Synchronous and asynchronous motors are different in how their rotors work with the spinning magnetic field. A synchronous motor always runs at the same speed. An asynchronous motor lets the speed change a little, which is called slip. This difference changes how electric motors work in real jobs. Many industries use both types of motors to get the best mix of efficiency, speed, and cost. Honest offers many motor choices for different industries’ needs.

Key Takeaways

Synchronous motors always run at the same speed as the power supply. This makes them good for jobs that need exact timing and control.

Asynchronous motors run a bit slower than the magnetic field. This is because of slip. Slip helps them make torque and deal with changing loads.

Synchronous motors work very well and save energy over time. But they cost more at first and need special ways to start.

Asynchronous motors are simple and dependable. They cost less at the start. They can start by themselves and do not need much care.

Picking the right motor depends on what your job needs. Think about speed control, load type, efficiency, cost, and care. Both types of motors are strong and work well.

Synchronous Motor Basics

Definition

A synchronous motor is a kind of AC motor. It always runs at a speed that matches the power supply’s frequency. The speed stays the same, even if the load changes. This makes it different from other motors like induction motors. Induction motors can slip and run slower than the supply frequency. The table below shows how synchronous motors are different from other motors:

Motor Type | Rotor Construction & Excitation | Key Characteristics & Control | Distinguishing Features Compared to Synchronous Motors |

|---|---|---|---|

Permanent Magnet Synchronous Motor (PMSM) | Rotor contains permanent magnets | High efficiency, high power factor, low noise, maintenance-free | Operates at synchronous speed; advanced control strategies |

Induction Motor (IM) | Rotor with aluminum or copper bars | Simple, robust, low cost, high reliability | Operates below synchronous speed; lower efficiency than PMSM |

Switched Reluctance Motor (SRM) | Rotor with salient poles, no windings or magnets | Simple, robust, high speed; high torque ripple | No rotor excitation winding or magnets; torque ripple issues |

Direct Current Motor (DCM) | Rotor with windings and brushes/commutators | Simple speed regulation; low efficiency | Uses mechanical commutation; not suitable for high-speed applications |

How It Works

The stator in a synchronous motor makes a spinning magnetic field. The rotor has either magnets or a winding with direct current. When the stator’s field spins, the rotor moves with it. The speed uses the formula Ns = (120f)/p. Here, f is the frequency and p is the number of poles. This means the motor always keeps the same speed as the field. The rotor does not fall behind, even if the load changes. Special electronics, like inverters, can change the frequency. This lets you control the speed very accurately.

Key Features

Synchronous motors have many good features:

They keep the same speed, even if the load changes.

They are very efficient, often above 95%, and have a high power factor.

They are quiet and need little maintenance, especially if they are brushless.

They can control speed and position very well, so they are great for jobs that need high precision.

They are smaller and lighter than many other motors.

