In the complex landscape of industrial machinery and B2B procurement, the choice between AC and DC motors is far more than a simple technical preference; it is a critical decision that directly impacts long-term operational costs, energy efficiency, and overall system reliability. This comprehensive guide is designed for engineers, facility managers, and procurement officers navigating these complexities. We will move beyond basic definitions to provide a data-driven framework for selection, focusing on Total Cost of Ownership TCO, regulatory compliance, and specific application strengths. By the end of this analysis, you will possess the clarity needed to make the optimal investment for your specific industrial demands.

Executive Summary

-

Motor Selection Imperatives: The final choice between AC and DC is driven by precision requirements, duty cycle, and long-term cost.

-

AC vs DC Trade-off: AC motors are optimal for continuous, high-power, low-maintenance applications; DC motors excel in precise speed control and high starting torque scenarios.

-

BLDC Advantage: Brushless DC motors are essential for modern industrial use due to their superior energy efficiency (90%+)and significantly reduced maintenance needs.

-

TCO Core Fact: The motor’s initial purchase price only represents 5%-10% of its Total Cost of Ownership (TCO); over 90% of the cost is consumed by electrical energy.

-

Procurement Standard: Selection must be based on a rigorous analysis of application needs, IE efficiency class compliance, and the minimization of TCO over the motor’s full lifetime.

Motor Fundamentals

lt is important to understand how motors work to make smart choices when buying for factories. An electric motor converts electrical energy into mechanical movement through electromagnetism. This fundamental principle, true for all electric motors, relies on the interaction of magnetic fields to generate motion. This idea is crucial when comparing AC’ vs DC motors.

