The motor is the core component of commercial and professional-grade coffee grinders. Its performance directly impacts grinding efficiency, equipment stability, and long-term maintenance costs. For manufacturers, service providers, and operators, a systematic understanding of common motor failures, precise diagnosis, and appropriate optimization measures are critical to ensuring high operational efficiency, minimizing downtime risk, and extending equipment lifespan. This guide provides a comprehensive technical reference to help users effectively identify issues, perform maintenance, and evaluate long-term upgrade solutions.

Key Takeaways

Understanding your grinder’s motor type (Universal, Brushed DC) is key to accurate failure diagnosis and evaluating upgrade feasibility.

Brushless DC (BLDC) motors offer distinct advantages over traditional AC/Universal motors in terms of energy efficiency, lower noise, and reliability, setting the trend for commercial product upgrades.

Systematic checks must cover both electrical and mechanical issues, including power cords, switches, internal wiring, capacitors, bearings, gears, and clearing obstructions from the burrs.

High-wear components like carbon brushes and bearings require regular, step-by-step replacement, along with commutator maintenance, to sustain motor performance.

Routine equipment cleaning and controlling grinding load are effective measures for extending motor life and preventing overheating.

Grinder Motor Types: Universal & Brushed DC

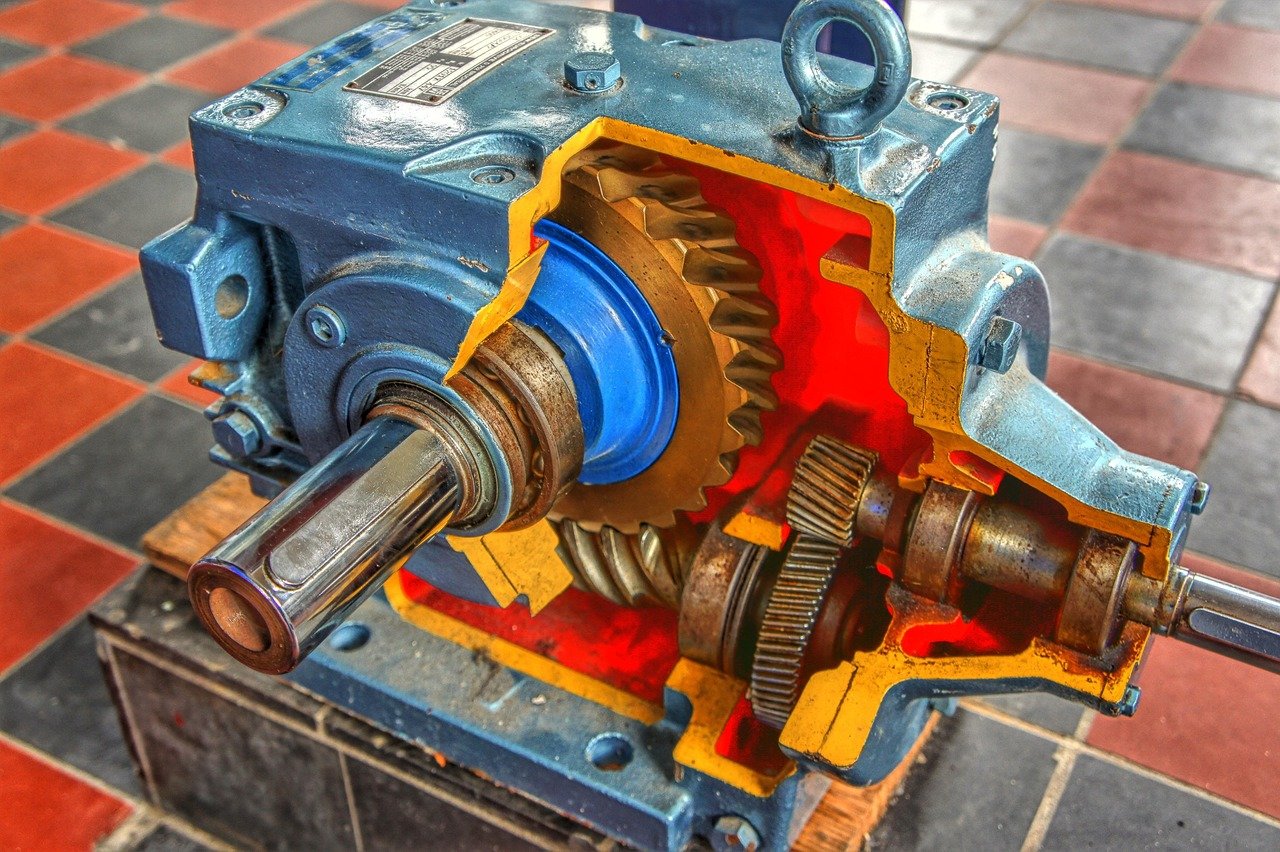

Knowing the motor type is a prerequisite for effective maintenance and optimization. Commercial coffee grinders typically use two main motor types: the Universal Motor and the Brushed DC Motor.

