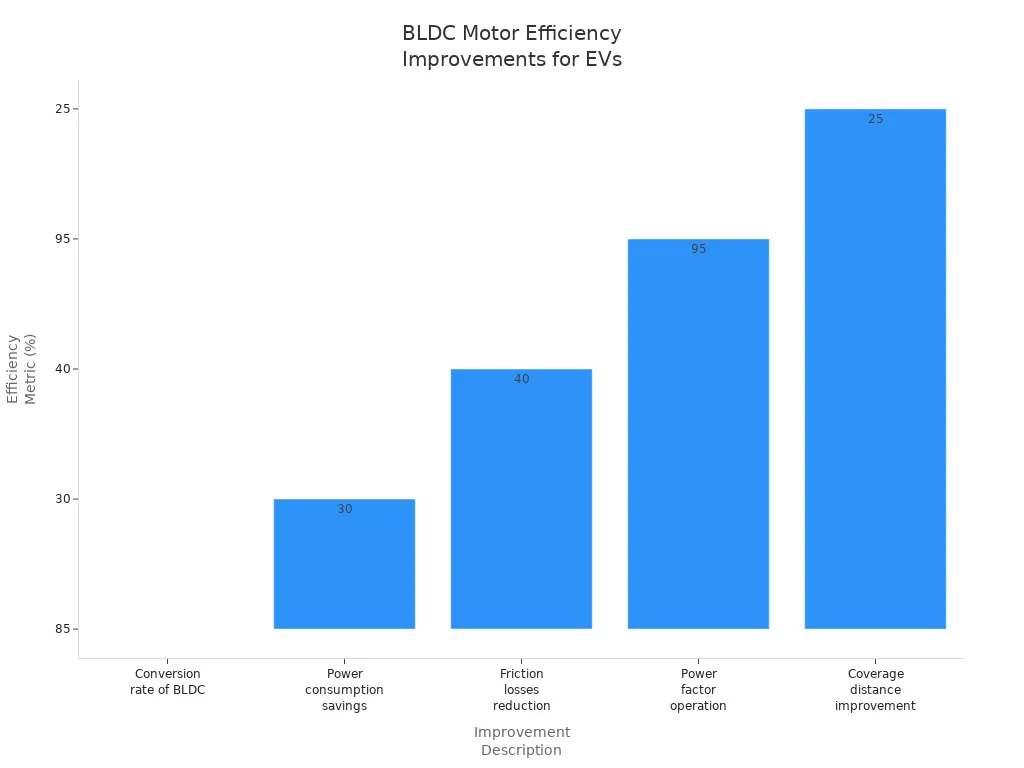

BLDC motors for electric vehicles have been steadily improving. Modern designs can convert up to 85% of electrical energy into mechanical power, which means you get more power from the same amount of electricity. Compared with traditional brushed motors, friction losses are reduced by around 40%, helping vehicles save roughly 30% of energy during typical driving. These motors can also operate at high power factors—up to 95%—allowing vehicles, such as patrol cars, to travel about 25% farther on a single charge.

Improvement Description | Efficiency Metric |

|---|---|

Conversion rate of BLDC motors | Up to 85% |

Power consumption savings in electric vehicles | About 30% |

Friction losses reduction compared to brushed motors | Up to 40% less |

Power factor operation capability | Up to 95% |

Increased coverage distance per charge for patrol cars | 25% improvement |

You see these new features help in real life. The Inner Rotor Brushless DC Motor is small and uses smart parts. It gives more power and works better. The Outer Rotor Brushless DC Motor gives strong torque and stays cool. It is good for cars that need to drive far and need strong motors. Both motors help save energy and can recover energy when braking.

Traction and Control Innovations

BLDC motors now help cars grip the road better. New control systems and sensors make driving smoother. Motors use special encoders and resolvers that tell the motor where the rotor is, even when starting or moving slowly. This enables smooth power delivery and fast response.

Engineers also use smart controls and programs to reduce vibration and extend motor life. For example, the Inner Rotor model reacts quickly and controls speed well for fast cars, while the Outer Rotor model delivers strong power for slow, heavy vehicles like e-bikes or delivery vans. These new BLDC motors are used in many types of vehicles, delivering strong torque, energy-efficient performance, and reliable operation.

PMSM Motor Advancements for Electric Vehicles

Power Density and Output

PMSM motors for electric cars have changed a lot. These motors now use rare-earth permanent magnets. This gives more power and better torque. New power electronics and control systems help each motor work better. These changes make motors smaller and lighter but much stronger.

Here is a table that shows some new PMSM motor advancements:

Advancement | Description |

|---|---|

Rare-earth permanent magnets | Improved torque and power output |

Power electronics and control | Better efficiency and controllability for electric vehicles |

Energy efficiency improvements | Less energy loss, more power for driving |

Increased power density | Smaller, lighter motors with higher performance |

High-output traction systems | Up to 1,200 kW per motor, with regenerative braking |

You can see these changes in Honest’s Permanent Magnet Synchronous Motor products. These motors have the highest power density of all traction motors. They are about one-third the size of most AC motors. This makes them easy to put in electric cars. You get strong overload ability and full torque at low speeds. This helps with city driving and quick starts.

Efficiency and Reliability

PMSM motors are now more efficient and reliable. Advanced cooling keeps the motor cool, even at high power. This helps the motor last longer and work better. Better magnetic field control lets you use energy smarter. You get faster acceleration and more range from your battery.

Here are some ways PMSM motors have gotten better:

Cooling systems keep the motor cool and help it last longer.

Better magnetic field control gives smooth power at all speeds.

New control methods, like predictive and sliding mode control, give steady performance.

Hybrid excitation PMSMs let you change magnetic flux for the best power and energy use.