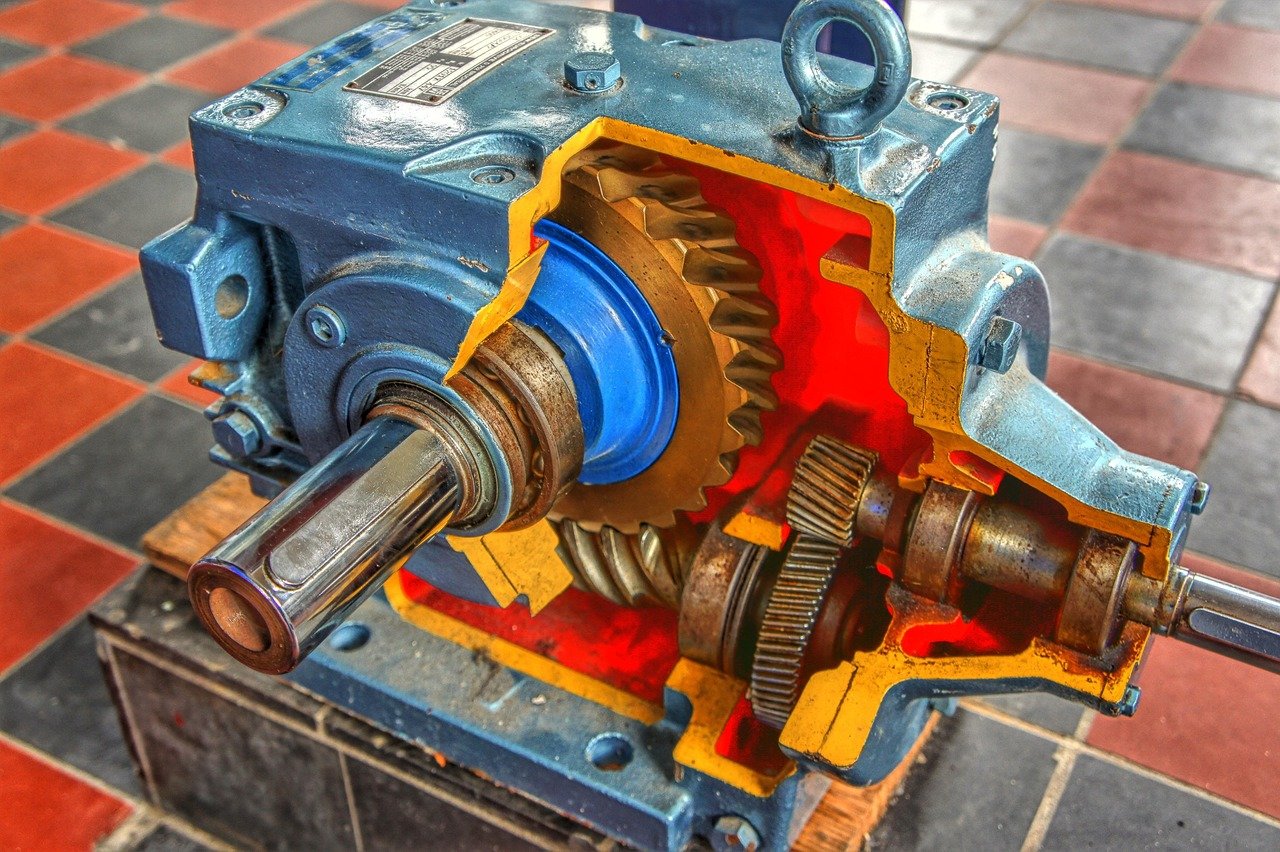

AC Motor Classification and Structure

AC motors are often used in factories. You can find them in many different kinds. Induction motors are the most common type. They are simple to build. They also work well and last a long time. Synchronous motors always spin at the same speed. Their spinning part matches the speed of the magnetic field. These motors are good when you need exact speed control. AC motors are also grouped by how many phases they have. Single-phase AC motors use one power line. They are good for smaller machines. Three-phase AC motors use three power lines. They make a spinning magnetic field. This makes them run smoothly and strongly. They are good for big jobs. A normal AC motor in a factory has two main parts. These are the stator and the rotor. The stator is the part that does not move. It makes the magnetic field. The rotor is the part that spins. It makes the motor move things. The motor’s outer case holds these parts. It also holds the bearings that help it spin.

