Covers critical processes like winding, commutator welding, and testing to ensure high precision, consistency, and efficiency in armature production.

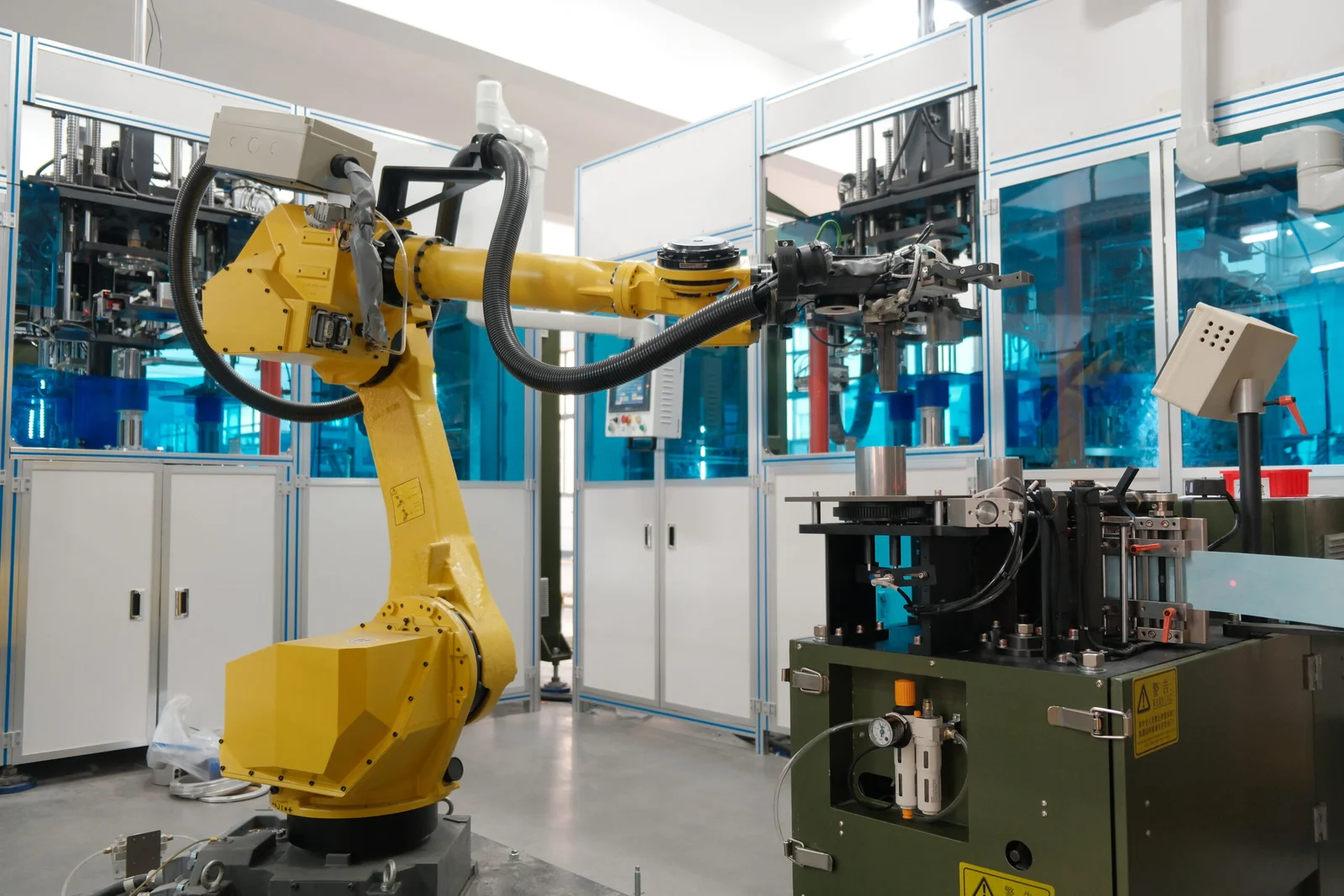

Automates the entire process of motor winding, insertion, binding, and shaping, enabling large-scale and standardized production.

