Manufacturers today face a tough challenge. You need to keep costs under control, but at the same time your products have to be reliable, and your brand reputation depends on it. The household and commercial appliance markets feel this pressure more than ever. Take raw materials for example — steel prices jumped by more than 110% in 2021, pushing production costs higher across the board. That’s why many OEMs are looking for ways to deliver quality without overspending. This is where low-cost Brushed DC motors come in. They strike a solid balance between affordability and dependable performance, making them a smart choice for a wide range of applications.

Year | Steel Price Change | Revenue Change | Key Factors Impacting Costs |

|---|---|---|---|

2021 | +110.5% | Increased demand due to housing boom | Volatile purchase costs, inflationary pressures |

2022 | Stabilization | Revenue decline begins | Interest rate hikes, price sensitivity |

2025 | Estimated $24.8B | -1.1% annualized | Slowing discretionary spending, market dynamics |

Key Takeaways

Brushed DC motors are a cost-effective choice for manufacturers. They offer a solid balance of affordability and dependable performance.

Regular care is important for brushed motors. This helps them last longer, usually between 2,000 and 5,000 hours.

When picking a motor, think about important things like voltage needs, speed, torque, and size for the best performance.

Check suppliers by looking at the total cost of ownership. This includes energy use and maintenance costs, not just the starting price.

Upgrading brushed DC motors can boost both performance and efficiency, but it’s worth weighing the upfront costs against the long-term benefits.

The Enduring Value of Brushed Motors

Why It Remains a Top Choice

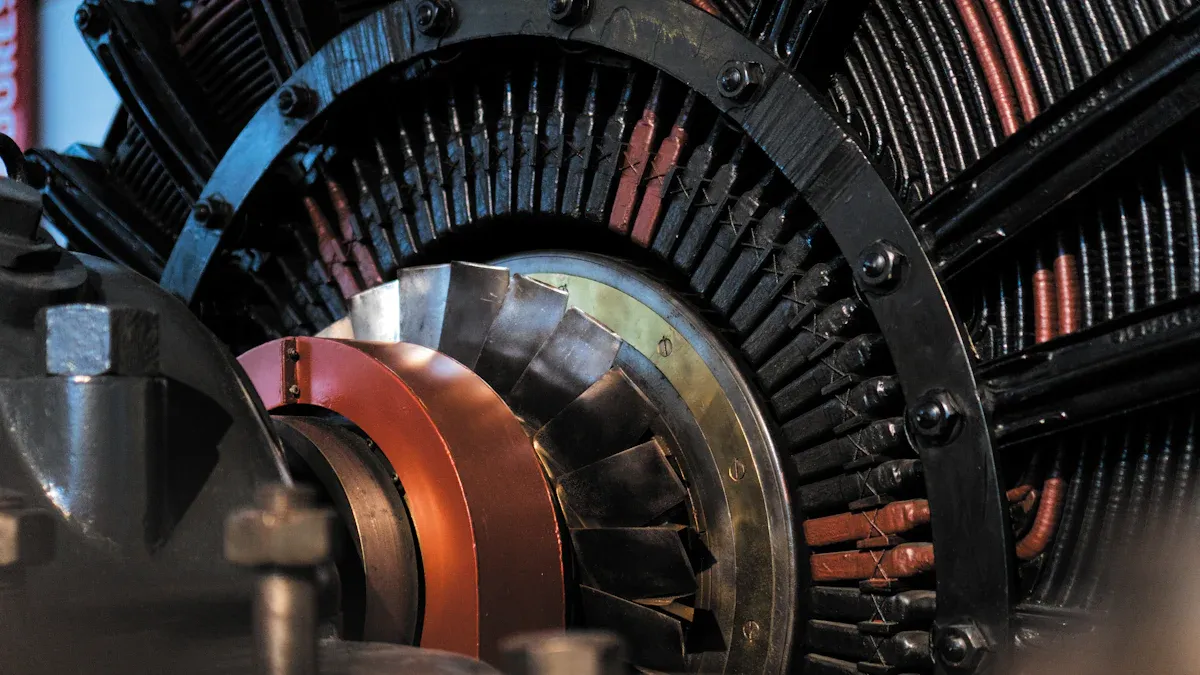

Brushed DC motors are very important in household and commercial appliances. You might ask why these motors are still popular with manufacturers. Here are some main reasons:

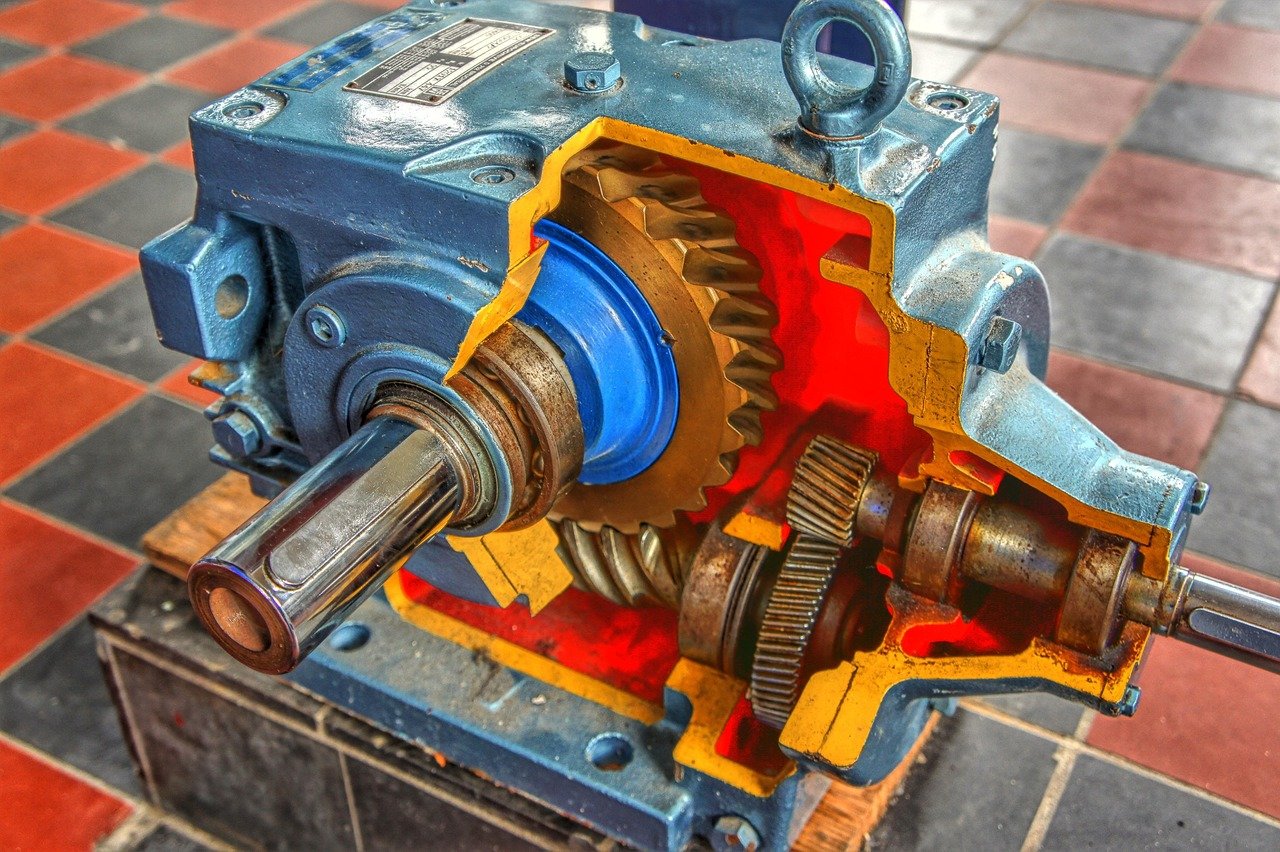

Simplicity: Brushed DC motors have a simple design. This makes them easy to use in many applications.

Low initial cost: They are cheaper to make and buy than other motor types.

High starting torque: These motors are great for quick acceleration. This makes them perfect for many home devices.

Versatility: You can find brushed DC motors in many products, like electric toothbrushes and washing machines.

In short, their mix of low cost and good performance makes them a top choice for many manufacturers.

The Strategic Balance of Cost vs. Performance

When picking motors for your appliances, you want to find the right balance between cost and performance. Low-Cost Brushed DC Motors are a great option. They give you the power and efficiency you need without costing too much.

Brushed motors do need regular care because of wear on brushes and commutators. Still, they are a dependable choice for places where money is tight. You can expect them to last between 2,000 and 5,000 hours, depending on how you use them. This makes them good for many everyday uses, such as:

Dishwashers: High voltage PMDC motors make them work better.

Washing machines: Heavy-duty DC motors manage wash cycles well.

Refrigerators: Small DC motors run compressors effectively.

Microwaves: Small motors turn the turntable smoothly.

Even though brushed motors may not be as efficient or long-lasting as brushless motors, their lower starting costs make them a smart choice for many manufacturers. If you don’t need the special features of brushless motors, choosing brushed motors can help you save money at first.

The OEM Selection Guide

When you choose Low-Cost Brushed DC Motors for your appliances, you need to think about some important factors. These factors can really affect how well your products work. Here’s a helpful checklist to assist you in the selection process:

Key Parameters: A Practical Checklist

Voltage Requirements:

Find out the voltage needed for your appliance’s power. Common voltage ranges for brushed DC motors are:

Voltage Range

Description

12-220V

Often used in many household appliances

110-230V

Normal range for commercial uses

220V

High voltage uses, usually in industrial areas

Speed and Torque Calculations:

Figure out the speed and torque needed for your application. This makes sure the motor can handle the expected loads well. Manufacturers often look at speed/torque curves and back EMF to find the best performance. You can get these curves using just two points: no-load speed and stall torque.