DC Motor Characteristics and Types

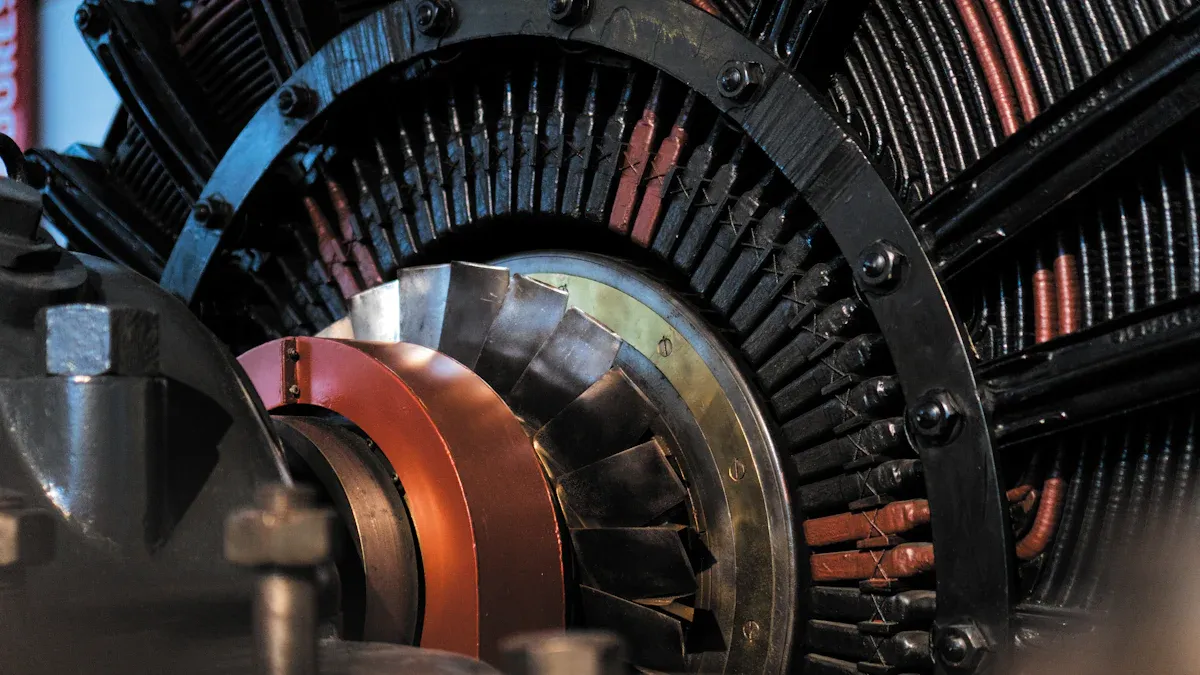

DC motors work in special ways. You will see how their speed and power are connected. The motor’s speed and power show how it will work. The amount of electricity the motor uses changes with how much work it does. The motor’s power output is its speed multiplied by its power. It works best when it is doing very little work. It uses more power when it is working its hardest. Some common types of DC motors are brushed DC motors. These use brushes to change the electricity. Separately excited DC motors use different power sources. Permanent magnet DC motors use strong magnets. Self-excited DC motors use only one power source. Shunt-wound, series-wound, and compound DC motors are self-excited. Brushless DC (BLDC) motors use electronics to change the electricity. Servo DC motors have a motor, gears, and a control system all together.

BLDC Motors: Core Advantages

BLDC motors are very good for factories. They last a very long time. This is because they do not have parts that wear out. These parts are like carbon brushes. You will not need to fix them as often. There are no brushes or parts to change. BLDC motors also make less noise. They also do not spark. They are small and light. This is a good thing. They work better. They can spin at many different speeds. They also react quickly. BLDC motors often work with 85-90% efficiency. Some newer ones work even better. This high efficiency saves electricity. It also keeps them from getting too hot in factories.

Performance and Cost Comparison

Efficiency and Power Density

When you compare industrial motors, how well they work and how much power they pack are key. DC motors usually have more power for their size. This means smaller DC motors can do the same work as bigger AC motors. But some AC motors, like Permanent Magnet Synchronous Motors (PMSM), also have a lot of power. A PMSM AC motor that weighs 20 kg can be as powerful as a 55 kg AC induction motor.

AC induction motors usually work at 85% to 95% efficiency. Synchronous AC motors can be over 90% efficient. This is true when they are working hard. Brushless DC motors and permanent magnet synchronous motors are very efficient. They often work over 90%. Brushed DC motors are usually 70–85% efficient. Remember, motors work best when they are at 75-80% of their full power.

Speed and Torque Control

DC motors are easier to control their speed. Their speed changes evenly with the power. AC motors need more complex ways to control speed. You can change the voltage for simple uses. Or you can use Variable Frequency Drives (VFDs). These give exact and good speed control. VFDs change both voltage and frequency. This keeps a steady ratio. For torque control, you can change DC motor torque by changing the voltage. You can also change the magnetic field current.

Maintenance, Life, and TCO

Thinking about upkeep, how long it lasts, and Total Cost of Ownership (TCO) is very important. Brushless DC motors work well and last a long time. This makes them very strong. An AC induction motor can work for 15 years or more. This is if it is taken care of. DC motors usually cost less to fix. They have simpler parts. But their brushes need to be changed. AC motors usually do not need much fixing.

The first price for industrial electric motors is only 5%-10% of the TCO. Most of the cost, 90%-95%, is from the electricity they use. This makes saving energy very important. This is true when talking about AC vs DC Motors. You should also think about repair costs. Also, think about unexpected stops and regular upkeep.

Operating Environment Factors

Where you use the motor really affects your choice. AC motors usually make less heat. This is because they are built simpler. They also move energy better. DC motors, especially those with brushes, make more heat. This comes from rubbing. This heat can make them work less well.

You must pick the right cover for tough places.

-

Totally Enclosed Fan-Cooled (TEFC) Enclosures stop dust and water from getting in.

-

Explosion-Proof Enclosures are for dangerous places. These have gas or dust that can catch fire.