Universal Motors

This motor type offers high performance; its design features the armature and field windings connected in series, allowing it to operate on both alternating current (AC) and direct current (DC). This configuration provides high starting torque and high speed, making the Universal Motor a common choice in commercial grinders for quickly processing hard beans or in applications requiring rapid grinding. However, a drawback of their high-speed operation and reliance on brushes is their tendency toward higher operational noise and a shorter service interval due to carbon brush wear. For identification, it typically plugs directly into an AC outlet and utilizes carbon brushes.

Brushed DC Motors

The Brushed DC motor relies on carbon brushes and a commutator to switch current direction, enabling precise speed control and good starting performance. These motors are often used in high-end commercial equipment that requires fine-tuned grind particle consistency. Power may be supplied via a dedicated DC adapter (common for smaller units) or by an integrated AC-to-DC converter located on the equipment’s internal control board (common for larger commercial units). Regardless of the power source, this motor type utilizes carbon brushes.

Identifying Your Grinder’s Motor

Accurate motor identification aids troubleshooting and simplifies the selection of replacement components. The quickest method is to check both the power source and the presence of carbon brushes:

Universal Motor: Plugs into an AC wall outlet and has visible carbon brushes (often viewable through vents or behind brush caps).

Brushed DC Motor: Relies on DC power (either via an external adapter or an internal AC/DC converter) and has carbon brushes.

By correctly identifying the motor type, troubleshooting and maintenance can be performed more efficiently, while also assessing the suitability for upgrading to a Brushless DC (BLDC) solution.

Initial Diagnostics: Motor Failure Identification

Early identification of motor anomalies is critical for preemptive maintenance and minimizing operational disruption. This section provides a systematic framework for recognizing and classifying common failure symptoms, enabling technical personnel to accurately isolate the source of the malfunction and accelerate the troubleshooting process.

No Power or Intermittent Operation

This symptom signals a failure in the electrical path, requiring a systematic technical inspection to minimize troubleshooting time.

Inspection Sequence: Verify the continuity and integrity of the power cord and plug connections (prone to fatigue failure in commercial use).

Internal Check: Inspect the mechanical condition of the main power switch/contactor; check all internal wiring harnesses for loose connections or evidence of arcing at terminal points.

Grinder Runs, Burrs Don’t Turn

Motor humming but burrs not rotating usually indicates an obstruction in the grinding area.

Causes: Foreign objects or densely packed coffee grounds.

Action: Immediately disconnect power, carefully clear the obstruction from the grinding chamber, and then retest the rotation.

Unusual Noises: Grinding, Whining, Clicking

Abnormal noise is a critical indicator of impending mechanical failure.

High-Pitched Whining: Typically suggests severe bearing wear or armature/rotor misalignment, forcing the motor to draw higher current.

Grinding/Rattling: Indicates physical contact between rotating and stationary components, possibly due to loose fasteners, fractured gearbox components, or severe burr misalignment.

Clicking/Tapping: Often points to a failure in the gear train (especially plastic gears), which is common under high load or stall conditions.

Overheating & Thermal Cutout

Grinder overheating may trigger a thermal protection switch.

Common Causes: Extended continuous operation, grinding very hard beans, or motor vents blocked by coffee dust.

Action: Allow the equipment to cool completely before restarting, and ensure clear ventilation.

Smoke or Burning Smell

Visible smoke or a distinct burning odor signals severe electrical or mechanical failure (e.g., winding damage or commutator failure). Immediately disconnect power, tag the unit, and refer to qualified technical service for repair.

Systematic Troubleshooting: Electrical & Mechanical

Precise identification of electrical faults requires a systematic, step-by-step diagnostic plan utilizing standard tools like a multimeter. Before beginning any electrical inspection, ensure the grinder is completely disconnected from the power source to guarantee personnel safety.

Electrical Troubleshooting

Component | Inspection Method / Focus | Key Failure Symptoms |

Power Supply & Cord | Multimeter for continuity; check plug for bent/darkened pins; susceptible to fatigue failure. | Open circuit, intermittent operation |

Switch & Control Board | Multimeter for switch continuity (ON/OFF); visual check of board for burn marks, bulging capacitors. | Switch failure, erratic function |

Thermal Fuse / Protection | Multimeter for continuity; if tripped frequently, check for excessive load or blocked ventilation. | Frequent automatic shutdown |

Capacitor | Visual inspection for bulging/leaks; safely discharge then measure capacitance against nameplate value. | Difficulty starting, unstable running |

Motor Winding Resistance | Multimeter set to Ohms; open circuit indicates broken wire; very low resistance indicates short circuit. | Motor fails to turn, overheating, burning smell |

Professional Tip:Winding Resistance Interpretation: Always isolate the motor winding before testing resistance. An open circuit (infinity/OL reading) or a resistance value approaching zero (inter-turn short) both confirm an internal motor winding failure, necessitating motor replacement.