Size and Weight:

Think about the motor’s physical size. It should fit in your appliance’s design without losing performance.

Duty Cycle:

Check the working life and type of duty cycle needed for your application. This helps make sure the motor can work continuously or sometimes as needed.

Cost vs. Reliability:

Weigh the motor’s cost against its reliability. While Low-Cost Brushed DC Motors are cheap, regular care is important to keep them lasting long and avoid problems from brush wear.

Core Applications

Brushed DC motors are used in many household and commercial applications. Here are some examples of where you might find them:

Household Appliances:

These motors run devices like dishwashers, washing machines, and refrigerators. Their reliability and easy control make them great for daily tasks.

Automotive Systems:

In cars, brushed DC motors give high starting torque and speed control. They are good for things like window lifts and seat adjustments.

Industrial Machinery:

These motors are flexible and efficient for many jobs, like conveyor systems and packaging machines.

Electric Power Propulsion:

They work well for propulsion systems in electric vehicles, giving the power needed for smooth operation.

Power Tools:

Their small and light design makes them ideal for tools like drills and saws, where being portable is important.

Steel Rolling Mills:

Brushed DC motors perform strongly under heavy loads, making them fit for tough industrial settings.

By knowing these key factors and main uses, you can make smart choices when picking Low-Cost Brushed DC Motors for your products. This knowledge will help you balance performance, reliability, and cost effectively.

Strategic Supplier Selection

When you choose suppliers for Low-Cost Brushed DC Motors, don’t just look at the first price. You should think about the total cost of ownership (TCO). This helps you make a smart investment.

Beyond Initial Cost: Total Cost of Ownership

The total cost of ownership has many parts that can affect your budget later. Here are some important things to think about:

Energy consumption: Check how much energy the motor will use over time. Efficient motors can lower your electricity bills.

Maintenance labor: Include costs for regular maintenance. Brushed motors need more checks and replacements, which can add up.

Replacement parts: Think about how easy it is to find replacement parts. If parts are hard to get or costly, it can raise your total costs.

Downtime costs: Consider how often the motor might break down and how that could hurt your work. Downtime can cause lost money and productivity.

By looking at these factors, you can make a better choice that goes beyond just the starting price.

Quality First: How to Evaluate a Supplier

When picking a supplier for your motors, quality should come first. You want to make sure the motors meet safety and performance rules. Here are some certifications to check for:

Certification | Description |

|---|---|

ISO9001 | Quality management standard |

CE | Shows that products meet health, safety, and environmental rules in Europe |

ROHS | Limits harmful substances in electrical and electronic items |

These certifications show that the supplier follows strict quality checks. Also, think about how well the supplier can provide parts over time. A good supplier can keep quality steady and deliver on time, which is important for your production schedule.

Customization: Optimizing Cost Without Sacrificing Quality

Customization can help you save money while keeping quality high. By changing the design and materials of Low-Cost Brushed DC Motors for your needs, you can improve performance and lifespan. This can lead to better efficiency and reliability, saving you money over time.

But remember, customization might raise initial costs because of special materials and manufacturing. It’s important to balance these costs with the benefits of better performance.

Budgeting Strategies for Motor Projects

When you plan your motor projects, good budgeting is important. Here are some strategies to think about:

Strategy | Description |

|---|---|

Keep costs low for Low-Cost Brushed DC Motors because of high volume needs. | |

Supplier Relationships | Build long-term ties with suppliers for reliable and high-quality parts. |

Customized Solutions | Choose customized motor options to fit specific needs. |

By using these strategies, you can manage your budget better and make the most of your investment in motors.

FAQ

What are the main advantages of using brushed DC motors?

Brushed DC motors are simple to use. They cost less at first and have strong starting power. They can be used in many household and commercial appliances. This makes them a favorite for manufacturers.

How long do brushed DC motors typically last?

Brushed DC motors usually last between 2,000 and 5,000 hours. This depends on how you use and care for them. Regular maintenance helps them last longer and work reliably.

Can I customize brushed DC motors for my specific needs?

Yes! Many suppliers, like Honest, let you customize brushed DC motors. You can change designs and materials to improve performance and meet your needs.

What maintenance do brushed DC motors require?

Brushed DC motors need regular care. This includes checking and changing brushes and commutators. Keeping them clean and lubricated helps prevent wear and keeps them running smoothly.

Are brushed DC motors energy-efficient?

Brushed DC motors are usually not as efficient as brushless motors. However, they can still be energy-efficient for many uses. Picking the right motor can help reduce energy use.