-

Washdown Duty Enclosures can handle being cleaned often.

-

Ingress Protection (IP) Ratings show how well they protect against solids and liquids. For example, an IP66 motor keeps out dust. It also protects against strong water sprays.

Honest Motor makes special motor solutions. These have things like explosion-proof enclosures. They also have coatings that stop rust. This is to meet what different industries need.

Applications, Compliance and Selection

Optimal Application Scenarios

You need to pick the right motor. This means knowing what each type does best. AC motors are often used in factories. They are strong. They can be used in many ways. They last a long time. They are easy to take care of. Three-phase AC motors are common. They run pumps. They run compressors. They run fans. They run conveyor belts. They also run heavy machines. For example, recycling plants use AC motors. They use them in car shredders. This is instead of bigger DC systems. This helps spread out the stress. It means less time when machines are stopped. It helps handle heavy loads better. It also makes the system more reliable.

AC motors are great for saving energy. This is true when they run at a steady speed. Special controllers help them use power well. This saves energy. They manage power well. This happens even when loads change. Permanent Magnet Motors (PMMs) with AC drives are powerful. They save a lot of energy. They work well when you need high efficiency. They also use little energy. Synchronous Reluctance Motors (SRMs) with AC drives also save energy. They cost less to run. They use less energy. They still work very well. You will find AC motors in many places. These include factories. They are in transportation. They are in heating and cooling systems. They are in water treatment. They are in green energy. This includes wind turbines. It also includes solar trackers.

DC motors are good for other things. They are very important for green energy. You use them in solar trackers. They move the panels. They change wind turbine blade angles. They help battery systems. They charge and discharge batteries well. In small power grids, they control power. They keep voltage steady. Airplanes and defense use DC motors. They guide missiles. They fly drones. They move satellite antennas.

You will also find DC motors in factory machines. They power conveyor belts. They power pumps. They power compressors. This is in car making. It is in food making. It is in cloth making. DC series motors are good for heavy loads. Cranes and lifts use them. They can hold a full load. They do this even when not moving. They are small. This makes them good for building sites. They are good for oil refineries. Shunt DC motors run at a constant speed. They have strong starting power. They work in pumps. They work in lifts. They work in weaving machines. They work in fans. Brushless DC motors are in computers. They are in disk drives. They are fast. They are efficient. They control speed very well. In cars, DC motors use battery power. They move side windows. They are simple. They control things well. For home items, DC motors power dishwashers. They power washing machines. They power refrigerators. They power microwaves. They are also in vacuum cleaners. They are in toys. They are in electric toothbrushes. The choice between AC vs DC Motors depends on what you need them for.

Regulations and Efficiency Standards

You must follow rules for industrial motors. These rules are in big markets. These rules make motors work better. They want very efficient motors. These are like IE3 and IE4 classes. Governments make these rules. They want to be green. They want to save money.

International IE Ratings

The main rule for AC motors is IEC 60034-30-1: 2014. This rule tells how efficient they are. IEC 60034-2-1: 2014 tells how to measure efficiency. This sets the efficiency classes. These rules cover certain motors. They are single-speed. They are induction or permanent magnet. They can be single or three-phase. They use normal power. They run at 50 or 60 Hz. They have 2, 4, 6, or 8 poles. Their power is from 0.12 kW to 1000 kW. Their voltage is from 50 V to 1000 V. They must run all the time. This is in temperatures from -20°C to +60°C. They can be used up to 4000m high.

The rule has four main efficiency classes:

-

IE1: Standard Efficiency

-

IE2: High Efficiency

-

IE3: Premium Efficiency

-

IE4: Super-premium Efficiency

IEC standards try to be the same everywhere. But some places use their own rules. Still, they are very similar. For example, NEMA premium in the U.S. is like IEC IE3. This is true for most motors.

Efficiency Standards

Rules for Minimum Energy Performance Standards (MEPS) help countries. They help save energy. They help reduce carbon. For motor users, MEPS make motors better. They make it easy to compare efficiency. Many countries use their own MEPS. But the rules can be different.