Mechanical Troubleshooting

Systematic mechanical inspection is necessary to diagnose operational noise, binding issues, and component wear that place excessive load on the motor.

Burrs & Grinding Chamber Obstruction: Clear foreign objects and ensure burrs can rotate freely.

Gearbox & Drive Train Inspection: Check gears for broken teeth or severe wear; inspect belts or couplers for looseness or breakage.

Bearing Wear & Lubrication: Check for noise and excessive shaft play (axial/radial); apply appropriate lubricant, avoiding grease that attracts coffee dust.

Motor Shaft Alignment: Ensure the motor shaft is precisely aligned with the burrs or gearbox to prevent vibration and additional wear.

Commutator & Brush Maintenance: Clean the commutator surface and carefully remove debris from the mica slots; check brush length and replace components worn past minimum limit.

Maintenance Warning:Acoustic Diagnosis Priority: Any abnormal operational noise (whining, rattling, clicking) should be treated as a priority failure indicator. Bearing wear is often the primary mechanical failure, leading to higher current draw and eventual winding burnout if not addressed early.

Motor Component Repair & Replacement

Motor Component Repair and Replacement is a crucial, high-frequency task for maintaining traditional Universal and Brushed DC grinder motors. It is critical to recognize that chronic component failure signals an inherent system flaw—a clear indicator that an upgrade to a maintenance-free BLDC solution may be required to reduce long-term Total Cost of Ownership (TCO) and warranty liabilities.

Carbon Brush Replacement(Universal / Brushed DC)

Disconnect Power: Ensure the unit is unplugged.

Locate: Find and remove the brush caps (often look like large screws).

Remove: Take out the old brushes and springs, noting their orientation.

Install: Insert new brushes, ensuring they move freely in the brush holder.

Secure: Screw the caps back on, but do not overtighten.

Break-In: New brushes require a short break-in period (minor sparking may occur).

Commutator Maintenance

Clean Surface: Wipe the commutator with a clean cloth to remove surface dust.

Wear Treatment: If minor scarring or unevenness exists, use very fine sandpaper or a dedicated polishing tool for light sanding to restore a smooth surface.

Clean Grooves: Use a non-conductive precision tool (like a toothpick) to carefully clear debris from the mica slots between the copper segments to prevent short circuits.

Bearing Replacement

Disassemble: Take the motor apart to access the bearings.

Remove: Use a bearing puller or appropriate tool to carefully remove the old bearings, avoiding damage to the shaft.

Install: Press new bearings onto the shaft. Pressure must be applied only to the outer race (using a socket or press tool) to avoid damaging the internal rolling elements.

Lubricate: Check if the new bearings are pre-lubricated; if not, apply a small amount of suitable motor grease.

Long-Term Maintenance and Optimization

Continuous preventive maintenance and targeted optimization upgrades are crucial strategies for ensuring long-term stable operation and reducing the Total Cost of Ownership (TCO) for commercial grinder motors.

Preventive Maintenance and Performance Enhancement

To extend motor lifespan and ensure peak performance, operators should focus on several key areas. First, equipment must be cleaned regularly, ensuring motor vents and the grinding chamber are free of powder build-up, which effectively prevents airflow obstruction and reduces motor load, thus mitigating overheating. Secondly, the grinding load should be strictly controlled, avoiding prolonged continuous operation, and allowing sufficient cool-down time between heavy grinding sessions. For mechanical components, consider bearing upgrades, such as switching to ceramic ball bearings or high-quality sealed bearings, which significantly reduce friction, lower noise, and extend component life. Furthermore, for high-duty cycle equipment, improving thermal management by adding small fans or heat sinks should be considered. Finally, routinely check all wiring and connection points to ensure power stability and prevent motor anomalies caused by poor contact.