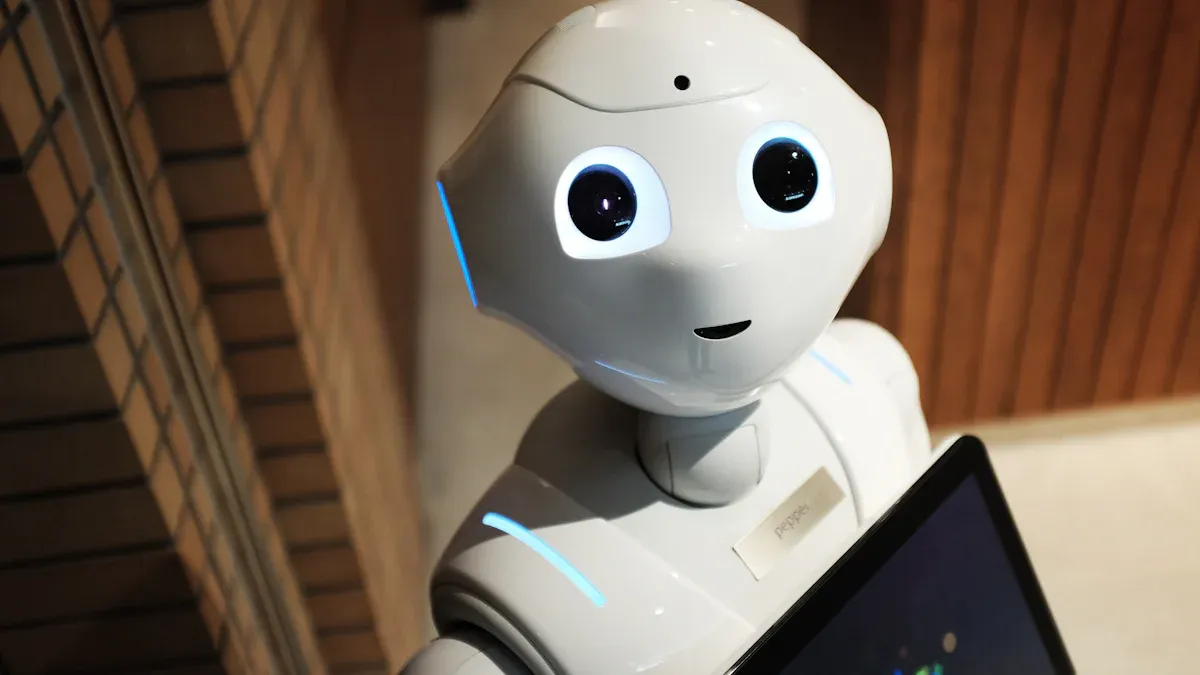

Honest makes many types of synchronous motors for industries that need exact speed and timing. These motors are good for machine tools, robots, and making computer chips. These jobs need motors that are very precise and reliable. Direct drive designs help the motors last longer and work smoothly. Honest’s technology helps customers save energy and get better results in tough jobs.

Asynchronous Motor (Induction Motor) Overview

Definition

An asynchronous motor is also called an induction motor. It is a kind of AC motor. It works using electromagnetic induction. The stator makes a spinning magnetic field. This field creates a current in the rotor. The rotor starts to turn because of this current. The rotor always spins a bit slower than the magnetic field. This small speed difference is called slip. Slip helps the induction motor make torque and keep running. Asynchronous motors are simple and very reliable. They do not need much maintenance. Many industries use them because they are cheap and easy to use.

How It Works

The induction motor uses electromagnetic induction to work. When AC power goes into the stator windings, it makes a spinning magnetic field. The rotor sits inside the stator and reacts to this field. The speed difference between the magnetic field and the rotor is called slip. Slip is needed for the motor to work. If the rotor moved as fast as the field, no current would be made. Then, the motor would stop making torque. Slip is usually between 0.5% and 5%. The formula for synchronous speed is n_s = 120f/p. Here, f is the frequency and p is the number of poles. The rotor always spins slower than the synchronous speed. This keeps the induction motor running well.

Key Features

Asynchronous motors have many important features:

Robust Design: The simple and strong build makes the induction motor very reliable. It can work with heavy loads and in tough places.

Versatility: These motors come in single-phase and three-phase types. Single-phase motors are used in home appliances. Three-phase motors are used in factories, pumps, fans, and conveyors.

High Starting Torque: Induction motors can start with a load and give strong torque. This makes them good for hard jobs.

Low Maintenance: The design has few moving parts. So, the asynchronous motor does not need much care.

Energy Efficiency: Modern induction motors work well with variable frequency drives. These help save energy and control speed better.

Wide Application Range: Many industries use asynchronous motors every day. These include manufacturing, HVAC, water treatment, and logistics.

Note: Honest sells both single-phase and three-phase asynchronous motors. These motors power things from home appliances to big machines. Honest’s motors are efficient and last a long time. They help industries that need strong and flexible motors.

Feature | Benefit | Application Example |

|---|---|---|

Simple construction | High reliability, low failure rate | Pumps, fans, compressors |

High starting torque | Handles heavy loads | Mills, crushers, conveyors |

Versatile design | Fits many voltage and power needs | Household, industrial use |

Low maintenance | Reduces downtime and costs | Continuous operation sites |

Synchronous vs Asynchronous Motor Comparison

Speed and Slip

Synchronous and asynchronous motors are different in how they handle speed. A synchronous motor always runs at a set speed. This speed depends on the power supply and number of poles. For example, a 4-pole synchronous motor at 60 Hz runs at 1800 RPM. The speed stays the same, even if the load changes. This is important for jobs that need exact timing.

