Your Application

Solution Definition

Mass Production

> Share where and how the motor is used, with a sample motor or drawings if available

> We match an existing model or configure a suitable solution

> Quotation follows based on the confirmed scope

Single-Phase

Induction motor

• Simple AC supply environments

• Small to medium power loads

• Cost-sensitive systems

• Continuous operation with low control demand

• Lower starting torque (vs. 3-phase)

• Lower efficiency & power factor

• Limited speed control

Three-Phase

Induction motor

• Speed varies with load (slip)

• Precise speed control not possible

• VFD required for speed regulation

PMSM (Permanent Magnet Synchronous motor)

• High efficiency (IE4/IE5)

• High torque density

• Precise speed & position control

• Dynamic response applications

BLDC motor

• High efficiency & low noise

• Long lifetime (no brushes)

• Wide speed regulation range

• Compact system design

• Requires dedicated controller

• Higher system complexity

• Higher cost than brushed DC

Brushed

DC Motor

• Simple speed control (voltage)

• Low initial cost

• Good starting torque

• Easy integration

• Brush wear limits lifetime

• Lower efficiency

• Higher maintenance

Motor universal

• Very high starting torque

• Very high speed capability

• Compact & lightweight

• Works on AC or DC

• Poor speed control accuracy

• High noise & vibration

• Low efficiency

• Short service life

Start Torque · Duty Cycle · Temp Rise · Noise · IP

Global 110V-240V, 50/60Hz support

Custom shafts, flanges & housings

Thermal protection & IP55+ options

Controller matching & tuning

Systematic gates from RFQ to Mass Production.

RFQ checklist completed

2-3 options w/ trade-offs

Sample plan & schedule

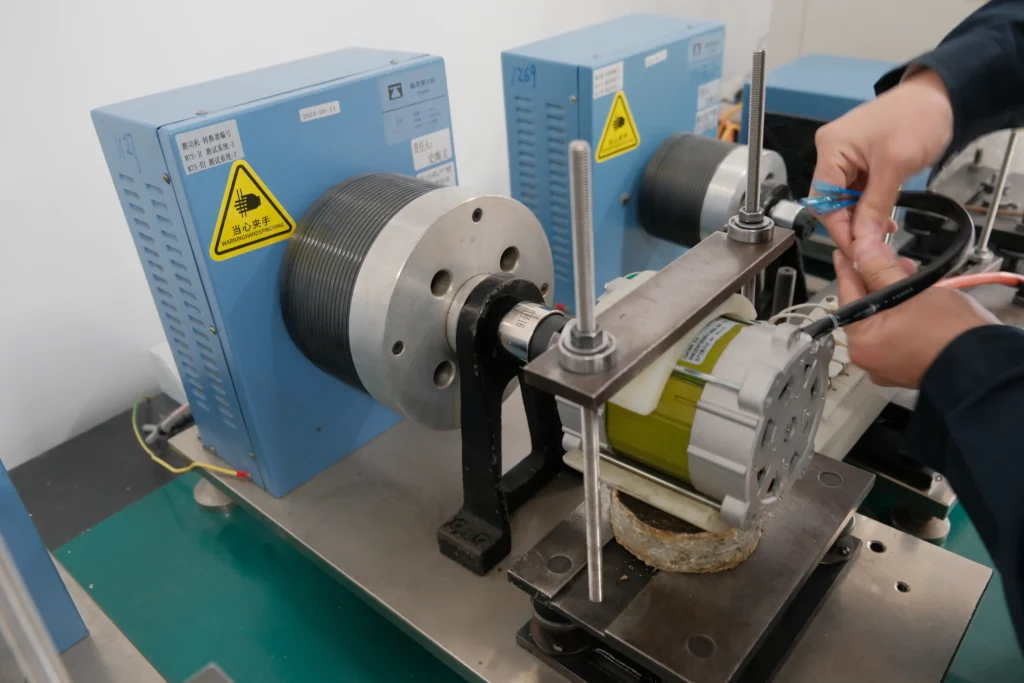

Test plan & criteria

PPAP package

Routine test & Delivery

Critical material inspection

Key manufacturing checkpoints

Hipot · IR ·

Ground

Current · Speed · Torque

NVH consistency control

Routine &

traceable

We mitigate geopolitical and supply chain risks through a diversified footprint. Your motors are produced where it makes the most sense for tariff, logistics, and material availability.

R&D Center + High-Volume Production (80k/mo capacity)

Export-focused assembly for US/EU compliance

Regional logistics hub & buffer stock

Sample: 7-10 Days | Pilot: 25 Days | Mass Production: 35-45 Days

Result:

Result:

Result:

Answer 3 steps to help our engineers build your platform shortlist.

Pro Tip: Uploading a nameplate photo helps us match 50% faster.

Ideally: Application duty cycle, torque/speed requirements, voltage/frequency, and mechanical interface dimensions. Photos of existing motors help significantly.

Yes. We configure windings for 100V, 110V, 120V, 220V, 230V, 240V at both 50Hz and 60Hz depending on your target market.

For standard platforms, MOQ is flexible. For highly customized tooling, we typically require 500-1000 units per order after pilot runs.

Our factories are ISO 9001 and IATF 16949 certified. We support component certification for UL, CE, CCC, RoHS, and REACH upon request.

Dirección:No.121,Xinlong Road,Zhonglou Xinzha Subdistrict,Ciudad de Changzhou, Provincia de Jiangsu, China

Teléfono: +86-18261152679

Whatsapp: +86-18261152679

Correo electrónico: sales@honestmotor.cn

Política de privacidad / Condiciones de servicio / Configuración de cookies / Mapa del sitio

2025 Honest Todos los derechos reservados.