Fully automatic imported high-precision instruments to ensure efficiency and large-scale standardization

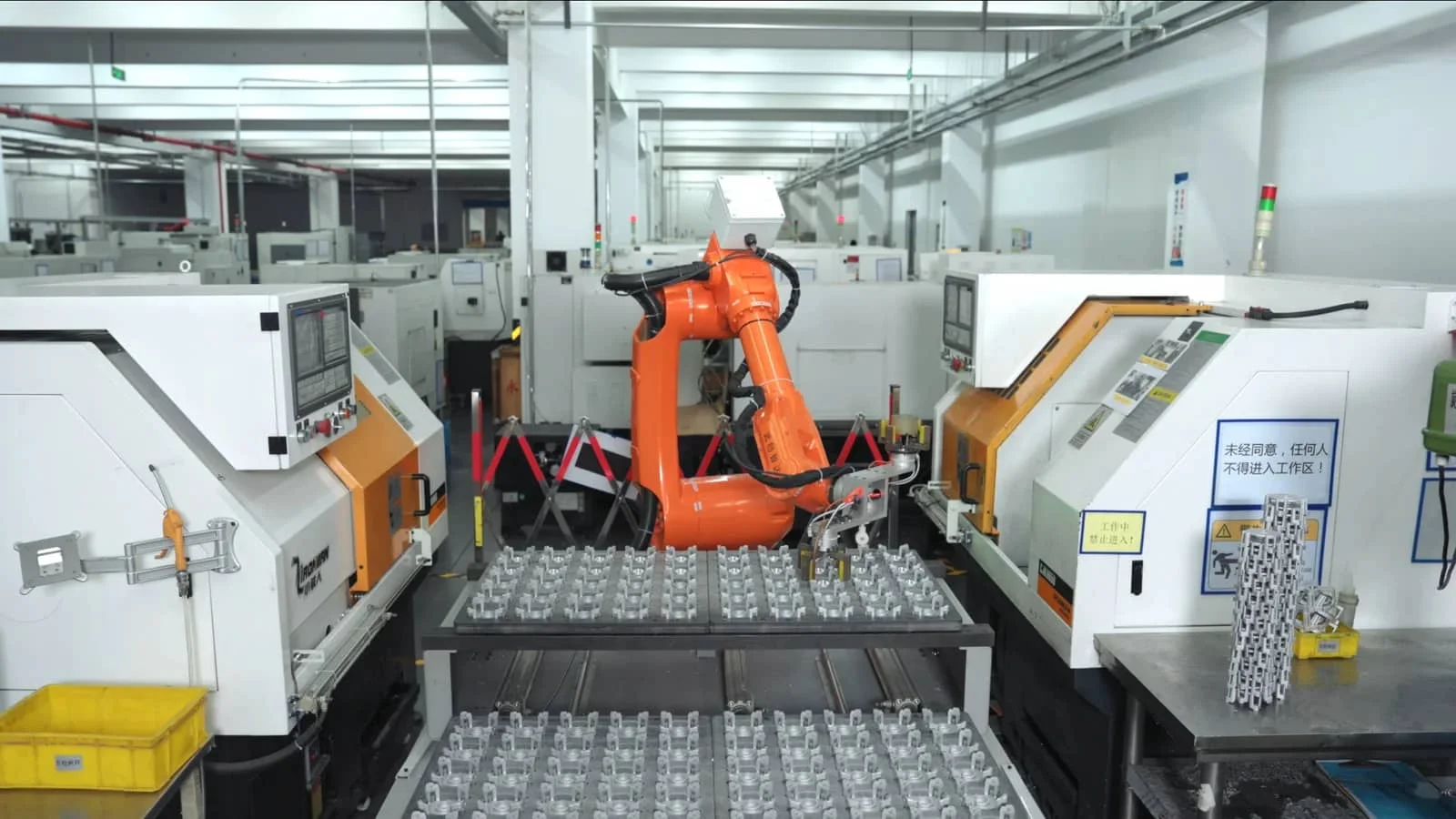

Overall view of the full-line automation process.

Machines precision metal components such as motor housings and end caps, achieving an accuracy level of 0.001mm.

Precision machining of motor housings and end caps.

Performs comprehensive electrical tests (voltage, insulation, inter-turn resistance) on motor stators in a vacuum environment, ensuring reliability and safety.

Measures torque, speed, and power to analyze motor performance and operating characteristics, supporting dynamic load simulation.

Detect the content of lead, mercury, cadmium and other harmful substances in electrical and electronic products to ensure compliance with the EU RoHS environmental standards.

Detects and measures motor noise and abnormal sounds, ensuring quiet operation and meeting noise regulations.

Measures the dimensional accuracy of motor parts, precision measurement of motor components to ensure correct assembly.

Complete testing system for electrical, mechanical, and safety performance of motors.

Address:No.121,Xinlong Road,Zhonglou Xinzha Subdistrict,Changzhou City, Jiangsu Province, China

Phone: +86-18261152679

Whatsapp: +86-18261152679

Email: sales@honestmotor.cn

Privacy Policy / Terms of Services / Cookie Settings / Site Map

© 2025 Honest All Rights Reserved.