An asynchronous motor works in another way. The rotor spins a little slower than the magnetic field. This small difference is called slip. Slip helps the motor make torque. For a 4-pole induction motor at 60 Hz, the top speed is 1800 RPM. But it usually runs at 1725-1750 RPM. Slip can be less than 1% in big motors. In small motors, slip can be up to 6%. When the load gets bigger, slip also gets bigger. The motor slows down a bit as a result.

Tip: Synchronous motors keep the same speed, no matter the load. Asynchronous motors slow down a little when the load is heavier.

Efficiency

Synchronous motors are known for being very efficient. Permanent magnet synchronous motors can be over 90% efficient. They keep this high efficiency even with a light load. These motors also have a power factor close to 1. This means they use energy well and waste less.

Induction motors lose some energy because of slip. Slip makes extra heat and lowers efficiency. Modern induction motors can be efficient, but not as much as synchronous motors. This is true, especially when the load is light. Synchronous motors do not have slip losses, so they save more energy over time.

Cost

Asynchronous motors cost less at first. They have a simple design and are easy to make. This makes them a good choice for many uses. But over time, they use more energy. This can make them cost more in the long run.

Synchronous motors cost more to buy. They use special parts like permanent magnets or DC systems. Even though they cost more at first, they save money later. Their high efficiency means lower energy bills. Over ten years, the savings can cover the higher price.

Note: High-efficiency motors may cost more at first, but they save money on energy and last longer.

Starting Methods

Synchronous motors cannot start by themselves. They need help to reach their running speed. One way is to use another motor to spin the rotor up to speed. Another way is to use damper windings. These let the motor start like an induction motor. When the rotor is fast enough, it switches to synchronous mode.

Induction motors are easy to start. They can use direct-on-line, star-delta, or auto-transformer starters. These help control the high current when starting. Induction motors can start with a load and do not need extra equipment.

Power Factor

Synchronous motors have a high power factor, often close to 1. This means they use electricity very well. A high power factor lowers the current needed and saves energy. Many factories use synchronous motors to help their whole system.

Induction motors have a lower power factor. The power factor drops when the load is light. This means they use more current for the same work. This can make energy costs go up.

Typical Uses

Synchronous and asynchronous motors are used for different jobs.

Synchronous motors:

Found in timing devices, compressors, blowers, fans, and servo drives.

Used for heavy jobs like cranes, air compressors, and rolling mills.

Good for jobs below 300 RPM or where power factor matters.

Asynchronous (induction) motors:

Used in lifts, cranes, hoists, big fans, lathes, crushers, and textile machines.

Power many electric and hybrid vehicles.

Common in pumps, conveyors, and compressors, especially with variable-frequency drives.

Chosen for their simple design, low cost, and ability to work in tough places.

Feature | محرك متزامن | Asynchronous Motor (Induction) |

|---|---|---|

Speed | Constant, matches supply frequency | Slightly less than supply frequency |

Slip | None | 0.5%–6% (increases with load) |

Efficiency | Very high (often >90%) | High, but lower than synchronous |

Power Factor | High (close to 1) | Lower, drops at light load |

Starting | Needs special methods | Self-starting |

Cost | Higher upfront, lower over time | Lower upfront, higher over time |

Typical Uses | Precision, constant speed, power factor correction | General industry, variable loads, cost-sensitive jobs |

Honest offers both synchronous and asynchronous motors for many needs. Honest’s motors are efficient and can be customized for any job, from medical devices to big factories.

Advantages and Disadvantages

Synchronous Motor Pros & Cons

Synchronous motors have many good points for different jobs. They always keep the same speed, even if the load changes. This is important for work that needs exact timing and control. Synchronous motors are very efficient in many uses. They can change the power factor, which helps save energy in electrical systems. These motors also give strong starting torque, so they are good for heavy work. Their strong build and fewer moving parts help them last a long time. Synchronous motors run quietly and do not shake much.