The industrial sector is continually advancing toward higher efficiency. For example, IE5 SynRM motors follow rules. They save a lot of energy. Choosing efficient motors makes machines better. It saves energy costs. It helps the environment. The EU Ecodesign Regulation sets new rules. These are for electric motors. They are for variable speed drives. This makes people choose more efficient motors. Rules also cover noise. They cover safety. They cover pollution from industrial motors. This helps make things eco-friendly.

Selection Criteria and Final Decision

When you pick an industrial motor, you need a list. This helps you choose the best one.

-

Efficiency and Performance Criteria:

-

Choose models that save energy. Motors use almost 70% of factory energy. A motor that is 92% efficient saves a lot of money.

-

Check the motor’s service factor. This shows if it handles heavy loads. It shows if it handles changing loads. It does this without getting too hot.

-

Look at how much torque it has. Think about starting torque. This is if you need a strong start.

-

See if you can get special options. Honest Motor makes custom motor solutions. These have special covers. They have rust-proof coatings.

-

-

Factors Influencing Selection:

-

Know what your machine needs. Is the load steady? Or does it change?

-

Look at where it will be used. Think about heat. Think about wetness. Think about dust. Think about rust. Motors in bad places may need special coatings. Hot places need extra cooling. Rules like NEMA MG 1-2016 (for motor covers) help. IEC 60034-1 (for performance) gives advice.

-

Make sure the power is enough. It must meet machine needs. It must save energy.

-

Think about upkeep. Are spare parts easy to get? Does the company offer help?

-

-

Operational Requirements:

-

Look at how the load acts.

-

Think about how it starts.

-

Decide if you need speed control. Do you need one speed? Or many speeds?

-

Think about horsepower. Think about torque. Think about position control.

-

Think about current and voltage. Higher voltage motors have more torque. They need the right power supply.

-

Check if the drive works with the motor. The drive must match voltage. It must match current. It must match frequency. It should control speed. It should control torque. It should control position.

-

-

Motor Type Considerations:

-

Brushed Motors: They are simple. They are cheap. They are good for high torque at slow speeds. But they need regular care.

-

Brushless Motors: They need less care. They are quieter. They are more efficient. They are more powerful for their size. They run at faster speeds.

-

AC Motors: They save electricity when starting. They are simple to build. They last long. They need less care. They are good for fixed speeds.

-

Making a smart choice about AC vs DC Motors helps your factory. It makes things work better. It saves money. It makes more products.

The final decision between AC and DC motors is highly application-specific and foundational to industrial success. This guide has provided the necessary framework: by meticulously comparing key metrics (e.g., TCO, efficiency, and control)and applying strict selection criteria, procurement teams can mitigate long-termoperational risks.

An informed decision is the direct route to optimized performance, drastically reduced costs, and enhanced productivity in your industrial settings. lf you require precise technical guidance or a tailored solution for your specific operational challenges, welcome to consult Honest Motor’s expert team for acomprehensive, customized proposal.

FAQ

What is the main difference between AC and DC motors?

AC motors use alternating current. They are good for steady speed. They are good for high power. DC motors use direct current. They control speed very well. They have strong starting power.

Which motor type is more efficient?

BLDC motors and PMSM motors are very efficient. They often work over 90%. AC induction motors also work well. This is true for bigger jobs. The best choice depends on what you need.

When should you pick an AC motor for factory use?

Pick AC motors for strong jobs. They need little fixing. They work well all the time. This is for pumps and fans. They cost less for steady speed jobs. They can handle heavy loads.

What is TCO for buying motors?

TCO means Total Cost of Ownership. It includes the buying price. It includes energy use. It includes fixing costs. It includes time when machines stop. Energy use is most of the TCO. It is 90-95%. Think about costs over time.

Are BLDC motors always the best for factories?

BLDC motors work very well. They last long. They control things exactly. They are great for many jobs. But they cost more to buy. Their controls are complex. They might not fit all budgets. They might not fit simple jobs.