For example, PMSM motors from Honest showcase these advanced features. They achieve higher efficiency than typical induction motors under standard operating conditions. With an improved power factor, these motors optimize energy use for the same workload. Low rotor electrical losses reduce heat generation and enhance overall energy performance. Maintenance costs are also lower, as there are no brushes or quickly wearing parts to replace.

Note: PMSM motors in electric cars help you drive farther, save energy, and enjoy reliable performance every day.

BLDC vs PMSM Motor Efficiency and Traction

Comparative Performance in Electric Vehicles

Electric cars need motors with strong grip and good power. BLDC and PMSM motors both work well, but each has special strengths. The table below shows how they are different:

Comparison Criteria | PMSM | BLDC |

|---|---|---|

Power Density | Higher power density | Slightly lower power density |

Efficiency | Generally higher efficiency | Good efficiency, slightly lower than PMSM |

Back EMF | Sinusoidal waveform, smoother operation | Trapezoidal waveform, increased harmonics |

Torque | High torque capabilities | Good torque, slightly lower than PMSM |

Core Loss | Lower core losses | Slightly higher core losses |

Switching Loss | Higher switching losses | Slightly lower switching losses |

Speed | Wide speed range, suitable for high speeds | Limited speed range, not suitable for high speeds |

PMSM motors give lots of power and run smoothly. They use smart parts and controls to make strong torque and go fast. This makes them great for cars that need quick starts and energy recovery when braking.

BLDC motors also work well and save energy. You see them in many cars where price and easy use matter. BLDC motors use electronics to control power and speed. They react quickly and give steady grip. These motors are good for cars that need to save energy and need little fixing.

Both motors help save energy and protect the environment. They can be used in city cars or delivery trucks. Advanced designs, improved cooling, and control systems help these motors work better and allow vehicles to travel farther.

Note: Tests show BLDC and PMSM motors meet the high efficiency needs of electric cars. You can trust these motors to give strong power and control every day.

Cost and Manufacturing Considerations

When picking a motor for electric cars, you should think about price, how it is made, and how long it lasts. The way BLDC and PMSM motors are built changes their cost and how well they work.

BLDC motors are simple. They have fewer parts and no brushes. This means you pay less for fixing and repairs. BLDC motors last a long time, over 50,000 hours, which is about 17 years. You do not have problems from brush wear, which causes most old motor failures. Many companies using BLDC motors see 40% less money spent on fixing and fewer breakdowns.

PMSM motors use special materials and smart parts. They give more power and work better, but are harder to build. PMSM motors also last a long time and need little fixing. They are good for cars that need top power and best energy use.

New ways to build motors are being used. Companies use smart designs, better controls, and sensors. These changes help produce motors that save energy and reduce costs, providing strong and energy-efficient performance for electric cars.

Here is a table showing how long motors last and how much fixing they need:

Motor Type | Lifespan | Maintenance Needs |

|---|---|---|

BLDC | Exceeds 50,000 hours (approx. 17 years) | Low, no brush wear |

PMSM | Similar to BLDC | Generally low, no brush wear |

Both BLDC and PMSM motors provide energy efficiency and low maintenance, supporting reliable EV operation.PMSM motors give top power and save energy for tough jobs. Both help save energy and protect the environment in South Korea.

Tip: Using advanced motor systems helps meet requirements for high-performance, energy-efficient EVs.

Market Trends in South Korea

Adoption in Electric Vehicles

There are significant changes in South Korea’s electric car market. Many companies prioritize motors that save energy and deliver strong power. Hyundai and Kia invest in research for better micro motors, often choosing BLDC motors due to their energy efficiency, compact size, and compatibility with smart technologies. These measures ensure compliance with environmental and safety regulations.

PMSM motors are increasingly popular for vehicles requiring high power density, strong torque, and smooth performance. They also support regenerative braking, enhancing energy savings on long trips. Honest provides both BLDC and PMSM motors, helping local companies develop energy-efficient and high-performance electric vehicles.

Note: Financial incentives, such as tax breaks and subsidies, encourage both consumers and manufacturers to adopt energy-efficient electric vehicles and motors.

Evidence Type | Description |

|---|---|

Regulatory Measures | The government wants to stop carbon pollution by 2050. This makes companies build better electric motors. |

Financial Incentives | Two ministries give tax breaks and money to help make more electric cars. |

Compliance with Global Standards | South Korea follows world rules from ISO and WTO. This helps companies sell cars in other countries. |

Integrated Manufacturer Insights

South Korean manufacturers select motors based on vehicle requirements:

PMSM motors provide high power density, strong torque, and efficient energy use. They are ideal for vehicles needing quick acceleration or long-range performance.

BLDC motors offer energy efficiency, long service life, and compact design, making them suitable for city vehicles and applications where maintenance needs to be minimal.

Trends in South Korea focus on energy saving, high performance, and smart technologies. Honest’s motor solutions demonstrate how local companies can meet these demands while complying with regulations and leveraging incentives.

Tips: Want your vehicle to enjoy high performance and energy efficiency? Check out Honest’s motor solutions for smart EV powertrain options.

FAQ

What is the main difference between BLDC and PMSM motors?

BLDC motors use electronics to work and do not need brushes. PMSM motors use permanent magnets to make strong power. Both motors help electric cars run well and save energy.

Why do electric vehicles in South Korea use these motors?

These motors help cars save energy and go farther. South Korean companies pick them to follow strict rules and make cars better.

How long does a motor in an electric vehicle last?

A motor can last more than 50,000 hours. This means you can drive for many years without many repairs.

Can you use both motor types in different electric vehicles?

BLDC motors are good for city cars. PMSM motors are better for fast or strong cars. Each motor works best for different car needs.