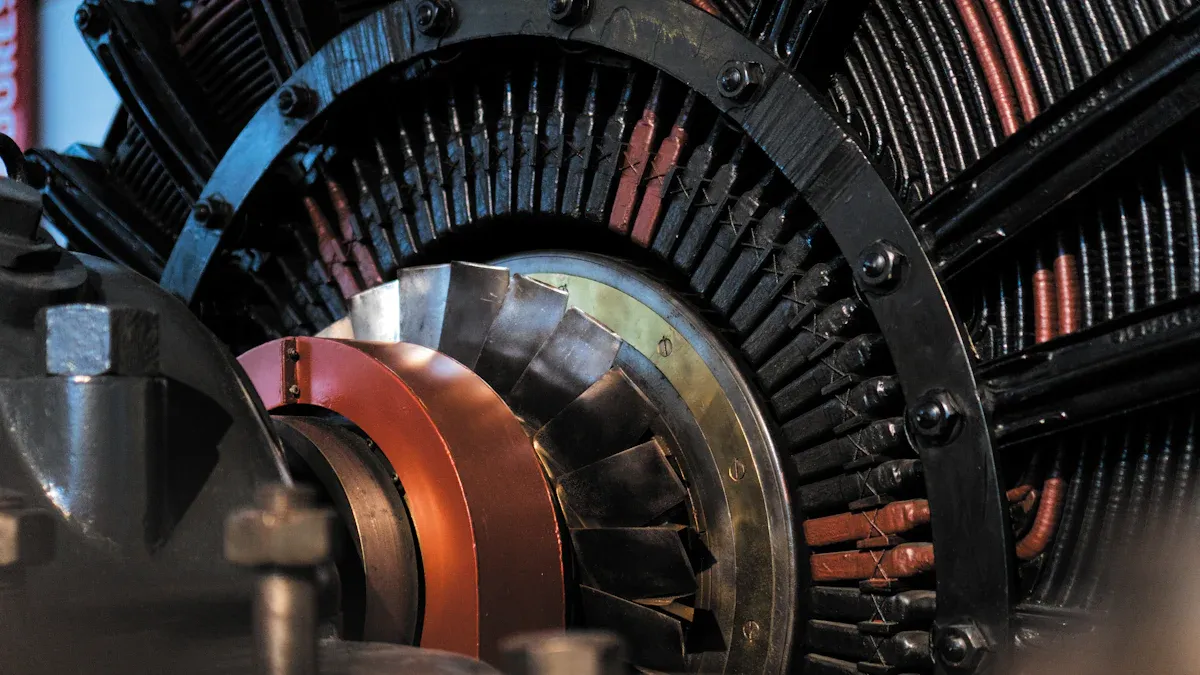

Brushless DC (BLDC) Upgrade Assessment

For commercial environments demanding the highest reliability and efficiency, upgrading to a Brushless DC (BLDC) motor is a significant optimization path. BLDC technology eliminates high-wear components like carbon brushes and commutators, drastically reducing friction and maintenance frequency, resulting in superior energy efficiency, lower operational noise, and a significantly extended service life. Given its high reliability, the BLDC motor can significantly reduce long-term TCO.

BLDC Compared to Traditional Motors (Key Advantages):

High Efficiency: BLDC motors are far more energy-efficient than traditional motors, effectively lowering long-term operating electricity costs.

Zero Maintenance: By eliminating wear parts like brushes and commutators, BLDC motors are essentially maintenance-free, significantly reducing downtime risk and repair costs.

High Reliability: BLDC technology features a longer Mean Time Between Failures (MTBF), overcoming the traditional motor’s bottleneck imposed by carbon brush lifespan.

Low Noise/Vibration: BLDC operation is quiet and smooth, significantly improving the commercial operating environment.

When evaluating an upgrade plan, enterprise users should customize motor specifications—including torque output and thermal design—according to the grinder’s load characteristics, usage frequency, and heat management requirements. This ensures the best match with the existing mechanism, maximizing equipment performance.

For business users looking to upgrade or retrofit motors, Honest Motor offers expert consultation and customized solutions, providing technical evaluation and engineering support from single units to entire facility equipment upgrades, helping to maximize equipment performance while reducing long-term maintenance costs.

FAQ

Why do coffee grinder motors fail?

Motors stop working for many reasons. Bad wires or parts can cause electrical problems. Worn parts, broken gears, or things stuck inside cause mechanical problems. Using the motor too much makes it hot. This makes it break faster.

How does one know if a coffee grinder motor is overheating?

A motor that is too hot feels warm. It might smell like burning. You might see smoke. Many grinders turn off by themselves. This happens when they get too hot.

What are the advantages of upgrading to a BLDC motor?

BLDC motors are much better. They use power well. They last longer because they have no brushes. BLDC motors are also quiet. They need less fixing.

How often should one clean a coffee grinder for motor longevity?

Cleaning often helps the motor last. Clean the grinding part every week. This stops stuff from building up. Clean the motor’s air holes every few months. This keeps air flowing. It stops the motor from getting too hot. It also makes the motor work easier.