Work efficiently and give steady results

Help improve the power factor of systems

Give strong starting torque for heavy jobs

Run quietly and smoothly

Last a long time because they are built strong

Honest’s synchronous motors help in fields like automation, medical tools, and factories. These motors let users control things exactly and save energy in hard jobs.

Asynchronous Motor Pros & Cons

Asynchronous motors, or induction motors, are simple and very reliable. They are easy to set up and do not need much care. Asynchronous motors can handle heavy work and tough places. They start by themselves, so no extra help is needed. These motors come in single-phase and three-phase types, so they fit many uses from homes to factories. New asynchronous motors from Honest work with variable frequency drives. This helps save energy and lets you change the speed easily.

Simple and strong build for high trust

Start by themselves and are easy to use

Fit many different jobs and uses

Can handle heavy loads and hard places

Work with energy-saving drives for better control

Honest’s asynchronous motors are great for jobs that need power you can count on and use in many ways.

Note: Both synchronous and asynchronous motors from Honest are efficient, reliable, and give good value for a long time.

Feature | محرك متزامن | Asynchronous Motor |

|---|---|---|

Speed | Always the same | Changes a little |

Efficiency | Very efficient | Efficient, but has slip |

Power Factor | Can be changed, high | Lower, lags behind |

Starting | Needs special way | Starts by itself |

Maintenance | Needs little care | Needs very little care |

Application Fit | For exact, heavy jobs | For many different jobs |

Choosing the Right Motor

Decision Factors

Picking the right motor depends on what the job needs. Some jobs need very steady speed. Others need strong starting power or a lower price. Synchronous motors and asynchronous motors are both good, but in different ways. Synchronous motors keep the same speed all the time. This is helpful for things like robots, medical machines, and factory systems. These motors are best when timing and accuracy are important. Induction motors (also called asynchronous motors) can handle loads that change. They are easy to start. These motors are good for pumps, fans, and belts in buildings or factories.

Think about these things when picking a motor:

Speed Control: Synchronous motors give exact speed. Induction motors let the speed change a bit.

Load Type: Heavy or steady loads may need synchronous motors. Loads that change often use induction motors.

Efficiency: Synchronous motors save more energy over time.

Cost: Induction motors usually cost less at first.

Maintenance: Both types from honest need little care, but some jobs may need more.

Tip: Pick the motor that fits the job best for good results.

honest Custom Solutions

honest is special because it makes custom motors for many jobs. The company works with customers to make motors that fit their needs. This helps customers work faster and spend less money.

Motor Diagnostic Systems also helps factories test motors and watch them in real time. These teams show how custom motors can make things better and help new ideas grow.

honest’s team uses new technology and knows a lot about many industries. They help people in healthcare, cars, and factory work. By listening to each customer, honest gives motors that work better and last longer.

Synchronous motors always run at the same speed. They are good for jobs that need accuracy and use less energy. Asynchronous motors are best when loads change a lot. They are simple and work well for many uses. Reports say each motor type has its own speed, starting, and efficiency traits. Experts say you should pick a motor that fits your job’s needs. Think about speed, torque, and where you will use it. Many companies get better results and save money by asking experts for help. If you want a motor made just for you, you can ask honest for advice.

FAQ

What is the main difference between a synchronous motor and an asynchronous motor?

A synchronous motor always runs at a steady speed. This speed matches the power supply frequency. An asynchronous motor, or induction motor, runs a bit slower. This happens because of something called slip.

Which motor type is better for energy savings?

Synchronous motors are usually more efficient. They also have a better power factor. These motors help save more energy. This is true when you need constant speed and high performance.

Can both motor types handle heavy loads?

Yes, both can handle heavy loads. Synchronous motors give steady torque for tough jobs. Asynchronous motors have strong starting torque. This makes them good for jobs with changing or heavy loads.

Where do people use synchronous motors most often?

People use synchronous motors where exact speed and timing matter. Some examples are industrial automation, robotics, and medical equipment.

Are induction motors easy to maintain?

Induction motors have a simple design. They do not have many moving parts. This makes them easy to take care of. They are also very reliable for long use.

Tip: Honest sells both types of motors and custom solutions for many industries. Visit honestmotor.com to learn more.